ASTM D2066-07(2012)

(Test Method)Standard Test Methods for Relative Tinting Strength of Paste-Type Printing Ink Dispersions

Standard Test Methods for Relative Tinting Strength of Paste-Type Printing Ink Dispersions

SIGNIFICANCE AND USE

5.1 Tinting strength is an essential property of printing ink dispersions. Although test results on wet drawdowns and tints do not guarantee equivalency of dry printed ink films, they provide useful parameters for quality assurance of established formulations, gaging relative degree of dispersion, and estimating the color value of colorants from different batches, sources, or grades.

SCOPE

1.1 These test methods cover procedures for determining the relative tinting strength of paste-type printing ink dispersions by visual or instrumental evaluation of tints prepared by manual or automated mixing.

1.2 These test methods are applicable to paste-type printing inks, flushed pigments, and other pigment dispersions that are essentially nonvolatile under ordinary room conditions and for which there is a wet reference standard of the same pigmentation and consistency. With proper choice of tinting base, they are applicable to dispersions of any color, including black and white. Note 1—The instrumental procedures for tinting strength are similar in principle to those described in Test Methods D387, D2745, D4838, and D6531.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2066 − 07 (Reapproved 2012)

Standard Test Methods for

Relative Tinting Strength of Paste-Type Printing Ink

Dispersions

This standard is issued under the fixed designation D2066; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Color Differences from Instrumentally Measured Color

Coordinates

1.1 These test methods cover procedures for determining

D2745Test Method for Relative Tinting Strength of White

the relative tinting strength of paste-type printing ink disper-

Pigments by Reflectance Measurements

sions by visual or instrumental evaluation of tints prepared by

D4838Test Method for Determining the Relative Tinting

manual or automated mixing.

Strength of Chromatic Paints

1.2 These test methods are applicable to paste-type printing

D6531Test Method for Relative Tinting Strength of Aque-

inks, flushed pigments, and other pigment dispersions that are

ous Ink Systems by Instrumental Measurement

essentially nonvolatile under ordinary room conditions and for

E284Terminology of Appearance

which there is a wet reference standard of the same pigmen-

E691Practice for Conducting an Interlaboratory Study to

tationandconsistency.Withproperchoiceoftintingbase,they

Determine the Precision of a Test Method

are applicable to dispersions of any color, including black and

E1331Test Method for Reflectance Factor and Color by

white.

Spectrophotometry Using Hemispherical Geometry

E1347Test Method for Color and Color-Difference Mea-

NOTE1—Theinstrumentalproceduresfortintingstrengtharesimilarin

principle to those described in Test Methods D387, D2745, D4838, and

surement by Tristimulus Colorimetry

D6531.

E1349Test Method for Reflectance Factor and Color by

1.3 The values stated in SI units are to be regarded as the Spectrophotometry Using Bidirectional (45°:0° or 0°:45°)

Geometry

standard. The values given in parentheses are for information

only.

2.2 ANSI Standards:

PH 2.17Geometric Conditions for Reflection Density

1.4 This standard does not purport to address all of the

PH2.18SpectralConditionsfortheMeasurementofOptical

safety concerns, if any, associated with its use. It is the

Density

responsibility of the user of this standard to establish appro-

PH 2.30 Viewing Conditions for Graphic Arts and

priate safety and health practices and determine the applica-

Photography—ColorPrints,TransparenciesandPhotome-

bility of regulatory limitations prior to use.

chanical Reproductions

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions relating to color attributes and color differ-

D16TerminologyforPaint,RelatedCoatings,Materials,and

ences are covered in Terminology D16 and E284.

Applications

D387Test Method for Color and Strength of Chromatic

3.2 Definitions of Terms Specific to This Standard:

Pigments with a Mechanical Muller

3.2.1 masstone (or masscolor), n—the color of a material

D2244Practice for Calculation of Color Tolerances and

that is thick enough to mask any background.

3.2.2 tinting strength, n—the ability of a material to impart

its color to a standard base; the reciprocal of the relative

These test methods are under the jurisdiction of ASTM Committee D01 on

concentration required to match the reference material in a

Paint and Related Coatings, Materials, and Applications and are the direct

standard base.

responsibility of Subcommittee D01.56 on Printing Inks.

Current edition approved June 1, 2012. Published August 2012. Originally

3.2.3 undertone (or undercolor), n—the color of a thin film

approved in 1991. Last previous edition approved in 2007 as D2066–07. DOI:

of a material.

