ASTM D8132/D8132M-23

(Test Method)Standard Test Method for Determination of Prepreg Impregnation by Permeability Measurement

Standard Test Method for Determination of Prepreg Impregnation by Permeability Measurement

SIGNIFICANCE AND USE

5.1 It is well known that the prepreg impregnation level affects handling characteristics, tack and drape, and final part quality. Resin impregnation level is the dominant factor in the ability of removing air and volatiles from the layup during processing. Partially impregnated prepreg materials can in some applications provide higher quality, lower void content composite parts, and are becoming increasingly more common due to the desire to cure out-of-autoclave, using vacuum bag-only processes. This test can identify small changes in the material impregnation level which can assist in definition of production processes or shipping and handling procedures. The value of permeability can be used for specifying ranges as acceptance requirements for prepreg materials, thus enabling the prepreg manufacturer and user greater confidence in the ability to produce repeatable and high quality parts. This test directly determines the actual air flow propensity of the material tested without any applied compaction pressure during testing.

5.2 Factors that influence the permeability of the tested prepreg material shall be reported including: prepreg material, orientation, location on roll, width, length, thickness, and actual atmospheric pressure.

SCOPE

1.1 This test method determines the in-plane permeability of composite prepreg (pre-impregnated) materials as a measure of level of impregnation. Permissible prepreg materials include those reinforced with carbon, glass, aramid, thermoplastic and other fibers impregnated with a thermoset or thermoplastic matrix resin, creating a single ply sheet material. The reinforcements may be unidirectional or woven fabrics.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8132/D8132M − 23

Standard Test Method for

Determination of Prepreg Impregnation by Permeability

1

Measurement

This standard is issued under the fixed designation D8132/D8132M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method determines the in-plane permeability of

E456 Terminology Relating to Quality and Statistics

composite prepreg (pre-impregnated) materials as a measure of

E691 Practice for Conducting an Interlaboratory Study to

level of impregnation. Permissible prepreg materials include

Determine the Precision of a Test Method

those reinforced with carbon, glass, aramid, thermoplastic and

other fibers impregnated with a thermoset or thermoplastic

3. Terminology

matrix resin, creating a single ply sheet material. The reinforce-

3.1 Definitions—Terminology D3878 defines terms relating

ments may be unidirectional or woven fabrics.

to high-modulus fibers and their composites. Terminology

1.2 The values stated in either SI units or inch-pound units

D883 defines terms relating to plastics. Terminology E456 and

are to be regarded separately as standard. The values stated in

Practice E177 define terms relating to statistics. In the event of

each system are not necessarily exact equivalents; therefore, to

a conflict between terms, Terminology D3878 shall have

ensure conformance with the standard, each system shall be

precedence over the other terminologies.

used independently of the other, and values from the two

3.2 Definitions of Terms Specific to This Standard:

systems shall not be combined.

3.2.1 as cast—pertaining to the transparent and smooth

1.2.1 Within the text, the inch-pound units are shown in

surface of an acrylic block.

brackets.

3.2.2 acrylic block assembly—the acrylic blocks nested

1.3 This standard does not purport to address all of the

together or clamped together but that are otherwise oriented or

safety concerns, if any, associated with its use. It is the

joined together only for a temporary process.

responsibility of the user of this standard to establish appro-

3.2.3 cut side—machined surface of an acrylic block.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.2.4 permeability—material property that determines flow

1.4 This international standard was developed in accor-

through a porous medium. Within this standard, used to

dance with internationally recognized principles on standard-

determine the air transport of prepreg materials in the in-plane

ization established in the Decision on Principles for the

directions.

Development of International Standards, Guides and Recom-

3.2.5 permeability test apparatus—the vacuum test chamber

mendations issued by the World Trade Organization Technical

with known volume where the permeability test specimen is

Barriers to Trade (TBT) Committee.

mounted and tested to determine permeability.

3.2.6 permeability test specimen—specimen prepared for

2. Referenced Documents

the permeability test.

2.1 ASTM Standards:

3.3 Symbols

D883 Terminology Relating to Plastics

A = cross-sectional area of the prepreg test specimen

D3878 Terminology for Composite Materials

CV = coefficient of variation of a sample population for a

E122 Practice for Calculating Sample Size to Estimate, With

given property (in percent)

Specified Precision, the Average for a Characteristic of a

FAW = fiber areal weight

Lot or Process

H = prepreg thickness

ID = inner diameter

1

K = permeability

This test method is under the jurisdiction of ASTM Committee D30 on

Composite Materials and is the direct responsibility of Subcommittee D30.03 on

K = normalized permeability (independent of prepreg

n

Constituent/Precursor Properties.

thickness)

Current edition approved Sept. 1, 2023. Published October 2023. Originally

L = length of prepreg sample

approved in 2017. Last previous edition approved in 2017 as D8132/D8132M – 17.

