ASTM B311-22

(Test Method)Standard Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity

Standard Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity

SIGNIFICANCE AND USE

5.1 For PM materials containing less than two percent porosity, a density measurement may be used to determine if the part has been densified, either overall or in a critical region, to the degree required for the intended application. Density alone cannot be used for evaluating the degree of densification because chemical composition and heat treatment affect the pore-free density.

5.2 For cemented carbides, a density measurement is normally used to determine if there is any significant deviation in composition of the carbide grade. For straight tungsten carbide-cobalt grades, the relationship is straightforward. For complex carbide grades (for example, grades containing tantalum carbide or titanium carbide, or both, in addition to tungsten carbide-cobalt), the situation is more complicated. If the measured density is beyond the specified limits, the composition is outside of the specified limits. A measured density within the specified limits does not ensure correct composition; compensation between two or more constituents could result in the expected density with the wrong composition. Density alone cannot be used for evaluating a cemented carbide grade.

SCOPE

1.1 This test method covers the determination of density for powder metallurgy (PM) materials containing less than two percent porosity and for cemented carbides. This test method is based on the water displacement method.

Note 1: A test specimen that gains mass when immersed in water indicates the specimen contains surface-connected porosity. Unsealed surface porosity will absorb water and result in calculated density values higher than the true value. This test method is not applicable if this problem occurs, and Test Methods B962 should be used instead.

1.2 Units—With the exception of the values for density and the mass used to determine density, for which the use of the gram per cubic centimetre (g/cm3) and gram (g) units is the long-standing industry practice, the values in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B311 − 22

Standard Test Method for

Density of Powder Metallurgy (PM) Materials Containing

1

Less Than Two Percent Porosity

This standard is issued under the fixed designation B311; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B962 Test Methods for Density of Compacted or Sintered

Powder Metallurgy (PM) Products Using Archimedes’

1.1 This test method covers the determination of density for

Principle

powder metallurgy (PM) materials containing less than two

E456 Terminology Relating to Quality and Statistics

percent porosity and for cemented carbides.This test method is

E691 Practice for Conducting an Interlaboratory Study to

based on the water displacement method.

Determine the Precision of a Test Method

NOTE 1—A test specimen that gains mass when immersed in water

indicates the specimen contains surface-connected porosity. Unsealed

3. Terminology

surface porosity will absorb water and result in calculated density values

higher than the true value. This test method is not applicable if this

3.1 Definitions of powder metallurgy (PM) terms can be

problem occurs, and Test Methods B962 should be used instead.

found in Terminology B243.Additional descriptive material is

1.2 Units—With the exception of the values for density and available under “General Information on PM” on the ASTM

the mass used to determine density, for which the use of the

B09 web page.

