ASTM D4871-11(2022)

(Guide)Standard Guide for Universal Oxidation/Thermal Stability Test Apparatus

Standard Guide for Universal Oxidation/Thermal Stability Test Apparatus

SIGNIFICANCE AND USE

4.1 This standard describes an apparatus that provides the versatility required to conduct oxidation or thermal stability tests on liquids using a wide variety of test conditions. It is sufficiently flexible so that new test conditions can be chosen in response to the changing demands of the marketplace.

4.2 Procedures using this apparatus are described in the following ASTM standard test methods: D5763, D5846, and D6514. Other procedures may be in use, but they have not been developed as ASTM standard test methods.

SCOPE

1.1 This guide covers an apparatus used to measure the oxidation or thermal stability of liquids by subjecting them to temperatures in the range from 50 °C to 375 °C in the presence of air, oxygen, nitrogen, or other gases at flow rates of 1.5 L/h to 13 L/h, or in the absence of gas flow. Stability may be measured in the presence or absence of water or soluble or insoluble catalysts. Gases evolved may be allowed to escape, condensed and collected, or condensed and returned to the test cell.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4871 − 11 (Reapproved 2022)

Standard Guide for

Universal Oxidation/Thermal Stability Test Apparatus

This standard is issued under the fixed designation D4871; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D664 Test Method for Acid Number of Petroleum Products

by Potentiometric Titration

1.1 This guide covers an apparatus used to measure the

D974 Test Method for Acid and Base Number by Color-

oxidation or thermal stability of liquids by subjecting them to

Indicator Titration

temperatures in the range from 50 °C to 375 °C in the presence

D1500 Test Method forASTM Color of Petroleum Products

of air, oxygen, nitrogen, or other gases at flow rates of 1.5 L⁄h

(ASTM Color Scale)

to 13 L⁄h, or in the absence of gas flow. Stability may be

D3339 Test Method forAcid Number of Petroleum Products

measured in the presence or absence of water or soluble or

by Semi-Micro Color Indicator Titration

insoluble catalysts. Gases evolved may be allowed to escape,

D5763 Test Method for Oxidation and Thermal Stability

condensed and collected, or condensed and returned to the test

Characteristics of Gear Oils Using Universal Glassware

cell.

D5770 Test Method for Semiquantitative Micro Determina-

1.2 The values stated in SI units are to be regarded as

tion of Acid Number of Lubricating Oils During Oxida-

standard. No other units of measurement are included in this

tion Testing

standard.

D5846 Test Method for Universal Oxidation Test for Hy-

1.3 This standard does not purport to address all of the

draulic and Turbine Oils Using the Universal Oxidation

safety concerns, if any, associated with its use. It is the Test Apparatus

responsibility of the user of this standard to establish appro-

D6514 Test Method for High Temperature Universal Oxida-

priate safety, health, and environmental practices and deter- tion Test for Turbine Oils

mine the applicability of regulatory limitations prior to use.

3. Summary of Guide

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.1 An apparatus is described in which a sample of test

ization established in the Decision on Principles for the

fluid, typically from 100 mL or 100 g, is subjected to thermal

Development of International Standards, Guides and Recom-

or oxidative degradation or both. Insoluble or soluble catalyst

mendations issued by the World Trade Organization Technical

may be added. Gas may be bubbled through the liquid to

Barriers to Trade (TBT) Committee.

provide agitation or to promote oxidation or both. Water or

water vapor may be added.At the end of the test or at intervals

2. Referenced Documents

throughout the test, the liquid is monitored for change in

2.1 ASTM Standards:

neutralization number, viscosity, weight loss, formation of

D91 Test Method for Precipitation Number of Lubricating

sludge, or for other parameters. The corrosivity of the fluid

Oils

toward any catalyst metals can be determined from the

D156 Test Method for Saybolt Color of Petroleum Products

appearance and weight change of the metal test specimens, if

(Saybolt Chromometer Method)

present, or by monitoring the oil and any sludge or water for

D445 Test Method for Kinematic Viscosity of Transparent

metal content. The test is terminated after a fixed time period

and Opaque Liquids (and Calculation of Dynamic Viscos-

or when a selected parameter reaches a condemning value.

ity)

NOTE 1—The volume of liquid at test temperature should be sufficient

to cover the catalysts and should not extend beyond the heated portion of

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum the bath.

