ASTM F2590-06(2022)

(Specification)Standard Specification for Bearing, Roller, Thrust, Two Channeled Race Surface, Rigid or Flat Seat Type

Standard Specification for Bearing, Roller, Thrust, Two Channeled Race Surface, Rigid or Flat Seat Type

ABSTRACT

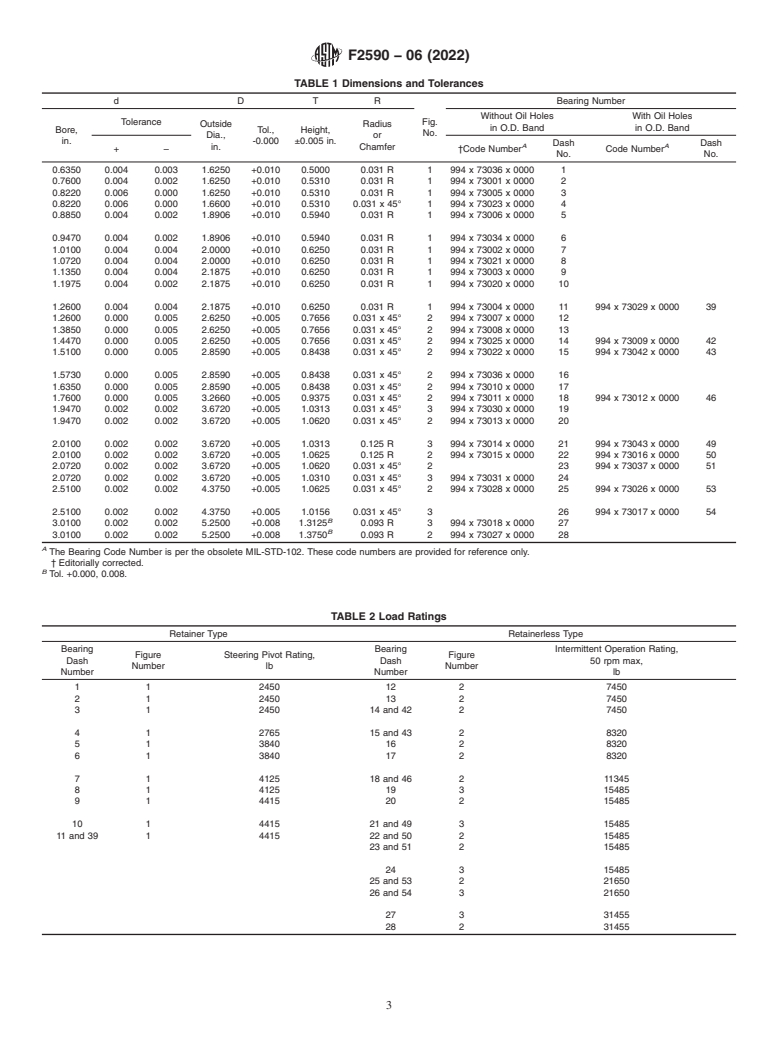

This specification covers requirements for rigid or flat seat type, two channeled race surface, thrust roller bearings intended for use in slow rotating or oscillating applications where pure thrust loads are applied. The thrust bearing shall be made of the specified high carbon chromium alloy steel. Requirements for (1) physical properties such as heat treatment, (2) dimensions and mass, and (3) surface finish are specified. Dimensions of retainer type, steering gear service and retainerless type, intermittent operation, are illustrated.

SCOPE

1.1 This specification covers requirements for rigid or flat seat type, two channeled race surface, thrust roller bearings.

1.2 Intended Use—The bearings covered in this specification are intended for use in slow rotating or oscillating applications where pure thrust loads are applied.

1.3 This specification contains many of the requirements of MS17169, which was originally developed by the Department of Defense and maintained by the Defense Supply Center in Richmond. The following government activity codes may be found in the Department of Defense, Standardization Directory SD-1.2

Preparing Activity

Custodians

Review Activities

DLA-GS4

Army-AT

Army-MI

Navy-MC

Air Force-84

Air Force-99

DLA-GS4

1.4 For design feature purposes, this specification takes precedence over procurement documents referenced herein.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F2590 −06 (Reapproved 2022)

Standard Specification for

Bearing, Roller, Thrust, Two Channeled Race Surface, Rigid

or Flat Seat Type

This standard is issued under the fixed designation F2590; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This specification covers requirements for rigid or flat

seat type, two channeled race surface, thrust roller bearings.

