ASTM E539-02

(Test Method)Standard Test Method for X-Ray Emission Spectrometric Analysis of 6AI-4V Titanium Alloy

Standard Test Method for X-Ray Emission Spectrometric Analysis of 6AI-4V Titanium Alloy

SCOPE

1.1 This test method covers the X-ray emission analysis of 6Al-4V titanium alloy for the following elements in the ranges indicated (Note 1): ElementConcentration Range, %Aluminum4.6 to 7.2Vanadium2.6 to 5.4Iron0.1 to 0.3

Note 1—The concentration ranges can be extended by use of suitable reference materials. The ranges for aluminum and vanadium represent the actual concentration ranges of the NIST Standard Reference Materials used when this method was tested. The maximum concentrations of the unknowns used in the cooperative test program were all lower than the reference materials. The iron concentration range was determined by in-house reference materials used by the cooperating laboratories.

1.2 This test method is designed for control analysis in the production of titanium alloys and for inspection testing of the product shipped to the consumer. It is applicable for analyzing cast or wrought samples having a diameter of approximately 32 mm and a thickness of approximately 25 mm.

Note 2—Samples of greater or lesser size than the size designed may be used with specially designed sample holders.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E539–02

Standard Test Method for

X-Ray Emission Spectrometric Analysis of 6AI-4V Titanium

1

Alloy

This standard is issued under the fixed designation E 539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the X-ray emission analysis of 2.1 ASTM Standards:

6Al-4V titanium alloy for the following elements in the ranges E 120 Test Methods for ChemicalAnalysis of Titanium and

3

indicated (Note 1): Titanium Alloys

E 135 Terminology Relating to Analytical Chemistry for

Element Concentration Range, %

3

Metals, Ores, and Related Materials

Aluminum 4.6 to 7.2

Vanadium 2.6 to 5.4

3. Terminology

Iron 0.1 to 0.3

3.1 Definitions:

NOTE 1—The concentration ranges can be extended by use of suitable

3.1.1 Refer to Terminology E 135.

reference materials. The ranges for aluminum and vanadium represent the

2

actual concentration ranges of the NIST Standard Reference Materialst

4. Summary of Test Method

used when this method was tested. The maximum concentrations of the

unknowns used in the cooperative test program were all lower than the

4.1 The sample is finished to a clean, uniform surface and

reference materials. The iron concentration range was determined by

then irradiated by an X-ray beam of high energy (short

in-house reference materials used by the cooperating laboratories.

wavelength). The secondary X rays produced are dispersed by

1.2 This test method is designed for control analysis in the means of crystals and the intensities measured by detectors at

production of titanium alloys and for inspection testing of the

selected wavelengths. The outputs of the detectors in voltage

product shipped to the consumer. It is applicable for analyzing pulses are integrated or counted. Data are collected using time

castorwroughtsampleshavingadiameterofapproximately32

requiredtoreachafixednumberofcountsorusingtotalcounts

mm and a thickness of approximately 25 mm. for a fixed time. Concentrations of the elements are determined

by relating the measured radiation of unknown samples to

NOTE 2—Samples of greater or lesser size than the size designed may

analytical curves or charts prepared from certified reference

be used with specially designed sample holders.

materials of known compositions.Afixed channel or polychro-

1.3 This standard does not purport to address all of the

mator system or a sequential system may be used to provide

safety concerns, if any, associated with its use. It is the

simultaneous or sequential determinations of elements.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use. Specific precau-

5.1 The chemical composition of 6A1-4V titanium alloy

tionary statements are given in Section 8.

must be accurately determined to ensure the desired metallur-

gical properties. This test method is suitable for manufacturing

control and inspection testing.

1

This test method is under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores and Related Materials and is the direct 6. Apparatus

responsibility of Subcommittee E1.06 on Ti, Zr, W, Mo, Ta, Nb, Hf.

