ASTM D714-02(2009)

(Test Method)Standard Test Method for Evaluating Degree of Blistering of Paints

Standard Test Method for Evaluating Degree of Blistering of Paints

SIGNIFICANCE AND USE

A phenomenon peculiar to painted surfaces is the formation of blisters relative to some system weakness. This test method provides a standard procedure of describing the size and density of the blisters so that comparisons of severity can be made.

SCOPE

1.1 This test method employs photographic reference standards to evaluate the degree of blistering that may develop when paint systems are subjected to conditions which will cause blistering. While primarily intended for use on metal and other nonporous surfaces, this test method may be used to evaluate blisters on porous surfaces, such as wood, if the size of blisters falls within the scope of these reference standards. When the reference standards are used as a specification of performance, the permissible degree of blistering of the paint system shall be agreed upon by the purchaser and the seller.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D714 − 02 (Reapproved 2009)

Standard Test Method for

Evaluating Degree of Blistering of Paints

This standard is issued under the fixed designation D714; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

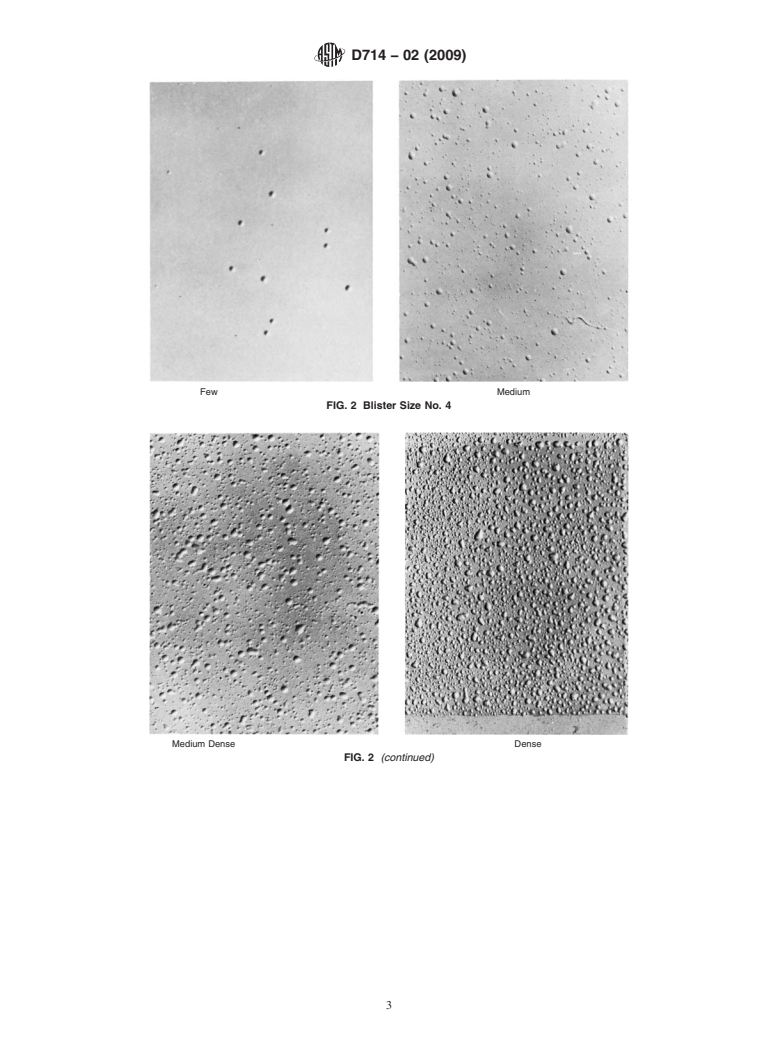

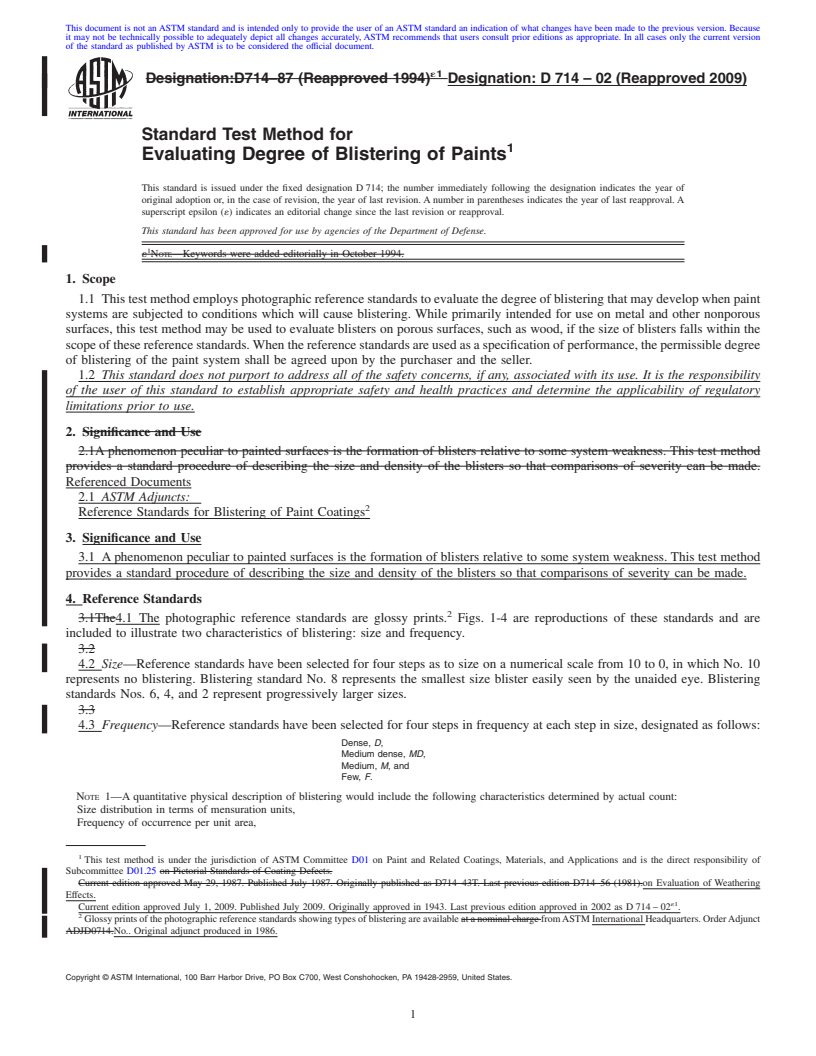

1. Scope 4.2 Size—Reference standards have been selected for four

steps as to size on a numerical scale from 10 to 0, in which No.

1.1 This test method employs photographic reference stan-

10representsnoblistering.BlisteringstandardNo.8represents

dards to evaluate the degree of blistering that may develop

the smallest size blister easily seen by the unaided eye.

when paint systems are subjected to conditions which will

Blistering standards Nos. 6, 4, and 2 represent progressively

cause blistering.While primarily intended for use on metal and

larger sizes.

other nonporous surfaces, this test method may be used to

evaluate blisters on porous surfaces, such as wood, if the size 4.3 Frequency—Reference standards have been selected for

of blisters falls within the scope of these reference standards. four steps in frequency at each step in size, designated as

When the reference standards are used as a specification of follows:

