ASTM F1056-04(2011)

(Specification)Standard Specification for Socket Fusion Tools for Use in Socket Fusion Joining Polyethylene Pipe or Tubing and Fittings

Standard Specification for Socket Fusion Tools for Use in Socket Fusion Joining Polyethylene Pipe or Tubing and Fittings

ABSTRACT

This specification covers socket fusion tools for use in making socket fusion joints between polyethylene pipe or tubing and fittings as specified by certain specifications. It covers newly manufactured heater faces and used heater faces which have been recoated. Heater faces may be manufactured from aluminum, steel, or other suitable heat conducting material. The manufacture of these socket fusion tools shall be in accordance with good commercial practice so as to produce socket fusion tools meeting the requirements specified. Heater faces shall have surfaces free of cracks, voids, foreign inclusions, or injurious defects.

SCOPE

1.1 This specification covers socket fusion tools for use in making socket fusion joints between polyethylene pipe or tubing and fittings as specified by Specifications D3035, D2513, D2447, and D2683. This specification covers newly manufactured heater faces and used heater faces which have been recoated. Requirements for materials, workmanship, and dimensions are included. Where applicable on this specification, “pipe” shall mean “pipe” and “tubing.”

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1056 −04 (Reapproved 2011) An American National Standard

Standard Specification for

Socket Fusion Tools for Use in Socket Fusion Joining

Polyethylene Pipe or Tubing and Fittings

This standard is issued under the fixed designation F1056; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3035 SpecificationforPolyethylene(PE)PlasticPipe(DR-

PR) Based on Controlled Outside Diameter

1.1 This specification covers socket fusion tools for use in

D3350 Specification for Polyethylene Plastics Pipe and Fit-

making socket fusion joints between polyethylene pipe or

tings Materials

tubing and fittings as specified by Specifications D3035,

F412 Terminology Relating to Plastic Piping Systems

D2513, D2447, and D2683. This specification covers newly

manufactured heater faces and used heater faces which have

3. Terminology

been recoated. Requirements for materials, workmanship, and

dimensions are included. Where applicable on this

3.1 Definitions:

specification, “pipe” shall mean “pipe” and “tubing.”

3.1.1 General—Definitions are in accordance with Termi-

nology F412 and abbreviations are in accordance with Termi-

1.2 The values stated in inch-pound units are to be regarded

nology D1600, unless otherwise specified.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3.2 Definitions of Terms Specific to This Standard:

and are not considered standard.

3.2.1 chamfer tool—a device that is used to chamfer the

outside edge of the pipe. The chamfer allows the pipe end to

2. Referenced Documents

easily enter the pipe heater face and easily enter the heated

2.1 ASTM Standards:

fitting. Chamfering is optional for all sizes but commonly done

D1248 Specification for Polyethylene Plastics Extrusion

for 1 ⁄4-in. IPS and larger sizes.

