ASTM B775-00

(Specification)Standard Specification for General Requirements for Nickel and Nickel Alloy Welded Pipe

Standard Specification for General Requirements for Nickel and Nickel Alloy Welded Pipe

SCOPE

1.1 This specification contains various requirements that, with the exception of Section 5 and Section 10, are mandatory requirements to the following ASTM nickel and nickel alloy, longitudinally welded piping specifications:Title of SpecificationASTMDesignationWelded UNS N08020, N08024, and N08026 Alloy PipeB 464Welded Nickel-Iron-Chromium Alloy PipeB 514Welded Nickel-Chromium-Iron-Alloy (UNS N06600, UNS N06603, UNS N06025 and UNS N06045) PipeB 517Welded Nickel and Nickel-Cobalt Alloy PipeB 619UNS N08904, UNS N08925, and UNS N08926 Welded PipeB 673UNS N08367 Welded PipeB 675Nickel-Alloy (UNS N06625, N06219, and N08825) Welded PipeB 705Ni-Cr-Mo-Co-W-Fe-Si Alloy (UNS N06333) Welded PipeB 723Welded Nickel (UNS N02200/UNS N02201) and Nickel Copper Alloy (UNS N04400) PipeB 725

1.2 One or more of the test requirements of Section 5 apply only if specifically stated in the product specification or in the purchase order.

1.3 In case of conflict between a requirement of the product specification and a requirement of this general specification, only the requirement of the product specification needs to be satisfied.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 775 – 00 An American National Standard

Standard Specification for

General Requirements for Nickel and Nickel Alloy Welded

Pipe

This standard is issued under the fixed designation B 775; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1.1 This specification contains various requirements that,

E 39 Test Methods for Chemical Analysis of Nickel

with the exception of Section 5 and Section 10, are mandatory

E 76 Test Methods for Chemical Analysis of Nickel Copper

requirements to the following ASTM nickel and nickel alloy,

Alloys

longitudinally welded piping specifications:

E 112 Test Methods for Determining the Average Grain

ASTM

Size

Title of Specification Designation

E 213 Practice for Ultrasonic Examination of Metal Pipe

Welded UNS N08020, UNS N08024, and UNS N08026 Alloy B 464

and Tubing

Pipe

E 426 Practice for Electromagnetic (Eddy-Current) Exami-

Welded Nickel-Iron-Chromium Alloy Pipe B 514

Welded Nickel-Chromium-Iron-Alloy (UNS N06600) Pipe B 517

nation of Seamless and Welded Tubular Products, Austen-

Welded Nickel and Nickel-Cobalt Alloy Pipe B 619

itic Stainless Steel and Similar Alloys

UNS N08904, UNS N08925, and UNS N08926 Welded Pipe B 673

UNS N08366 and UNS N08367 Welded Pipe B 675 E 571 Practice for Electromagnetic (Eddy-Current) Exami-

Nickel-Alloy (UNS N06625 and N08825) Welded Pipe B 705

nation of Nickel and Nickel Alloy Tubular Products

Ni-Cr-Mo-Co-W-Fe-Si Alloy (UNS N06333) Welded Pipe B 723

E 1473 Test Methods for Chemical Analysis of Nickel,

Welded Nickel (UNS N02200/UNS N02201) and Nickel B 725

Cobalt, and High-Temperature Alloys

Copper Alloy (UNS N04400) Pipe

2.2 ANSI Standards:

1.2 One or more of the test requirements of Section 5 apply

B 1.20.1 Pipe Threads

only if specifically stated in the product specification or in the

B 36.10 Welded and Seamless Wrought Steel Pipe

purchase order.

B 36.19 Stainless Steel Pipe

1.3 In case of conflict between a requirement of the product

specification and a requirement of this general specification,

3. Terminology

only the requirement of the product specification needs to be

3.1 Definitions:

satisfied.