performance, the permissible degree of blistering of the paint

Dense, D,

Medium dense, MD,

system shall be agreed upon by the purchaser and the seller.

Medium, M, and

1.2 This standard does not purport to address all of the

Few, F.

safety concerns, if any, associated with its use. It is the

NOTE1—Aquantitativephysicaldescriptionofblisteringwouldinclude

responsibility of the user of this standard to establish appro-

the following characteristics determined by actual count:

priate safety and health practices and determine the applica-

Size distribution in terms of mensuration units,

Frequency of occurrence per unit area,

bility of regulatory limitations prior to use.

Pattern of distribution over the surface, and

Shape of blister

2. Referenced Documents

For the usual tests, an actual count is more elaborate than is necessary.

2.1 ASTM Adjuncts:

5. Procedure

Reference Standards for Blistering of Paint Coatings

5.1 Subject the paint film to the test conditions agreed upon

3. Significance and Use

by the purchaser and the seller.Then evaluate the paint film for

the degree of blistering by comparison with the photographic

3.1 A phenomenon peculiar to painted surfaces is the

formation of blisters relative to some system weakness. This reference standards in Figs. 1-4.

test method provides a standard procedure of describing the

6. Report

size and density of the blisters so that comparisons of severity

can be made. 6.1 Report blistering as a number (Note 2) designating the

size of the blisters and a qualitative term or symbol indicating

4. Reference Standards

the frequency.

4.1 The photographic reference standards are glossy

6.2 Intermediate steps in size or frequency of blisters may

prints. Figs. 1-4 are reproductions of these standards and are

be judged by interpolation.

included to illustrate two characteristics of blistering: size and

6.3 When the distribution of blisters over t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D714–87 (Reapproved 1994) Designation: D 714 – 02 (Reapproved 2009)

Standard Test Method for

Evaluating Degree of Blistering of Paints

This standard is issued under the fixed designation D 714; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Keywords were added editorially in October 1994.

