ASTM D4793-09(2023)

(Test Method)Standard Test Method for Sequential Batch Extraction of Waste with Water

Standard Test Method for Sequential Batch Extraction of Waste with Water

SIGNIFICANCE AND USE

4.1 This test method is intended as a means for obtaining sequential extracts of a waste. The extracts may be used to estimate the release of certain constituents of the waste under the laboratory conditions described in this test method.

4.2 This test method is not intended to provide extracts that are representative of the actual leachate produced from a waste in the field or to produce extracts to be used as the sole basis of engineering design.

4.3 This test method is not intended to simulate site-specific leaching conditions. It has not been demonstrated to simulate actual disposal site leaching conditions.

4.4 An intent of this test method is that the final pH of each of the extracts reflects the interaction of the extractant with the buffering capacity of the waste.

4.5 An intent of this test method is that the water extractions reflect conditions where the waste is the dominant factor in determining the pH of the extracts.

4.6 This test method produces extracts that are amenable to the determination of both major and minor constituents. When minor constituents are being determined, it is especially important that precautions are taken in sample storage and handling to avoid possible contamination of the samples.

4.7 This test method has been tested to determine its applicability to certain inorganic components in the waste. This test method has not been tested for applicability to organic substances, volatile matter (see Note 3 in 5.15), or biologically active samples.

4.8 The agitation technique, rate, liquid-to-solid ratio, and filtration conditions specified in the procedure may not be suitable for extracting all types of wastes (see Sections 7, 8, and the discussion in Appendix X1).

SCOPE

1.1 This test method is a procedure for the sequential leaching of a waste containing at least five percent solids to generate solutions to be used to determine the constituents leached under the specified testing conditions.

1.2 This test method calls for the shaking of a known weight of waste with water of a specified purity and the separation of the aqueous phase for analysis. The procedure is conducted ten times in sequence on the same sample of waste and generates ten aqueous solutions.

1.3 This test method is intended to describe the procedure for performing sequential batch extractions only. It does not describe all types of sampling and analytical requirements that may be associated with its application.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4793 − 09 (Reapproved 2023)

Standard Test Method for

Sequential Batch Extraction of Waste with Water

This standard is issued under the fixed designation D4793; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D420 Guide for Site Characterization for Engineering De-

sign and Construction Purposes

1.1 This test method is a procedure for the sequential

D653 Terminology Relating to Soil, Rock, and Contained

leaching of a waste containing at least five percent solids to

Fluids

generate solutions to be used to determine the constituents

D1129 Terminology Relating to Water

leached under the specified testing conditions.

D1193 Specification for Reagent Water

1.2 This test method calls for the shaking of a known weight

D2216 Test Methods for Laboratory Determination of Water

of waste with water of a specified purity and the separation of

(Moisture) Content of Soil and Rock by Mass

the aqueous phase for analysis. The procedure is conducted ten

D2234/D2234M Practice for Collection of a Gross Sample

times in sequence on the same sample of waste and generates

of Coal

ten aqueous solutions.

D2777 Practice for Determination of Precision and Bias of

Applicable Test Methods of Committee D19 on Water

1.3 This test method is intended to describe the procedure

for performing sequential batch extractions only. It does not D3370 Practices for Sampling Water from Flowing Process

Streams

describe all types of sampling and analytical requirements that

may be associated with its application.

3. Terminology

1.4 The values stated in SI units are to be regarded as

3.1 Definitions:

standard. No other units of measurement are included in this

3.1.1 For definitions of terms used in this test method, see

standard.

Terminology D1129.

1.5 This standard does not purport to address all of the

3.2 Symbols:

safety concerns, if any, associated with its use. It is the

3.2.1 Variables listed in this test method are defined in the

responsibility of the user of this standard to establish appro-

individual sections where they are discussed. A list of defined

priate safety, health, and environmental practices and deter-

variables is also given in Section 11.

mine the applicability of regulatory limitations prior to use.

