ASTM C1469-22

(Test Method)Standard Test Method for Shear Strength of Joints of Advanced Ceramics at Ambient Temperature

Standard Test Method for Shear Strength of Joints of Advanced Ceramics at Ambient Temperature

SIGNIFICANCE AND USE

5.1 Advanced ceramics can be candidate materials for structural applications requiring high degrees of wear and corrosion resistance, often at elevated temperatures.

5.2 Joints are produced to enhance the performance and applicability of materials. While the joints between similar materials are generally made for manufacturing complex parts and repairing components, those involving dissimilar materials usually are produced to exploit the unique properties of each constituent in the new component. Depending on the joining process, the joint region may be the weakest part of the component. Since under mixed-mode and shear loading the load transfer across the joint requires reasonable shear strength, it is important that the quality and integrity of joint under in-plane shear forces be quantified. Shear strength data are also needed to monitor the development of new and improved joining techniques.

5.3 Shear tests provide information on the strength and deformation of materials under shear stresses.

5.4 This test method may be used for material development, material comparison, quality assurance, characterization, and design data generation.

5.5 For quality control purposes, results derived from standardized shear test specimens may be considered indicative of the response of the material from which they were taken for given primary processing conditions and post-processing heat treatments.

SCOPE

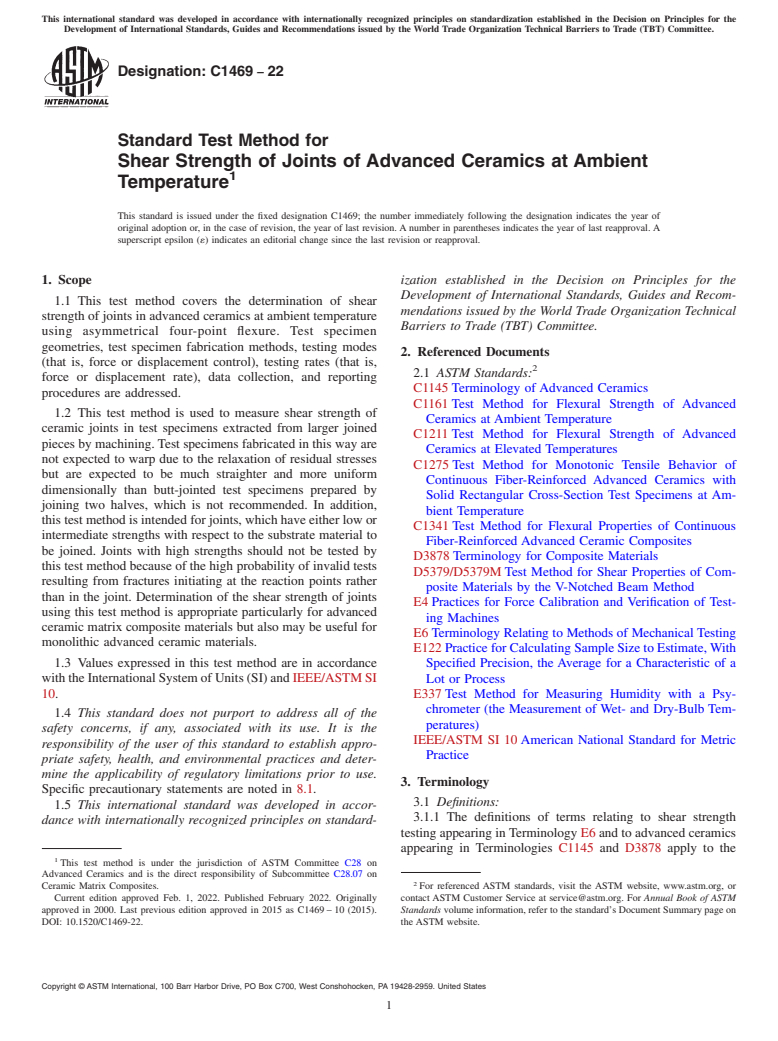

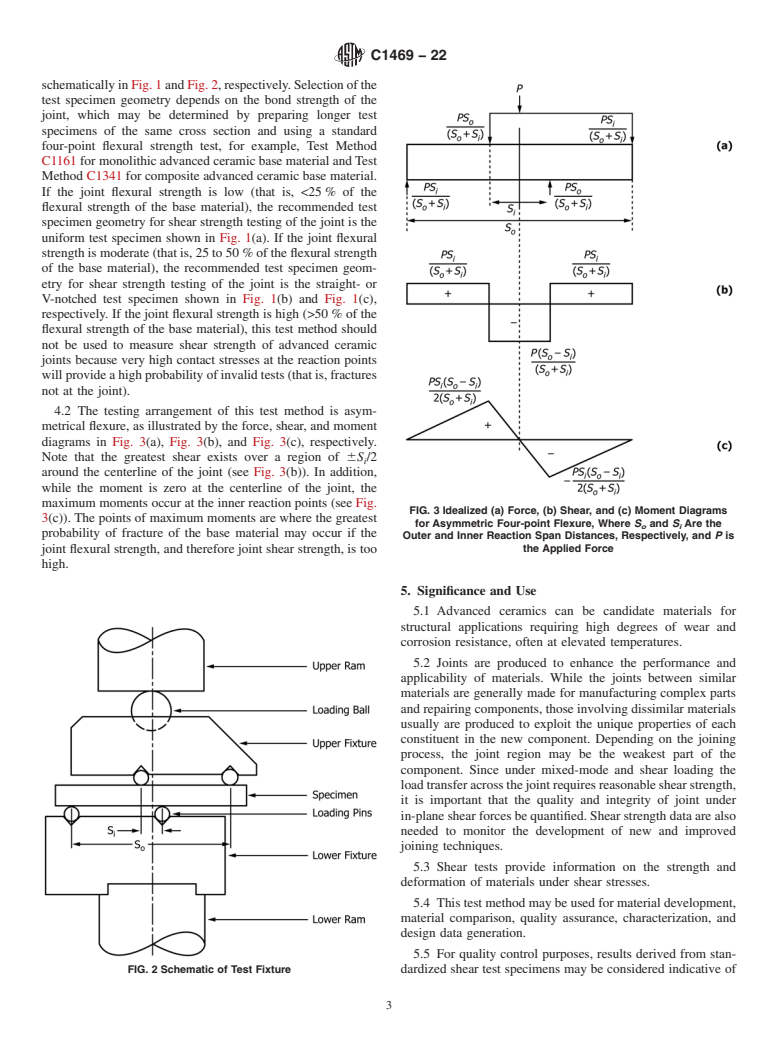

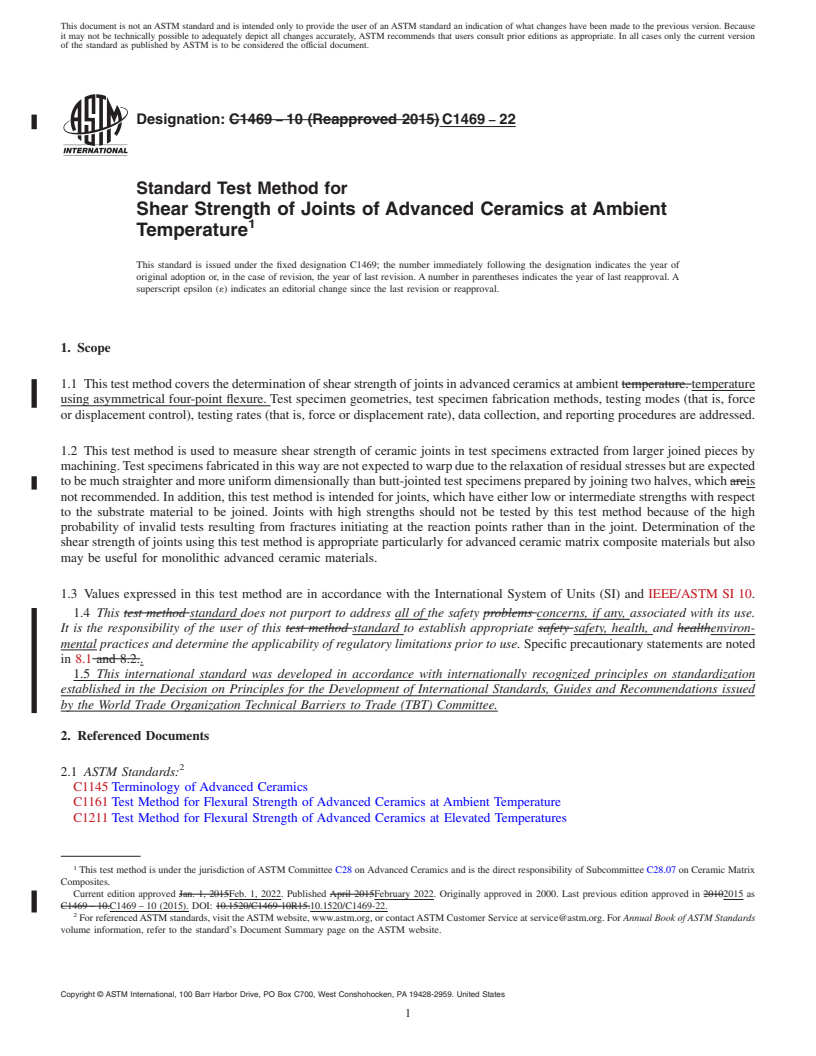

