ASTM F1673-04(2009)

(Specification)Standard Specification for Polyvinylidene Fluoride (PVDF) Corrosive Waste Drainage Systems

Standard Specification for Polyvinylidene Fluoride (PVDF) Corrosive Waste Drainage Systems

ABSTRACT

This specification covers requirements for polyvinylidene drainage systems for corrosive applications. Requirements for material, pipe and fittings are included. Polyvinylidene fluoride includes emulsion/suspension polymerization and copolymers of vinylidene fluoride/hexafluoropropylene produced by either method. These requirements apply to Schedule 40 and 80 IPS and SDR 21 pipe sizes. Pipe and fittings are to be joined by heat fusion or mechanical methods. The following tests shall be performed: chemical resistance; water absorption; joint tests— hydrostatic pressure tests; mechanical joint pullout test; threads; flattening; and impact resistance for PVDF pipe and fittings.

SCOPE

1.1 This specification covers requirements for polyvinylidene drainage systems for corrosive applications. Requirements for material, pipe and fittings are included. Polyvinylidene fluoride includes emulsion/suspension polymerization and copolymers of vinylidene fluoride/hexafluoropropylene produced by either method.

1.2 These requirements apply to Schedule 40 and 80 IPS and SDR 21 pipe sizes. Pipe and fittings are to be joined by heat fusion or mechanical methods using the equipment supplied by the manufacturers.

1.3 This specification is not intended to provide for interchangeability between plastic pipe and fittings from different manufacturers, but it does allow for transition fittings for joining one manufacturer's product to another's product, provided the joining technique used is other than heat fusion.

1.4 This specification is not for polyvinylidene pressure systems.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 Notes and appendixes are not a mandatory part of this specification.

1.7 The following safety hazard caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1673 – 04 (Reapproved 2009)

Standard Specification for

Polyvinylidene Fluoride (PVDF) Corrosive Waste Drainage

Systems

This standard is issued under the fixed designation F1673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D543 Practices for Evaluating the Resistance of Plastics to

Chemical Reagents

1.1 This specification covers requirements for polyvi-

D570 Test Method for Water Absorption of Plastics

nylidene drainage systems for corrosive applications. Require-

D618 Practice for Conditioning Plastics for Testing

ments for material, pipe and fittings are included. Polyvi-

D883 Terminology Relating to Plastics

nylidenefluorideincludesemulsion/suspensionpolymerization

D1599 TestMethodforResistancetoShort-TimeHydraulic

and copolymers of vinylidene fluoride/hexafluoropropylene

Pressure of Plastic Pipe, Tubing, and Fittings

produced by either method.

D1600 Terminology for Abbreviated Terms Relating to

1.2 These requirements apply to Schedule 40 and 80 IPS

Plastics

and SDR 21 pipe sizes. Pipe and fittings are to be joined by

D2122 Test Method for Determining Dimensions of Ther-

heat fusion or mechanical methods using the equipment

moplastic Pipe and Fittings

supplied by the manufacturers.

D2321 Practice for Underground Installation of Thermo-

1.3 This specification is not intended to provide for inter-

plastic Pipe for Sewers and Other Gravity-Flow Applica-

changeability between plastic pipe and fittings from different

tions

manufacturers, but it does allow for transition fittings for

D2412 Test Method for Determination of External Loading

joining one manufacturer’s product to another’s product, pro-

Characteristics of Plastic Pipe by Parallel-Plate Loading

vided the joining technique used is other than heat fusion.

D2444 Test Method for Determination of the Impact Resis-

1.4 This specification is not for polyvinylidene pressure

tance of Thermoplastic Pipe and Fittings by Means of a

systems.

Tup (Falling Weight)

1.5 The values stated in inch-pound units are to be regarded

D2657 Practice for Heat Fusion Joining of Polyolefin Pipe

as standard. The values given in parentheses are mathematical

and Fittings

conversions to SI units that are provided for information only

D3222 Specification for Unmodified Poly(Vinylidene Fluo-

and are not considered standard.

ride) (PVDF) Molding Extrusion and Coating Materials

1.6 Notes and appendixes are not a mandatory part of this

D3311 Specification for Drain, Waste, and Vent (DWV)

specification.

Plastic Fittings Patterns

1.7 The following safety hazard caveat pertains only to the

D5575 Classification System for Copolymers ofVinylidene

test method portion, Section 8, of this specification: This

Fluoride (VDF) with Other Fluorinated Monomers

standard does not purport to address all of the safety concerns,

F412 Terminology Relating to Plastic Piping Systems

if any, associated with its use. It is the responsibility of the user

F1290 Practice for Electrofusion Joining Polyolefin Pipe

of this standard to establish appropriate safety and health

and Fittings

practices and determine the applicability of regulatory limita-

F1498 Specification for Taper Pipe Threads 60° for Ther-

tions prior to use.

moplastic Pipe and Fittings

2. Referenced Documents 2.2 Federal Standard:

Fed. Std. No. 123 Marking for Shipment

2.1 ASTM Standards:

2.3 Military Standard:

MIL-STD129 Marking for Shipment and Storage

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV.

