ASTM D2457-08

(Test Method)Standard Test Method for Specular Gloss of Plastic Films and Solid Plastics

Standard Test Method for Specular Gloss of Plastic Films and Solid Plastics

SIGNIFICANCE AND USE

Specular gloss is used primarily as a measure of the shiny appearance of films and surfaces. Precise comparisons of gloss values are meaningful only when they refer to the same measurement procedure and same general type of material. In particular, gloss values for transparent films should not be compared with those for opaque films, and vice versa. Gloss is a complex attribute of a surface which cannot be completely measured by any single number.

Specular gloss usually varies with surface smoothness and flatness. It is sometimes used for comparative measurements of these surface properties.

SCOPE

1.1 This test method describes procedures for the measurement of gloss of plastic films and solid plastics, both opaque and transparent. It contains four separate gloss angles (Note 1):

1.1.1 60-deg, recommended for intermediate-gloss films,

1.1.2 20-deg, recommended for high-gloss films,

1.1.3 45-deg, recommended for intermediate and low-gloss films, and

1.1.4 75-deg, recommended for plastic siding and soffit.

Note 1—The 75-deg, 60-deg, and 20-deg apparatus and method of measurement duplicate those in Test Method D 523; those for the 45° procedure are similarly taken from Test Method C 346.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2—There is no similar or equivalent ISO standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2457–08

Standard Test Method for

1

Specular Gloss of Plastic Films and Solid Plastics

This standard is issued under the fixed designation D2457; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Spectrophotometry Using Bidirectional (45°:0° or 0°:45°)

Geometry

1.1 This test method describes procedures for the measure-

ment of gloss of plastic films and solid plastics, both opaque

3. Terminology

and transparent. It contains four separate gloss angles (Note 1):

3.1 Definitions—For definitions of terms used in this test

1.1.1 60-deg, recommended for intermediate-gloss films,

method, see Terminology E284.

1.1.2 20-deg, recommended for high-gloss films,

1.1.3 45-deg, recommended for intermediate and low-gloss

4. Significance and Use

films, and

4.1 Specular gloss is used primarily as a measure of the

1.1.4 75-deg, recommended for plastic siding and soffit.

shiny appearance of films and surfaces. Precise comparisons of

NOTE 1—The 75-deg, 60-deg, and 20-deg apparatus and method of

gloss values are meaningful only when they refer to the same

measurement duplicate those in Test Method D523; those for the 45°

measurement procedure and same general type of material. In

procedure are similarly taken from Test Method C346.

particular, gloss values for transparent films should not be

1.2 This standard does not purport to address all of the

compared with those for opaque films, and vice versa. Gloss is

safety concerns, if any, associated with its use. It is the

a complex attribute of a surface which cannot be completely

responsibility of the user of this standard to establish appro-

measured by any single number.

priate safety and health practices and determine the applica-

4.2 Specular gloss usually varies with surface smoothness

bility of regulatory limitations prior to use.

and flatness. It is sometimes used for comparative measure-

ments of these surface properties.

NOTE 2—There is no similar or equivalent ISO standard.