1. Scope

1.1 This test method employs photographic reference standards to evaluate the degree of blistering that may develop when paint

systems are subjected to conditions which will cause blistering. While primarily intended for use on metal and other nonporous

surfaces, this test method may be used to evaluate blisters on porous surfaces, such as wood, if the size of blisters falls within the

scope of these reference standards.When the reference standards are used as a specification of performance, the permissible degree

of blistering of the paint system shall be agreed upon by the purchaser and the seller.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Significance and Use

2.1A phenomenon peculiar to painted surfaces is the formation of blisters relative to some system weakness. This test method

provides a standard procedure of describing the size and density of the blisters so that comparisons of severity can be made.

Referenced Documents

2.1 ASTM Adjuncts:

Reference Standards for Blistering of Paint Coatings

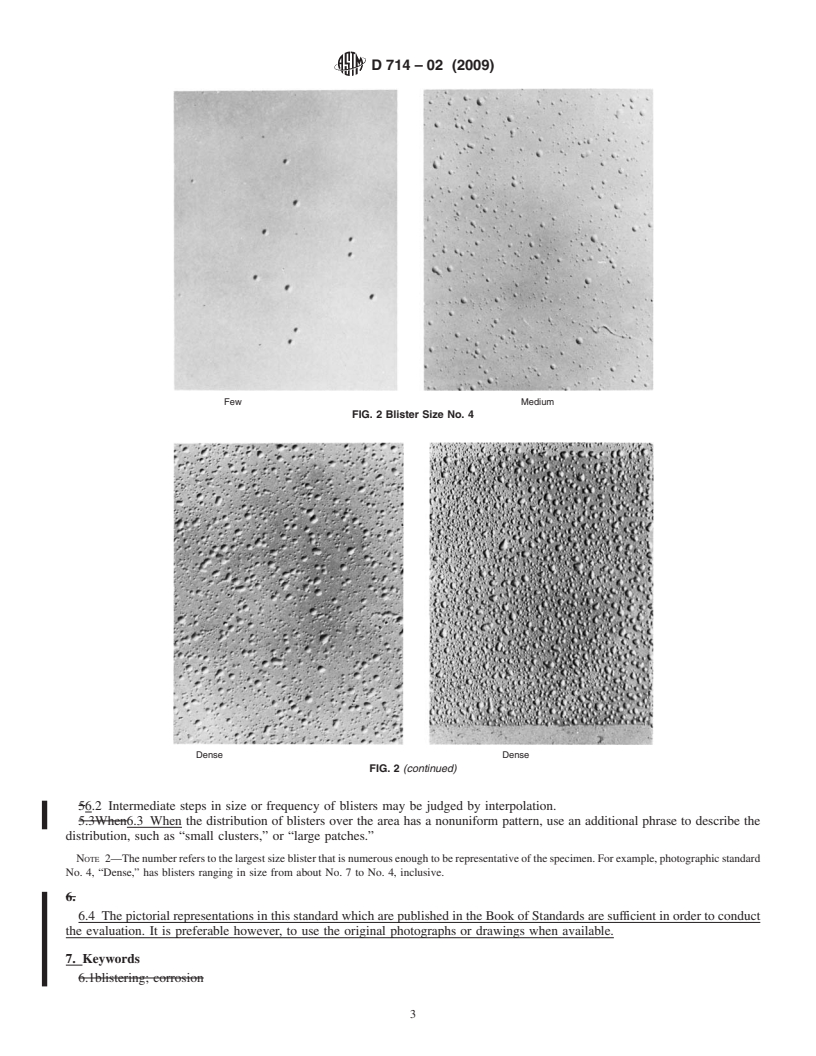

3. Significance and Use

3.1 Aphenomenon peculiar to painted surfaces is the formation of blisters relative to some system weakness. This test method

provides a standard procedure of describing the size and density of the blisters so that comparisons of severity can be made.

4. Reference Standards

3.1The4.1 The photographic reference standards are glossy prints. Figs. 1-4 are reproductions of these standards and are

included to illustrate two characteristics of blistering: size and frequency.

3.2

4.2 Size—Reference standards have been selected for four steps as to size on a numerical scale from 10 to 0, in which No. 10

represents no blistering. Blistering standard No. 8 represents the smallest size blister easily seen by the unaided eye. Blistering

standards Nos. 6, 4, and 2 represent progressively larger sizes.

3.3

4.3 Frequency—Reference standards have been selected for four steps in frequency at each step in size, designated as follows:

Dense, D,

Medium dense, MD,

Medium, M, and

Few, F.

NOTE 1—A quantitative physical description of blistering would include the following characteristics determined by actual count:

Size distribution in terms of mensuration units,

Frequency of occurrence per unit area,

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.25 on Pictorial Standards of Coating Defects.

Current edition approved May 29, 1987. Published July 1987. Originally published as D714–43T. Last previous

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.