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

mittee D02.09.0D on Oxidation of Lubricants.

4. Significance and Use

Current edition approved April 1, 2022. Published April 2022. Originally

4.1 This standard describes an apparatus that provides the

approved in 1988. Last previous edition approved in 2016 as D4871 – 11 (2016).

DOI: 10.1520/D4871-11R22.

versatility required to conduct oxidation or thermal stability

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tests on liquids using a wide variety of test conditions. It is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sufficientlyflexiblesothatnewtestconditionscanbechosenin

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. response to the changing demands of the marketplace.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4871 − 11 (2022)

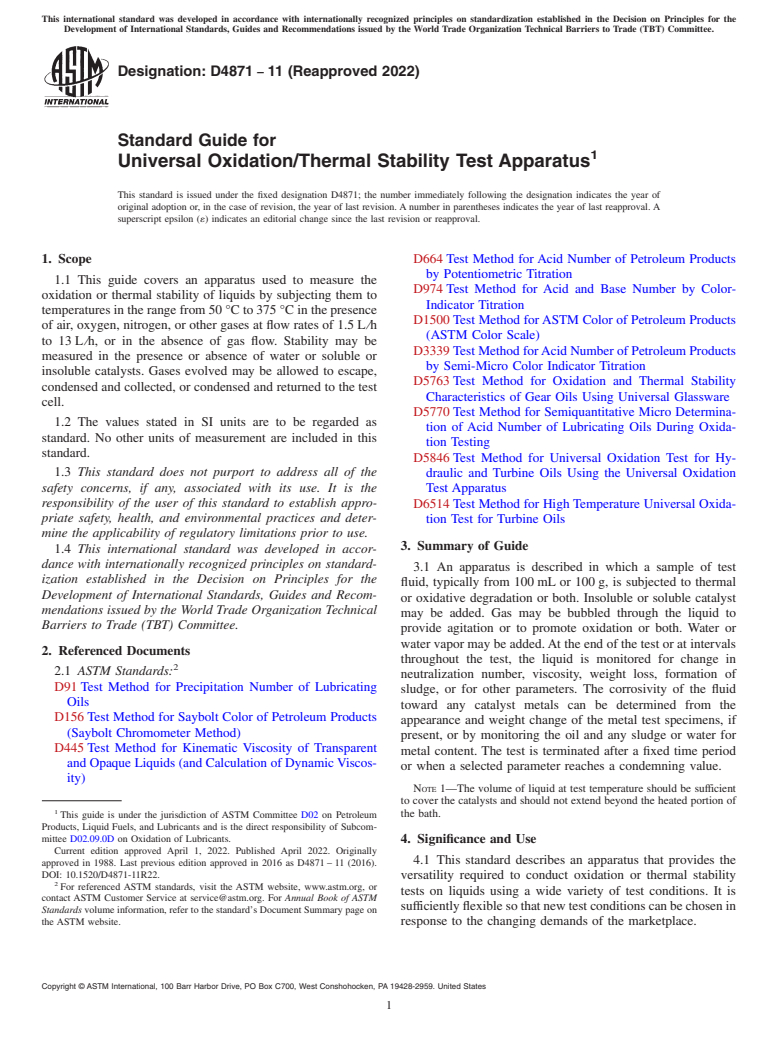

FIG. 1 Universal Oxidation Test Apparatus

4.2 Procedures using this apparatus are described in the 5.1.3 The heating system shall be geometrically and ther-

following ASTM standard test methods: D5763, D5846, and mally balanced. For thermal balance, sizes and locations of the

D6514.Otherproceduresmaybeinuse,buttheyhavenotbeen heaters are proportioned against heat losses.

developed as ASTM standard test methods. 5.1.4 The block is cylindrical and constructed from forged

aluminum. The block has a minimum thickness of 38 mm of

5. Apparatus insulation on all sides, top and bottom. An insulation of

thermally efficient ceramic fiber material is suggested.

5.1 Heating Block, as shown at the lower right in Fig. 1,to

5.1.5 The exterior jacket, sides and top are stainless steel or

provide a controlled constant temperature for conducting tests.

equivalent.

5.1.1 Test cells are maintained at constant elevated tempera-

5.1.6 The block is equipped with a well for a temperature

ture by means of a heated aluminum block which surrounds

measuring device and a thermometer.

each test cell.