5. Apparatus

2. Referenced Documents

2

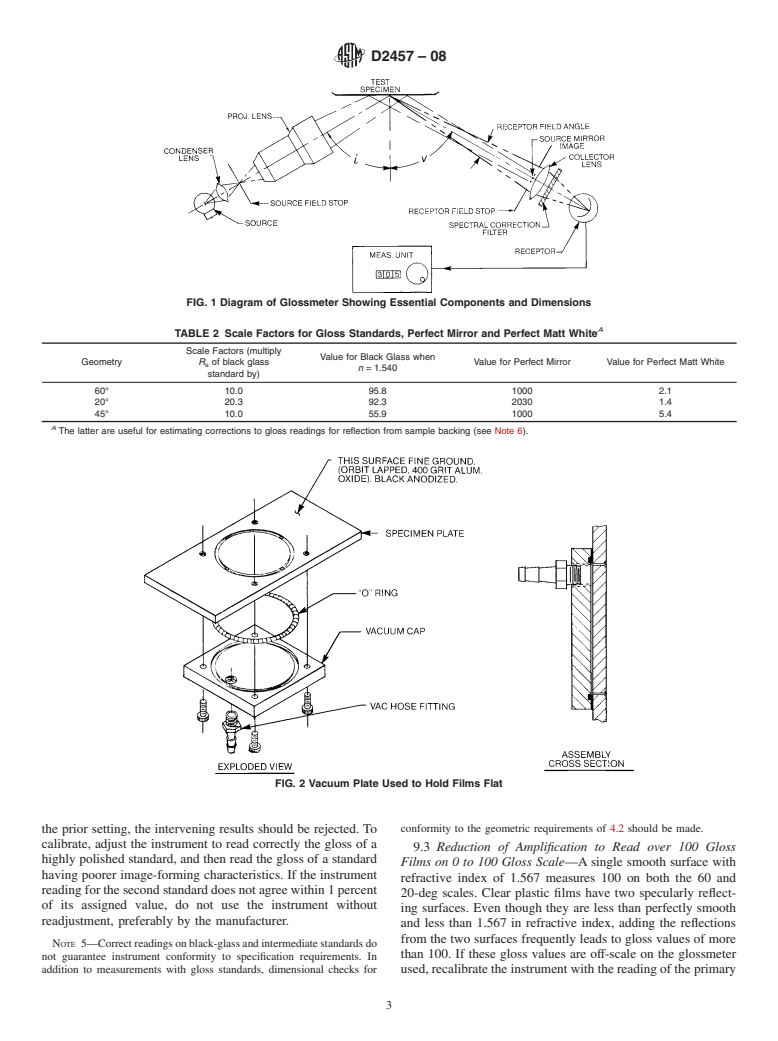

5.1 Instrumental Components—Each apparatus (Note 3)

2.1 ASTM Standards:

shall consist of an incandescent light source furnishing an

C346 Test Method for 45-deg Specular Gloss of Ceramic

incident beam, means for locating the surface of the specimen,

Materials

and a receptor located to receive the required pyramid of rays

D523 Test Method for Specular Gloss

reflected by the specimen. The receptor shall be a photosensi-

E284 Terminology of Appearance

tive device responding to visible radiation.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

NOTE 3—The 75-, 60-, and 20-deg procedures require apparatus iden-

E1347 Test Method for Color and Color-Difference Mea-

tical to that specified in Test Method D523. The 45° procedure requires

apparatus like that specified in Test Method C346.

surement by Tristimulus Colorimetry

E1349 Test Method for Reflectance Factor and Color by

5.2 Geometric Conditions—The axis of the incident beam

shall be at one of the specified angles fromthe perpendicular to

the specimen surface. The axis of the receptor shall be at the

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

mirror reflection of the axis of the incident beam. With a flat

and is the direct responsibility of Subcommittee D20.40 on Optical Properties.

piece of polished black glass or other front-surface mirror in

Current edition approved March 1, 2008. Published March 2008. Originally

specimen position, an image of the source shall be formed at

approved in 1965. Last previous edition approved in 2003 as D2457 – 03. DOI:

10.1520/D2457-08.

the center of the receptor field stop (receptor window). The

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

length of the illuminated area of the specimen shall be equal to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

not more than one third of the distance from the center of this

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. area to the receptor field stop. The angular dimensions and