3.1.1 average diameter—the average of the maximum and

1.4 The values stated in inch-pound units are to be regarded

minimum outside diameters, as determined at any one cross

as the standard. The values given in parentheses are for

section of the pipe.

information only.

3.1.2 nominal wall—a specified wall thickness with a plus

or minus tolerance from the specified thickness.

2. Referenced Documents

3.1.3 welded pipe—a round hollow produced by forming

2.1 ASTM Standards:

flat stock and joining the single longitudinal seam by welding,

B 880 Specification for General Requirements for Chemical

and produced to the particular dimensions commercially

Check Analysis Limits for Nickel, Nickel Alloys and

known as pipe sizes (NPS).

Cobalt Alloys

E 8 Test Methods for Tension Testing of Metallic Materials

4. Chemical Composition

E 18 Test Methods for Rockwell Hardness and Rockwell

4.1 In case of disagreement, the chemical composition shall

Superficial Hardness of Metallic Materials

be determined in accordance with the following methods:

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 14.02.

B02.07 on Refined Nickel and Cobalt and Their Alloys. Annual Book of ASTM Standards, Vol 03.05.

Current edition approved May 10, 2000. Published June 2000. Originally Annual Book of ASTM Standards, Vol 03.03.

published as B 775 – 87. Last previous edition B 775 – 99. Annual Book of ASTM Standards, Vol 03.06.

2 8

Annual Book of ASTM Standards, Vol 02.04. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 03.01. Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 775

detecting significant discontinuities, especially of the short,

UNS No. Prefixes ASTM Method

abrupt type.

N02 E 39

5.3.1.1 Unless otherwise specified by the purchaser, the

N04 E 76

calibration standard shall contain, at the option of the manu-

N06, N08 E 1473

facturer, any one of the following discontinuities to establish a

4.2 The ladle analysis of the material shall conform to the

minimum sensitivity level for rejection. The discontinuity shall

chemical requirements prescribed by the individual product

be placed in the weld if visible.

specification.

5.3.1.2 Drill Hole—A hole not larger than 0.031 in. (0.79

4.3 The product (check) analysis of the material shall meet

mm) diameter shall be drilled radially and completely through

the requirements for the ladle analysis within the tolerance

the wall, care being taken to avoid distortion of the material

limits prescribed in B 880.

while drilling.

5.3.1.3 Transverse Tangential Notch—Using a round file or

5. Test Requirements

tool with a ⁄4 in. (6 mm) diameter, a notch shall be filed or

5.1 Flattening Test:

milled on the pipe outside diameter tangential to the surface

5.1.1 A length of pipe not less than three times the specified

and transverse to the longitudinal axis of the material. Said

diameter or 4 in. (102 mm), whichever is longer, shall be

notch shall have a depth not exceeding 12.5 % of the specified

flattened under a load applied gradually at room temperature

wall thickness of the material, or 0.004 in. (0.10 mm),

until the distance between the platens is five times the wall

whichever is greater.

thickness. The weld shall be positioned 90° from the direction

5.3.2 Ultrasonic Testing—Testing shall be conducted in

of the applied flattening force.

accordance with Practice E 213. The ultrasonic examination

5.1.2 The flattened specimen shall not exhibit cracks.

referred to in this specification is intended to detect longitudi-

5.1.3 Superficial ruptures resulting from surface imperfec-

nal discontinuities having a reflective area similar to or larger

tions shall not be a cause for rejection.

than the calibration reference notches specified in 5.3.2.1. The

5.2 Pressure (Leak Test):

examination may not detect circumferentially oriented imper-

5.2.1 Hydrostatic— Each pipe shall be tested by the manu- fections or short, deep defects.

facturer to an internal hydrostatic pressure of 1000 psi (6.9 5.3.2.1 For ultrasonic testing, longitudinal calibration

MPa) provided that the fiber stress, calculated from the

notches shall be machined on the outside and inside diameter

following equation, does not exceed the allowable fiber stress surfaces. The depth of the notches shall not exceed 12.5 % of

for the material:

the specified wall thickness or 0.004 in. (0.10 mm), whichever

is greater. The notch shall be placed in the weld, if visible.