3

gram per cubic centimetre (g/cm ) and gram (g) units is the

long-standing industry practice, the values in SI units are to be

4. Summary of Test Method

regarded as standard. The values given in parentheses after SI

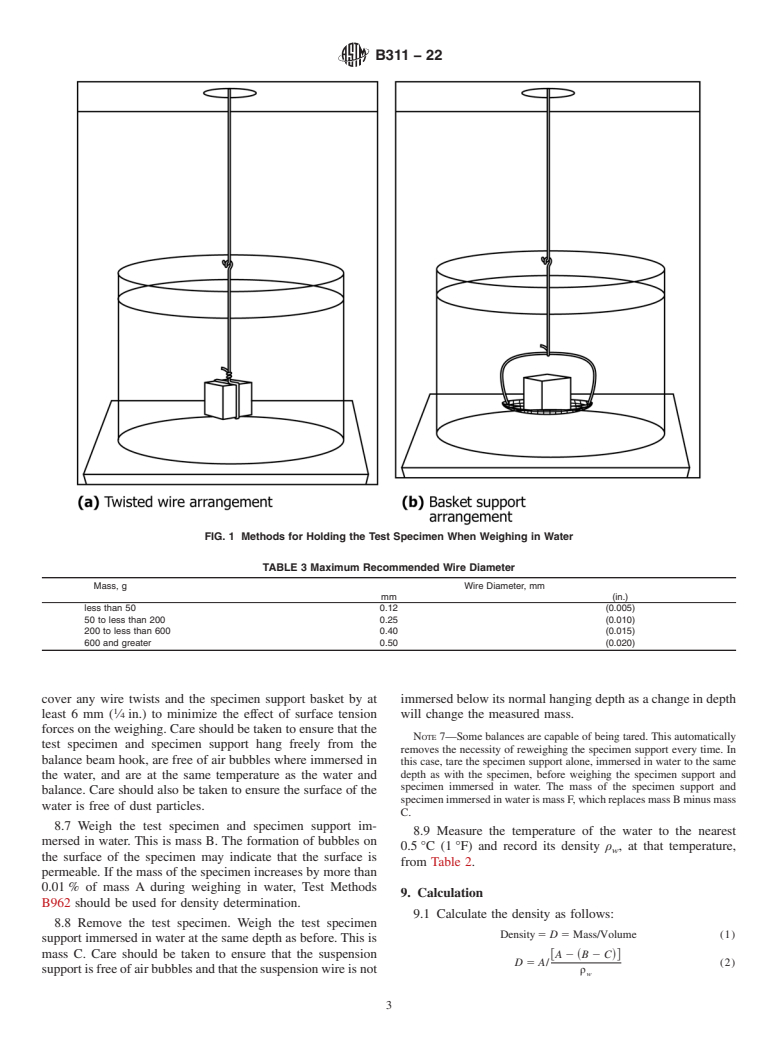

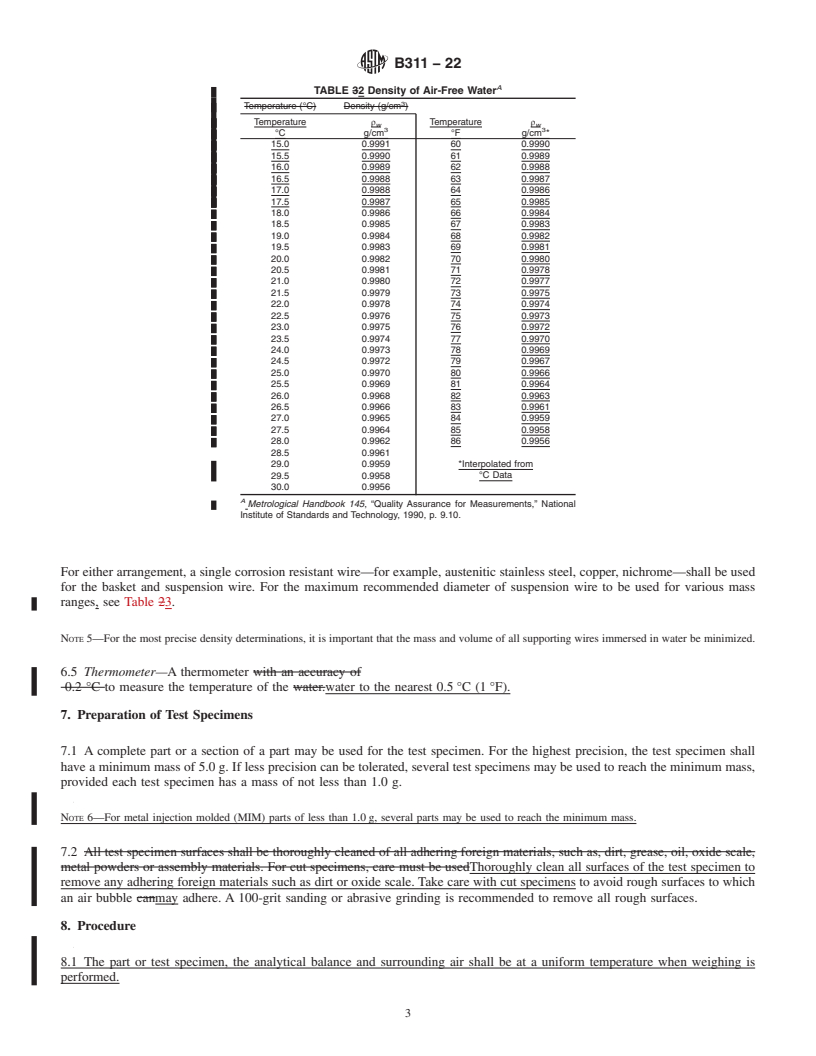

4.1 Using an analytical balance, the test specimen is first

units are provided for information only and are not considered

weighed in air and then in water. The density is determined by

standard.

