ASTM D4693-07(2021)

(Test Method)Standard Test Method for Low-Temperature Torque of Grease-Lubricated Wheel Bearings

Standard Test Method for Low-Temperature Torque of Grease-Lubricated Wheel Bearings

SIGNIFICANCE AND USE

5.1 This test method differentiates among greases having distinctly different low-temperature characteristics. This test is used for specification purposes and correlates with its precursor which has been used to predict the performance of greases in automotive wheel bearings in low-temperature service.5 It is the responsibility of the user to determine the correlation with other types of service.

SCOPE

1.1 This test method covers the determination of the extent to which a test grease retards the rotation of a specially-manufactured, spring-loaded, automotive-type wheel bearing assembly when subjected to low temperatures. Torque values, calculated from restraining-force determinations, are a measure of the viscous resistance of the grease. This test method was developed with greases giving torques of less than 35 N·m at −40 °C.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use Caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4693 − 07 (Reapproved 2021)

Standard Test Method for

Low-Temperature Torque of Grease-Lubricated Wheel

Bearings

This standard is issued under the fixed designation D4693; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the determination of the extent

D217Test Methods for Cone Penetration of Lubricating

to which a test grease retards the rotation of a specially-

Grease

manufactured, spring-loaded, automotive-type wheel bearing

D1403Test Methods for Cone Penetration of Lubricating

assembly when subjected to low temperatures. Torque values,

Grease Using One-Quarter and One-Half Scale Cone

calculatedfromrestraining-forcedeterminations,areameasure

Equipment

of the viscous resistance of the grease. This test method was

D3527Test Method for Life Performance of Automotive

developed with greases giving torques of less than 35N·m

Wheel Bearing Grease

at−40°C.

D4175Terminology Relating to Petroleum Products, Liquid

1.2 The values stated in SI units are to be regarded as

Fuels, and Lubricants

standard. No other units of measurement are included in this

E1Specification for ASTM Liquid-in-Glass Thermometers

standard.

E77Test Method for Inspection and Verification of Ther-

mometers

1.3 WARNING—Mercury has been designated by many

E220Test Method for Calibration of Thermocouples By

regulatory agencies as a hazardous substance that can cause

Comparison Techniques

serious medical issues. Mercury, or its vapor, has been dem-

E230Specification for Temperature-Electromotive Force

onstrated to be hazardous to health and corrosive to materials.

(emf) Tables for Standardized Thermocouples

Use Caution when handling mercury and mercury-containing

E563Practice for Preparation and Use of an Ice-Point Bath

products. See the applicable product Safety Data Sheet (SDS)

as a Reference Temperature

for additional information. The potential exists that selling

E585/E585M Specification for Compacted Mineral-

mercury or mercury-containing products, or both, is prohibited

Insulated, Metal-Sheathed, Base Metal Thermocouple

by local or national law. Users must determine legality of sales

Cable

in their location.

E608/E608MSpecification for Mineral-Insulated, Metal-

Sheathed Base Metal Thermocouples

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

2.2 Military Standard:

responsibility of the user of this standard to establish appro-

MIL-G-10924FSpecification for Automotive and Artillery

priate safety, health, and environmental practices and deter-

2.3 ABMA Standard:

mine the applicability of regulatory limitations prior to use.

Anti-Friction Bearing ManufacturerAssoc. (AFBMA) Stan-

1.5 This international standard was developed in accor-

dard19, 1974 (ANSI B.3.19-1975)

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3. Terminology

Development of International Standards, Guides and Recom-

3.1 Definitions:

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of Committee D02 on Petroleum Standards volume information, refer to the standard’s Document Summary page on

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom- the ASTM website.

mittee D02.G0 on Lubricating Grease. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Current edition approved Oct. 1, 2021. Published November 2021. Originally Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

approved in 1987. Last previous edition approved in 2017 as D4693–07 (2017). Available from American Bearing Manufacturers Association (ABMA), 2025

DOI: 10.1520/D4693-07R21. M St., NW, Suite 800, Washington, DC 20036. www.americanbearings.org

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4693 − 07 (2021)

FIG. 1 Low-Temperature Torque Apparatus

3.1.1 automotive wheel bearing grease, n—a lubricating usedforspecificationpurposesandcorrelateswithitsprecursor

grease specifically formulated to lubricate automotive wheel

which has been used to predict the performance of greases in

bearings at relatively high grease temperatures and bearing automotive wheel bearings in low-temperature service. It is

speeds. D3527

the responsibility of the user to determine the correlation with

other types of service.