Current edition approved Aug. 1, 2009. Published September 2009. Originally

approved in 1995. Last previous edition approved in 2004 as F1673-04. DOI:

10.1520/F1673-04R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1673 – 04 (2009)

2.4 Other Standard: D2122. The tolerance for out-of-roundness shall apply only to

Uniform Plumbing Code pipe prior to shipment.

6.1.1.2 Toe-In—The outside diameter, when measured in

3. Terminology

accordance with Method D2122, shall meet the requirements

3.1 Definitions:

of Table 1 and Table 2 at any point within 1.5 pipe diameters

3.1.1 Definitionsusedinthisspecificationareinaccordance

or 11.8 in. (300 mm), whichever is less, to the cut end of the

withthedefinitionsgiveninTerminologiesD883andF412and

pipe length.

abbreviations are in accordance with Terminology D1600,

6.1.2 Fittings:

unless otherwise indicated.

6.1.2.1 The minimum wall thickness of the body all fittings

3.1.2 Theplumbingterminologyusedinthisspecificationis

shall not be less than the corresponding Schedule 40 pipe size

in accordance with the definitions given in the Uniform

and shall be measured in accordance with Method D2122.

Plumbing Code, unless otherwise indicated.

6.1.2.2 Spigot ends of fittings shall conform to the diameter

and out-of-roundness requirements for pipe.

4. Classification

6.1.2.3 Socket ends of fittings shall conform to the dimen-

4.1 General—This specification covers PVDF pipe and

sional requirements for size and tolerances as provided by the

fittings made from PVDF or VF/HFP copolymers in Schedule

manufacturer.

40 and 80 IPS sizes and in SDR 21.

6.1.2.4 The average minimum diameters of waterways of

4.2 This specification also includes molded fittings and the

fittings, excluding adapters, shall be as specified in Table 3.

larger sizes (8, 10, 12 in.) of fabricated fittings.

4.3 This specification covers PVDF pipe (SDR 21) made 6.1.2.5 Taper pipe threads in any fittings shall be as speci-

from PVDF defined by a hydrostatic design stress of 2300 psi

fied in Specification F1498.The tolerance shall be 1 ⁄2 large or

(15.85 MPa). small turns from the basic thread dimension and gaged in

accordance with 8.7.

5. Materials and Manufacture

6.1.2.6 The patterns, dimensions, and laying lengths of

5.1 Polyvinylidene fluoride (PVDF) material for pipe or

molded fittings, including adaptors, shall meet the require-

fittings shall conform to the requirements of Type I or Type II

ments of Specification D3311, or shall be of a proven design

PVDF as defined in Specification D3222 or copolymers as

and allow a smooth transition of fluid flow from one direction

defined in Specification D5575.

to another.

5.2 The PVDF material may contain pigment and fillers not

6.1.2.7 Cleanouts, cleanout plugs, and caps as commonly

detrimental to the pipe and fittings, provided the pipe and

used in the manufacturer’s laboratory drainage system, shall

fittings produced meet the requirements of this specification.

have a thread size and depth sufficient to ensure that the

5.3 Rework Material—Clean rework material, generated

minimum waterway sizes are maintained.

fromthemanufacturer’spipeandfittingsproductsmaybeused

6.1.2.8 Traps—Alltrapsshallhaveaminimumwatersealof

by the same manufacturer, provided that the pipe or fittings

2 in.

produced meet the requirements of this specification.

6.2 Chemical Resistance—Pipe and fittings material shall

be evaluated in accordance with Practice D543, Procedures I

6. Requirements Requirements

and II, using the chemicals listed in 8.3. The weight change

6.1 Dimensions and Tolerances—Pipe and Fittings:

shall not exceed 2%, nor shall the apparent tensile strength

6.1.1 Pipe:

change by more than 10%. In cases where there is a change in

6.1.1.1 Dimensions and tolerances for pipe shown in Table

the apparent tensile strength greater than 10%, a further

1 and Table 2 shall be measured in accordance with Method

evaluation shall be made after removal from the chemical and

conditioning for 72 h. If there is a minimum of 50% recovery

4 of tensile strength after 72 h, and that figure is within 610%

Available from International Association of Plumbing and Mechanical Offi-

of the original tensile strength, the specimen shall be consid-

cials, 5001 E. Philadelphia St., Ontario, CA 91761, http://www.iapmo.org.

ered acceptable.

