ASTM E1652-00

(Specification)Standard Specification for Magnesium Oxide and Aluminum Oxide Powder and Crushable Insulators Used in the Manufacture of Metal-Sheathed Platinum Resistance Thermometers, Base Metal Thermocouples, and Noble Metal Thermocouples

Standard Specification for Magnesium Oxide and Aluminum Oxide Powder and Crushable Insulators Used in the Manufacture of Metal-Sheathed Platinum Resistance Thermometers, Base Metal Thermocouples, and Noble Metal Thermocouples

SCOPE

1.1 This specification covers the requirements for magnesium oxide (MgO) and aluminum oxide (Al2O3) powders and crushable insulators used to manufacture metal-sheathed cables of platinum resistance thermometers (PRTs) and noble metal thermocouples.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1652 – 00

Standard Specification for

Magnesium Oxide and Aluminum Oxide Powder and

Crushable Insulators Used in the Manufacture of Metal-

Sheathed Platinum Resistance Thermometers, Base Metal

Thermocouples, and Noble Metal Thermocouples

This standard is issued under the fixed designation E 1652; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2858 Test Method for Thermal Conductivity of Electrical

Grade Magnesium Oxide

1.1 This specification covers the requirements for magne-

E 228 Test Method for Linear Thermal Expansion of Solid

sium oxide (MgO) and aluminum oxide (Al O ) powders and

2 3

Materials with a Vitreous Silica Dilatometer

crushable insulators used to manufacture metal-sheathed plati-

E 235 Specification for Thermocouples, Sheathed, Type K,

num resistance thermometers (PRTs), noble metal thermo-

for Nuclear or for Other High-Reliability Applications

couples, base metal thermocouples, and their respective cables.

E 344 Terminology Relating to Thermometry and Hydrom-

1.2 The values stated in SI units are to be regarded as the

etry

standard. The values given in parentheses are for information

E 585 Specification for Compacted Mineral-Insulated,

only.

Metal-Sheathed, Base Metal Thermocouple Cable

1.3 This standard does not purport to address all of the

E 1137 Specification for Industrial Platinum Resistance

safety concerns, if any, associated with its use. It is the

Thermometers

responsibility of the user of this standard to establish appro-

E 1225 Test Method for Thermal Conductivity of Solids by

priate safety and health practices and determine the applica-

Means of the Guarded-Comparative-Longitudinal Heat

bility of regulatory limitations prior to use.

Flow Technique

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 The definitions given in Terminology E 344 shall apply

B 329 Test Method for Apparent Density of Metal Powders

to this specification.

and Related Compounds Using the Scott Volumeter

C 573 Methods for Chemical Analysis of Fireclay and

4. Significance and Use

High-Alumina Refractories

4.1 Magnesium oxide and aluminum oxide are used to

C 574 Method for Chemical Analysis of Magnesite and

electrically isolate and mechanically support the thermoele-

Dolomite Refractories

ments of a thermocouple (see Specifications E 235 and E 585)

C 809 Test Method for Chemical, Mass Spectrometric, and

and the connecting wires of a PRT (see Specification E 1137)

Spectrochemical Analysis of Nuclear-Grade Aluminum

within a metal sheath. The metal sheath is typically reduced in

Oxide and Aluminum Oxide-Boron Carbide Composite

5 diameter to compact the oxide powder or crushable oxide

Pellets

insulators around the thermoelements or wires.

C 832 Test Method for Measuring the Thermal Expansion

6 4.2 In order to be suitable for this purpose, the materials

and Creep of Refractories Under Load

shall meet certain criteria for purity and for mechanical and

D 2766 Test Method for Specific Heat of Liquids and

7 dimensional characteristics. Material that does not meet the

Solids

purity criteria may cause premature failure of the sensor.

4.3 Use of this specification for the procurement of powder

and crushable insulators will help to ensure that the product

This specification is under the jurisdiction of ASTM Committee E20 on

Temperature Measurement and is the direct responsibility of Subcommittee E20.04 obtained is suitable for the intended purpose.

on Thermocouples.

4.4 Useful information about alumina and magnesia is given

Current edition approved Oct. 10, 2000. Published December 2000. Originally

in the appendixes.

published as E 1652–95. Last previous edition E 1652–95.

Annual Book of ASTM Standards, Vol 02.05.

Discontinued. See 1993 Annual Book of ASTM Standards, Vol 03.05.

Discontinued. See 1995 Annual Book of ASTM Standards, Vol 03.06.

5 8

Annual Book of ASTM Standards, Vol 12.01. Annual Book of ASTM Standards, Vol 10.01.

6 9

Annual Book of ASTM Standards, Vol 15.01. Annual Book of ASTM Standards, Vol 14.02.