calculation using Archimedes’ principle.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 For PM materials containing less than two percent

priate safety, health, and environmental practices and deter-

porosity, a density measurement may be used to determine if

mine the applicability of regulatory limitations prior to use.

the part has been densified, either overall or in a critical region,

1.4 This international standard was developed in accor-

to the degree required for the intended application. Density

dance with internationally recognized principles on standard-

alone cannot be used for evaluating the degree of densification

ization established in the Decision on Principles for the

because chemical composition and heat treatment affect the

Development of International Standards, Guides and Recom-

pore-free density.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 5.2 For cemented carbides, a density measurement is nor-

mally used to determine if there is any significant deviation in

2. Referenced Documents

composition of the carbide grade. For straight tungsten

2

2.1 ASTM Standards:

carbide-cobalt grades, the relationship is straightforward. For

B243 Terminology of Powder Metallurgy

complex carbide grades (for example, grades containing tan-

talum carbide or titanium carbide, or both, in addition to

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal

tungsten carbide-cobalt), the situation is more complicated. If

Powders and Metal Powder Products and is the direct responsibility of Subcom-

the measured density is beyond the specified limits, the

mittee B09.11 on Near Full Density Powder Metallurgy Materials.

composition is outside of the specified limits. A measured

Current edition approved Sept. 1, 2022. Published September 2022. Originally

density within the specified limits does not ensure correct

approved in 1956. Last previous edition approved in 2017 as B311 – 17. DOI:

10.1520/B0311-22.

composition; compensation between two or more constituents

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

could result in the expected density with the wrong composi-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tion. Density alone cannot be used for evaluating a cemented

Standards volume information, refer to the sta

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B311 − 17 B311 − 22

Standard Test Method for

Density of Powder Metallurgy (PM) Materials Containing

1

Less Than Two Percent Porosity

This standard is issued under the fixed designation B311; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers the determination of density for powder metallurgy (PM) materials containing less than two percent

porosity and for cemented carbides. This test method is based on the water displacement method.

NOTE 1—A test specimen that gains mass when immersed in water indicates the specimen contains surface-connected porosity. Unsealed surface porosity

will absorb water and cause result in calculated density values higher than the true value. This test method is not applicable if this problem occurs.occurs,

and Test Methods B962 should be used instead.

1.2 Units—With the exception of the values for density and the mass used to determine density, for which the use of the gram per

3

cubic centimetre (g/cm ) and gram (g) units is the long-standing industry practice, the values in SI units are to be regarded as

standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B243 Terminology of Powder Metallurgy

B962 Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E456 Terminology Relating to Quality and Statistics

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of Subcommittee B09.11

on Near Full Density Powder Metallurgy Materials.

Current edition approved April 1, 2017Sept. 1, 2022. Published April 2017September 2022. Originally approved in 1956. Last previous edition approved in 20082017 as

B311 – 08.B311 – 17. DOI: 10.1520/B0311-17.10.1520/B0311-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B311 − 22

3. Terminology

3.1 Definitions of powder metallurgy (PM) terms can be found in Terminology B243. Additional descriptive material is available

in the Related Material section of Vol. 02.05 of the under “General Information on PM” on the Annual Book of ASTM

Standards.ASTM B09 web page.

4. Summary of Test Method

4.1 Using an analytical balance, the test specimen is first weighed in air and then in water. The density is determined by calculation

using Archimedes’ principle.

5. Significance and Use

5.1 For PM materials containing less than two percent porosity, a density measurement may be used to determine if the part has

been densified, either overall or in a critical region, to the degree required for the intended application. Density alone cannot be

used for evaluating the degree of densification because chemical composition and heat treatment affect the pore-free density.

5.2 For cemented carbides, a density measurement is normally used to determine if there is any significant deviation in

composition of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.