ASTM B573-24

(Specification)Standard Specification for Nickel-Molybdenum-Chromium-Iron Alloys Bar or Rod

Standard Specification for Nickel-Molybdenum-Chromium-Iron Alloys Bar or Rod

ABSTRACT

This specification covers rods of nickel-molybdenum-chromium-iron alloys with UNS Nos. N10003 and N10242 for use in general corrosive service. Specimens shall be sampled and prepared, then tested accordingly to examine their conformance to dimensional (diameter, length, out-of-roundness, weight, and straightness), mechanical (tensile and yield strengths, and elongation), and chemical composition requirements.

SCOPE

1.1 This specification2 covers nickel-molybdenum-chromium-iron alloys in the form of bar or rod. The alloys are typically for general corrosive service but not limited to this usage.

1.2 Alloys that can currently be certified to this specification are UNS N10003 and UNS N10242.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B573 − 24

Standard Specification for

1

Nickel-Molybdenum-Chromium-Iron Alloys Bar or Rod

This standard is issued under the fixed designation B573; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B899 Terminology Relating to Non-ferrous Metals and Al-

2

loys

1.1 This specification covers nickel-molybdenum-

E8/E8M Test Methods for Tension Testing of Metallic Ma-

chromium-iron alloys in the form of bar or rod. The alloys are

terials

typically for general corrosive service but not limited to this

E29 Practice for Using Significant Digits in Test Data to

usage.

Determine Conformance with Specifications

1.2 Alloys that can currently be certified to this specification

E1473 Test Methods for Chemical Analysis of Nickel,

are UNS N10003 and UNS N10242.

Cobalt, and High-Temperature Alloys

1.3 The values stated in inch-pound units are to be regarded

3. Terminology

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 3.1 Common B02.07 terminology is found in Specification

B899.

and are not considered standard.

1.4 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the 3.2.1 bar, n—an elongated, forged or rolled metal product

responsibility of the user of this standard to become familiar

with uniform strength, length and diameter.

with all hazards including those identified in the appropriate

3.2.2 rod, n—a hot-finished product of round solid section

Safety Data Sheet (SDS) for this product/material as provided

furnished in straight lengths.

by the manufacturer, to establish appropriate safety, health,

and environmental practices, and determine the applicability 4. Ordering Information

of regulatory limitations prior to use.

4.1 It is the responsibility of the purchaser to specify all

1.5 This international standard was developed in accor-

requirements that are necessary for the safe and satisfactory

dance with internationally recognized principles on standard-

performance of material ordered under this specification.

ization established in the Decision on Principles for the

4.2 Examples of such requirements include but are not

Development of International Standards, Guides and Recom-

limited to the following:

mendations issued by the World Trade Organization Technical

4.2.1 Dimensions—See Section 8.

Barriers to Trade (TBT) Committee.

4.2.2 Purchaser Inspection—See Section 13.

4.2.3 Samples for Product (Check) Analysis—See Section

2. Referenced Documents

10.

3

2.1 ASTM Standards:

B880 Specification for General Requirements for Chemical 5. Materials and Manufacture

Check Analysis Limits for Nickel, Nickel Alloys and

5.1 The finish options for products certified to this specifi-

Cobalt Alloys

cation are:

5.1.1 Hot-Finished, Annealed, and Descaled Rod,

5.1.2 Hot-Finished, Annealed, and Ground Bar,

1

This specification is under the jurisdiction of ASTM Committee B02 on

5.1.3 Hot-Finished, Annealed, and Turned Bar,

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

5.1.4 Cold-Finished and Annealed Bar, and

B02.07 on Refined Nickel and Cobalt and Their Alloys.

5.1.5 Cold-Finished, Annealed, and Ground Bar.

Current edition approved April 1, 2024. Published April 2024. Originally

approved in 1972. Last previous edition approved in 2016 as B573 – 06 (2016).