7 10

Annual Book of ASTM Standards, Vol 05.02. Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1652

5. Ordering Information Specific density requirements, as well as the test method to be

used to determine density, shall be negotiated between the

5.1 The purchaser shall specify the following when order-

purchaser and manufacturer. See Appendix X3 for suggested

ing:

test methods.

5.1.1 Material—from 5.1.1.1 through 5.1.1.5 below:

7.2 Modulus of Rupture—In the past, a breaking force test

5.1.1.1 Al O Type 1 per Table 1.

2 3

has been used that is based on a relative modulus of rupture and

5.1.1.2 Al O Type 2 per Table 1 and Supplementary

2 3

is related to crushability. However, with variations in modulus

Requirement S1.

from 21 to 83 MPa (3000 to 12 000 lb/in. ) influenced by

5.1.1.3 MgO Type 1 per Table 1.

insulator configuration, number of holes, and cross-sectional

5.1.1.4 MgO Type 2 per Table 1 and Supplementary Re-

dimensions, specific modulus requirements cannot be listed for

quirement S1.

each configuration. The modulus of rupture is best used for lot

5.1.1.5 MgO Type 3 per Supplementary Requirement S2.

to lot comparison of a given insulator size and configuration.

5.1.2 Insulator Outside Diameter.

See Appendix X4 for a suggested test method.

5.1.3 Hole Diameter.

5.1.4 Number of Holes.

8. Dimensional Requirements

5.1.5 Hole Pattern.

8.1 Outside diameter and hole diameter tolerances for insu-

5.1.6 Length.

lators shall be as specified in Table 2 and Table 3, respectively,

5.1.7 Particle Size (if supplied as powder).

unless otherwise agreed to between purchaser and manufac-

5.1.8 Minimum Inside Diameter of Tubing, into which

turer.

insulators will be inserted.

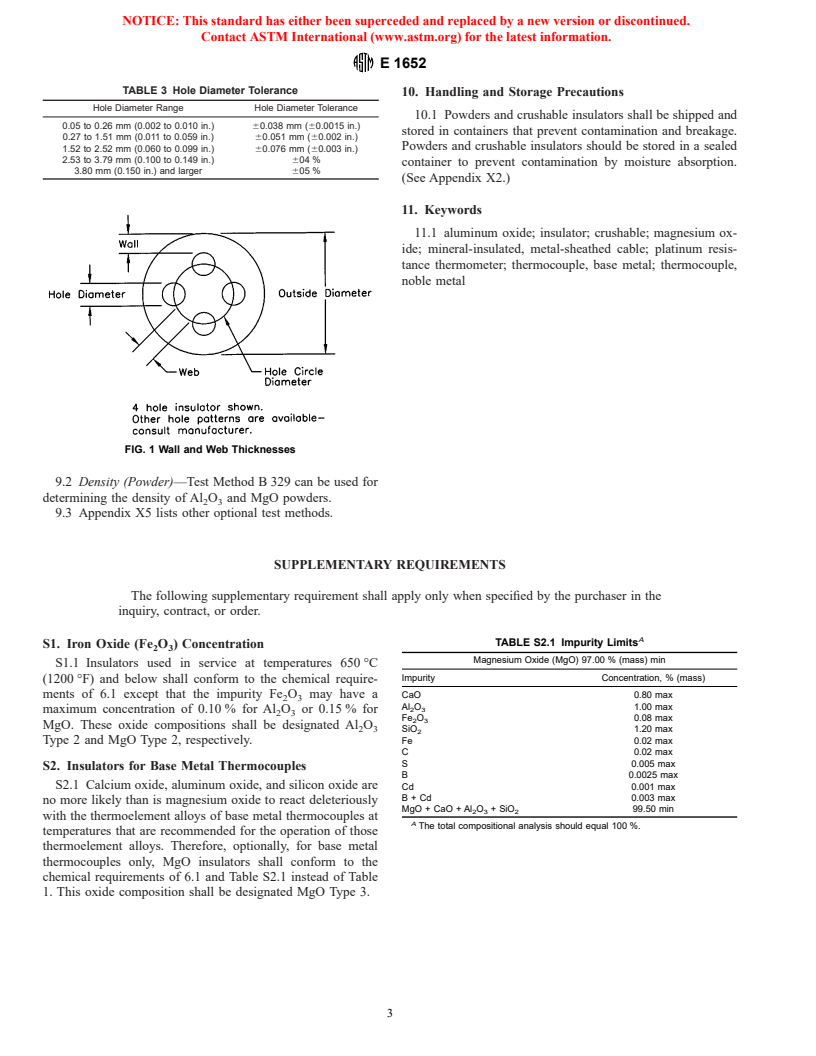

8.2 Wall and web thicknesses (see Fig. 1) shall be equal

5.2 Consult the insulator manufacturer for limitations of

within outside diameter tolerance as specified in Table 2 unless

relationships between outside diameter, hole diameters, hole

otherwise agreed to between purchaser and manufacturer.

patterns, and length.