TABLE 1 Outside Diameters and Tolerances for PVDF Pipe

6.3 Water Absorption—Pipe and fitting materials shall not

Schedules 40 and 80 and SDR 21, in. (mm)

change in weight more than 0.50% when tested in accordance

Nominal Pipe Average Outside Tolerance Out-of-Roundness

with 8.4.

Size Diameter (Maximum Diameter

6.4 System Integrity:

Minus Minimum

Diameter)

6.4.1 Fused joints and associated pipe shall withstand a

1 ⁄4 1.660 (42.16) 60.005 (60.13) 0.050 (1.28)

pressure of 50 psi (345 kPa) without leaking when tested in

1 ⁄2 1.900 (48.26) 60.006 (60.15) 0.060 (1.52)

accordance with 8.5.1.

2 2.375 (60.32) 60.006 (60.15) 0.070 (1.78)

3 3.500 (88.90) 60.008 (60.20) 0.080 (2.04) 6.4.2 Mechanical joints shall withstand a pressure of 14.5

4 4.500 (114.30) 60.009 (60.23) 0.100 (2.54)

psi (100 kPa) without leaking when tested in accordance with

6 6.625 (168.28) 60.011 (60.28) 0.100 (2.54)

8.5.2.

8 8.625 (219.08) 60.015 (60.38) 0.150 (3.80)

10 10.750 (273.05) 60.015 (60.38) 0.150 (3.80)

NOTE 1—Mechanical joints include transition, compression, threaded,

12 12.750 (323.85) 60.015 (60.38) 0.150 (3.80)

and other type mechanical joints.

F1673 – 04 (2009)

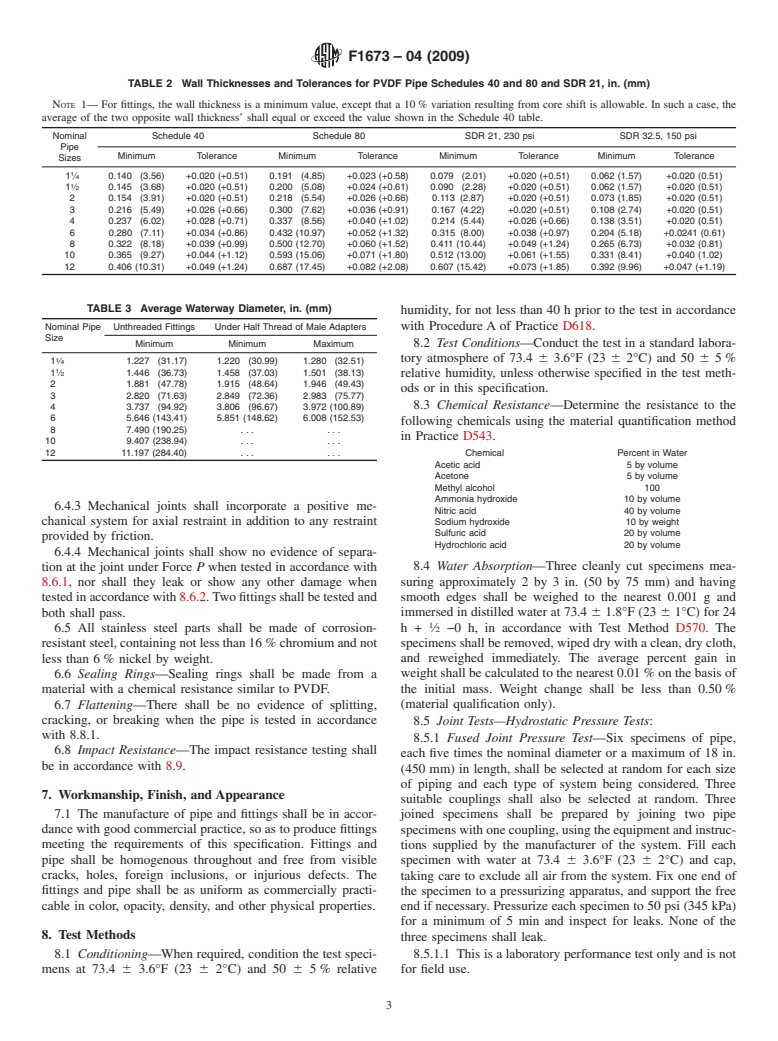

TABLE 2 Wall Thicknesses and Tolerances for PVDF Pipe Schedules 40 and 80 and SDR 21, in. (mm)

NOTE 1— For fittings, the wall thickness is a minimum value, except that a 10% variation resulting from core shift is allowable. In such a case, the

average of the two opposite wall thickness’ shall equal or exceed the value shown in the Schedule 40 table.