DOI: 10.1520/D8132_D8132M-23. OD = outer diameter

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

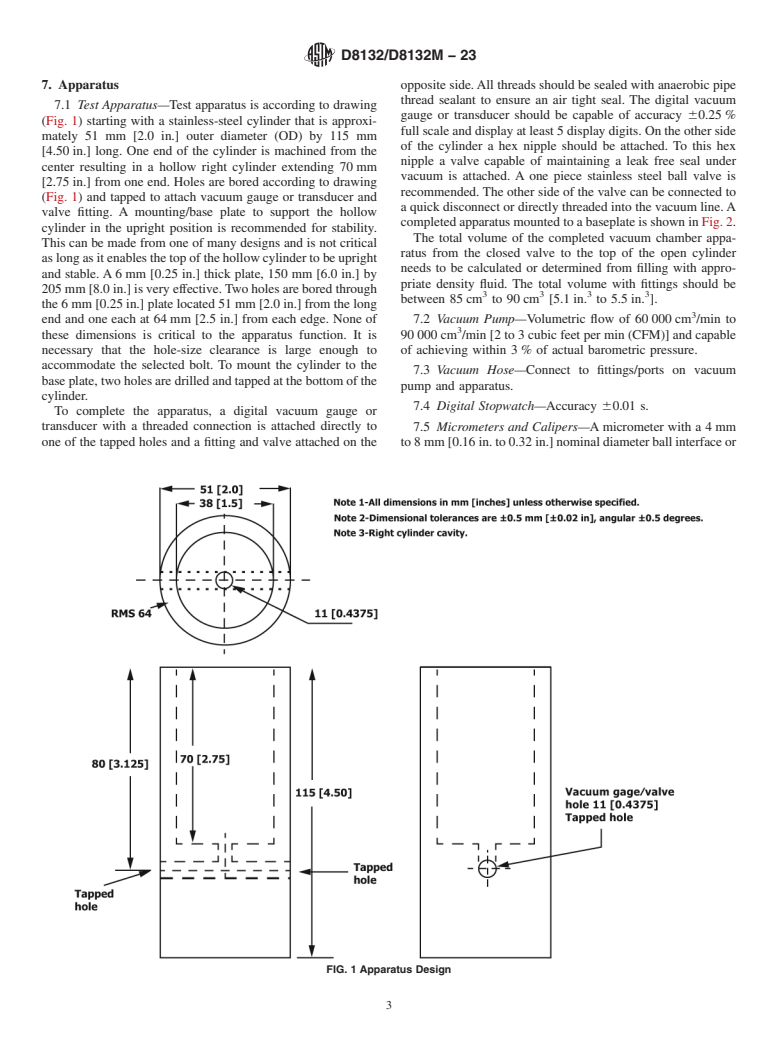

D8132/D8132M − 23

P = absolute pressure in vacuum chamber (P as a function of orientation, location on roll, width, length, thickness, and

time) actual atmospheric pressure.

P = actual atmospheric pressure

atm

P = init

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D8132/D8132M − 17 D8132/D8132M − 23

Standard Test Method for

Determination of Prepreg Impregnation by Permeability

1

Measurement

This standard is issued under the fixed designation D8132/D8132M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method determines the in-plane permeability of composite prepreg (pre-impregnated) materials as a measure of level

of impregnation. Permissible prepreg materials include those reinforced with carbon, glass, aramid, thermoplastic and other fibers

impregnated with a thermoset or thermoplastic matrix resin, creating a single ply sheet material. The reinforcements may be

unidirectional or woven fabrics.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other, and values from the two systems shall not be combined.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D3878 Terminology for Composite Materials

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—Terminology D3878 defines terms relating to high-modulus fibers and their composites. Terminology D883

1

This test method is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.03 on

Constituent/Precursor Properties.

Current edition approved Aug. 1, 2017Sept. 1, 2023. Published September 2017October 2023. Originally approved in 2017. Last previous edition approved in 2017 as

D8132/D8132M – 17. DOI: 10.1520/D8132_D8132M-1710.1520/D8132_D8132M-23.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8132/D8132M − 23

defines terms relating to plastics. Terminology E456 and Practice E177 define terms relating to statistics. In the event of a conflict

between terms, Terminology D3878 shall have precedence over the other terminologies.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 as cast—pertaining to the transparent and smooth surface of an acrylic block.

3.2.2 acrylic block assembly—the acrylic blocks nested together or clamped together but that are otherwise oriented or joined

together only for a temporary process.

3.2.3 cut side—machined surface of an acrylic block.

3.2.4 permeability—Materialmaterial property that determines flow through a porous medium. Used Within this standard, used to

determine the air transport of prepreg materials in the in-plane directions.

3.2.5 permeability test apparatus—the vacuum test chamber with known volume where the permeability test specimen is mounted

and tested to determine permeability.

3.2.6 permeability test specimen—the vacuum test chamber with known volume where the permeability test specimen is mounted

and tested to determine permeability.specimen prepared for the permeability test.

3.3 Symbols

A = cross-sectional area of the prepreg test specimen

CV = coefficient of variation statistic of a sample population for a given property (in percent)

FAW = fiber areal weight

H = prepreg thickness

ID = inner diameter

K =

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.