ASTM D4000-23

(Classification)Standard Classification System for Specifying Plastic Materials

Standard Classification System for Specifying Plastic Materials

SIGNIFICANCE AND USE

4.1 The purpose of this classification system is to provide a method of adequately identifying plastic materials in order to give industry a system that can be used universally for plastic materials. It further provides a means for specifying these materials by the use of a simple line call-out designation.

4.2 This classification system was developed to permit the addition of property values for future plastics.

SCOPE

1.1 This standard provides a classification system for tabulating the properties of unfilled, filled, and reinforced plastic materials suitable for processing into parts.

Note 1: The classification system serves many of the needs of industries using plastic materials. The standard is subject to revision as the need requires; therefore, the latest revision should always be used.

1.2 The classification system and subsequent line call-out (specification) is intended to be a means of identifying plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection should be made by those having expertise in the plastics field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the inherent properties of the material not covered in this document, and the economic factors.

1.3 This classification system is based on the premise that plastic materials can be arranged into broad generic families using basic properties to arrange the materials into groups, classes, and grades. A system is thus established which, together with values describing additional requirements, permits as complete a description as desired of the selected material.

1.4 In all cases where the provisions of this classification system would conflict with the referenced ASTM specification for a particular material, the latter shall take precedence.

Note 2: When using this classification system the two-letter, three-digit suffix system applies.

Note 3: When a material is used to fabricate a part where the requirements are too specific for a broad material call-out, it is advisable for the user to consult the supplier to secure a call-out of the properties to suit the actual conditions to which the part is to be subjected.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4000 − 23

Standard Classification System for

1

Specifying Plastic Materials

This standard is issued under the fixed designation D4000; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This standard provides a classification system for tabu-

mine the applicability of regulatory limitations prior to use.

lating the properties of unfilled, filled, and reinforced plastic

1.6 This international standard was developed in accor-

materials suitable for processing into parts.

dance with internationally recognized principles on standard-

NOTE 1—The classification system serves many of the needs of

ization established in the Decision on Principles for the

industries using plastic materials. The standard is subject to revision as the

Development of International Standards, Guides and Recom-

need requires; therefore, the latest revision should always be used.

mendations issued by the World Trade Organization Technical

1.2 The classification system and subsequent line call-out

Barriers to Trade (TBT) Committee.

(specification) is intended to be a means of identifying plastic

materials used in the fabrication of end items or parts. It is not

2. Referenced Documents

intended for the selection of materials. Material selection

2

2.1 ASTM Standards:

should be made by those having expertise in the plastics field

D149 Test Method for Dielectric Breakdown Voltage and

after careful consideration of the design and the performance

Dielectric Strength of Solid Electrical Insulating Materials

required of the part, the environment to which it will be

at Commercial Power Frequencies

exposed, the fabrication process to be employed, the inherent

D150 Test Methods for AC Loss Characteristics and Permit-

properties of the material not covered in this document, and the

tivity (Dielectric Constant) of Solid Electrical Insulation

economic factors.

D256 Test Methods for Determining the Izod Pendulum

1.3 This classification system is based on the premise that

Impact Resistance of Plastics

plastic materials can be arranged into broad generic families

D257 Test Methods for DC Resistance or Conductance of

using basic properties to arrange the materials into groups,

Insulating Materials

classes, and grades. A system is thus established which,

D395 Test Methods for Rubber Property—Compression Set

together with values describing additional requirements, per-

D412 Test Methods for Vulcanized Rubber and Thermoplas-

mits as complete a description as desired of the selected

tic Elastomers—Tension

material.

D471 Test Method for Rubber Property—Effect of Liquids

D495 Test Method for High-Voltage, Low-Current, Dry Arc

1.4 In all cases where the provisions of this classification

Resistance of Solid Electrical Insulation

system would conflict with the referenced ASTM specification

D569 Method for Measuring the Flow Properties of Ther-

for a particular material, the latter shall take precedence.

3

moplastic Molding Materials (Withdrawn 1995)

NOTE 2—When using this classification system the two-letter, three-

D570 Test Method for Water Absorption of Plastics

digit suffix system applies.

D573 Test Method for Rubber—Deterioration in an Air

NOTE 3—When a material is used to fabricate a part where the

Oven

requirements are too specific for a broad material call-out, it is advisable

for the user to consult the supplier to secure a call-out of the properties to

D575 Test Methods for Rubber Properties in Compression

suit the actual conditions to which the part is to be subjected.

D618 Practice for Conditioning Plastics for Testing

1.5 This standard does not purport to address all of the

D624 Test Method for Tear Strength of Conventional Vul-

safety concerns, if any, associated with its use. It is the

canized Rubber and Thermoplastic Elastomers

1 2

This classification system is under the jurisdiction of ASTM Committee D20 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Materials. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 15, 2023. Publish

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4000 − 20 D4000 − 23

Standard Classification System for

1

Specifying Plastic Materials

This standard is issued under the fixed designation D4000; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This standard provides a classification system for tabulating the properties of unfilled, filled, and reinforced plastic materials

suitable for processing into parts.