Nominal Schedule 40 Schedule 80 SDR 21, 230 psi SDR 32.5, 150 psi

Pipe

Minimum Tolerance Minimum Tolerance Minimum Tolerance Minimum Tolerance

Sizes

1 ⁄4 0.140 (3.56) +0.020 (+0.51) 0.191 (4.85) +0.023 (+0.58) 0.079 (2.01) +0.020 (+0.51) 0.062 (1.57) +0.020 (0.51)

1 ⁄2 0.145 (3.68) +0.020 (+0.51) 0.200 (5.08) +0.024 (+0.61) 0.090 (2.28) +0.020 (+0.51) 0.062 (1.57) +0.020 (0.51)

2 0.154 (3.91) +0.020 (+0.51) 0.218 (5.54) +0.026 (+0.66) 0.113 (2.87) +0.020 (+0.51) 0.073 (1.85) +0.020 (0.51)

3 0.216 (5.49) +0.026 (+0.66) 0.300 (7.62) +0.036 (+0.91) 0.167 (4.22) +0.020 (+0.51) 0.108 (2.74) +0.020 (0.51)

4 0.237 (6.02) +0.028 (+0.71) 0.337 (8.56) +0.040 (+1.02) 0.214 (5.44) +0.026 (+0.66) 0.138 (3.51) +0.020 (0.51)

6 0.280 (7.11) +0.034 (+0.86) 0.432 (10.97) +0.052 (+1.32) 0.315 (8.00) +0.038 (+0.97) 0.204 (5.18) +0.0241 (0.61)

8 0.322 (8.18) +0.039 (+0.99) 0.500 (12.70) +0.060 (+1.52) 0.411 (10.44) +0.049 (+1.24) 0.265 (6.73) +0.032 (0.81)

10 0.365 (9.27) +0.044 (+1.12) 0.593 (15.06) +0.071 (+1.80) 0.512 (13.00) +0.061 (+1.55) 0.331 (8.41) +0.040 (1.02)

12 0.406 (10.31) +0.049 (+1.24) 0.687 (17.45) +0.082 (+2.08) 0.607 (15.42) +0.073 (+1.85) 0.392 (9.96) +0.047 (+1.19)

TABLE 3 Average Waterway Diameter, in. (mm)

humidity, for not less than 40 h prior to the test in accordance

Nominal Pipe Unthreaded Fittings Under Half Thread of Male Adapters with Procedure A of Practice D618.

Size

Minimum Minimum Maximum 8.2 Test Conditions—Conduct the test in a standard labora-

1 tory atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 65%

1 ⁄4 1.227 (31.17) 1.220 (30.99) 1.280 (32.51)

1 ⁄2 1.446 (36.73) 1.458 (37.03) 1.501 (38.13)

relative humidity, unless otherwise specified in the test meth-

2 1.881 (47.78) 1.915 (48.64) 1.946 (49.43)

ods or in this specification.

3 2.820 (71.63) 2.849 (72.36) 2.983 (75.77)

4 3.737 (94.92) 3.806 (96.67) 3.972 (100.89) 8.3 Chemical Resistance—Determine the resistance to the

6 5.646 (143.41) 5.851 (148.62) 6.008 (152.53)

following chemicals using the material quantification method

8 7.490 (190.25) . . . . . .

in Practice D543.

10 9.407 (238.94) . . . . . .

12 11.197 (284.40) . . . . . . Chemical Percent in Water

Acetic acid 5 by volume

Acetone 5 by volume

Methyl alcohol 100

Ammonia hydroxide 10 by volume

6.4.3 Mechanical joints shall incorporate a positive me-

Nitric acid 40 by volume

chanical system for axial restraint in addition to any restraint Sodium hydroxide 10 by weight

Sulfuric acid 20 by volume

provided by friction.

Hydrochloric acid 20 by volume

6.4.4 Mechanical joints shall show no evidence of separa-

tion at the joint under Force P when tested in accordance with 8.4 Water Absorption—Three cleanly cut specimens mea-

suring approximately 2 by 3 in. (50 by 75 mm) and having

8.6.1, nor shall they leak or show any other damage when

testedinaccordancewith8.6.2.Twofittingsshallbetestedand smooth edges shall be weighed to the nearest 0.001 g and

immersed in distilled water at 73.4 6 1.8°F (23 6 1°C) for 24

both shall pass.

6.5 All stainless steel parts shall be made of corrosion- h+ ⁄2 −0 h, in accordance with Test Method D570. The

specimensshallberemoved,wipeddrywithaclean,drycloth,

resistantsteel,containingnotlessthan16%chromiumandnot

less than 6% nickel by weight. and reweighed immediately. The average percent gain in

weight shall be calculated to the nearest 0.01% on the basis of

6.6 Sealing Rings—Sealing rings shall be made from a

material with a chemical resistance similar to PVDF. the initial mass. Weight change shall be less than 0.50%

6.7 Flattening—There shall be no evidence of splitting, (material qualification only).

cracking, or breaking when the pipe is tested in accordance

8.5 Joint Tests—Hydrostatic Pressure Tests:

with 8.8.1.

