ASTM B733-22

(Specification)Standard Specification for Autocatalytic (Electroless) Nickel-Phosphorus Coatings on Metal

Standard Specification for Autocatalytic (Electroless) Nickel-Phosphorus Coatings on Metal

ABSTRACT

This specification establishes the requirements for autocatalytic (electroless) nickel-phosphorus coatings applied from acidic aqueous solutions to metallic products for use in engineering functions operating at elevated temperatures. The coatings covered here are alloys of nickel and phosphorus produced by self-sustaining autocatalytic chemical reduction with hypophosphite. The coatings are grouped into the following classification systems: types, which are based on the general composition with respect to phosphorus; service condition numbers, which are based on the severity of exposure to which the coating is intended to perform and the corresponding minimum thickness that will provide satisfactory performance; and post heat treatment class, which are based on post-plating heat treatment temperature and time to produce the desired adhesion and hardness improvements. Prior to plating, substrates should be pretreated by stress relief for reducing risks of hydrogen embrittlement, peening, and racking. The coatings shall be sampled and tested accordingly to evaluate both acceptance (appearance, thickness, adhesion, and porosity) and qualification requirements (composition, microhardness, and hydrogen embrittlement). Thickness shall be assessed either by microscopical method, a magnetic induction instrument, beta backscatter method, a micrometer, weigh-plate-weigh method, coulometric method, or X-ray spectrometry. Adhesion shall be examined either by bend, impact, or thermal shock tests. And porosity shall be inspected either by ferroxyl test, boiling water test, aerated water test, or alizarin test.

SCOPE

1.1 This specification covers requirements for autocatalytic (electroless) nickel-phosphorus coatings applied from aqueous solutions to metallic products for engineering (functional) uses.

1.2 The coatings are alloys of nickel and phosphorus produced by autocatalytic chemical reduction with hypophosphite. Because the deposited nickel alloy is a catalyst for the reaction, the process is self-sustaining. The chemical and physical properties of the deposit vary primarily with its phosphorus content and subsequent heat treatment. The chemical makeup of the plating solution and the use of the solution can affect the porosity and corrosion resistance of the deposit. For more details, see ASTM STP 265 (1)2 and Refs (2), (3), (4), and (5).

1.3 The coatings are generally deposited from acidic solutions operating at elevated temperatures.

1.4 The process produces coatings of uniform thickness on irregularly shaped parts, provided the plating solution circulates freely over their surfaces.

1.5 The coatings have multifunctional properties, such as hardness, heat hardenability, abrasion, wear and corrosion resistance, magnetics, electrical conductivity provide diffusion barrier, and solderability. They are also used for the salvage of worn or mismachined parts.