P 5 2St/D (1)

5.3.3 Calibration Frequency—The frequency of calibration

where:

checks shall be as follows:

P 5 hydrostatic test pressure, psi (MPa),

5.3.3.1 At the beginning of each production run.

S 5 allowable fiber stress, for material in the condition

5.3.3.2 At least every four hours during testing.

(temper) furnished as specified in the product specifi-

5.3.3.3 At the end of each production run.

cation (S is calculated as the lower of ⁄3 of the

5.3.3.4 After any suspected equipment malfunction or work

specified minimum 0.2 % offset yield strength or ⁄4 of

stoppage.

the specified minimum ultimate strength for the mate-

5.3.3.5 If, during any check, the equipment fails to detect

rial),

the calibration defects, the instrument must be recalibrated and

t 5 minimum wall thickness permitted, in. (mm), includ-

all material tested since the last satisfactory check shall be

ing minus tolerance, if any, and

retested.

D 5 nominal outside diameter of the pipe, in. (mm).

5.3.4 Acceptance and Rejection—Material producing a sig-

5.2.1.1 The test pressure must be held for a minimum of 5

nal equal to or greater than the calibration defect shall be

s.

subject to rejection.

NOTE 1—Testing at a pressure greater than 1000 psi may be performed

5.3.4.1 Test signals that are produced by imperfections that

upon agreement between the purchaser and manufacturer provided that the

cannot be identified or that are produced by cracks or crack-

allowable fiber stress is not exceeded.

like imperfections shall result in rejection of the pipe, subject

5.2.2 Pneumatic (Air Underwater Test)—Each pipe shall be

to rework and retest.

tested at a pressure of 150 psi (1.05 MPa). The test pressure

5.3.4.2 If the imperfection is judged as not fit for use, the

shall be held for a minimum of 5 s. Visual examination is to be

tube shall be rejected, but may be reconditioned and retested

made when the material is submerged and under pressure. The

providing the wall thickness requirements are met. To be

full length of pipe must be examined for leaks.

accepted, retested material shall meet the original electric test

5.2.3 If any pipe shows leaks during hydrostatic or pneu-

requirements.

matic testing, it shall be rejected.

5.3.4.3 If the imperfection is explored to the extent that it

5.3 Nondestructive Electric Test:

can be identified, and the pipe is determined to be fit for use,

5.3.1 Eddy Current Testing—Testing shall be conducted in the material may be accepted without further testing providing

accordance with Practices E 426 or E 571. The eddy current the imperfection does not encroach on minimum wall thickness

examination reference in this specification has the capability of requirements.

B 775

5.4 Tension Test— Tension testing shall be conducted in be rounded in accordance with the rounding method of Practice

accordance with Test Methods E 8. E 29:

Rounded Unit for Observed

5.4.1 The material shall conform to the tensile properties

Requirements or Calculated Value

prescribed in the individual product specification.

Chemical composition and tolerances nearest unit in the last right-hand

5.5 Hardness Test— Hardness testing shall be conducted in

place of figures of the specified limit

accordance with Test Methods E 18.

Tensile strength and yield strength nearest 1000 psi (7 MPa)