3.1.2 lubricant, n—any material interposed between two

surfacesthatreducesthefrictionorwearbetweenthem. D4175

6. Apparatus

3.1.3 lubricating grease, n—a semi-fluid to solid product of

6,7

a dispersion of a thickener in a liquid lubricant.

6.1 Low-Temperature Wheel Bearing Torque Apparatus,

3.1.3.1 Discussion—Thedispersionofthethickenerformsa

illustrated in Fig. 1.

two-phase system and immobilizes the liquid lubricant by

NOTE 1—Several apparatus configurations are available, differing

surfacetensionandotherphysicalforces.Otheringredientsare

mainly in the drive system. For example, with large cold chambers, a

commonly included to impact special properties. D217

unitizedapparatus(seeFig.1)canbeusedtotallywithinthecoldchamber.

3.1.4 thickener, n—in lubricating grease, a substance com- With small cold chambers, the drive system can be mounted externally

and only the test unit subjected to low temperature. Regardless of the

posed of finely-divided particles dispersed in a liquid lubricant

exact configuration, the essential apparatus consists of a 1/3 hp electric

to form the product’s structure.

motor connected to a gear reducer by means of a timing belt and pulleys,

3.1.4.1 Discussion—The solid thickener can be fibers (such

which drive a specially-manufactured spindle-bearings-hub assembly

as various metallic soaps) or plates or spheres (such as certain

equipped with a spring-loading mechanism. For apparatus contained

non-soap thickeners) which are insoluble or, at the most, only totally within the cold chamber, the drive system should be prepared by

replacingthegreaseinthemotorbearingswithasuitablelow-temperature

very slightly soluble in the liquid lubricant. The general

grease (<1 N·m torque at−40°C), such as one meeting the requirements

requirements are that the solid particles be extremely small,

of Specification MIL-G-10924F or similar, and the lubricant in the gear

uniformly dispered, and capable of forming a relatively stable,

reducer should be replaced with a suitable low-temperature (<−50°C

7,8

gel-like structure with the liquid lubricant. D217

pour point) worm-gear lubricant. In addition, if not already so-

equipped, large-diameter (152mm), narrow-width (13mm) timing pul-

4. Summary of Test Method

leys and a suitable timing belt should be used.

4.1 A freshly stirred and worked sample of test grease is

packed into the bearings of a specially-manufactured,

automotive-type spindle-bearings-hub assembly.The assembly 5

Verdura, T. M., “Performance of Service Station Wheel Bearing Greases in a

is heated and then cold soaked at−40°C, unless another test New Low-Temperature Test,” NLGI Spokesman 35 10-21, 1971.

The sole source of supply of the apparatus known to the committee at this time

temperature is specified by the grease specification. The

is available from Koehler Instrument Company, Inc., 1595 Sycamore Avenue,

spindle is rotated at 1 rpm and the torque required to prevent

Bohemia, NY 11716.

rotation of the hub is measured at 60s.

If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider-

5. Significance and Use ation at a meeting of the responsible technical committee, which you may attend.

The sole source of supply of the apparatus known to the committee at this time

5.1 This test method differentiates among greases having

isMobilSHC624(orsimilar),availablefromMobilOilCorporation,3225Gallows

distinctly different low-temperature characteristics. This test is Rd., Fairfax, VA 22037.

