ASTM G93/G93M-19

(Guide)Standard Guide for Cleanliness Levels and Cleaning Methods for Materials and Equipment Used in Oxygen-Enriched Environments

Standard Guide for Cleanliness Levels and Cleaning Methods for Materials and Equipment Used in Oxygen-Enriched Environments

SIGNIFICANCE AND USE

5.1 The purpose of this guide is to furnish qualified technical personnel with pertinent information for the selection of cleaning methods for cleaning materials and equipment to be used in oxygen-enriched environments. This guide furnishes qualified technical personnel with guidance in the specification of oxygen system cleanliness needs. It does not actually specify cleanliness levels.

5.2 Insufficient cleanliness of components used in oxygen systems can result in the ignition of contaminants or components by a variety of mechanisms such as particle, mechanical, or pneumatic impact. These mechanisms are explained in detail in Guide G88.

5.3 Adequate contamination control in oxygen systems is imperative to minimize hazards and component failures that can result from contamination. Contamination must also be minimized to ensure an acceptable product purity.

5.4 Removal of contaminants from materials and components depends on system configuration, materials of construction, and type and quantity of contaminant.

5.5 Examples of cleaning procedures contained herein may be followed or specified for those materials, components, and equipment indicated. The general cleaning text can be used to establish cleaning procedures for materials, components, equipment, and applications not addressed in detail. See Guide G127 for discussion of cleaning agent and procedure selection.

SCOPE

1.1 This guide covers the selection of methods and apparatus for cleaning materials and equipment intended for service in oxygen-enriched environments. Contamination problems encountered in the use of enriched air, mixtures of oxygen with other gases, or any other oxidizing gas may be solved by the same cleaning procedures applicable to most metallic and nonmetallic materials and equipment. Cleaning examples for some specific materials, components, and equipment, and the cleaning methods for particular applications, are given in the appendixes.

1.2 This guide includes levels of cleanliness used for various applications and the methods used to obtain and verify these levels.

1.3 This guide applies to chemical-, solvent-, and aqueous-based processes.

1.4 This guide describes nonmandatory material for choosing the required levels of cleanliness for systems exposed to oxygen or oxygen-enriched atmospheres.