NOTE 3—It is not within the scope of this test method to prescribe all

Current edition approved March 10, 2002. Published March 2002. Originally

e1

published as E 539 – 75. Last previous edition E 539 – 90 (1996) . details of equipment to be used. Equipment varies between laboratories.

2

NIST Standard Reference Materialst used when this study include NIST

SRMt 653, 654, and 655 from NIST SRMt Program, 100 Bureau Drive, Mail Stop

3

2322, Building 202, Room 204, Gaithersburg, MP 20899–2322. Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

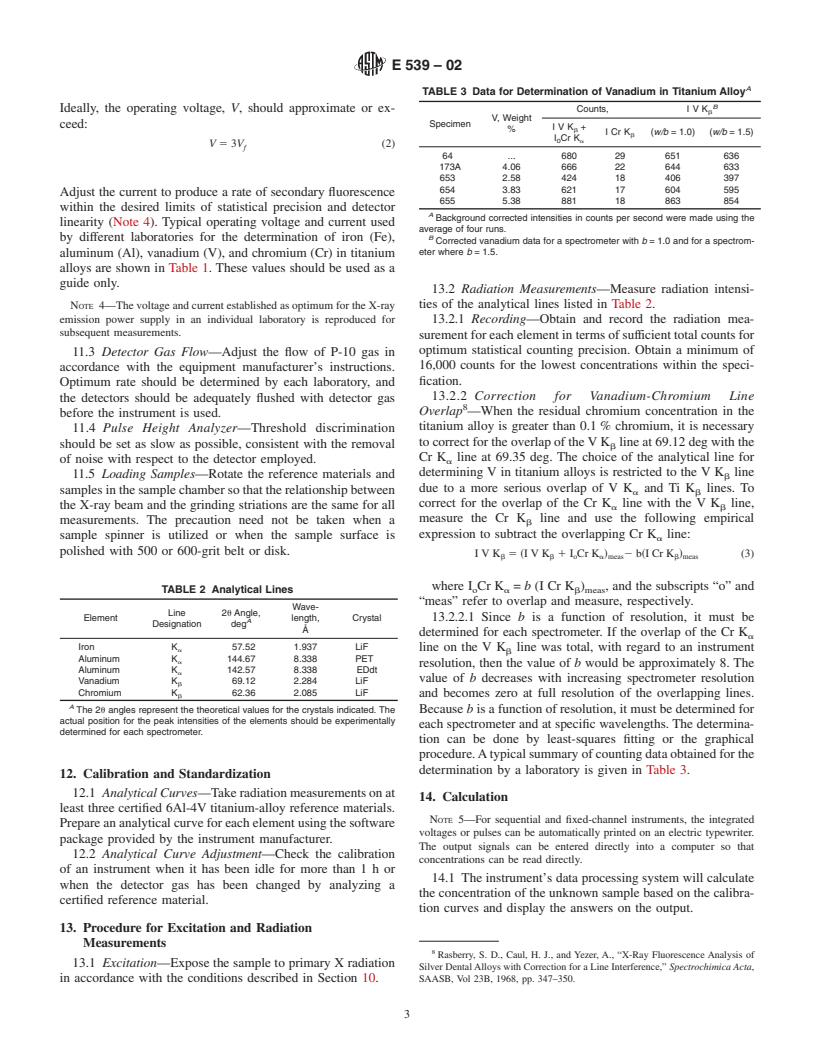

E539–02

6.1 Sample Preparation Equipment: eter installations. It is also recommended that personnel follow

6.1.1 Surface Grinder, with 60 to 600-grit silicon carbide the guidelines of safe operating procedures given in the NIST

5

belts or disks capable of providing test specimens with a Handbook X-Ray Protection, HB76, the booklet Radiation

uniform flat finish. A wet belt or wet disk grinder is preferred Safety Recommendations for X-Ray Diffraction and Spectro-

6

to prevent work hardening of the sample. graphicEquipment,#MORP68-14,1968, byT.M.Mooreand

6.2 Excitation Source: D. J. McDonald, and the U. S. Government Handbook 93,

6.2.1 X-Ray G

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.