ASTM C1142-95(2013)

(Specification)Standard Specification for Extended Life Mortar for Unit Masonry (Withdrawn 2019)

Standard Specification for Extended Life Mortar for Unit Masonry (Withdrawn 2019)

ABSTRACT

This specification covers extended life mortar of types RM, RS, RN, and RO, for use in construction of non-reinforced or reinforced unit masonry. Materials used as ingredients in extended life mortar shall be of the following: Portland cement, masonry cement, hydrated lime, aggregates, water, and admixtures. Water shall be clean and free of oils, acids, alkalines, salts, organic materials or other substances that may be deleterious to mortar or corrosive to metals in the masonry. Mortar shall conform to average compressive strength, water retention, and air content indicated in this specification. Specimen for laboratory testing shall have attained final set. Moreover, moist storage and curing condition of specimen shall conform to the specification. For testing, the cone penetration method shall be utilized to determine the consistency of the mortar. The air content of the mortar shall be determined by either the pressure method or the volumetric method.

SCOPE

1.1 This specification covers extended life mortar as delivered for use in construction of non-reinforced or reinforced unit masonry.

1.2 This specification is a property standard.

1.3 Four types of mortar are covered: RM, RS, RN, and RO. These types of mortar can be manufactured by using one of the four mortar formulations with masonry aggregate: portland cement, portland cement-lime, masonry cement, or masonry cement with portland cements. The materials are listed in Section 5.

1.4 Appendix X1 provides a rationale statement and commentary.

WITHDRAWN RATIONALE

This specification covers extended life mortar as delivered for use in construction of non-reinforced or reinforced unit masonry.

Formerly under the jurisdiction of Committee C12 on Mortars and Grouts for Unit Masonry, this specification was withdrawn in May 2019. This standard is being withdrawn without replacement. On technical review, it was realized that the specification contains compressive-strength requirements that are unrealistic, including C270 values for C780 field-cast specimens in either cubes or cylinders. There are currently no acceptable absolute compressive-strength values for C780 field-cast specimens. The C12 committee has purposely not put absolute values for of C780 field-cast compressive-strength specimens. The inclusion of absolute values for field-cast specimens in C1142 could create undesired precedents for other standards. In addition, the task group is not aware of any current users of extended-life mortar.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1142 −95 (Reapproved 2013)

Standard Specification for

Extended Life Mortar for Unit Masonry

This standard is issued under the fixed designation C1142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Document:

National Institute of Standards and Technology, Handbook

1.1 This specification covers extended life mortar as deliv-

44, Specifications, Tolerances, and Other Technical Re-

eredforuseinconstructionofnon-reinforcedorreinforcedunit

quirements for Commercial Weighing and Measuring

masonry.

Devices

1.2 This specification is a property standard.

3. Terminology

1.3 Fourtypesofmortararecovered:RM,RS,RN,andRO.

3.1 Definitions of Terms Specific to This Standard:

These types of mortar can be manufactured by using one of the

3.1.1 All terms in this specification have their conventional

four mortar formulations with masonry aggregate: portland

meaning, except as follows:

cement, portland cement-lime, masonry cement, or masonry

3.1.2 extended life mortars—mortar consisting of cementi-

cement with portland cements. The materials are listed in

tious materials, aggregate, water and set-control admixtures

Section 5.

which are measured and mixed at a central location, using

1.4 Appendix X1 provides a rationale statement and com-

weight-or-volume-controlequipment.Thismortar,asdelivered

mentary.

to a construction site, shall be usable for a period in excess of

2 ⁄2 h.

2. Referenced Documents

4. Ordering Information

2.1 ASTM Standards:

4.1 The purchaser shall specify the following:

C91 Specification for Masonry Cement

4.1.1 The mortar type in Table 1,

C144 Specification for Aggregate for Masonry Mortar

4.1.2 Length of workability time for the mortar, and

C150 Specification for Portland Cement

4.1.3 Desired consistency satisfactory for the mason’s use

C207 Specification for Hydrated Lime for Masonry Pur-

when tested by the manufacturer in accordance with 10.2.

poses

C270 Specification for Mortar for Unit Masonry

4.2 At the request of the purchaser, the producer shall, prior

C780 Test Method for Preconstruction and Construction

to delivery, furnish laboratory and field performance data

Evaluation of Mortars for Plain and Reinforced Unit

satisfactory to the purchaser that the materials to be used will

Masonry

produce mortar of the type specified.

C1072 Test Methods for Measurement of Masonry Flexural

NOTE 1—The purchase order or contract may list the mortar ingredients

Bond Strength

desired and may state a list of optional data, which are in addition to the

E447 Test Method for Compressive Strength of Laboratory

performance requirements in Section 7. Examples of such tests are: Test

Constructed Masonry Prisms (Withdrawn 1997) Method C1072, Test Methods E518, Test Methods E447, and test data for

mortar that has been re-tempered.