8.5.1 Fused Joint Pressure Test—Six specimens of pipe,

6.8 Impact Resistance—The impact resistance testing shall

each five times the nominal diameter or a maximum of 18 in.

be in accordance with 8.9.

(450 mm) in length, shall be selected at random for each size

of piping and each type of system being considered. Three

7. Workmanship, Finish, and Appearance

suitable couplings shall also be selected at random. Three

7.1 The manufacture of pipe and fittings shall be in accor- joined specimens shall be prepared by joining two pipe

dance with good commercial practice, so as to produce fittings specimenswithonecoupling,usingtheequipmentandinstruc-

meeting the requirements of this specification. Fittings and tions supplied by the manufacturer of the system. Fill each

pipe shall be homogenous throughout and free from visible specimen with water at 73.4 6 3.6°F (23 6 2°C) and cap,

cracks, holes, foreign inclusion

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F 1673–02 Designation: F 1673 – 04 (Reapproved 2009)

Standard Specification for

Polyvinylidene Fluoride (PVDF) Corrosive Waste Drainage

Systems

This standard is issued under the fixed designation F 1673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers requirements for polyvinylidene drainage systems for corrosive applications. Requirements for

material, pipe and fittings are included. Polyvinylidene fluoride includes emulsion/suspension polymerization and copolymers of

vinylidene fluoride/hexafluoropropylene produced by either method.

1.2 TheserequirementsapplytoSchedule40and80IPSandSDR21pipesizes.Pipeandfittingsaretobejoinedbyheatfusion

or mechanical methods using the equipment supplied by the manufacturers.

1.3 This specification is not intended to provide for interchangeability between plastic pipe and fittings from different

manufacturers, but it does allow for transition fittings for joining one manufacturer’s product to another’s product, provided the

joining technique used is other than heat fusion.

1.4 This specification is not for polyvinylidene pressure systems.

1.5The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 Notes and appendixes are not a mandatory part of this specification.

1.7 The following safety hazard caveat pertains only to the test method portion, Section 8, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D543 Practices for Evaluating the Resistance of Plastics to Chemical Reagents

D570 Test Method for Water Absorption of Plastics

D618 Practice for Conditioning Plastics and Electrical Insulating Materials for Testing Practice for Conditioning Plastics for

Testing

D883 Terminology Relating to Plastics

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2321 Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 TestMethodforDeterminationoftheImpactResistanceofThermoplasticPipeandFittingsbyMeansofaTup(Falling

Weight)

D2657 Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings

D3222 Specification for Unmodified Poly(Vinylidene Fluoride) (PVDF) Molding, Extrusion,Molding Extrusion and Coating

Materials

D3311 Specification for Drain, Waste, and Vent (DWV) Plastic Fittings Patterns

D5575 Specification Classification System for Copolymers of Vinylidene Fluoride (VDF) with Other Fluorinated Monomers

F412 Terminology Relating to Plastic Piping Systems

F1290 Practice for Electrofusion Joining Polyolefin Pipe and Fittings

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV.

Current edition approved Apr. 10, 2002. Published June 2002. Originally published as F1673-95. Last previous edition F1673-95.

Current edition approved Aug. 1, 2009. Published September 2009. Originally approved in 1995. Last previous edition approved in 2004 as F1673-04.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1673 – 04 (2009)

F1498 Specification for Taper Pipe Threads (60°) and60 for Thermoplastic Pipe and Fittings

2.2 Federal Standard:

Fed. Std. No. 123 Marking for Shipment

2.3 Military Standard:

MIL-STD129Marking for Shipment and Storage

MIL-STD129 Marking for Shipment and Storage

Annual Book of ASTM Standards, Vol 08.04.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

F 1673 – 04 (2009)

2.4 Other Standard:

Uniform Plumbing Code

3. Terminology

3.1 Definitions:

3.1.1 Definitions used in this specification are in accordance with the definitions given in Terminologies D833 and F412 and

abbreviations are in accordance with Terminology D1600, unless otherwise indicated.

3.1.2 The plumbing terminology used in this specification is in accordance with the definitions given in the Uniform Plumbing

Code, unless otherwise indicated.

4. Classification

4.1 General—This specification covers PVDF pipe and fittings made from PVDF or VF/HFP copolymers in Schedule 40 and

80 IPS sizes and in SDR 21.

4.2 This specification also includes molded fittings and the larger sizes (8, 10, 12 in.) of fabricated fittings.

4.3 This specification covers PVDF pipe (SDR 21) made from PVDF defined by a hydrostatic design stress of 2300 psi (15.85

MPa).

