ASTM F545-95

(Specification)Specification for PVC and ABS Injected Solvent Cemented Plastic Pipe Joints (Withdrawn 2001)

Specification for PVC and ABS Injected Solvent Cemented Plastic Pipe Joints (Withdrawn 2001)

SCOPE

1.1 This specification covers requirements for materials, dimensions, and test methods for PVC and ABS plastic pipe joints in which an annular sealed space between pipe and socket surfaces is injected with solvent cement.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 7, of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3.1 For safe handling, see Practice F402.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 545 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

PVC and ABS Injected Solvent Cemented Plastic Pipe

1

Joints

This standard is issued under the fixed designation F 545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

4

1. Scope Butadiene-Styrene (ABS) Plastic Pipe and Fittings

D 2564 Specification for Solvent Cements for Poly(Vinyl

1.1 This specification covers requirements for materials,

4

Chloride) (PVC) Plastic Piping Systems

dimensions, and test methods for PVC and ABS plastic pipe

F 402 Practice for Safe Handling of Solvent Cements,

joints in which an annular sealed space between pipe and

Primers, and Cleaners Used for Joining Thermoplastic Pipe

socket surfaces is injected with solvent cement.

4

and Fittings

1.2 The values stated in inch-pound units are to be regarded

4

F 412 Terminology Relating to Plastic Piping Systems

as the standard. The values given in parentheses are for

information only.

3. Terminology

1.3 The following precautionary caveat pertains only to the

3.1 Definitions—Definitions are in accordance with Termi-

test methods portion, Section 7, of this specification: This

nology F 412, and abbreviations are in accordance with Ter-

standard does not purport to address all of the safety concerns,

minology D 1600, unless otherwise specified.

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

4. General Description

practices and determine the applicability of regulatory limita-

4.1 The injected type of solvent cemented joint is one in

tions prior to use.

which an annular cavity formed between a pipe and a socket is

1.4 For safe handling, see Practice F 402.

sealed at socket bottom and socket entrance and is injected

with suitable cements to form a rigid bonded joint.

2. Referenced Documents

2.1 ASTM Standards:

5. Materials and Manufacture

D 618 Practice for Conditioning Plastics and Electrical

2 5.1 Pipes, fittings, and belled pipes shall meet the require-

Insulating Materials for Testing

3 ments of applicable ASTM specifications.

D 1084 Test Methods for Viscosity of Adhesives

5.2 The injected cement shall meet the requirements of 6.2

D 1527 Specification for Acrylonitrile-Butadiene-Styrene

4 for PVC or 6.2.3 for ABS components.