D4693 − 07 (2021)

7,10

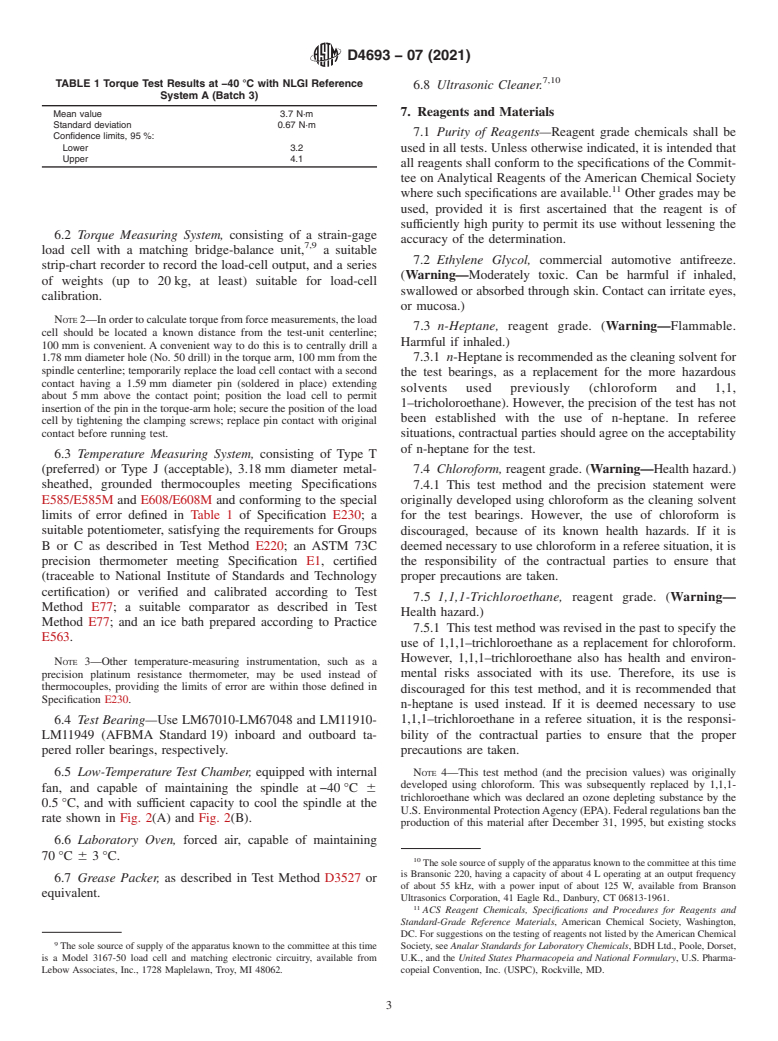

TABLE 1 Torque Test Results at −40 °C with NLGI Reference

6.8 Ultrasonic Cleaner.

System A (Batch 3)

Mean value 3.7 N·m 7. Reagents and Materials

Standard deviation 0.67 N·m

7.1 Purity of Reagents—Reagent grade chemicals shall be

Confidence limits, 95 %:

Lower 3.2

used in all tests. Unless otherwise indicated, it is intended that

Upper 4.1

all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

6.2 Torque Measuring System, consisting of a strain-gage

accuracy of the determination.

7,9

load cell with a matching bridge-balance unit, a suitable

7.2 Ethylene Glycol, commercial automotive antifreeze.

strip-chart recorder to record the load-cell output, and a series

(Warning—Moderately toxic. Can be harmful if inhaled,

of weights (up to 20kg, at least) suitable for load-cell

swallowed or absorbed through skin. Contact can irritate eyes,

calibration.

or mucosa.)

NOTE2—Inordertocalculatetorquefromforcemeasurements,theload

7.3 n-Heptane, reagent grade. (Warning—Flammable.

cell should be located a known distance from the test-unit centerline;

Harmful if inhaled.)