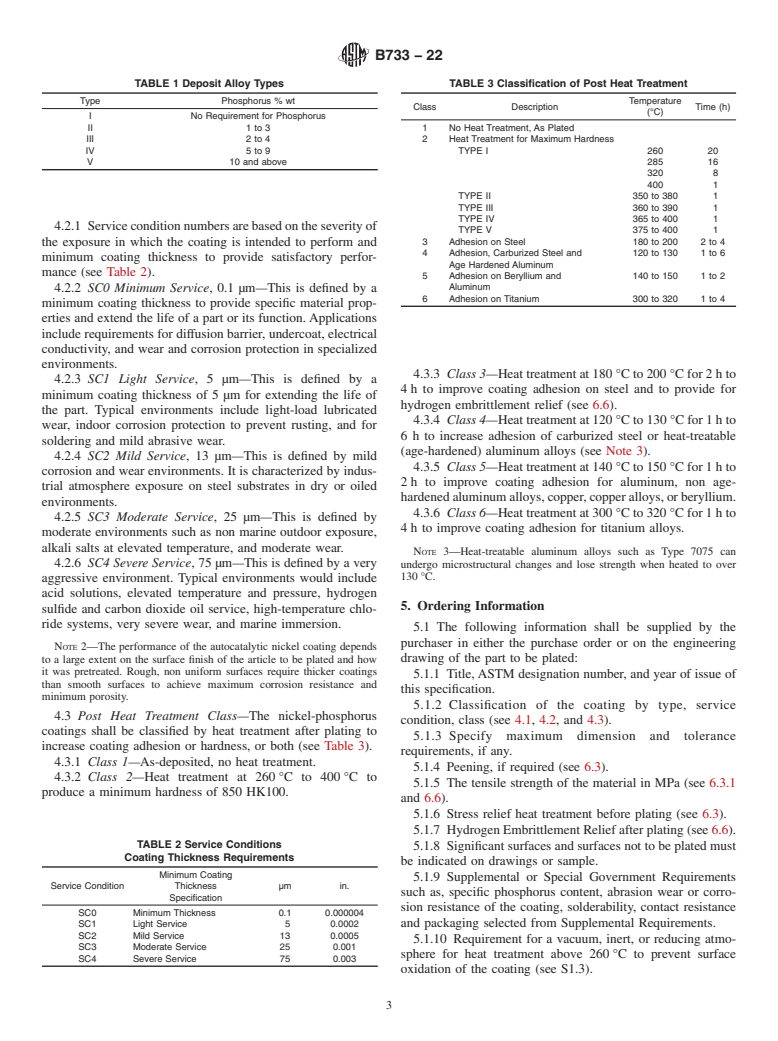

1.6 The low phosphorus (2 to 4 % P) coatings are microcrystalline and possess high as-plated hardness (620 to 750 HK 100). These coatings are used in applications requiring abrasion and wear resistance.

1.7 Lower phosphorus deposits in the range between 1 % and 3 % phosphorus are also microcrystalline. These coatings are used in electronic applications providing solderability, bondability, increased electrical conductivity, and resistance to strong alkali solutions.

1.8 The medium phosphorous coatings (5 to 9 % P) are most widely used to meet the general purpose requirements of wear and corrosion resistance.

1.9 The high phosphorous (more than 10 % P) coatings have superior salt-spray and acid resistance in a wide range of applications. They are used on beryllium and titanium parts for low stress properties. Coatings with phosphorus contents greater than 11.2 % P are not considered to be ferromagnetic.

1.10 Units—The values stated in SI units are to be regarded as standard.

1.11 The following precautionary statement pertains onl...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B733 −22

Standard Specification for

Autocatalytic (Electroless) Nickel-Phosphorus Coatings on

1

Metal

This standard is issued under the fixed designation B733; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* bondability, increased electrical conductivity, and resistance to

strong alkali solutions.

1.1 This specification covers requirements for autocatalytic

(electroless) nickel-phosphorus coatings applied from aqueous 1.8 Themediumphosphorouscoatings(5to9%P)aremost

widely used to meet the general purpose requirements of wear

solutionstometallicproductsforengineering(functional)uses.

and corrosion resistance.

1.2 The coatings are alloys of nickel and phosphorus pro-

1.9 The high phosphorous (more than 10% P) coatings

ducedbyautocatalyticchemicalreductionwithhypophosphite.

have superior salt-spray and acid resistance in a wide range of

Becausethedepositednickelalloyisacatalystforthereaction,

applications.Theyareusedonberylliumandtitaniumpartsfor

the process is self-sustaining. The chemical and physical

low stress properties. Coatings with phosphorus contents

properties of the deposit vary primarily with its phosphorus

greater than 11.2% P are not considered to be ferromagnetic.

content and subsequent heat treatment. The chemical makeup

oftheplatingsolutionandtheuseofthesolutioncanaffectthe

1.10 Units—The values stated in SI units are to be regarded

porosity and corrosion resistance of the deposit. For more

as standard.

2

details, seeASTM STP265 (1) and Refs (2), (3), (4), and (5).

1.11 Thefollowingprecautionarystatementpertainsonlyto

1.3 The coatings are generally deposited from acidic solu-

the test method portion, Section 9, of this specification. This

tions operating at elevated temperatures.

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

1.4 The process produces coatings of uniform thickness on

of this standard to establish appropriate safety, health, and

irregularly shaped parts, provided the plating solution circu-

environmental practices and determine the applicability of

lates freely over their surfaces.

regulatory limitations prior to use.