5.1.2 Holes in the aluminum block to accommodate the test

5.2 Temperature Control System, as shown at lower left in

cells shall provide 1.0 mm max clearance for 38 mm outside Fig. 1, to maintain the heating block at a set temperature.

diameter glass tubes. The glass test cells shall fit into the block

5.2.1 The temperature controller shall be capable of main-

to a depth of 225 mm 6 5 mm.

taining the block temperature within 60.5 °C of the desired

test temperature for the duration of the test. The preferred

NOTE 2—The original test blocks were made with spaces for ten test

controller shall have proportional and integral control modes,

cells. Blocks with different number of holes are acceptable if other

requirements are met. and a heater malfunction alarm.

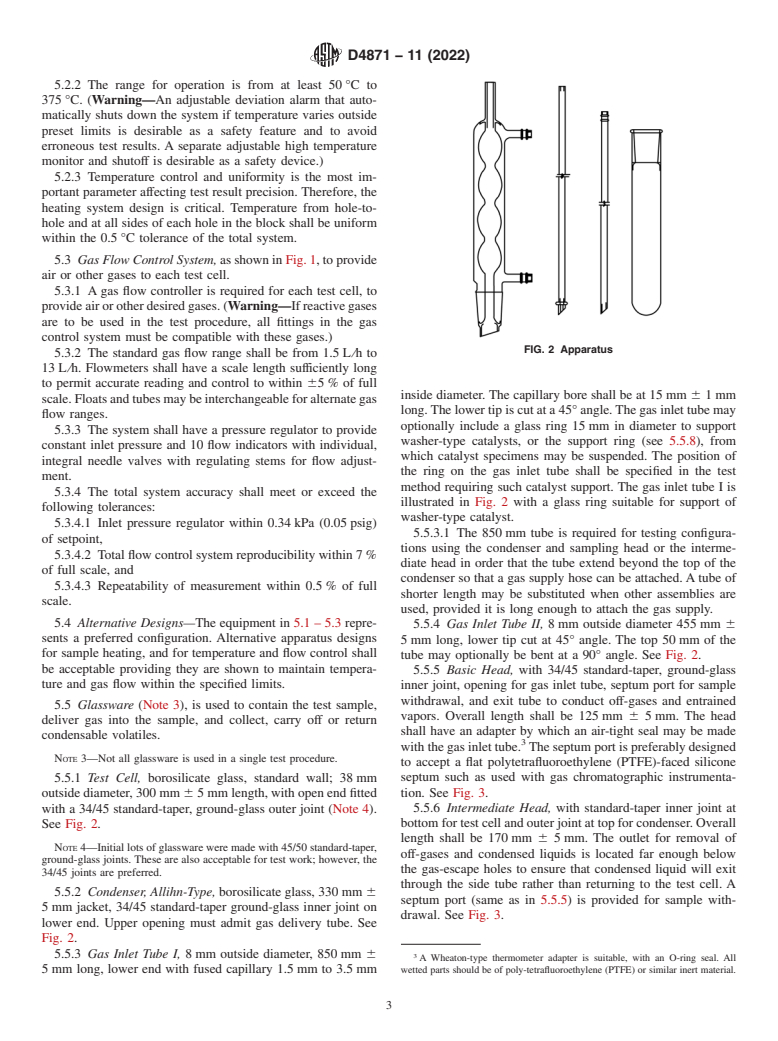

D4871 − 11 (2022)

5.2.2 The range for operation is from at least 50 °C to

375 °C. (Warning—An adjustable deviation alarm that auto-

matically shuts down the system if temperature varies outside

preset limits is desirable as a safety feature and to avoid

erroneous test results. A separate adjustable high temperature

monitor and shutoff is desirable as a safety device.)

5.2.3 Temperature control and uniformity is the most im-

portant parameter affecting test result precision. Therefore, the

heating system design is critical. Temperature from hole-to-

hole and at all sides of each hole in the block shall be uniform

within the 0.5 °C tolerance of the total system.

5.3 GasFlowControlSystem,asshowninFig.1,toprovide

air or other gases to each test cell.

5.3.1 A gas flow controller is required for each test cell, to

provideairorotherdesiredgases.(Warning—Ifreactivegases

are to be used in th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.