10.1520/D2066-07R12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2066 − 07 (2012)

4. Summary of Test Methods 6.5 Putty Knife, with an 80 to 120 mm wide blade having a

smooth straight edge (for use as a drawdown blade).

4.1 Thin and thick films of the standard and unknown

dispersions are drawn down in juxtaposition on bond and on 6.6 Standard Daylight, preferably a D50 light source con-

coated paper. Visual evaluation of the relative undertone and forming to ANSI Standard PH 2.30.

masstone provides a check on color equivalency.

6.7 Reflectance Measuring Instrument, (for instrumental

4.2 Thestandardandunknowndispersionsareeachreduced evaluation).Unlessotherwiseagreedupon,theinstrumentshall

to the same concentration in a suitable tinting base. Thick wet be a spectrophotometer with hemispherical (integrating-

drawdownsofthetwotintsareevaluatedfortintingstrengthby sphere) geometry conforming to Test Method E1331, a spec-

Test Methods A or B. trophotometer with bidirectional (45/0 or 0/45) geometry

4.2.1 Test Method A—Visual Evaluation: If the strength of conforming to Test Method E1349, or a tristimulus (filter)

the tints is judged unequal, aliquots of the stronger tint are colorimeter with either geometry conforming to Test Method

further reduced until equivalence is obtained. The tinting E1347. Alternatively, a reflection densitometer conforming to

strength of the unknown dispersion is calculated from the ANSI Standard PH 2.17 and having a set of Status T or Status

5,6

weight of extra tinting base added per unit weight of the E filters (see 12.3.2), conforming toANSI Standard PH 2.18

stronger tint. may be used for certain colors.

4.2.2 Test Method B—Instrumental Evaluation: Reflectance

NOTE 2—The filter systems in typical densitometers are suitable only

measurementsaremadeonthickwetfilmsoftheoriginaltints.

for use with black, white, and the three process colors (yellow, magenta

The tinting strength of the unknown dispersion is calculated

and cyan). Instrumental evaluation of other colors requires a spectropho-

tometer or a colorimeter.

according to a Kubelka-Munk equation.

4.3 Preparation of a confirming tint is recommended as an

7. Materials

unbiased method of verification. The preferred approach is to

7.1 Reference (Standard) Dispersion, having the same pig-

prepareanewtintoftheunknownataconcentrationcalculated

mentation and consistency as the test (unknown) dispersion.

to match the standard tint.

7.2 Tinting Base, as agreed upon between the producer and

5. Significance and Use

user, consisting of a suitable pigment well dispersed in a

5.1 Tinting strength is an essential property of printing ink vehicle that is compatible with the vehicle in the test disper-

dispersions.Although test results on wet drawdowns and tints sion. The consistency of the base should not be appreciably

do not guarantee equivalency of dry printed ink films, they lower than that of the test dispersion. Driers are not generally

provide useful parameters for quality assurance of established used because they may affect the color of the base and

formulations,gagingrelativedegreeofdispersion,andestimat-

corresponding tints.

5,7

ingthecolorvalueofcolorantsfromdifferentbatches,sources, 7.2.1 White Base, for testing colored and black disper-

or grades.

sions.Asuitable white base may contain by weight 30 to 60%

ofeitherzincoxideortitaniumdioxideand40to70%vehicle.

6. Apparatus

7.2.2 Black Base, for testing white dispersions. A suitable

black base may contain by weight 4% black pigment (prefer-

6.1 Laboratory Balance, sensitive to at least 1.0 mg, pref-

ably non-flocculating), 43% precipitated calcium carbonate,

erably 0.1 mg.

and 53% vehicle. Alternatively, a neutral black nondrying

4,5

6.2 FlackTek Speed Mixer (optional, for automated mix-

printing ink such as a news ink.

ing). Essential accessories include:

7.2.3 Dark Blue Base (optional), for visual testing of white

6.2.1 PlasticCup,preferablyMax15,formixing10to15g.

dispersions. A suitable dark blue base may contain by weight

Alarger cup, such as Max 40, may be useful for mixing 20 or

42% ultramarine blue, 18% precipitated calcium carbonate,

more g of tinting base prior to use.

and 40% vehicle.