100mm is convenient. A convenient way to do this is to centrally drill a

1.78mm diameter hole (No. 50 drill) in the torque arm, 100mm from the 7.3.1 n-Heptaneisrecommendedasthecleaningsolventfor

spindle centerline; temporarily replace the load cell contact with a second

the test bearings, as a replacement for the more hazardous

contact having a 1.59mm diameter pin (soldered in place) extending

solvents used previously (chloroform and 1,1,

about 5mm above the contact point; position the load cell to permit

1–tricholoroethane). However, the precision of the test has not

insertion of the pin in the torque-arm hole; secure the position of the load

been established with the use of n-heptane. In referee

cell by tightening the clamping screws; replace pin contact with original

contact before running test. situations, contractual parties should agree on the acceptability

of n-heptane for the test.

6.3 Temperature Measuring System, consisting of Type T

(preferred) or Type J (acceptable), 3.18mm diameter metal- 7.4 Chloroform, reagent grade. (Warning—Health hazard.)

sheathed, grounded thermocouples meeting Specifications 7.4.1 This test method and the precision statement were

E585/E585M and E608/E608M and conforming to the special originally developed using chloroform as the cleaning solvent

limits of error defined in Table 1 of Specification E230;a for the test bearings. However, the use of chloroform is

suitable potentiometer, satisfying the requirements for Groups discouraged, because of its known health hazards. If it is

B or C as described in Test Method E220; an ASTM 73C deemed necessary to use chloroform in a referee situation, it is

precision thermometer meeting Specification E1, certified the responsibility of the contractual parties to ensure that

(traceable to National Institute of Standards and Technology proper precautions are taken.

certification) or verified and calibrated according to Test

7.5 1,1,1-Trichloroethane, reagent grade. (Warning—

Method E77; a suitable comparator as described in Test

Health hazard.)

Method E77; and an ice bath prepared according to Practice

7.5.1 This test method was revised in the past to specify the

E563.

use of 1,1,1–trichloroethane as a replacement for chloroform.

However, 1,1,1–trichloroethane also has health and environ-

NOTE 3—Other temperature-measuring instrumentation, such as a

precision platinum resistance thermometer, may be used instead of mental risks associated with its use. Therefore, its use is

thermocouples, providing the limits of error are within those defined in

discouraged for this test method, and it is recommended that

Specification E230.

n-heptane is used instead. If it is deemed necessary to use

6.4 Test Bearing—Use LM67010-LM67048 and LM11910- 1,1,1–trichloroethane in a referee situation, it is the responsi-

LM11949 (AFBMA Standard19) inboard and outboard ta- bility of the contractual parties to ensure that the proper

pered roller bearings, respectively. precautions are taken.

6.5 Low-Temperature Test Chamber, equipped with internal NOTE 4—This test method (and the precision values) was originally

developed using chloroform. This was subsequently replaced by 1,1,1-

fan, and capable of maintaining the spindle at−40°C 6

trichloroethane which was declared an ozone depleting substance by the

0.5°C, and with sufficient capacity to cool the spindle at the

U.S.EnvironmentalProtectionAgency(EPA).Federalregulationsbanthe

rate shown in Fig. 2(A) and Fig. 2(B).

production of this material after December 31, 1995, but existing stocks

6.6 Laboratory Oven, forced air, capable of maintaining

70°C 6 3°C.

Thesolesourceofsupplyoftheapparatusknowntothecommitteeatthistime

is Bransonic 220, having a capacity of about 4 L operating at an output frequency

6.7 Grease Packer, as described in Test Method D3527 or

of about 55 kHz, with a power input of about 125 W, available from Branson

equivalent.

Ultrasonics Corporation, 41 Eagle Rd., Danbury, CT 06813-1961.

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

Standard-Grade Reference Materials, American Chemical Society, Washington,

DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

The sole source of supply of the apparatus known to the committee at this time Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

is a Model 3167-50 load cell and matching electronic circuitry, available from U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

Lebow Associates, Inc., 1728 Maplelawn, Troy, MI 48062. copeial Convention, Inc. (USPC), Rockville, MD.

D4693 − 07 (2021)

FIG. 2 (A) Upper and Lower Limits of Cooling Rate and Test Tempera

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.