1.1 This test method covers the determination of shear strength of joints in advanced ceramics at ambient temperature using asymmetrical four-point flexure. Test specimen geometries, test specimen fabrication methods, testing modes (that is, force or displacement control), testing rates (that is, force or displacement rate), data collection, and reporting procedures are addressed.

1.2 This test method is used to measure shear strength of ceramic joints in test specimens extracted from larger joined pieces by machining. Test specimens fabricated in this way are not expected to warp due to the relaxation of residual stresses but are expected to be much straighter and more uniform dimensionally than butt-jointed test specimens prepared by joining two halves, which is not recommended. In addition, this test method is intended for joints, which have either low or intermediate strengths with respect to the substrate material to be joined. Joints with high strengths should not be tested by this test method because of the high probability of invalid tests resulting from fractures initiating at the reaction points rather than in the joint. Determination of the shear strength of joints using this test method is appropriate particularly for advanced ceramic matrix composite materials but also may be useful for monolithic advanced ceramic materials.

1.3 Values expressed in this test method are in accordance with the International System of Units (SI) and IEEE/ASTM SI 10.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are noted in 8.1.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1469 − 22

Standard Test Method for

Shear Strength of Joints of Advanced Ceramics at Ambient

1

Temperature

This standard is issued under the fixed designation C1469; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method covers the determination of shear

mendations issued by the World Trade Organization Technical

strength of joints in advanced ceramics at ambient temperature

Barriers to Trade (TBT) Committee.

using asymmetrical four-point flexure. Test specimen

geometries, test specimen fabrication methods, testing modes