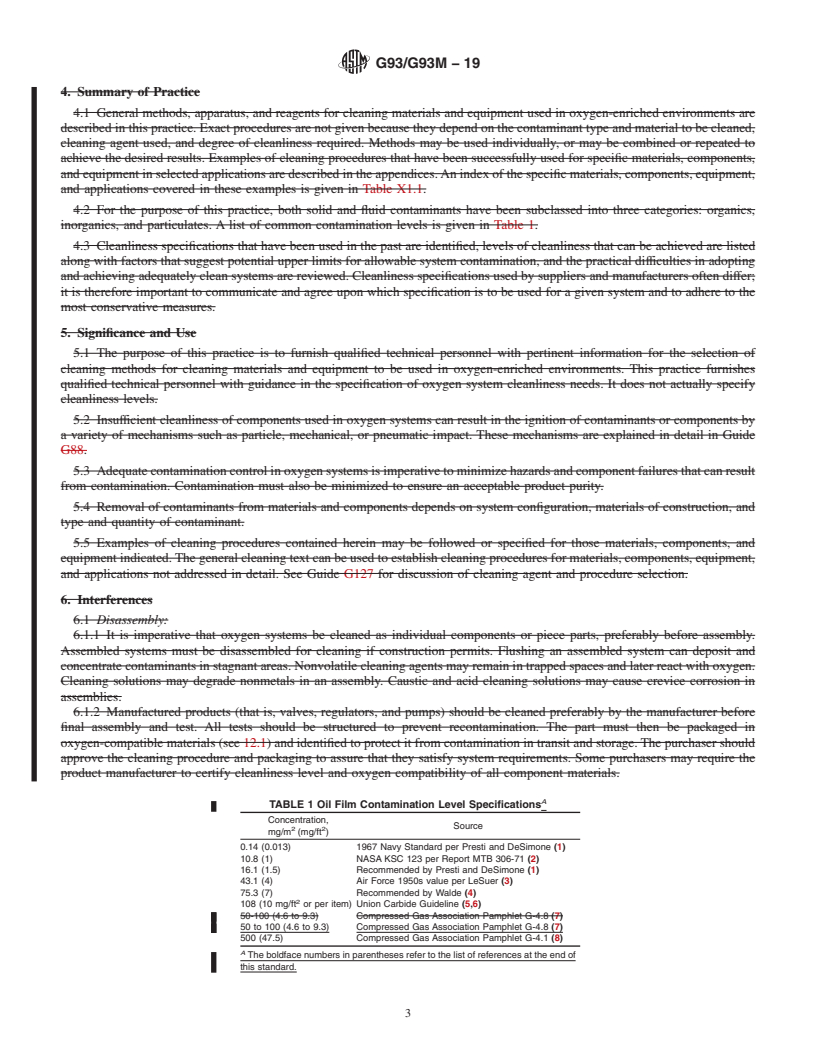

1.5 This guide proposes a practical range of cleanliness levels that will satisfy most system needs, but it does not deal in quantitative detail with the many conditions that might demand greater cleanliness or that might allow greater contamination levels to exist. Furthermore, it does not propose specific ways to measure or monitor these levels from among the available methods.

1.6 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Federal, state, and local safety and disposal regulations concerning the particular hazardous materials, reagents, operations, and equipment being used should be reviewed by the user. The user is encouraged to obtain the Material Safety Data Sheet (MSDS) from the manufacturer for any material incorporated into a cleaning process. Specific cautions are given in Section 8.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guide...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G93/G93M −19

Standard Guide for

Cleanliness Levels and Cleaning Methods for Materials and

1

Equipment Used in Oxygen-Enriched Environments

This standard is issued under the fixed designation G93/G93M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This guide covers the selection of methods and appara-

mine the applicability of regulatory limitations prior to use.

tus for cleaning materials and equipment intended for service

Federal, state, and local safety and disposal regulations con-

in oxygen-enriched environments. Contamination problems

cerning the particular hazardous materials, reagents,

encounteredintheuseofenrichedair,mixturesofoxygenwith

operations, and equipment being used should be reviewed by

other gases, or any other oxidizing gas may be solved by the

the user. The user is encouraged to obtain the Material Safety

same cleaning procedures applicable to most metallic and

Data Sheet (MSDS) from the manufacturer for any material

nonmetallic materials and equipment. Cleaning examples for

incorporated into a cleaning process. Specific cautions are

some specific materials, components, and equipment, and the

given in Section 8.

cleaning methods for particular applications, are given in the

1.8 This international standard was developed in accor-

appendixes.

dance with internationally recognized principles on standard-

1.2 This guide includes levels of cleanliness used for

ization established in the Decision on Principles for the

various applications and the methods used to obtain and verify

Development of International Standards, Guides and Recom-

these levels.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.3 This guide applies to chemical-, solvent-, and aqueous-

based processes.

2. Referenced Documents

1.4 This guide describes nonmandatory material for choos-

2

2.1 ASTM Standards:

ing the required levels of cleanliness for systems exposed to

D1193 Specification for Reagent Water

oxygen or oxygen-enriched atmospheres.

D2200 Practice for Use of Pictorial Surface Preparation

1.5 This guide proposes a practical range of cleanliness

Standards and Guides for Painting Steel Surfaces

levels that will satisfy most system needs, but it does not deal

E312 Practice for Description and Selection of Conditions

in quantitative detail with the many conditions that might

for Photographing Specimens Using Analog (Film) Cam-

demand greater cleanliness or that might allow greater con-

3

eras and Digital Still Cameras (DSC) (Withdrawn 2017)

tamination levels to exist. Furthermore, it does not propose

F312 Test Methods for Microscopical Sizing and Counting

specific ways to measure or monitor these levels from among

Particles from Aerospace Fluids on Membrane Filters

the available methods.