8.3 Camber shall not exceed 0.3 % of the length. Insulator

shall be capable of passing through a rigid straight tube longer

6. Chemical Requirements

than the insulator and with an inside diameter as specified in

6.1 The final product shall be chemically analyzed using

5.1.8.

appropriate methods listed in 9.1. Major impurities shall not

8.4 Helical twist of holes shall not exceed 2° per cm (5° per

exceed the limits indicated in Table 1 unless permitted by

in.) of length.

supplementary requirements. Any detected impurity with a

8.5 Length shall be as specified in 5.1.6 with a tolerance

concentration greater than 0.001 % (mass) shall be reported to

of +6/−0.00 mm ( +0.25/−0.00 in.).

the purchaser.

8.6 The ends of each insulator should be cut square and not

be chipped.

7. Physical Properties

7.1 Density—The density of crushable magnesium oxide

9. Test Methods

and aluminum oxide insulators typically ranges from 2060

9.1 Chemical Composition:

3 3 3 3

kg/m (0.074 lbm/in. ) to 3060 kg/m (0.111 lbm/in. ).

9.1.1 Wet chemical analysis, or fusion calorimetric analysis,

or both, can be used for quantitative determination of silicon

A

TABLE 1 Impurity Limits dioxide (SiO ), iron oxide (Fe O ), and zirconium oxide

2 2 3

(ZrO ) with gravimetric determination for SiO and Fe O .

Aluminum Oxide (Al O ) 99.65 % Magnesium Oxide (MgO) 99.40 % 2 2 2 3

2 3

(mass) min (mass) min

The SiO filtrate can be used for further calcium oxide (CaO)

determination.

Concentration, Concentration,

Impurity Impurity

% (mass) % (mass)

9.1.2 Test Method C 809 can be used for quantitative

B C

Fe O 0.04 max CaO 0.35 max

analysis of elemential impurities.

2 3

D C

SiO 0.08 max Al O 0.15 max

2 2 3

9.1.3 Methods C 573 can be used for quantitative analysis

B,C

CaO 0.08 max Fe O 0.04 max

2 3

C,D

of Fe O , SiO , CaO, MgO, and sodium monoxide (Na O) in

MgO 0.08 max SiO 0.13 max 2 3 2 2

ZrO 0.08 max C 0.02 max

Al O .

2 3

Na O 0.06 max S 0.005 max

9.1.4 Method C 574 can be used for quantitative analysis of

C 0.01 max B 0.0025 max

CaO, Al O ,Fe O , and SiO in MgO.

S 0.005 max Cd 0.001 max

2 3 2 3 2

Cd 0.001 max B + Cd 0.003 max

9.1.5 Any method used for quantitative determination

B 0.001 max

should have a detection sensitivity of at least 0.001 % (mass).

A

The total compositional analysis should equal 100 %.

B

The presence of Fe O can adversely affect the electrical resistivity of these

2 3

TABLE 2 Outside Diameter (O.D.) Tolerance

insulators. Moreover, changes in the thermometric properties of platinum and its

alloys that are exposed to Fe O concentrations above 0.04 % become more

2 3

O.D. Range O.D. Tolerance

pronounced when exposed to the higher service temperatures, for example, above

650 °C (1200 °F), for prolonged periods. However, at lower service temperatures, 0.25 to 1.48 mm (0.010 to 0.058 in.) 60.051 mm (60.002 in.)

1.49 to 2.27 mm (0.059 to 0.089 in.) 60.076 mm (60.003 in.)

purchaser may choose to allow Fe O concentrations of up to 0.1 % in Al O or

2 3 2 3

0.15 % in MgO. See Supplemental Requirement S1. 2.28 to 3.28 mm (0.090 to 0.129 in.) 60.076 mm (60.003 in.)

C

3.29 to 6.33 mm (0.130 to 0.249 in.) 60.076 mm (60.003 in.)

See Supplemental Requirement S2 for base-metal thermocouple applications.

D

The presence of SiO can, at elevated temperatures, lead to changes in the 6.34 to 9.51 mm (0.250 to 0.374 in.) 60.10 mm (60.004 in.)

electrical resistivity, thermoelectric characteristics, and mechanical properties of 9.52 mm (0.375 in.) and larger 60.15 mm (60.006 in.)

platinum and its alloys.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1652

TABLE 3 Hole Diameter Tolerance

10. Handling and Storage Precautions

Hole Diameter Range Hole Diameter Tolerance

10.1 Powders and crushable insulators shall be shipped and

0.05 to 0.26 mm (0.002 to 0.010 in.) 60.038 mm (60.0015 in.)

stored in containers that prevent contamination and breakage.

0.27 to 1.51 mm (0.011 to 0.059 in.) 60.051 mm (60.002 in.)