2. Referenced Documents

(that is, force or displacement control), testing rates (that is,

2

2.1 ASTM Standards:

force or displacement rate), data collection, and reporting

C1145 Terminology of Advanced Ceramics

procedures are addressed.

C1161 Test Method for Flexural Strength of Advanced

1.2 This test method is used to measure shear strength of

Ceramics at Ambient Temperature

ceramic joints in test specimens extracted from larger joined

C1211 Test Method for Flexural Strength of Advanced

pieces by machining.Test specimens fabricated in this way are

Ceramics at Elevated Temperatures

not expected to warp due to the relaxation of residual stresses

C1275 Test Method for Monotonic Tensile Behavior of

but are expected to be much straighter and more uniform

Continuous Fiber-Reinforced Advanced Ceramics with

dimensionally than butt-jointed test specimens prepared by

Solid Rectangular Cross-Section Test Specimens at Am-

joining two halves, which is not recommended. In addition,

bient Temperature

this test method is intended for joints, which have either low or

C1341 Test Method for Flexural Properties of Continuous

intermediate strengths with respect to the substrate material to

Fiber-Reinforced Advanced Ceramic Composites

be joined. Joints with high strengths should not be tested by

D3878 Terminology for Composite Materials

this test method because of the high probability of invalid tests

D5379/D5379M Test Method for Shear Properties of Com-

resulting from fractures initiating at the reaction points rather

posite Materials by the V-Notched Beam Method

than in the joint. Determination of the shear strength of joints

E4 Practices for Force Calibration and Verification of Test-

using this test method is appropriate particularly for advanced

ing Machines

ceramic matrix composite materials but also may be useful for

E6 Terminology Relating to Methods of Mechanical Testing

monolithic advanced ceramic materials.