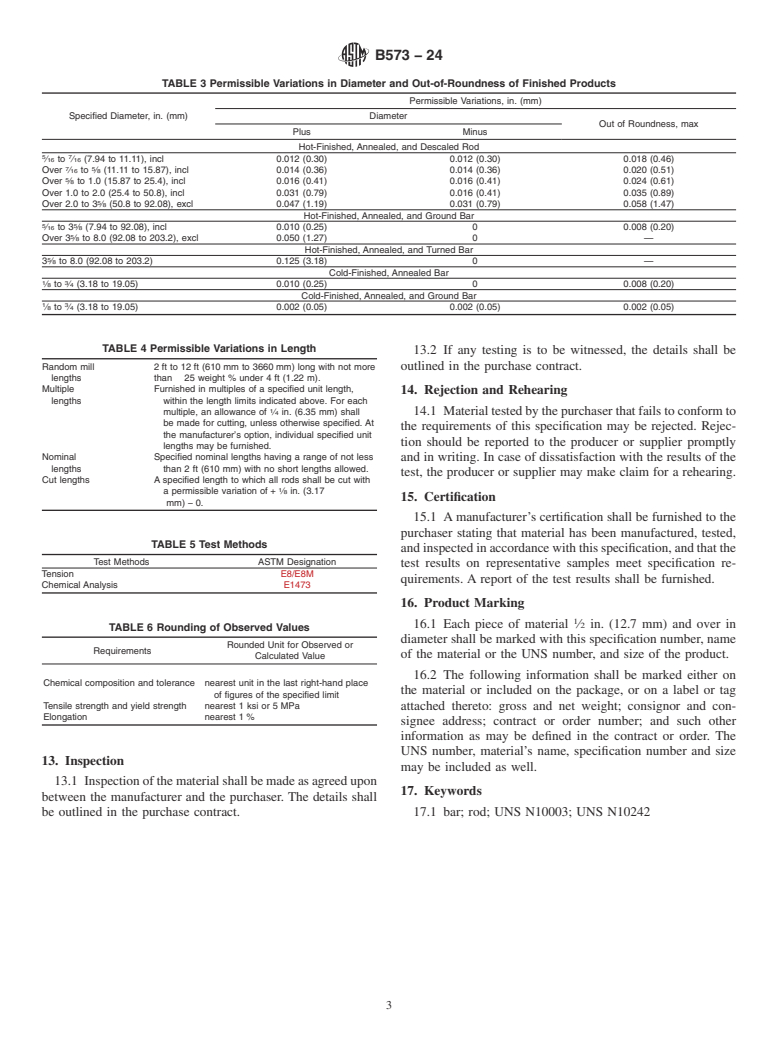

5.2 The diameters permitted for certification for each finish

DOI: 10.1520/B0573-24.

2

appear in the left column of Table 3.