Materials for Wire and Cable

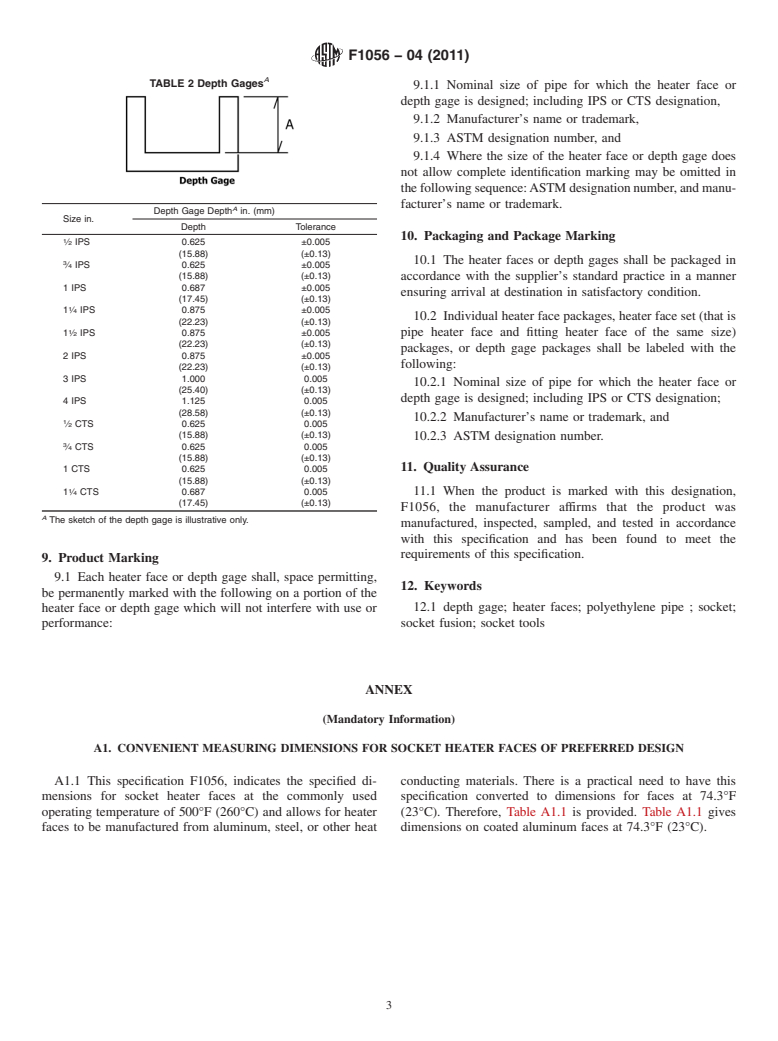

3.2.2 depth gage—a device that is used to locate the

D1600 Terminology forAbbreviatedTerms Relating to Plas-

rounding clamp a prescribed distance from the end of the pipe.

tics

3.2.3 heating tool—a device used to heat the heater faces.

D2122 Test Method for Determining Dimensions of Ther-

moplastic Pipe and Fittings

3.2.4 fitting heater face or adapter—A block of heat con-

D2447 Specification for Polyethylene (PE) Plastic Pipe,

ducting material that attaches to the heating tool and is

Schedules 40 and 80, Based on Outside Diameter (With-

dimensioned to melt the internal surface of the fitting socket.

drawn 2010)

3.2.5 pipe heater face or adapter— A block of heat con-

D2513 Specification for Polyethylene (PE) Gas Pressure

ducting material that attaches to the heating tool and is

Pipe, Tubing, and Fittings

dimensioned to melt the external surface of the pipe.

D2657 Practice for Heat Fusion Joining of Polyolefin Pipe

NOTE1—Thefittingheaterfaceandpipeheaterfacecanbeinoneblock

and Fittings

of heat conducting material.

D2683 Specification for Socket-Type Polyethylene Fittings

for Outside Diameter-Controlled Polyethylene Pipe and 3.2.6 rounding clamp or cold ring—a device that is clamped

aroundthepipetoroundthepipeandlimitthedistancethepipe

Tubing

end goes into the pipe heater face and the socket fitting.

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

4. Materials and Manufacture

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

Current edition approved Feb. 1, 2011. Published March 2011. Originally

4.1 Heater faces may be manufactured from aluminum,

approved in 1987. Last previous edition approved in 2004 as F1056 – 04. DOI:

steel, or other suitable heat conducting material.

10.1520/F1056-04R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 2—Polyethylene may stick to hot metal heating surfaces. This

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sticking may be minimized by covering the heating surfaces with a

Standards volume information, refer to the standard’s Document Summary page on

stick-resistant coating such as polytetrafluoroethylene (PTFE) or polyphe-

the ASTM website.

The last approved version of this historical standard is referenced on nylene sulfide (PPS). Copper or copper alloys are not suitable without

www.astm.org. coating because some polyolefins react with copper.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1056−04 (2011)

5. Dimensions, Mass, and Permissible Variations tion. Heater faces shall have surfaces free of cracks, voids,

foreign inclusions, or injurious defects.

5.1 Heaterfacedimensionsandtolerancesshallbeasshown

in Table 1.The dimensions in Table 1 are for heater faces at the

7. Sampling

commonly used operating temperature of 500°F (260°C).

Annex A1 contains Table A1.1 which gives dimensions to

7.1 Select at random a sufficient quantity of socket fusion

measure for coated aluminum faces at 73.4°F (23°C). tools from each lot to be tested to determine that the basic

properties and dimensions are in conformance with this speci-

5.2 Depthgagedimensionsandtolerancesshallbeasshown

fication.

in Table 2.