5. Materials and Manufacture

5.1 Polyvinylidene fluoride (PVDF) material for pipe or fittings shall conform to the requirements of Type I or Type II PVDF

as defined in Specification D3222 or copolymers as defined in Specification D5575.

5.2 The PVDF material may contain pigment and fillers not detrimental to the pipe and fittings, provided the pipe and fittings

produced meet the requirements of this specification.

5.3 Rework Material—Cleanreworkmaterial,generatedfromthemanufacturer’spipeandfittingsproductsmaybeusedbythe

same manufacturer, provided that the pipe or fittings produced meet the requirements of this specification.

6. Requirements Requirements

6.1 Dimensions and Tolerances—Pipe and Fittings:

6.1.1 Pipe:

6.1.1.1 DimensionsandtolerancesforpipeshowninTable1andTable2shallbemeasuredinaccordancewithMethodD2122.

The tolerance for out-of-roundness shall apply only to pipe prior to shipment.

6.1.1.2 Toe-In—Theoutsidediameter,whenmeasuredinaccordancewithMethodD2122,shallmeettherequirementsofTable

1 and Table 2 at any point within 1.5 pipe diameters or 11.8 in. (300 mm), whichever is less, to the cut end of the pipe length.

6.1.2 Fittings:

6.1.2.1 The minimum wall thickness of the body all fittings shall not be less than the corresponding Schedule 40 pipe size and

shall be measured in accordance with Method D2122.

6.1.2.2 Spigot ends of fittings shall conform to the diameter and out-of-roundness requirements for pipe.

6.1.2.3 Socket ends of fittings shall conform to the dimensional requirements for size and tolerances as provided by the

manufacturer.

6.1.2.4 The average minimum diameters of waterways of fittings, excluding adapters, shall be as specified in Table 3.

6.1.2.5 Taper pipe threads in any fittings shall be as specified in Specification F1498.The tolerance shall be 1 ⁄2 large or small

turns from the basic thread dimension and gaged in accordance with 8.7.

Annual Book of ASTM Standards, Vol 08.02.

Available from International Association of Plumbing and Mechanical Officials, 5001 E. Philadelphia St., Ontario, CA 91761, http://www.iapmo.org.

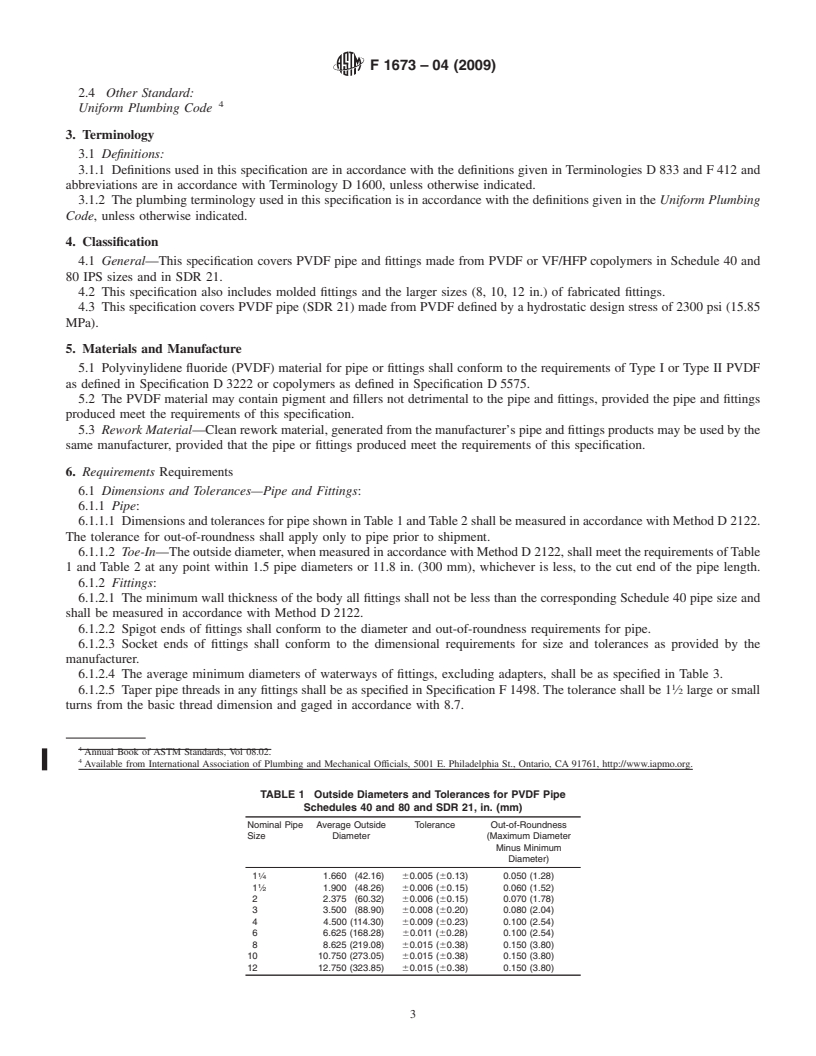

TABLE 1 Outside Diameters and Tolerances for PVDF Pipe

Schedules 40 and 80 and SDR 21, in. (mm)