E518 Test Methods for Flexural Bond Strength of Masonry

5. Materials

5.1 Materials used as ingredients in extended life mortar

This specification is under the jurisdiction of ASTM Committee C12 on

shall conform to the requirements specified in 5.1.1 through

Mortars and Grouts for Unit Masonry and is the direct responsibility of Subcom-

5.1.4.2.

mittee C12.03 on Specifications for Mortars.

Current edition approved June 1, 2013. Published June 2013. Originally

5.1.1 Cementitious Materials—Cementitious materials shall

approved in 1990. Last previous edition approved in 2007 as C1142 – 95 (2007).

conform to the following ASTM specifications.

DOI: 10.1520/C1142-95R13.

5.1.1.1 Portland Cement—Types I, II or III of Specification

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM C150.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available from Superintendent of Documents, U.S. Government Printing

www.astm.org. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1142−95 (2013)

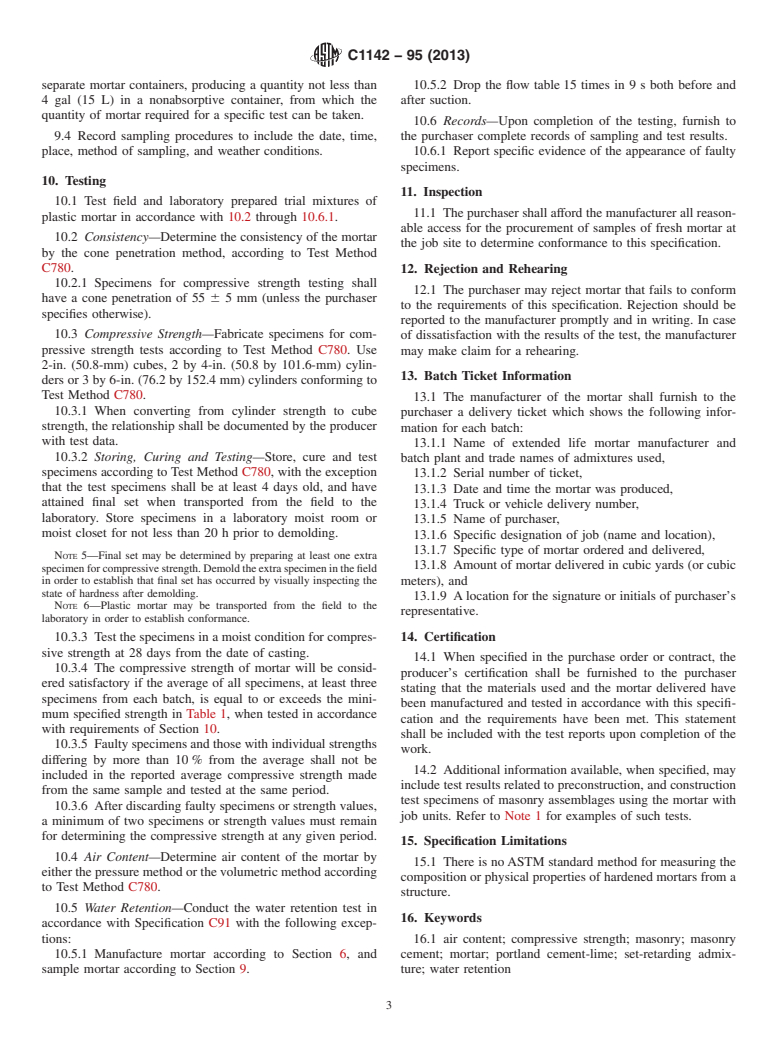

TABLE 1 Property Specification Requirements

6.4.1 Thoroughly mix and deliver to the construction site

A

Avg Compressive mortar with a satisfactory degree of workability and without

Water

Air

Strength

B

Mortar Type Retention

Content, segregation of ingredients.

at 28 days,

max, %

min, %

min psi, (MPa)

6.4.2 Temperature of the mortar at time of delivery shall be

Cubes

40 to 120°F (4 to 49°C).

RM 2500 (17.2) 75 18

RS 1800 (12.4) 75 18

7. Property Requirements

RN 750 (5.2) 75 18

RO 350 (2.4) 75 18

7.1 When sampled and tested in accordance with Sections 9

A

Twenty-eight days old from date of casting. Refer to 10.3.1. The strength values

and 10 respectively, the mortar shall comply with the appro-

as shown are the standard values. Intermediate values may be specified in

priate sections of Table 1.

accordance with project requirements.