For ASME Boiler and Pressure Vessel Code applications see Specification

SB-573 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Chemical Composition

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

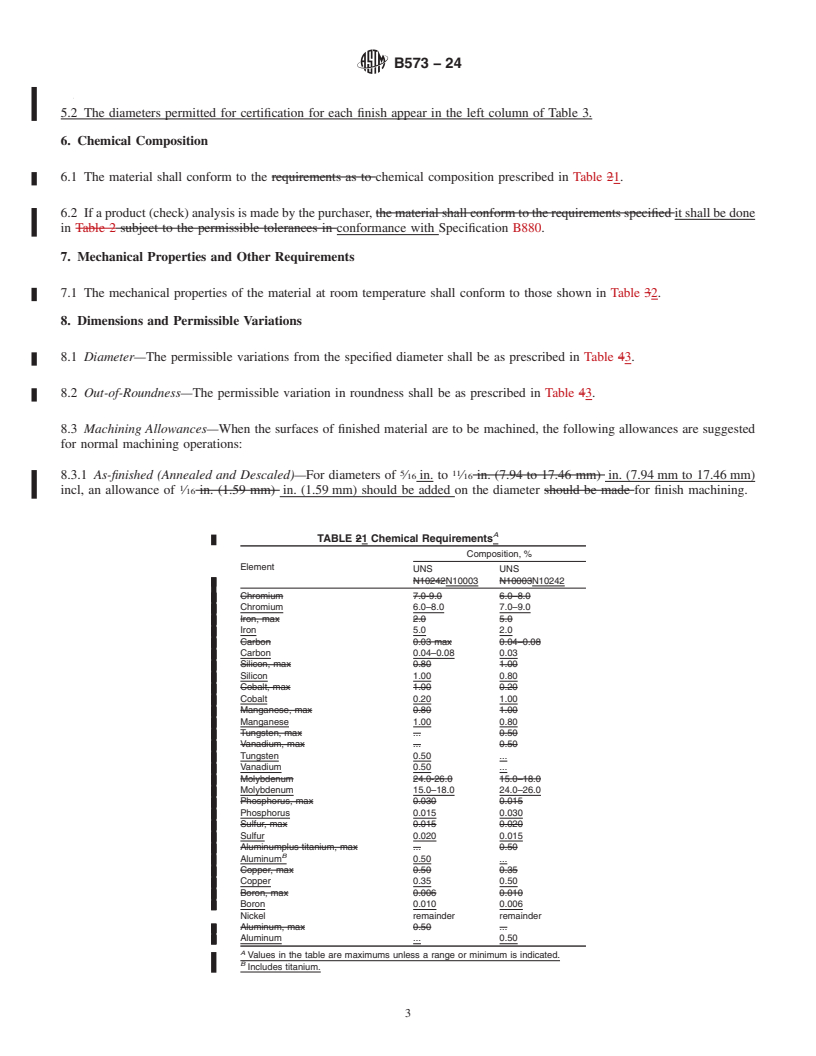

6.1 The material shall conform to the chemical composition

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. prescribed in Table 1.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B573 − 24

A

TABLE 1 Chemical Requirements

8.5.2 Rods or bars ordered to cut lengths shall be furnished

Composition, %

with square saw cut or machined ends.

Element

UNS N10003 UNS N10242

8.6 Weight

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B573 − 06 (Reapproved 2016) B573 − 24

Standard Specification for

Nickel-Molybdenum-Chromium-Iron Alloys (UNS N10003,

1

N10242) Bar or Rod

This standard is issued under the fixed designation B573; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

2

1.1 This specification covers nickel-molybdenum-chromium-iron alloys (UNS N10003 and UNS N10242)in the form of bar rod

for use in general corrosive service.or rod. The alloys are typically for general corrosive service but not limited to this usage.

1.2 The following products are covered under this specification:Alloys that can currently be certified to this specification are UNS

N10003 and UNS N10242.

5 3

1.2.1 Rods ⁄16 to ⁄4 in. (7.94 to 19.05 mm) excl in diameter, hot or cold finished, annealed, and pickled or mechanically descaled.

3 1

1.2.2 Rods ⁄4 to 3 ⁄2 in. (19.05 to 88.9 mm) incl in diameter, hot or cold finished, annealed, ground, or turned.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet

(SDS) for this product/material as provided by the manufacturer, to establish appropriate safety and healthsafety, health, and

environmental practices, and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

B880 Specification for General Requirements for Chemical Check Analysis Limits for Nickel, Nickel Alloys and Cobalt Alloys

B899 Terminology Relating to Non-ferrous Metals and Alloys

E8E8/E8M Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E1473 Test Methods for Chemical Analysis of Nickel, Cobalt, and High-Temperature Alloys

1

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on Refined

Nickel and Cobalt and Their Alloys.

Current edition approved June 1, 2016April 1, 2024. Published June 2016April 2024. Originally approved in 1972. Last previous edition approved in 20112016 as

B573 – 06 (2011).(2016). DOI: 10.1520/B0573-06R16.10.1520/B0573-24.

2

For ASME Boiler and Pressure Vessel Code applications see Specification SB-573 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B573 − 24

3. Terminology

3.1 Common B02.07 terminology is found in Specification B899.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 bar, n—an elongated, forged or rolled metal product with uniform strength, length and diameter.

3.2.2 rod, n—a hot-finished product of round solid section furnished in straight lengths.

4. Ordering Information

4.1 It is the responsibility of the purchaser to specify all requirements that are necessary for the safe and satisfactory performance

of material ordered under this specification. Examples of such requirements include but are not limited to the following:

4.1.1 Dimensions—Nominal diameter and length. The shortest usable multiple length shall be specified (Table 1).

4.1.2 Certification—State if certification or a report of test results is required (Section 15).

4.1.3 Purchase

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.