1.5 The coatings have multifunctional properties, such as

1.12 This international standard was developed in accor-

hardness, heat hardenability, abrasion, wear and corrosion

dance with internationally recognized principles on standard-

resistance, magnetics, electrical conductivity provide diffusion

ization established in the Decision on Principles for the

barrier, and solderability.They are also used for the salvage of

Development of International Standards, Guides and Recom-

worn or mismachined parts.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.6 The low phosphorus (2 to 4% P) coatings are microc-

rystalline and possess high as-plated hardness (620 to 750 HK

2. Referenced Documents

100). These coatings are used in applications requiring abra-

3

2.1 ASTM Standards:

sion and wear resistance.

B368Test Method for Copper-AcceleratedAceticAcid-Salt

1.7 Lower phosphorus deposits in the range between 1%

Spray (Fog) Testing (CASS Test)

and 3% phosphorus are also microcrystalline. These coatings

B374Terminology Relating to Electroplating

are used in electronic applications providing solderability,

B380Test Method for Corrosion Testing of Decorative

Electrodeposited Coatings by the Corrodkote Procedure

B487Test Method for Measurement of Metal and Oxide

1

This specification is under the jurisdiction of ASTM Committee B08 on

Coating Thickness by Microscopical Examination of

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

Cross Section

B08.03 on Engineering Coatings.

Current edition approved May 1, 2022. Published May 2022. Originally

3

approved in 1984. Last previous edition approved in 2021 as B733–21. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/B0733-22. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers given in parentheses refer to a list of references at the Standards volume information, refer to the standard’s Document Summary page on

end of the text. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B733 − 21 B733 − 22

Standard Specification for

Autocatalytic (Electroless) Nickel-Phosphorus Coatings on

1

Metal

This standard is issued under the fixed designation B733; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers requirements for autocatalytic (electroless) nickel-phosphorus coatings applied from aqueous

solutions to metallic products for engineering (functional) uses.

1.2 The coatings are alloys of nickel and phosphorus produced by autocatalytic chemical reduction with hypophosphite. Because

the deposited nickel alloy is a catalyst for the reaction, the process is self-sustaining. The chemical and physical properties of the

deposit vary primarily with its phosphorus content and subsequent heat treatment. The chemical makeup of the plating solution

and the use of the solution can affect the porosity and corrosion resistance of the deposit. For more details, see ASTM STP 265

2

(1) and Refs (2), (3), (4), and (5).

1.3 The coatings are generally deposited from acidic solutions operating at elevated temperatures.

1.4 The process produces coatings of uniform thickness on irregularly shaped parts, provided the plating solution circulates freely

over their surfaces.

1.5 The coatings have multifunctional properties, such as hardness, heat hardenability, abrasion, wear and corrosion resistance,

magnetics, electrical conductivity provide diffusion barrier, and solderability. They are also used for the salvage of worn or

mismachined parts.

1.6 The low phosphorus (2 to 4 % P) coatings are microcrystalline and possess high as-plated hardness (620 to 750 HK 100).

These coatings are used in applications requiring abrasion and wear resistance.

1.7 Lower phosphorus deposits in the range between 1 % and 3 % phosphorus are also microcrystalline. These coatings are used

in electronic applications providing solderability, bondability, increased electrical conductivity, and resistance to strong alkali

solutions.

1.8 The medium phosphorous coatings (5 to 9 % P) are most widely used to meet the general purpose requirements of wear and

corrosion resistance.

1

This specification is under the jurisdiction of ASTM Committee B08 on Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee B08.03 on

Engineering Coatings.

Current edition approved Oct. 15, 2021May 1, 2022. Published November 2021May 2022. Originally approved in 1984. Last previous edition approved in 20152021 as

B733 – 15.B733 – 21. DOI: 10.1520/B0733-21. 10.1520/B0733-22.

2

The boldface numbers given in parentheses refer to a list of references at the end of the text.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B733 − 22

1.9 The high phosphorous (more than 10 % P) coatings have superior salt-spray and acid resistance in a wide range of applications.

They are used on beryllium and titanium parts for low stress properties. Coatings with phosphorus contents greater than 11.2 %

P are not considered to be ferromagnetic.

1.10 Units—The values stated in SI units are to be regarded as standard.

1.11 The following precautionary statement pertains only to the test method portion, Section 9, of this specification. This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

1.12 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

B368 Test Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS Test)

B374 Terminology Relating to Electroplating

B380 Test Method for Corrosion Testing of De

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.