Nominal Pipe Average Outside Tolerance Out-of-Roundness

Size Diameter (Maximum Diameter

Minus Minimum

Diameter)

1 ⁄4 1.660 (42.16) 60.005 (60.13) 0.050 (1.28)

1 ⁄2 1.900 (48.26) 60.006 (60.15) 0.060 (1.52)

2 2.375 (60.32) 60.006 (60.15) 0.070 (1.78)

3 3.500 (88.90) 60.008 (60.20) 0.080 (2.04)

4 4.500 (114.30) 60.009 (60.23) 0.100 (2.54)

6 6.625 (168.28) 60.011 (60.28) 0.100 (2.54)

8 8.625 (219.08) 60.015 (60.38) 0.150 (3.80)

10 10.750 (273.05) 60.015 (60.38) 0.150 (3.80)

12 12.750 (323.85) 60.015 (60.38) 0.150 (3.80)

F 1673 – 04 (2009)

TABLE 2 Wall Thicknesses and Tolerances for PVDF Pipe Schedules 40 and 80 and SDR 21, in. (mm)

NOTE 1— For fittings, the wall thickness is a minimum value, except that a 10% variation resulting from core shift is allowable. In such a case, the

average of the two opposite wall thickness’ shall equal or exceed the value shown in the Schedule 40 table.

Nominal Schedule 40 Schedule 80 SDR 21, 230 psi SDR 32.5, 150 psi

Pipe

Minimum Tolerance Minimum Tolerance Minimum Tolerance Minimum Tolerance

Sizes

1 ⁄4 0.140 (3.56) +0.020 (+0.51) 0.191 (4.85) +0.023 (+0.58) 0.062 (1.57) +0.020 (+0.51) 0.062 (1.57) +0.020 (0.51)

1 ⁄4 0.140 (3.56) +0.020 (+0.51) 0.191 (4.85) +0.023 (+0.58) 0.079 (2.01) +0.020 (+0.51) 0.062 (1.57) +0.020 (0.51)

1 ⁄2 0.145 (3.68) +0.020 (+0.51) 0.200 (5.08) +0.024 (+0.61) 0.062 (1.57) +0.020 (+0.51) 0.062 (1.57) +0.020 (0.51)

1 ⁄2 0.145 (3.68) +0.020 (+0.51) 0.200 (5.08) +0.024 (+0.61) 0.090 (2.28) +0.020 (+0.51) 0.062 (1.57) +0.020 (0.51)

2 0.154 (3.91) +0.020 (+0.51) 0.218 (5.54) +0.026 (+0.66) 0.077 (1.96) +0.020 (+0.51) 0.073 (1.85) +0.020 (0.51)

2 0.154 (3.91) +0.020 (+0.51) 0.218 (5.54) +0.026 (+0.66) 0.113 (2.87) +0.020 (+0.51) 0.073 (1.85) +0.020 (0.51)

3 0.216 (5.49) +0.026 (+0.66) 0.300 (7.62) +0.036 (+0.91) 0.114 (2.90) +0.026 (+0.6651) 0.108 (2.74) +0.020 (0.51)

3 0.216 (5.49) +0.026 (+0.66) 0.300 (7.62) +0.036 (+0.91) 0.167 (4.22) +0.020 (+0.51) 0.108 (2.74) +0.020 (0.51)

4 0.237 (6.02) +0.028 (+0.71) 0.337 (8.56) +0.040 (+1.02) 0.147 (3.73) +0.026 (+0.66) 0.138 (3.51) +0.71)

4 0.237 (6.02) +0.028 (+0.71) 0.337 (8.56) +0.040 (+1.02) 0.214 (5.44) +0.026 (+0.66) 0.138 (3.51) +0.020 (0.51)

6 0.280 (7.11) +0.034 (+0.86) 0.432 (10.97) +0.052 (+1.32) 0.216 (5.49) +0.034 (+0.97) 0.204 (5.18) +0.0241 (0.6)

6 0.280 (7.11) +0.034 (+0.86) 0.432 (10.97) +0.052 (+1.32) 0.315 (8.00) +0.038 (+0.97) 0.204 (5.18) +0.0241 (0.61)

8 0.322 (8.18) +0.039 (+0.99) 0.500 (12.70) +0.060 (+1.52) 0.281 (7.14) +0.039 (+1.24) 0.99265 (6.73) +0.032 (0.81)