3.2.2 Explanation of Variables:

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

¯

X = total mean value

ization established in the Decision on Principles for the

t

¯

X = analytical mean value (calculated using data from

Development of International Standards, Guides and Recom- a

analysis of standards)

mendations issued by the World Trade Organization Technical

S = total standard deviation

Barriers to Trade (TBT) Committee. tt

S = analytical standard deviation

ta

S = estimated standard deviation due to the extraction

te

2. Referenced Documents

procedure

2.1 ASTM Standards:

S = total single operator standard deviation

ot

D75/D75M Practice for Sampling Aggregates

S = analytical single operator standard deviation

oa

S = estimated single operator standard deviation due to

oe

the extraction procedure

This test method is under the jurisdiction of ASTM Committee D34 on Waste

4. Significance and Use

Management and is the direct responsibility of Subcommittee D34.01.04 on Waste

Leaching Techniques.

4.1 This test method is intended as a means for obtaining

Current edition approved Nov. 1, 2023. Published November 2023. Originally

sequential extracts of a waste. The extracts may be used to

approved in 1988. Last previous edition approved in 2017 as D4793 – 09 (2017).

estimate the release of certain constituents of the waste under

DOI: 10.1520/D4793-09R23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or the laboratory conditions described in this test method.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 This test method is not intended to provide extracts that

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. are representative of the actual leachate produced from a waste

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4793 − 09 (2023)

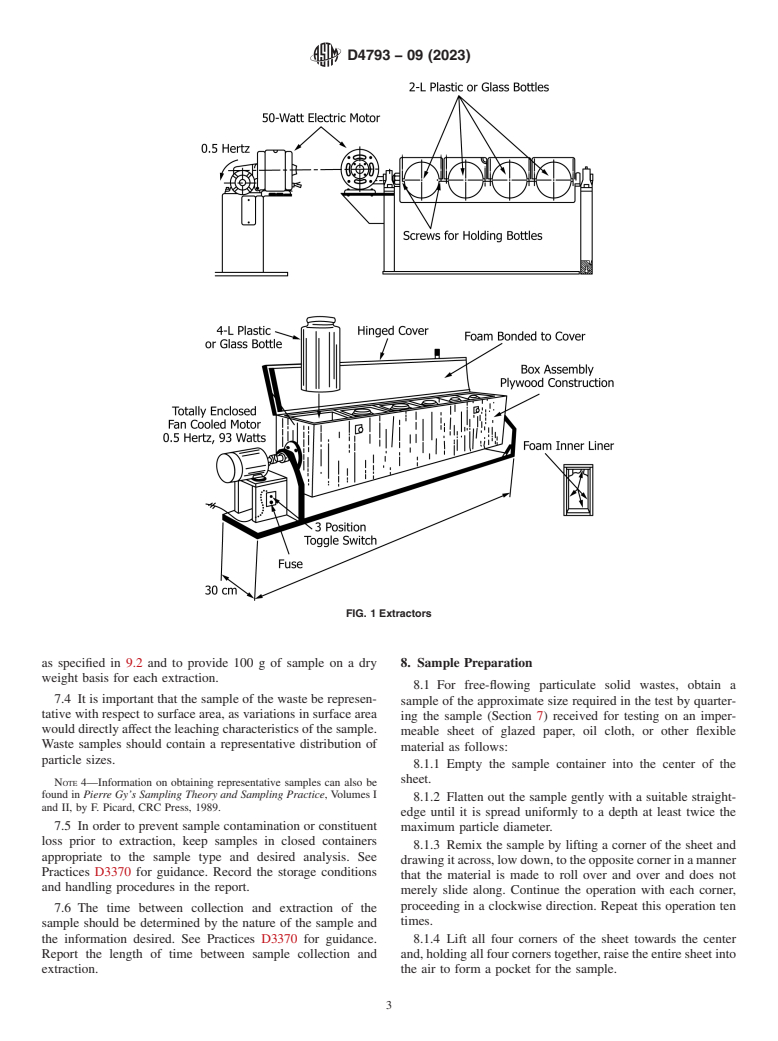

in the field or to produce extracts to be used as the sole basis through the center of the bottle (see Fig. 1 and the discussion

of engineering design. of agitation in Appendix X1).

4.3 This test method is not intended to simulate site-specific

NOTE 1—Similar devices having a different axial arrangement may be

used if equivalency can be demonstrated.

leaching conditions. It has not been demonstrated to simulate

actual disposal site leaching conditions.