(ABS) Plastic Pipe, Schedules 40 and 80

D 1599 Test Method for Short-Time Hydraulic Failure Pres-

6. Requirements

4

sure of Plastic Pipe, Tubing, and Fittings

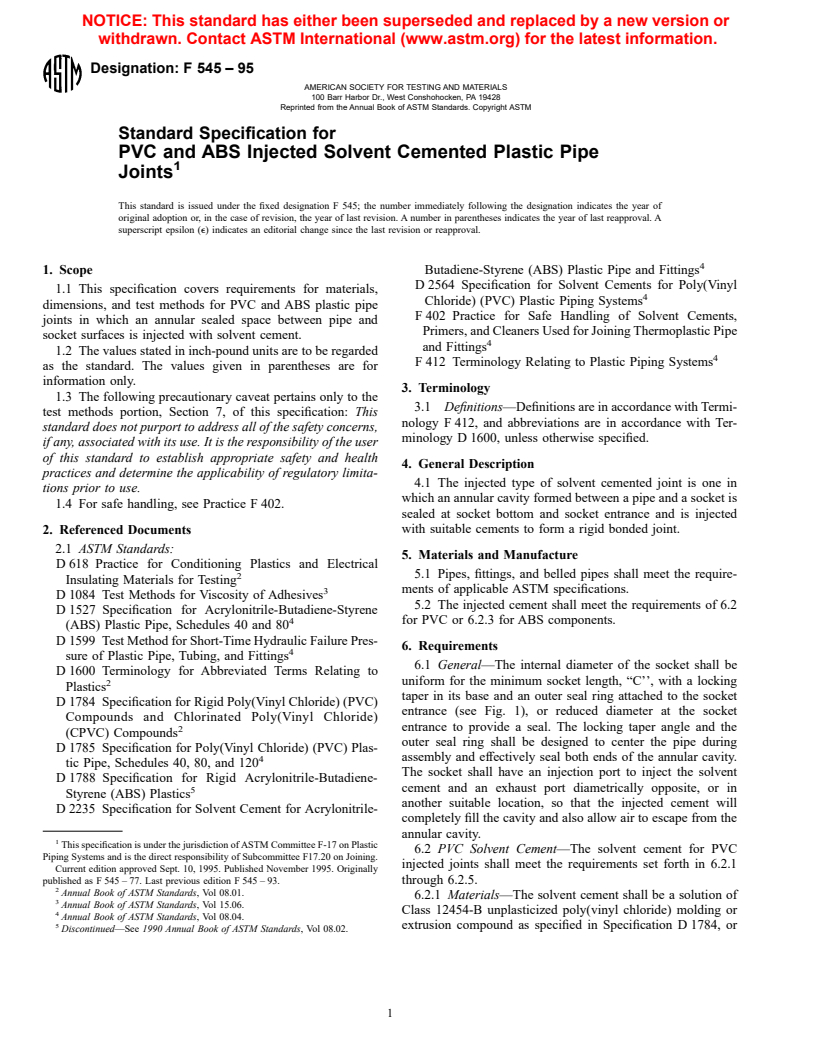

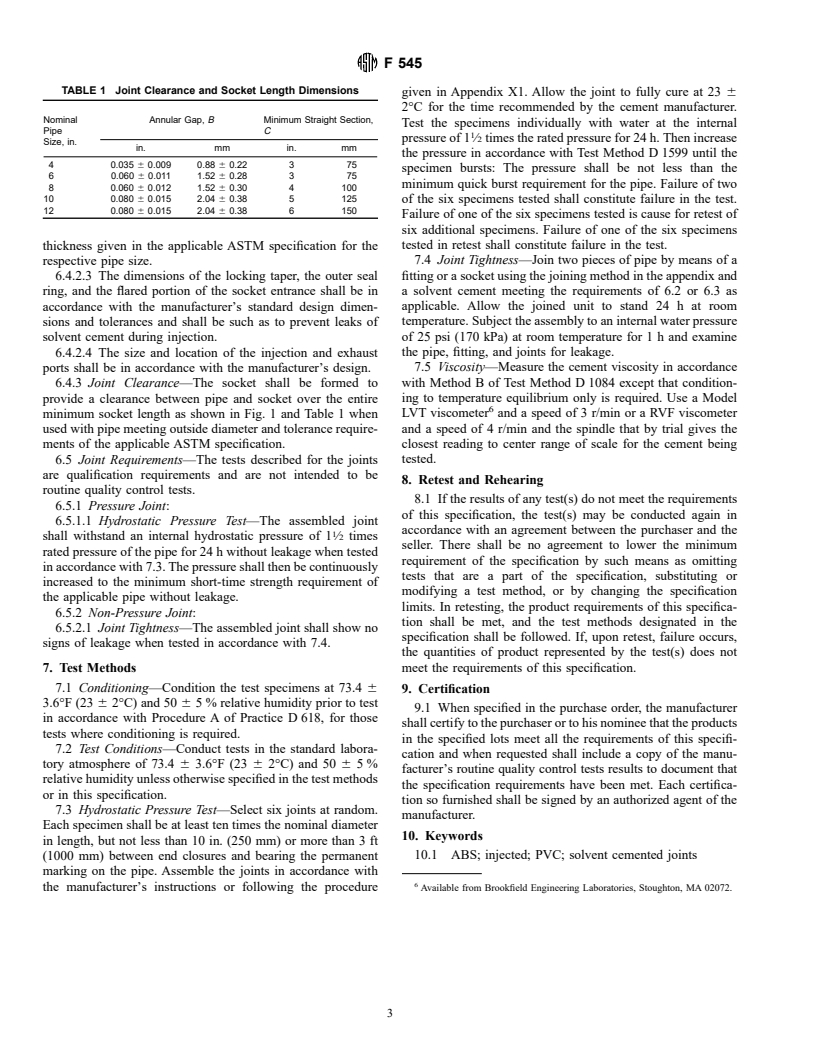

6.1 General—The internal diameter of the socket shall be

D 1600 Terminology for Abbreviated Terms Relating to

uniform for the minimum socket length, “C’’, with a locking

2

Plastics

taper in its base and an outer seal ring attached to the socket

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

entrance (see Fig. 1), or reduced diameter at the socket

Compounds and Chlorinated Poly(Vinyl Chloride)

entrance to provide a seal. The locking taper angle and the

2

(CPVC) Compounds

outer seal ring shall be designed to center the pipe during

D 1785 Specification for Poly(Vinyl Chloride) (PVC) Plas-

assembly and effectively seal both ends of the annular cavity.

4

tic Pipe, Schedules 40, 80, and 120

The socket shall have an injection port to inject the solvent

D 1788 Specification for Rigid Acrylonitrile-Butadiene-

cement and an exhaust port diametrically opposite, or in

5

Styrene (ABS) Plastics

another suitable location, so that the injected cement will

D 2235 Specification for Solvent Cement for Acrylonitrile-

completely fill the cavity and also allow air to escape from the

annular cavity.

1

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

6.2 PVC Solvent Cement—The solvent cement for PVC

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

injected joints shall meet the requirements set forth in 6.2.1

Current edition approved Sept. 10, 1995. Published November 1995. Originally

through 6.2.5.

published as F 545 – 77. Last previous edition F 545 – 93.

2

Annual Book of ASTM Standards, Vol 08.01.

6.2.1 Materials—The solvent cement shall be a solution of

3

Annual Book of ASTM Standards, Vol 15.06.

Class 12454-B unplasticized poly(vinyl chloride) molding or

4

Annual Book of ASTM Standards, Vol 08.04.

5

extrusion compound as specified in Specification D 1784, or

Discontinued—See 1990 Annual Book of ASTM Standards, Vol 08.02.

1

---------------------- Page: 1 ----------------------

F 545

FIG. 1 Injection Joint

the base PVC resin used

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.