Elongation nearest 1 %

5.6 Grain Size—The measurement of average grain size

6. Dimensions and Permissible Variations

may be carried out by the planimetric method, the comparison

method, or the intercept method described in Test Methods

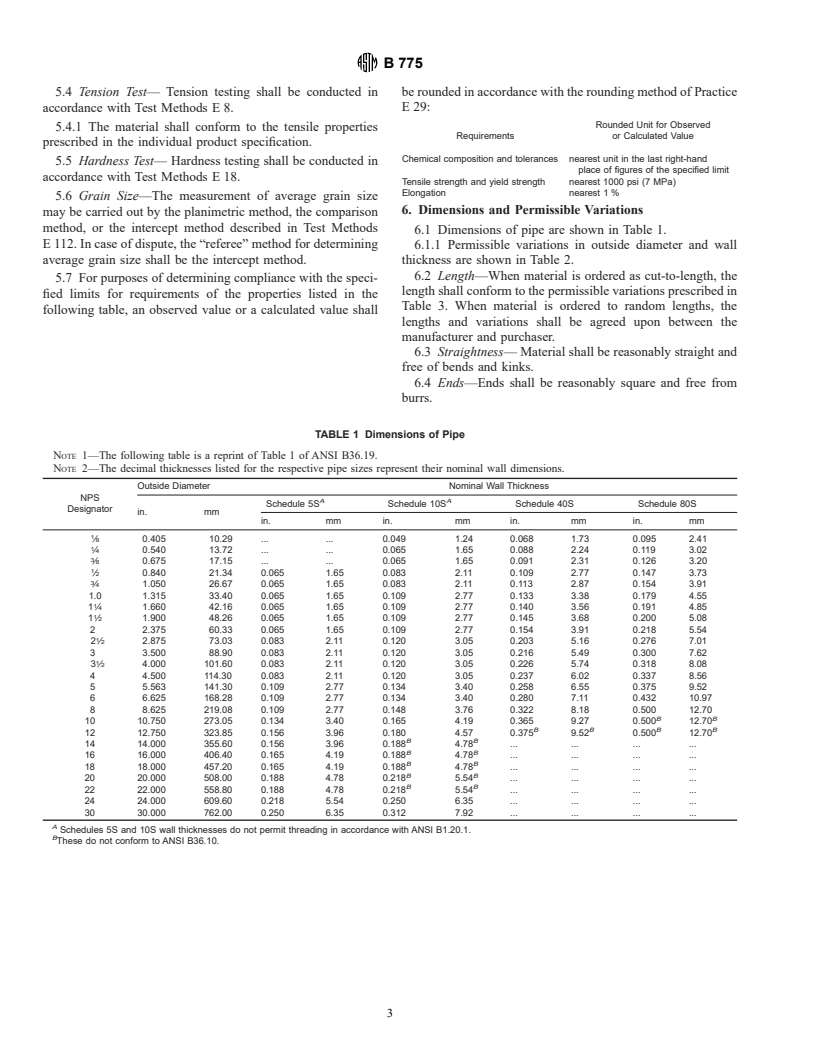

6.1 Dimensions of pipe are shown in Table 1.

E 112. In case of dispute, the “referee” method for determining

6.1.1 Permissible variations in outside diameter and wall

average grain size shall be the intercept method.

thickness are shown in Table 2.

6.2 Length—When material is ordered as cut-to-length, the

5.7 For purposes of determining compliance with the speci-

length shall conform to the permissible variations prescribed in

fied limits for requirements of the properties listed in the

Table 3. When material is ordered to random lengths, the

following table, an observed value or a calculated value shall

lengths and variations shall be agreed upon between the

manufacturer and purchaser.

6.3 Straightness— Material shall be reasonably straight and

free of bends and kinks.

6.4 Ends—Ends shall be reasonably square and free from

burrs.

TABLE 1 Dimensions of Pipe

NOTE 1—The following table is a reprint of Table 1 of ANSI B36.19.

NOTE 2—The decimal thicknesses listed for the respective pipe sizes represent their nominal wall dimensions.