5.14 Pressure Filtration Assembly—A pressure filtration

device of a composition suitable to the nature of the analyses

4.4 An intent of this test method is that the final pH of each

to be performed and equipped with a 0.45 or 0.8 μm pore size

of the extracts reflects the interaction of the extractant with the

filter (see Note 7, pertaining to 9.4).

buffering capacity of the waste.

5.15 Extraction Vessels, cylindrical, wide-mouth, of a com-

4.5 An intent of this test method is that the water extractions

position suitable to the nature of the waste and analyses to be

reflect conditions where the waste is the dominant factor in

performed, constructed of materials that will not allow sorption

determining the pH of the extracts.

of constituents of interest, and sturdy enough to withstand the

4.6 This test method produces extracts that are amenable to

impact of the falling sample fragments. Container size should

the determination of both major and minor constituents. When

be selected so that the sample plus extraction fluid occupy

minor constituents are being determined, it is especially

approximately 95 % of the container. Containers must have

important that precautions are taken in sample storage and

watertight closure. Containers for samples where gases may be

handling to avoid possible contamination of the samples.

released should be provided with a venting mechanism.

4.7 This test method has been tested to determine its

NOTE 2—Suitable container sizes range from 10 to 11 cm in diameter

applicability to certain inorganic components in the waste. This

and 22 to 33 cm in height.

test method has not been tested for applicability to organic

substances, volatile matter (see Note 3 in 5.15), or biologically NOTE 3—Venting the container has the potential to affect the concen-

tration of volatile compounds in the extracts.

active samples.

5.15.1 Extraction vessels should be cleaned in a manner

4.8 The agitation technique, rate, liquid-to-solid ratio, and

consistent with the analyses to be performed. See Section 13 of

filtration conditions specified in the procedure may not be

Practices D3370.

suitable for extracting all types of wastes (see Sections 7, 8,

and the discussion in Appendix X1).

6. Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be

5. Apparatus

used in all tests. Unless otherwise indicated, it is intended that

5.1 Straightedge, such as a thin-edged yardstick.

all reagents shall conform to the specifications of the American

Chemical Society, where such specifications are available.

5.2 Impermeable Sheet, of glazed paper, oil cloth, or other

Other grades may be used, provided it is first ascertained that

flexible material of a composition suitable to the analytes of

the reagent is of sufficiently high purity to permit its use

interest.

without lessening the accuracy of the determination.

5.3 Drying Pans or Dishes—Two per waste (for example,

6.2 Purity of Water—Unless otherwise indicated, references

aluminum tins, porcelain dishes, or glass weighing pans),

to water shall be understood to mean Type IV reagent water at

suitable to the waste being tested and the instructions given in

18 to 27 °C (Specification D1193). The method by which the

9.2.

water is prepared, that is, distillation, ion exchange, reverse

5.4 Drying Oven—Any thermostatically controlled drying

osmosis, electrodialysis, or a combination thereof, should

oven capable of maintaining a steady temperature of 62 °C in

remain constant throughout testing.

a range from 100 to 110 °C.

7. Sampling

5.5 Desiccator, having the capacity to hold the drying pans

described in 5.3 and the crucibles described in 5.8.

7.1 Obtain a representative sample of the waste to be tested

using ASTM sampling methods developed for the specific

5.6 Laboratory Balance, capable of weighing to 0.1 g.

industry where available (see Practice D75/D75M, Guide

5.7 Pipet, 10 mL capacity.

D420, Terminology D653, and Test Method D2234/D2234M).

5.8 Crucibles—Two per waste, porcelain, 20 mL capacity

7.2 Where no specific methods are available, sampling

each.

methodology for material of similar physical form shall be

5.9 Analytical Balance, capable of weighing to 0.1 mg.

used.

5.10 Large Glass Funnel. 7.3 The amount of sample to be sent to the laboratory

should be sufficient to perform the solids content determination

5.11 Wash Bottle, 500 mL capacity.

5.12 pH Meter—Any pH meter with a readability of 0.01

Reagent Chemicals, American Chemical Society Specifications, American

units and an accuracy of 60.05 units at 25 °C is acceptable.