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2457–08

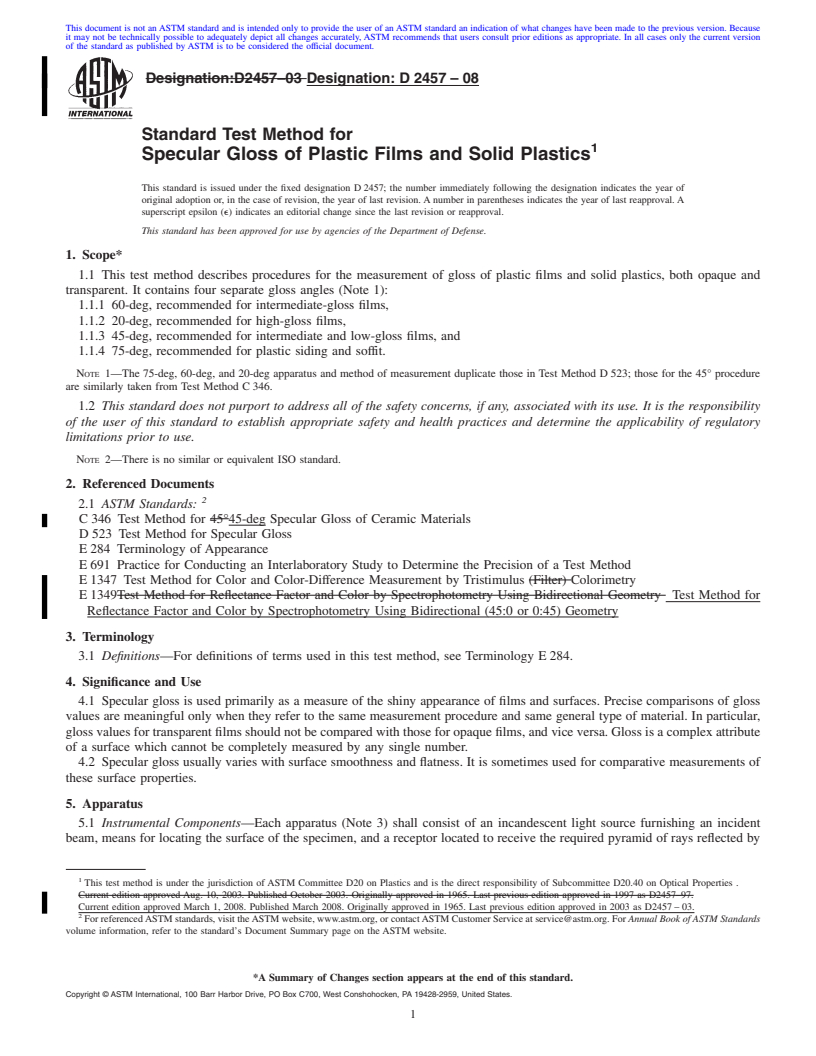

TABLE 1 Angular Dimensions and Tolerances of Geometry of Source and Receptor Field Stops

Source Field Stop Receptor Field Stop

In Plane of Measur

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2457–03 Designation:D2457–08

Standard Test Method for

1

Specular Gloss of Plastic Films and Solid Plastics

This standard is issued under the fixed designation D 2457; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method describes procedures for the measurement of gloss of plastic films and solid plastics, both opaque and

transparent. It contains four separate gloss angles (Note 1):

1.1.1 60-deg, recommended for intermediate-gloss films,

1.1.2 20-deg, recommended for high-gloss films,

1.1.3 45-deg, recommended for intermediate and low-gloss films, and

1.1.4 75-deg, recommended for plastic siding and soffit.

NOTE 1—The 75-deg, 60-deg, and 20-deg apparatus and method of measurement duplicate those in Test Method D 523; those for the 45° procedure

are similarly taken from Test Method C 346.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 2—There is no similar or equivalent ISO standard.

2. Referenced Documents

2

2.1 ASTM Standards:

C 346 Test Method for 45°45-deg Specular Gloss of Ceramic Materials

D 523 Test Method for Specular Gloss

E 284 Terminology of Appearance

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E 1347 Test Method for Color and Color-Difference Measurement by Tristimulus (Filter) Colorimetry

E 1349Test Method for Reflectance Factor and Color by Spectrophotometry Using Bidirectional Geometry Test Method for

Reflectance Factor and Color by Spectrophotometry Using Bidirectional (45:0 or 0:45) Geometry

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, see Terminology E 284.

4. Significance and Use

4.1 Specular gloss is used primarily as a measure of the shiny appearance of films and surfaces. Precise comparisons of gloss

values are meaningful only when they refer to the same measurement procedure and same general type of material. In particular,

gloss values for transparent films should not be compared with those for opaque films, and vice versa. Gloss is a complex attribute

of a surface which cannot be completely measured by any single number.