2. Referenced Documents

1.2 Intended Use—The bearings covered in this specifica- 3

2.1 ABMA Standard:

tion are intended for use in slow rotating or oscillating

ABMAStd. 1 Terminology forAnti-Friction Ball and Roller

applications where pure thrust loads are applied.

Bearings and Parts

1.3 This specification contains many of the requirements of 2.2 ASME Standard:

MS17169, which was originally developed by the Department ASME B46.1 Surface Texture (Surface Roughness,

of Defense and maintained by the Defense Supply Center in Waviness, and Lay)

Richmond. The following government activity codes may be 2.3 ISO Standard:

found in the Department of Defense, Standardization Directory ISO 5593 Rolling Bearings—Vocabulary

2 6

SD-1. 2.4 Military Standards:

MIL-STD-102 Electronic and Electrical Component Parts

Preparing Activity Custodians Review Activities

DLA-GS4 Army-AT Army-MI

MIL-STD-129 Military Marking for Shipment and Storage

Navy-MC Air Force-84

MIL-STD-130 Identification Marking of U.S. Military Prop-

Air Force-99

erty

DLA-GS4

2.5 SAE Standard:

1.4 For design feature purposes, this specification takes

SAEAMS-STD-66 Steel: Chemical Composition and Hard-

precedence over procurement documents referenced herein.

enability

1.5 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3. Terminology

conversions to SI units that are provided for information only

3.1 Definitions—For definitions of terms used in this

and are not considered standard.

specification, refer to ABMA Std. 1 and ISO 5593.

1.6 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 steering pivot rating—steering pivot rating is used to

responsibility of the user of this standard to establish appro-

determine what size bearing is needed for a particular appli-

priate safety, health, and environmental practices and deter-

cation. Bearings with this rating were originally designed and

mine the applicability of regulatory limitations prior to use.

intended for use in the king pins of front axles on large trucks.

1.7 This international standard was developed in accor-

In this application, the bearings are subject to only oscillation

dance with internationally recognized principles on standard-

motion, with a lot of shock and vibration loading. The steering

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

Available from Techstreet, 777 E. Eisenhower Parkway,AnnArbor, MI 48108.

Available from American Society of Mechanical Engineers (ASME), ASME

This specification is under the jurisdiction ofASTM Committee F34 on Rolling International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

Element Bearings and is the direct responsibility of Subcommittee F34.04 on www.asme.org.

Automotive/Industrial Bearing. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved Jan. 1, 2022. Published January 2022. Originally 4th Floor, New York, NY 10036.

approved in 2006. Last previous edition approved in 2013 as F2590 – 06(2013). Available from the DOD’s Assist internet site located at: http://

DOI: 10.1520/F2590-06R22. assist.daps.dla.mil/online/start/. Available from DLA Document Services, Building

The Military codes that are listed in SD-1 give the address and phone numbers 4/D, 700 Robbins Ave., Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

of the DoD contacts. These are found in the DoD’s ASSIST website http:// Available from the Society of Automotive Engineers (SAE), 400 Common-

assist.daps.dla.mil/online/start/ wealth Dr. Warrendale, PA 15096-0001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2590−06 (2022)

pivot rating includes a safety factor of approximately 2.0 to

compensate for the indeterminate shock and vibration.

Therefore, when these bearings are used in crane hook appli-

cations or other similar steady pull applications, the steering

pivot rating can be doubled. It should also be kept in mind that

these bearings were designed for oscillating or slow rotation

applications only and should never be operated at speeds

higher than 5 rpm.

FIG. 2Retainerless Type—Intermittent Operation—50 RPM Max

3.2.2 intermittent operation rating—the intermittent opera-

tion rating is used to determine what size bearing is needed for

a particular application. Bearings with this rating were origi-

7. Dimensions, Mass, and Permissible Variations

nally designed and intended for rotational applications operat-

7.1 See Figs. 1 and 2 and Tables 1 and 2.

ing at speeds of 50 rpm or less.

4. Ordering Information

8. Workmanship, Finish, and Appearance

4.1 Procurement documents should specify the following:

8.1 Surface Finish—Surfaces described below shall have a

4.1.1 Title, number, and date of this specification,

surface fini

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.