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

5.13 Agitation Equipment, of any type that rotates the

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

extraction vessel in an end-over-end fashion at a rate of 0.5 6

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

0.03 Hz, such that the axis of rotation is horizontal and it goes MD.

D4793 − 09 (2023)

FIG. 1 Extractors

as specified in 9.2 and to provide 100 g of sample on a dry 8. Sample Preparation

weight basis for each extraction.

8.1 For free-flowing particulate solid wastes, obtain a

7.4 It is important that the sample of the waste be represen-

sample of the approximate size required in the test by quarter-

tative with respect to surface area, as variations in surface area

ing the sample (Section 7) received for testing on an imper-

would directly affect the leaching characteristics of the sample.

meable sheet of glazed paper, oil cloth, or other flexible

Waste samples should contain a representative distribution of

material as follows:

particle sizes.

8.1.1 Empty the sample container into the center of the

sheet.

NOTE 4—Information on obtaining representative samples can also be

found in Pierre Gy’s Sampling Theory and Sampling Practice, Volumes I

8.1.2 Flatten out the sample gently with a suitable straight-

and II, by F. Picard, CRC Press, 1989.

edge until it is spread uniformly to a depth at least twice the

7.5 In order to prevent sample contamination or constituent

maximum particle diameter.

loss prior to extraction, keep samples in closed containers

8.1.3 Remix the sample by lifting a corner of the sheet and

appropriate to the sample type and desired analysis. See

drawing it across, low down, to the opposite corner in a manner

Practices D3370 for guidance. Record the storage conditions

that the material is made to roll over and over and does not

and handling procedures in the report.

merely slide along. Continue the operation with each corner,

proceeding in a clockwise direction. Repeat this operation ten

7.6 The time between collection and extraction of the

times.

sample should be determined by the nature of the sample and

the information desired. See Practices D3370 for guidance. 8.1.4 Lift all four corners of the sheet towards the center

Report the length of time between sample collection and and, holding all four corners together, raise the entire sheet into

extraction. the air to form a pocket for the sample.

D4793 − 09 (2023)

8.1.5 Repeat 8.1.2. 9.3 Extraction Procedure—If the entire procedure cannot be

conducted without interruption, at least the first four extraction

8.1.6 With a straightedge (such as a thin-edged yardstick),

sequences must be conducted without interruption.

one at least as long as the flattened mound of sample, gently

9.3.1 Determine the mass of the extraction vessel to be used

divide the sample into quarters. Make an effort to avoid using

in the extraction procedure to the nearest 0.1 g. Record the

pressure on the straightedge sufficient to cause damage to the

mass of the extraction vessel, M . Use one extraction vessel

particles.

v1

per waste throughout the sequence of extractions.

8.1.7 Discard alternate quarters.

9.3.2 Add 100 g (weighed to 60.1 g) of solid waste on a dry

8.1.8 If further reduction of sample size is necessary, repeat

weight basis to the extraction vessel. Calculate the amount of

8.1.3 – 8.1.7. Use a sample size to give 100 g of solid for each

waste as received to add using the following equation:

extraction. Provide additional samples for determination of

solids content. If smaller samples are used in the test, report 100

M 5 (2)

this fact.

S

NOTE 5—For other acceptable methods for mixing and subsampling where:

free-flowing solid particulate wastes, see Pierre Gy’s Sampling Theory

M = mass of waste as received to add to the extraction vessel

and Sampling Practice, Volumes I and II, by F. Picard, CRC Press, 1989.

to give 100 g (weighed to 60.1 g) of solid waste.

The method of subsampling should be determined by the physical

properties of the waste, analytes of interest, and equipment available.

9.3.2.1 If a mass of solid waste on a dry weight basis other

than 100 g is used, Eq 2-4 must be modified to reflect the use

8.2 For field-cored solid wastes or castings produced in the

of a mass other than 100 g. Replace 100 in these equations with

laboratory, cut a representative section weighing approxi-

the mass used. Use of a mass other than 100 g is not

mately 100 g for testing plus samples for determination for

recommended.

solids content. Shape the sample so that the leaching solution

9.3.3 Add a volume in millilitres, V , of test water (see 6.2)

will cover the material to be leached.

vl

to the extraction vessel determined using the following equa-

8.3 For multiphasic wastes, mix thoroughly to ensure that a

tions:

representative sample will be withdrawn. Take samples for

M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.