F331 Test Method for Nonvolatile Residue of Solvent Ex-

1.6 Units—The values stated in either SI units or inch-

tract from Aerospace Components (Using Flash Evapora-

pound units are to be regarded separately as standard. The

tor)

values stated in each system are not necessarily exact equiva-

G63 Guide for Evaluating Nonmetallic Materials for Oxy-

lents; therefore, to ensure conformance with the standard, each

gen Service

system shall be used independently of the other, and values

G88 Guide for Designing Systems for Oxygen Service

from the two systems shall not be combined.

G122 Test Method for Evaluating the Effectiveness of

Cleaning Agents

1.7 This standard does not purport to address all of the

G127 Guide for the Selection of Cleaning Agents for

safety concerns, if any, associated with its use. It is the

1 2

This guide is under the jurisdiction ofASTM Committee G04 on Compatibility For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Sensitivity of Materials in Oxygen Enriched Atmospheres and is the direct contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

responsibility of Subcommittee G04.02 on Recommended Practices. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2019. Published October 2019. Originally the ASTM website.

3

approved in 1987. Last previous edition approved in 2011 as G93 – 03(2011). DOI: The last approved version of this historical standard is referenc

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G93 − 03 (Reapproved 2011) G93/G93M − 19

Standard PracticeGuide for

Cleaning Methods and Cleanliness Levels for Materialand

Cleaning Methods for Materials and Equipment Used in

1

Oxygen-Enriched Environments

This standard is issued under the fixed designation G93;G93/G93M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the selection of methods and apparatus for cleaning materials and equipment intended for service in

oxygen-enriched environments. Contamination problems encountered in the use of enriched air, mixtures of oxygen with other

gases, or any other oxidizing gas may be solved by the same cleaning procedures applicable to most metallic and nonmetallic

materials and equipment. Cleaning examples for some specific materials, components, and equipment, and the cleaning methods

for particular applications, are given in the appendices.

1.2 This practice includes levels of cleanliness used for various applications and the methods used to obtain and verify these

levels.

1.3 This practice applies to chemical-, solvent-, and aqueous-based processes.

1.4 This practice describes nonmandatory material for choosing the required levels of cleanliness for systems exposed to oxygen

or oxygen-enriched atmospheres.

1.5 This practice proposes a practical range of cleanliness levels that will satisfy most system needs, but it does not deal in

quantitative detail with the many conditions that might demand greater cleanliness or that might allow greater contamination levels

to exist. Furthermore, it does not propose specific ways to measure or monitor these levels from among the available methods.

1.6 The values stated in both inch-pound and SI units are to be regarded separately as the standard unit. The values given in

parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Federal, state and local safety and disposal regulations concerning the particular hazardous materials,

reagents, operations, and equipment being used should be reviewed by the user. The user is encouraged to obtain the Material

Safety Data Sheet (MSDS) from the manufacturer for any material incorporated into a cleaning process. Specific cautions are given

in Section 8.

2. Referenced Documents

2

2.1 ASTM Standards:

A380 Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment, and Systems

D1193 Specification for Reagent Water

E312 Practice for Description and Selection of Conditions for Photographing Specimens Using Analog (Film) Cameras and

3

Digital Still Cameras (DSC) (Withdrawn 2017)

E1235 Test Method for Gravimetric Determination of Nonvolatile Residue (NVR) in Environmentally Controlled Areas for

Spacecraft

E2042 Practice for Cleaning and Maintaining Controlled Areas and Clean Rooms

F312 Test Methods for Microscopical Sizing and Counting Particles from Aerospace Fluids on Membrane Filters

1

This practiceguide is under the jurisdiction of ASTM Committee G04 on Compatibility and Sensitivity of Materials in Oxygen Enriched Atmospheres and is the direct

responsibility of Subcommittee G04.02 on Recommended Practices.

Current edition approved April 1, 2011Oct. 1, 2019. Published April 2011 October 2019. Originally approved in 1987. Last previous edition approved in 20032011 as

G93 – 03e01.G93 – 03(2011). DOI: 10.1520/G0093-03R11.10.1520/G0093_G0093M-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G93/G93M − 19

F331 Test Method for Nonvolatile Residue of Solvent Extract from Aerospace Components (Using Flash Evaporator)

G63 Guide for Evaluating Nonmetallic Materials for Oxygen S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.