8 0.322 (8.18) +0.039 (+0.99) 0.500 (12.70) +0.060 (+1.52) 0.411 (10.44) +0.049 (+1.24) 0.265 (6.73) +0.032 (0.81)

10 0.365 (9.27) +0.044 (+1.12) 0.593 (15.06) +0.071 (+1.80) 0.350 (8.90) +0.044 (+1.55) 0.331 (8.41) +0.040 (1.02)

10 0.365 (9.27) +0.044 (+1.12) 0.593 (15.06) +0.071 (+1.80) 0.512 (13.00) +0.061 (+1.55) 0.331 (8.41) +0.040 (1.02)

12 0.406 (10.31) +0.049 (+1.24) 0.687 (17.45) +0.082 (+2.08) 0.415 (10.54) +0.049 (+1.85) 0.392 (9.96) +0.04)

12 0.406 (10.31) +0.049 (+1.24) 0.687 (17.45) +0.082 (+2.08) 0.607 (15.42) +0.073 (+1.85) 0.392 (9.96) +0.047 (+1.19)

TABLE 3 Average Waterway Diameter, in. (mm)

Nominal Pipe Unthreaded Fittings Under Half Thread of Male Adapters

Size

Minimum Minimum Maximum

1 ⁄4 1.227 (31.17) 1.220 (30.99) 1.280 (32.51)

1 ⁄2 1.446 (36.73) 1.458 (37.03) 1.501 (38.13)

2 1.881 (47.78) 1.915 (48.64) 1.946 (49.43)

3 2.820 (71.63) 2.849 (72.36) 2.983 (75.77)

4 3.737 (94.92) 3.806 (96.67) 3.972 (100.89)

6 5.646 (143.41) 5.851 (148.62) 6.008 (152.53)

8 7.490 (190.25) . . . . . .

10 9.407 (238.94) . . . . . .

12 11.197 (284.40) . . . . . .

6.1.2.6 The patterns, dimensions, and laying lengths of molded fittings, including adaptors, shall meet the requirements of

Specification D3311, or shall be of a proven design and allow a smooth transition of fluid flow from one direction to another.

6.1.2.7 Cleanouts, cleanout plugs, and caps as commonly used in the manufacturer’s laboratory drainage system, shall have a

thread size and depth sufficient to ensure that the minimum waterway sizes are maintained.

6.1.2.8 Traps—All traps shall have a minimum water seal of 2 in.

6.2 Chemical Resistance—Pipe and fittings material shall be evaluated in accordance with Practice D543, Procedures I and II,

using the chemicals listed in 8.3. The weight change shall not exceed 2%, nor shall the apparent tensile strength change by more

than 10%. In cases where there is a change in the apparent tensile strength greater than 10%, a further evaluation shall be made

after removal from the chemical and conditioning for 72 h. If there is a minimum of 50% recovery of tensile strength after 72 h,

and that figure is within 610% of the original tensile strength, the specimen shall be considered acceptable.

6.3 Water Absorption—Pipe and fitting materials shall not change in weight more than 0.50% when tested in accordance with

8.4.

6.4 System Integrity:

6.4.1 Fusedjointsandassociatedpipeshallwithstandapressureof50psi(345kPa)withoutleakingwhentestedinaccordance

with 8.5.1.

6.4.2 Mechanical joints shall withstand a pressure of 14.5 psi (100 kPa) without leaking when tested in accordance with 8.5.2.

NOTE 1—Mechanical joints include transition, compression, threaded, and other type mechanical joints.

6.4.3 Mechanical joints shall incorporate a positive mechanical system for axial restraint in addition to any restraint provided

by friction.

6.4.4 Mechanical joints shall show no evidence of separation at the joint under Force P when tested in accordance with 8.6.1,

norshalltheyleakorshowanyotherdamagewhentestedinaccordancewith8.6.2.Twofittingsshallbetestedandbothshallpass.

6.5 Allstainlesssteelpartsshallbemadeofcorrosion-resistantsteel,containingnotlessthan16%chromiumandnotlessthan

6% nickel by weight.

6.6 Sealing Rings—Sealing rings shall be made from a material with a chemical resistance similar to PVDF.

F 1673 – 04 (2009)

6.7 Flattening—There shall be no evidence of splitting, cracking, or breaking when the pipe is tested in accordance with 8.8.1.

6.8 Impact Resistance—The impact resistance testing shall be in accordance with 8.9.

7. Workmanship, Finish, and Appearance

7.1 Themanufactureofpipeandfittingsshallbeinaccordancewithgoodcommercialpractice,soastoproducefittingsmeeting

therequirementsofthisspecification.Fittingsandpipeshallbehomogenousthroughoutandfreefromvisi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.