Outside Diameter Nominal Wall Thickness

NPS

A A

Schedule 5S Schedule 10S Schedule 40S Schedule 80S

Designator

in. mm

in. mm in. mm in. mm in. mm

⁄8 0.405 10.29 . . 0.049 1.24 0.068 1.73 0.095 2.41

⁄4 0.540 13.72 . . 0.065 1.65 0.088 2.24 0.119 3.02

⁄8 0.675 17.15 . . 0.065 1.65 0.091 2.31 0.126 3.20

⁄2 0.840 21.34 0.065 1.65 0.083 2.11 0.109 2.77 0.147 3.73

⁄4 1.050 26.67 0.065 1.65 0.083 2.11 0.113 2.87 0.154 3.91

1.0 1.315 33.40 0.065 1.65 0.109 2.77 0.133 3.38 0.179 4.55

1 ⁄4 1.660 42.16 0.065 1.65 0.109 2.77 0.140 3.56 0.191 4.85

1 ⁄2 1.900 48.26 0.065 1.65 0.109 2.77 0.145 3.68 0.200 5.08

2 2.375 60.33 0.065 1.65 0.109 2.77 0.154 3.91 0.218 5.54

2 ⁄2 2.875 73.03 0.083 2.11 0.120 3.05 0.203 5.16 0.276 7.01

3 3.500 88.90 0.083 2.11 0.120 3.05 0.216 5.49 0.300 7.62

3 ⁄2 4.000 101.60 0.083 2.11 0.120 3.05 0.226 5.74 0.318 8.08

4 4.500 114.30 0.083 2.11 0.120 3.05 0.237 6.02 0.337 8.56

5 5.563 141.30 0.109 2.77 0.134 3.40 0.258 6.55 0.375 9.52

6 6.625 168.28 0.109 2.77 0.134 3.40 0.280 7.11 0.432 10.97

8 8.625 219.08 0.109 2.77 0.148 3.76 0.322 8.18 0.500 12.70

B B

10 10.750 273.05 0.134 3.40 0.165 4.19 0.365 9.27 0.500 12.70

B B B B

12 12.750 323.85 0.156 3.96 0.180 4.57 0.375 9.52 0.500 12.70

B B

14 14.000 355.60 0.156 3.96 0.188 4.78 . . . .

B B

16 16.000 406.40 0.165 4.19 0.188 4.78 . . . .

B B

18 18.000 457.20 0.165 4.19 0.188 4.78 . . . .

B B

20 20.000 508.00 0.188 4.78 0.218 5.54 . . . .

B B

22 22.000 558.80 0.188 4.78 0.218 5.54 . . . .

24 24.000 609.60 0.218 5.54 0.250 6.35 . . . .

30 30.000 762.00 0.250 6.35 0.312 7.92 . . . .

A

Schedules 5S and 10S wall thicknesses do not permit threading in accordance with ANSI B1.20.1.

B

These do not conform to ANSI B36.10.

B 775

A ,B

TABLE 2 Permissible Variations in Outside Diameter and Wall

8.2.1 Chemical Analysis—Representative samples from

C

Thickness For Welded Pipe

each lot shall be taken during pouring or subsequent process-

Permissible Variations in Outside Diameter

ing.

NPS Designator Over Under

8.2.2 Mechanical and Other Properties—Samples of the

material to provide test specimens for mechanical and other

in. mm in. mm

properties shall be taken from such locations in each lot as to

1 1 1 1

⁄8to 1 ⁄2, incl ⁄64 (0.015) 0.4 ⁄32 (0.031) 0.8

1 1 1

Over 1 ⁄2 to 4, incl ⁄32 (0.031) 0.8 ⁄32 (0.031) 0.8 be representative of that lot. Test specimens shall be taken from

1 1

Over 4 to 8, incl ⁄16 (0.062) 1.6 ⁄32 (0.031) 0.8

material in the final condition (temper).

3 1

Over 8 to 18, incl ⁄32 (0.093) 2.4 ⁄32 (0.031) 0.8

1 1

Over 18 to 26, incl ⁄8 (0.125) 3.2 ⁄32 (0.031) 0.8

9. Retests and Retreatment

5 1

Over 26 to 34, incl ⁄32 (0.156) 4.0 ⁄32 (0.031) 0.8

3 1

Over 34 to 48, incl ⁄16 (0.187) 4.8 ⁄32 (0.031) 0.8

9.1 Retests—If the results of the mechanical tests of any

A

group or lot do not conform to the requirements specified in the

These permissible variations in outside diamet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.