6.2.2 Cup Holder, of a size appropriate to the cup used in

7.2.4 LightBlueBase(optional),forvisualtestingofyellow

6.2.1.

dispersions. A suitable light blue base may contain by weight

6.2.3 Thermometer, small, reading close to room tempera-

1% phthalocyanine blue dispersion and 99% white base.

ture, for measuring temperature of tints prepared on the

FlackTek. NOTE 3—Mixtures of a light blue base with yellow samples produce

green tints, differences between which are more easily detected by eye

6.3 Spatulas,(2)withflexibleblades80to120mminlength

than are mixtures of white and yellow. However, false results may be

(for weighing and mixing).

obtained. The use of a blue base is not recommended for visual tests on

greenish-yellowcolorantsandisnotpermittedforinstrumentalevaluation

6.4 Mixing Surface, such as a glass or similar slab fixed to

of any yellow colorant.

a work bench.

4 6

The sole source of supply of the apparatus known to the committee at this time StatusTfilters are available in the USA, Status E in other countries.The major

is FlackTek Inc., 1708 Highway 11, Building G, Landrum, SC 29356, http:// difference is in the peak transmission of the blue filter.

www.speedmixer.com/. The sole source of supply of the spectrophotochemically controlled NPIRI

If you are aware of alternative suppliers, please provide this information to Bleach White X-1025 known to the committee at this time is Colorcon, No-Tox

ASTM International Headquarters. Your comments will receive careful consider- Products, 171 New Britain Boulevard, Chalfont, PA 18914–1833, http://

ation at a meeting of the responsible technical committee, which you may attend. www.colorcon.com/no-tox/index.html.

D2066 − 07 (2012)

NOTE 5—If the hue or cleanliness of the test dispersion is significantly

7.3 Weighing Substrate (for manual mixing), nonabsorbent,

differentfromthestandarddispersion,tintingstrengthcannotbetestedby

such as skin paper or small glass plates ca 75 to 100 mm

the procedures covered in this test method. A numerical assessment of

square.

such systems may be obtained by making color measurements according

toTestMethodsE1331,E1347,orE1349andcalculatingcolordifferences

7.4 Drawdown Substrates, one consisting of white bond

by the 1976 CIELAB equations in accordance with Practice D2244.

paper at least 50-mm wide and 150-mm long with a black bar

at least 20-mm wide imprinted across the short dimension

10. Preparation of Tints

about half way down the length of the sheet, and a second one

10.1 Manual Mixing:

consisting of white coated paper.

10.1.1 Select a tinting base appropriate to the sample being

7.5 Microscope Cover Glasses (for instrumental measure-

tested (see 7.2). Examine the base for uniformity. If there are

ments), made of fine optical glass, 50 by 45 mm, 0.13 to 0.17

signs of separation or settling, stir thoroughly in container. If

mm thick.

necessary, transfer the quantity required for testing to a slab

7.6 Standard Spacer (for instrumental measurements), such and mix to ensure that the same composition of base will be

as cardstock the same size as the cover glass described in 7.5,

used for both the standard and the unknown samples.

about 1-mm thick, with a 35-mm diameter hole.