Powders and crushable insulators should be stored in a sealed

1.52 to 2.52 mm (0.060 to 0.099 in.) 60.076 mm (60.003 in.)

2.53 to 3.79 mm (0.100 to 0.149 in.) 604 %

container to prevent contamination by moisture absorption.

3.80 mm (0.150 in.) and larger 605 %

(See Appendix X2.)

11. Keywords

11.1 aluminum oxide; insulator; crushable; magnesium ox-

ide; mineral-insulated, metal-sheathed cable; platinum resis-

tance thermometer; thermocouple, base metal; thermocouple,

noble metal

FIG. 1 Wall and Web Thicknesses

9.2 Density (Powder)—Test Method B 329 can be used for

determining the density of Al O and MgO powders.

2 3

9.3 Appendix X5 lists other optional test methods.

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirement shall apply only when specified by the purchaser in the

inquiry, contract, or order.

A

TABLE S2.1 Impurity Limits

S1. Iron Oxide (Fe O ) Concentration

2 3

Magnesium Oxide (MgO) 97.00 % (mass) min

S1.1 Insulators used in service at temperatures 650 °C

Impurity Concentration, % (mass)

(1200 °F) and below shall conform to the chemical require-

ments of 6.1 except that the impurity Fe O may have a CaO 0.80 max

2 3

Al O 1.00 max

2 3

maximum concentration of 0.10 % for Al O or 0.15 % for

2 3

Fe O 0.08 max

2 3

MgO. These oxide compositions shall be designated Al O

2 3

SiO 1.20 max

Type 2 and MgO Type 2, respectively. Fe 0.02 max

C 0.02 max

S 0.005 max

S2. Insulators for Base Metal Thermocouples

B 0.0025 max

S2.1 Calcium oxide, aluminum oxide, and silicon oxide are

Cd 0.001 max

B + Cd 0.003 max

no more likely than is magnesium oxide to react deleteriously

MgO + CaO + Al O + SiO 99.50 min

2 3 2

with the thermoelement alloys of base metal thermocouples at

A

The total compositional analysis should equal 100 %.

temperatures that are recommended for the operation of those

thermoelement alloys. Therefore, optionally, for base metal

thermocouples only, MgO insulators shall conform to the

chemical requirements of 6.1 and Table S2.1 instead of Table

1. This oxide composition shall be designated MgO Type 3.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1652

APPENDIXES

(Nonmandatory Information)

X1. MATERIALS AND MANUFACTURE

X1.1 Alumina (Al O ) X1.1.2.4 Dielectric Strength—5600 kV/m (142 000 V/in.).

2 3

X1.1.2.5 Hardness (MOHS)—9.

X1.1.1 Sources:

X1.1.2.6 Softening Temperature—1750 °C (3182 °F).

X1.1.1.1 Bauxite is the principal source of alumina. Gibb-

X1.1.2.7 Melting Temperature—2050 °C (3722 °F).

site, Al(OH) , is the most stable phase. Boehmite, AlO(OH),

X1.1.2.8 Molecular Weight—101.94.

also occurs in nature. High grade bauxite is low in iron and

X1.1.2.9 Typical Electrical Resistivity—See Table X1.1.

silica content. The major use of purified alumina is in the

X1.1.2.10 Specific Heat— 8.8 3 10 J/kg·K@ 20 °C (0.21

production of aluminum metal.

Btu/lbm °F @ 68 °F). 1.2 3 10 J/kg·K @ 1000 °C (0.28

X1.1.1.2 Depending upon the application, the economics,

Btu/lbm °F @ 1832 °F).

and the purity of the bauxite, the purification process could be

X1.1.2.11 Typical Thermal Conductivity—See Table X1.2.

wet alkaline, wet acid, alkaline furnace, carbothermic furnace,

X1.1.2.12 Macroscopic Thermal Neutron Absorption Cross

or electrolytic processes.

−1 −1

Section—1.0 m (0.03 in. ).

X1.1.1.3 The wet alkaline processes are most economical.

Gibbsite bauxite is easier to dissolve. It is digested in sodium

X1.2 Magnesia (MgO)

hydroxide (NaOH) solution at about 150 °C (302 °F) at 345

2 X1.2.1 Sources:

kPa (50 lb/in. ). Boehmitic bauxite, AlO(OH), is more difficult

X1.2.1.1 Magnesia can be made by the oxidation of mag-

to dissolve. It requires a higher concentration of NaOH

2 nesium metal or by heating easily decomposed oxy-compounds

solution, a pressure of 1930 to 4826 kPa (280 to 700 lb/in. ),

of magnesium, such as the hydroxide, Mg(OH) , the oxalate,

and a temperature of about 238 °C (545 °F).

MgC O , or the naturally occurring carbonate (magnesite),

2 4

X1.1.1.4 Wh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.