B

When structural reinforcement is incorporated in mortar, the maximum air

7.2 Atest for compressive strength is the average of at least

content shall be 12 %, or bond strength test data shall be provided to justify higher

three specimens from one batch.

air content.

7.3 Mortar of known higher strength shall not be indiscrimi-

nately substituted when a mortar type of anticipated lower

strength is specified.

5.1.1.2 Masonry Cement—TypesM,S,orNofSpecification

C91.

7.4 Do not change the established proportions for extended

5.1.1.3 Hydrated Lime—Specification C207, Type S.

life mortar designed for a particular job, nor utilize materials

with different physical characteristics in the mix unless com-

NOTE 2—Type N limes may be permitted if shown by test or

pliance with the requirements of this specification are reestab-

performance record to be not detrimental by the autoclave expansion.

lished.

5.1.2 Aggregates—The aggregate shall comply with Speci-

7.4.1 Alter the dosage of the admixture which controls the

fication C144.

setting time when needed to maintain a similar time of set

5.1.3 Water—Water shall be clean and free of oils, acids,

during seasonal temperature changes.

alkalies, salts, organic materials or other substances that may

be deleterious to mortar or corrosive to metals in the masonry. NOTE 3—Consistency of the mortar should be correlated with the

particular masonry unit to be used because certain mortars are more

5.1.4 Admixtures—Admixtures are permitted for use only at

compatible with certain masonry units. The specifier should consult the

the production plant.

admixture manufacturer to evaluate the interaction of the mortar type and

5.1.4.1 Evidence satisfactory to the purchaser shall be

masonry unit specified. Masonry units having a high initial rate of

provided to show that the admixtures do not cause nor

absorption will have greater compatibility with mortar of high-water

retentivity. Refer to the Related Items That Have an Effect on Properties

accelerate corrosion of metal which will be in contact with

section in Appendix X1 of Specification C270.

mortar.

5.1.4.2 Any admixture to be used shall be subject to written

8. Field Practice

certification from the manufacturer, supported by evidence that

8.1 Tempering Mortars—Mortars that have stiffened due to

the admixture will have no adverse effect on the long-term

loss of water by evaporation shall be re-tempered not more

strength, durability, or appearance of the mortar nor on any

than one time during the working life of the mortar by adding

material or component in contact with the mortar, nor any

water to restore the required consistency.

assemblage of which the mortar forms a part.

8.1.1 Do not use mortar beyond the period of time estab-

6. Manufacture and Delivery lished by the manufacturer. This time period shall be docu-

mented with test data.

6.1 Storage of Materials—Cementitious materials and ag-

gregates shall be stored in such a manner as to prevent

NOTE 4—Extended life mortar is usually designed to have a workability

period between 24 to 36 h.

deterioration and contamination.

8.2 Storage at the Site—The mortar shall be protected from

6.2 Measurement of Materials—Measurematerialsinaccor-

freezing and evaporation.

dance with 6.2.1 through 6.2.4.

6.2.1 Cementitious materials and the aggregate shall be

9. Sampling

measured by weight or by volume. Volumetric measurement

shall be calibrated by weight. 9.1 Sampling Materials—The mortar materials for labora-

6.2.2 Scales for batching mortar ingredients shall conform tory tests shall be sampled at the plant where the mortar is

to the applicable sections of the current edition of the National manufactured. Water, aggregate and cementitious material

Institute of Standards and Technology, Handbook 44. shall be sampled in accordance with Test Method C780.

6.2.3 Measure water by weight or by volume.

9.2 Sampling Plastic Mortar at the Plant—Discharge from

6.2.4 Measure admixtures by weight or by volume.

the mixer a thoroughly mixed sample of mortar not less than 4

6.3 Mixing—Mix extended life mortar ingredients at a gal (15 L) into a nonabsorptive container, from which the

central location using either truck mixers or stationary mixers. quantity of mortar required for a specific quality control test

6.3.1 Agitation, not mixing, is allowed during transport. can be taken.

6.4 Delivery—Unless otherwise specified, a delivery of the 9.3 Sampling Plastic Mortar at the Site—Obtain a compos-

mortar shall conform to 6.4.1 and 6.4.2. ite sample by combining at least three equal portions from

C1142−95 (2013)

separate mortar containers, producing a quantity not less than 10.5.2 Drop the flow table 15 times in 9 s both before and

4 gal (15 L) in a nonabsorptive container, from which the after suction.

quantity of mortar required for a specific test can be taken.

10.6 Records—Upon completion of the testing, furnish to

9.4 Record sampling procedures to include the date, time, the purchaser complete records of sampling and test results.

place, method of sampling, and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.