E122 Practice for Calculating Sample Size to Estimate,With

1.3 Values expressed in this test method are in accordance

Specified Precision, the Average for a Characteristic of a

withtheInternationalSystemofUnits(SI)andIEEE/ASTMSI Lot or Process

10.

E337 Test Method for Measuring Humidity with a Psy-

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

1.4 This standard does not purport to address all of the

peratures)

safety concerns, if any, associated with its use. It is the

IEEE/ASTM SI 10 American National Standard for Metric

responsibility of the user of this standard to establish appro-

Practice

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3. Terminology

Specific precautionary statements are noted in 8.1.

3.1 Definitions:

1.5 This international standard was developed in accor-

3.1.1 The definitions of terms relating to shear strength

dance with internationally recognized principles on standard-

testing appearing inTerminology E6 and to advanced ceramics

appearing in Terminologies C1145 and D3878 apply to the

1

This test method is under the jurisdiction of ASTM Committee C28 on

Advanced Ceramics and is the direct responsibility of Subcommittee C28.07 on

2

Ceramic Matrix Composites. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2022. Published February 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2000. Last previous edition approved in 2015 as C1469 – 10 (2015). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C1469-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1469 − 10 (Reapproved 2015) C1469 − 22

Standard Test Method for

Shear Strength of Joints of Advanced Ceramics at Ambient

1

Temperature

This standard is issued under the fixed designation C1469; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of shear strength of joints in advanced ceramics at ambient temperature. temperature

using asymmetrical four-point flexure. Test specimen geometries, test specimen fabrication methods, testing modes (that is, force

or displacement control), testing rates (that is, force or displacement rate), data collection, and reporting procedures are addressed.

1.2 This test method is used to measure shear strength of ceramic joints in test specimens extracted from larger joined pieces by

machining. Test specimens fabricated in this way are not expected to warp due to the relaxation of residual stresses but are expected

to be much straighter and more uniform dimensionally than butt-jointed test specimens prepared by joining two halves, which areis

not recommended. In addition, this test method is intended for joints, which have either low or intermediate strengths with respect

to the substrate material to be joined. Joints with high strengths should not be tested by this test method because of the high

probability of invalid tests resulting from fractures initiating at the reaction points rather than in the joint. Determination of the

shear strength of joints using this test method is appropriate particularly for advanced ceramic matrix composite materials but also

may be useful for monolithic advanced ceramic materials.

1.3 Values expressed in this test method are in accordance with the International System of Units (SI) and IEEE/ASTM SI 10.

1.4 This test method standard does not purport to address all of the safety problems concerns, if any, associated with its use.

It is the responsibility of the user of this test method standard to establish appropriate safety safety, health, and healthenviron-

mental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are noted

in 8.1 and 8.2.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C1145 Terminology of Advanced Ceramics

C1161 Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature

C1211 Test Method for Flexural Strength of Advanced Ceramics at Elevated Temperatures

1

This test method is under the jurisdiction of ASTM Committee C28 on Advanced Ceramics and is the direct responsibility of Subcommittee C28.07 on Ceramic Matrix

Composites.

Current edition approved Jan. 1, 2015Feb. 1, 2022. Published April 2015February 2022. Originally approved in 2000. Last previous edition approved in 20102015 as

C1469 – 10.C1469 – 10 (2015). DOI: 10.1520/C1469-10R15.10.1520/C1469-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1469 − 22

C1275 Test Method for Monotonic Tensile Behavior of Continuous Fiber-Reinforced Advanced Ceramics with Solid

Rectangular Cross-Section Test Specimens at Ambient Temperature

C1341 Test Method for Flexural Properties of Continuous Fiber-Reinforced Advanced Ceramic Composites

D3878 Terminology for Composite Materials

D5379/D5379M Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method

E4 Practices for Force Calibration and Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E337 Test Method for Measuring Humid

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.