4.2 Specular gloss usually varies with surface smoothness and flatness. It is sometimes used for comparative measurements of

these surface properties.

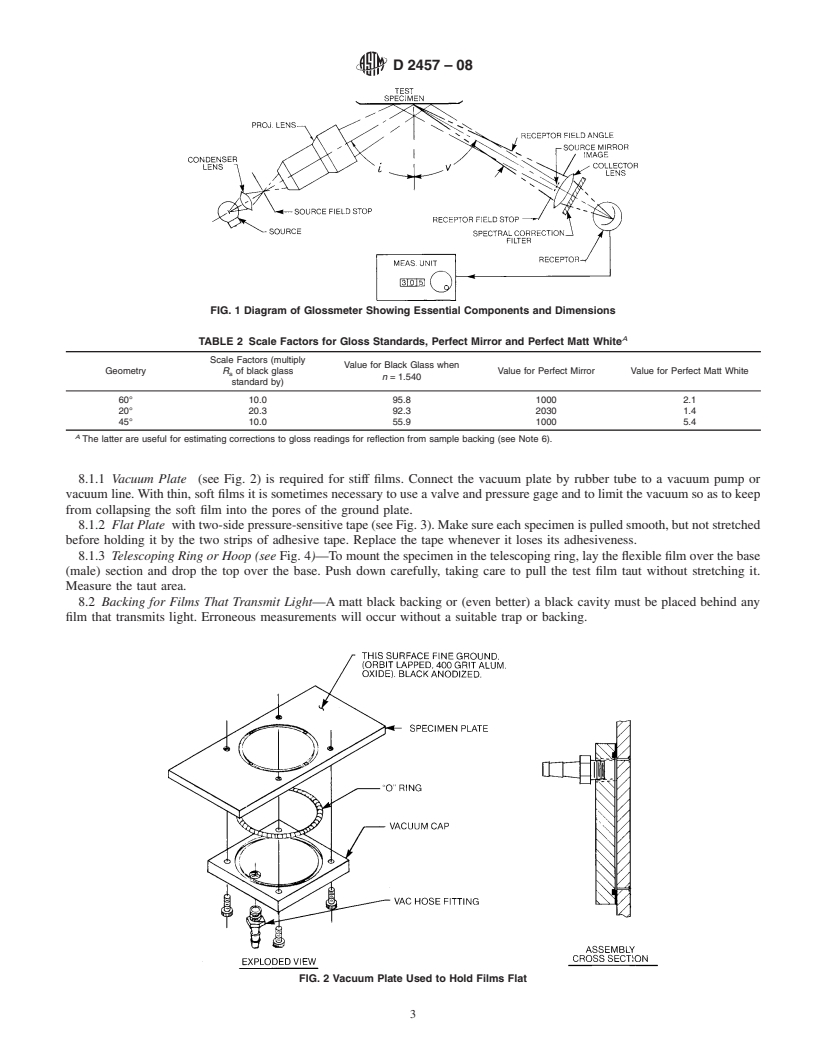

5. Apparatus

5.1 Instrumental Components—Each apparatus (Note 3) shall consist of an incandescent light source furnishing an incident

beam, means for locating the surface of the specimen, and a receptor located to receive the required pyramid of rays reflected by

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.40 on Optical Properties .

Current edition approved Aug. 10, 2003. Published October 2003. Originally approved in 1965. Last previous edition approved in 1997 as D2457–97.

Current edition approved March 1, 2008. Published March 2008. Originally approved in 1965. Last previous edition approved in 2003 as D2457 – 03.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2457–08

the specimen. The receptor shall be a photosensitive device responding to visible radiation.

NOTE 3—The 75-, 60-, and 20-deg procedures require apparatus identical to that specified inTest Method D 523.The 45° procedure requires apparatus

like that specified in Test Method C 346.

5.2 Geometric Conditions—The axis of the incident beam shall be at one of the specified angles from the perpendicular to the

specimen surface. The axis of the receptor shall be at the mirror reflection of the axis of the incident beam. With a fla

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.