NOTE 1—The classification system serves many of the needs of industries using plastic materials. The standard is subject to revision as the need requires;

therefore, the latest revision should always be used.

1.2 The classification system and subsequent line call-out (specification) is intended to be a means of identifying plastic materials

used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection should be made

by those having expertise in the plastics field after careful consideration of the design and the performance required of the part,

the environment to which it will be exposed, the fabrication process to be employed, the inherent properties of the material not

covered in this document, and the economic factors.

1.3 This classification system is based on the premise that plastic materials can be arranged into broad generic families using basic

properties to arrange the materials into groups, classes, and grades. A system is thus established which, together with values

describing additional requirements, permits as complete a description as desired of the selected material.

1.4 In all cases where the provisions of this classification system would conflict with the referenced ASTM specification for a

particular material, the latter shall take precedence.

NOTE 2—When using this classification system the two-letter, three-digit suffix system applies.

NOTE 3—When a material is used to fabricate a part where the requirements are too specific for a broad material call-out, it is advisable for the user to

consult the supplier to secure a call-out of the properties to suit the actual conditions to which the part is to be subjected.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This classification system is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

Current edition approved Dec. 1, 2020March 15, 2023. Published December 2020March 2023. Originally approved in 1982. Last previous edition approved in 20162020

as D4000 - 16.D4000 - 20. DOI: 10.1520/D4000-20.10.1520/D4000-23.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4000 − 23

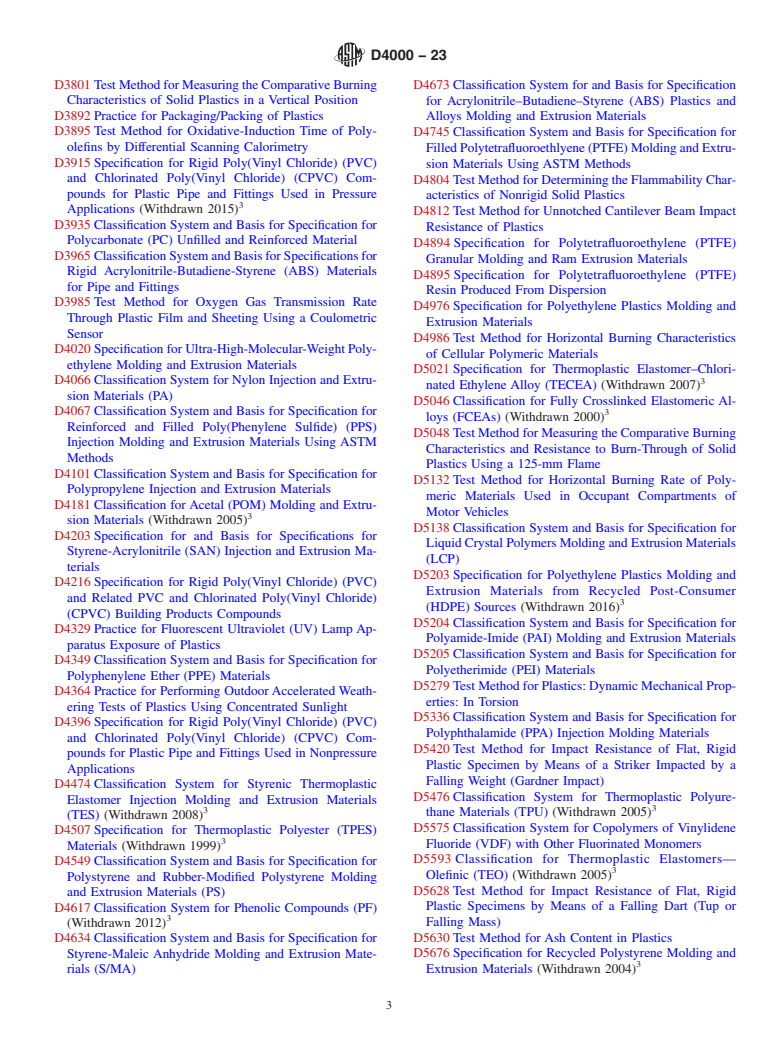

2. Referenced Documents

2

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

D256 Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D395 Test Methods for Rubber Property—Compression Set

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D471 Test Method for Rubber Property—Effect of Liquids

D495 Test Method for High-Voltage, Low-Current, Dry Arc Resistance of Solid Electrical Insulation

3

D569 Method for Measuring the Flow Properties of Thermoplastic Molding Materials (Withdrawn 1995)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.