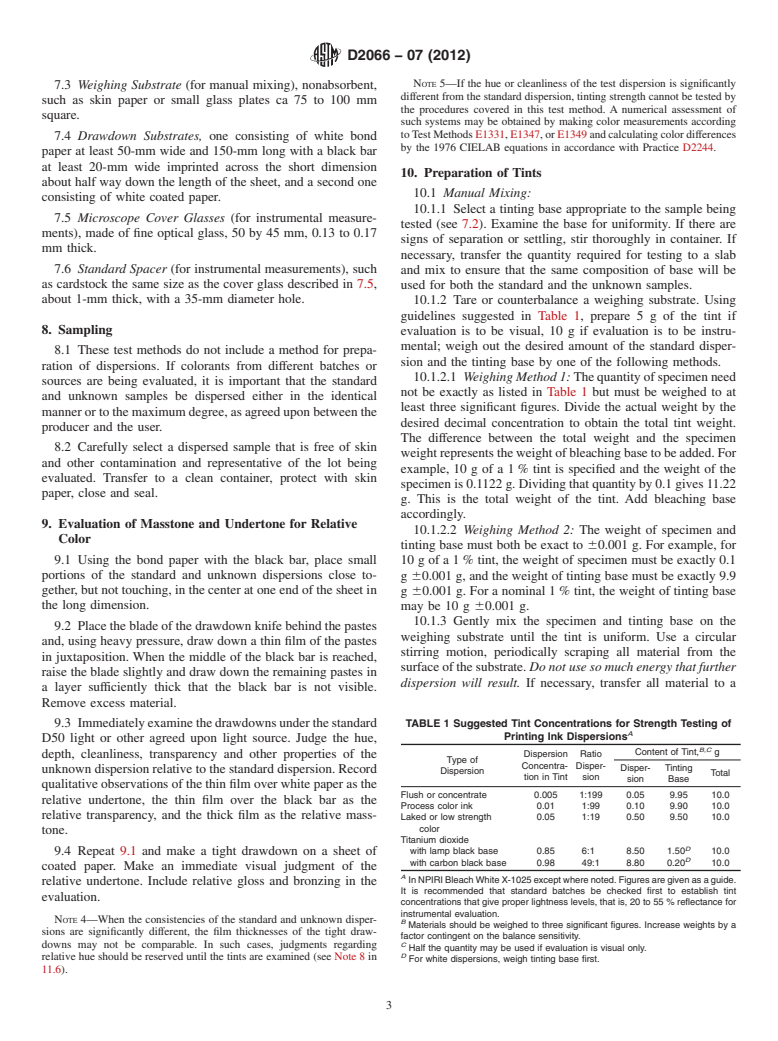

10.1.2 Tare or counterbalance a weighing substrate. Using

guidelines suggested in Table 1, prepare5gofthe tint if

8. Sampling

evaluation is to be visual, 10 g if evaluation is to be instru-

mental; weigh out the desired amount of the standard disper-

8.1 These test methods do not include a method for prepa-

sion and the tinting base by one of the following methods.

ration of dispersions. If colorants from different batches or

10.1.2.1 WeighingMethod1:Thequantityofspecimenneed

sources are being evaluated, it is important that the standard

not be exactly as listed in Table 1 but must be weighed to at

and unknown samples be dispersed either in the identical

least three significant figures. Divide the actual weight by the

mannerortothemaximumdegree,asagreeduponbetweenthe

desired decimal concentration to obtain the total tint weight.

producer and the user.

The difference between the total weight and the specimen

8.2 Carefully select a dispersed sample that is free of skin

weightrepresentstheweightofbleachingbasetobeadded.For

and other contamination and representative of the lot being

example, 10 g of a 1% tint is specified and the weight of the

evaluated. Transfer to a clean container, protect with skin

specimenis0.1122g.Dividingthatquantityby0.1gives11.22

paper, close and seal.

g. This is the total weight of the tint. Add bleaching base

accordingly.

9. Evaluation of Masstone and Undertone for Relative

10.1.2.2 Weighing Method 2: The weight of specimen and

Color

tinting base must both be exact to 60.001 g. For example, for

9.1 Using the bond paper with the black bar, place small 10 g of a 1% tint, the weight of specimen must be exactly 0.1

portions of the standard and unknown dispersions close to-

g 60.001 g, and the weight of tinting base must be exactly 9.9

gether,butnottouching,inthecenteratoneendofthesheetin g 60.001 g. For a nominal 1% tint, the weight of tinting base

the long dimension.

may be 10 g 60.001 g.

10.1.3 Gently mix the specimen and tinting base on the

9.2 Placethebladeofthedrawdownknifebehindthepastes

weighing substrate until the tint is uniform. Use a circular

and, using heavy pressure, draw down a thin film of the pastes

stirring motion, periodically scraping all material from the

in juxtaposition. When the middle of the black bar is reached,

surfaceofthesubstrate.Donotusesomuchenergythatfurther

raise the blade slightly and draw down the remaining pastes in

dispersion will result. If necessary, transfer all material to a

a layer sufficiently thick that the black bar is not visible.

Remove excess material.

9.3 Immediatelyexaminethedrawdownsunderthestandard

TABLE 1 Suggested Tint Concentrations for Strength Testing of

A

Printing Ink Dispersions

D50 light or other agreed upon light source. Judge the hue,

B,C

Content of Tint, g

depth, cleanliness, transparency and other properties of the Dispersion Ratio

Type of

Concentra- Disper-

Disper- Tinting

unknowndispersionrelativetothestandarddispersion.Record

Dispersion

Total

tion in Tint si

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.