5.3 Chamfer dimensions shall be limited to a maximum of

8. Inspection

20 % of the ASTM depth gage depth along the pipe wall and

8.1 Inspection of socket fusion tools shall be agreed upon

60 % of the wall thickness.

between the purchaser and the supplier as part of the purchase

6. Workmanship, Finish, and Appearance contract.

6.1 The manufacture of these socket fusion tools shall be in 8.2 Inspection for dimensional accuracy shall be done with

accordance with good commercial practice so as to produce dial calipers, micrometers, or similar devices that have an

socket fusion tools meeting the requirements of this specifica- accuracy within 0.001 in. (0.025 mm).

A,B,C,D

TABLE 1 Socket Fusion Heater Faces

Fitting Heater Face Pipe Heater Face

Size in. A Diameter, in. (mm) B Diameter, in. (mm) C Depth, in. (mm) D Diameter, in. (mm) E Diameter, in. (mm) F Depth, in. (mm)

max Tolerance max Tolerance max Tolerance min Tolerance min Tolerance min Tolerance

⁄2 IPS 0.837 –0.007 0.793 –0.007 0.625 −0.010 0.851 +0.007 0.807 +0.007 0.625 +0.010

(21.26) (−0.18) (20.14) (−0.18) (15.88) (−0.25) (21.62) (+0.18) (20.50) (+0.18) (15.88) (+0.25)

⁄4 IPS 1.046 –0.008 1.004 –0.008 0.625 −0.010 1.062 +0.008 1.020 +0.008 0.625 +0.010

(26.57) (−0.20) (25.50) (−0.20) (15.88) (−0.25) (26.97) (+0.20) (25.91) (+0.20) (15.88) (+0.25)

1 IPS 1.312 –0.008 1.259 –0.008 0.687 −0.010 1.328 +0.008 1.275 +0.008 0.687 +0.010

(33.32) (−0.20) (31.98) (−0.20) (17.45) (−0.25) (33.73) (+0.20) (32.39) (+0.20) (17.45) (+0.25)

1 ⁄4 IPS 1.657 –0.008 1.604 –0.008 0.875 −0.010 1.673 +0.008 1.620 +0.008 0.875 +0.010

(42.09) (−0.20) (40.74) (−0.20) (22.23) (−0.25) (42.49) (+0.20) (41.15) (+0.20) (22.23) (+0.25)

1 ⁄2 IPS 1.896 –0.010 1.840 –0.010 0.875 −0.010 1.916 +0.010 1.860 +0.010 0.875 +0.010

(48.16) (−0.25) (46.74) (−0.25) (22.23) (−0.25) (48.67) (+0.25) (47.24) (+0.25) (22.23) (+0.25)

2 IPS 2.371 –0.010 2.315 –0.010 0.875 −0.010 2.391 +0.010 2.335 +0.010 0.875 +0.010

(60.22) (−0.25) (58.80) (−0.25) (22.23) (−0.25) (60.22) (+0.25) (59.31) (+0.25) (22.23) (+0.25)

3 IPS 3.494 –0.014 3.426 –0.014 1.000 −0.010 3.522 +0.014 3.454 +0.014 1.000 +0.010

(88.75) (−0.36) (87.02) (−0.36) (25.40) (−0.25) (89.46) (+0.36) (87.73) (+0.36) (25.40) (+0.25)

4 IPS 4.495 –0.014 4.421 −0.014 1.125 −0.010 4.523 +0.014 4.449 +0.014 1.125 +0.010

(114.17) (−0.36) (112.29) (−0.36) (28.58) (−0.25) (114.88) (+0.36) (113.00) (+0.36) (28.58) (+0.25)

⁄2 CTS 0.622 –0.007 0.571 −0.007 0.625 −0.010 0.636 +0.007 0.585 +0.007 0.625 +0.010

(15.80) (−0.18) (14.50) (−0.18) (15.88) (−0.25) (16.15) (+0.18) (14.86) (+0.18) (15.88) (+0.25)

⁄4 CTS 0.871 –0.008 0.817 −0.008 0.625 −0.010 0.887 +0.008 0.833 +0.008 0.625 +0.010

(22.12) (−0.20) (20.75) (−0.20) (15.88) (−0.25) (22.53) (+0.20) (21.16) (+0.20) (15.88) (+0.25)

1 CTS 1.122 –0.008 1.059 −0.008 0.625 −0.010 1.138 +0.008 1.075 +0.008 0.625 +0.010

(28.50) (−0.20) (26.85) (−0.20) (15.88) (−0.25) (28.91) (+0.20) (27.31) (+0.20) (15.88) (+0.25)

1 ⁄4 CTS 1.372 –0.008 1.314 −0.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.