ASTM D322-97(2002)e1

(Test Method)Standard Test Method for Gasoline Diluent in Used Gasoline Engine Oils by Distillation

Standard Test Method for Gasoline Diluent in Used Gasoline Engine Oils by Distillation

SCOPE

1.1 This test method covers determination of the amount of dilution in crankcase oils of engines when gasoline has been used as the fuel.

Note 1—There may be cases in dispute, therefore, the user of this test method is advised to establish whether this method will be accepted. There may be cases where Test Method D 3525 results will be set as the referee value.

1.2 The values stated in acceptable SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statement, see 6.4, 7.1, and 9.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D322–97 (Reapproved 2002)

Designation: 23/2000

Standard Test Method for

Gasoline Diluent in Used Gasoline Engine Oils by

Distillation

This standard is issued under the fixed designation D 322; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Warning notes were editorially moved into the standard text in March 2003.

1. Scope D 4175 Terminology Relating to Petroleum, Petroleum

Products, and Lubricants

1.1 This test method covers determination of the amount of

D 4177 Practice for Automatic Sampling of Petroleum and

dilution in crankcase oils of engines when gasoline has been

Petroleum Products

used as the fuel.

2.2 IP Methods for Analyses and Testing, Vol II, Part I

NOTE 1—There may be cases in dispute, therefore, the user of this test

methodisadvisedtoestablishwhetherthismethodwillbeaccepted.There

may be cases where Test Method D 3525 results will be set as the referee

3. Terminology

value.

3.1 Definitions:

1.2 The values stated in acceptable SI units are to be

3.1.1 fuel diluent, n—in used oil analysis, unburnt fuel

regarded as the standard.

components that enter the engine crankcase causing dilution of

1.3 This standard does not purport to address all of the

the oil.

safety concerns, if any, associated with its use. It is the

3.1.1.1 Discussion—In this test method, the fuel diluent

responsibility of the user of this standard to establish appro-

components being determined are from gasoline.

priate safety and health practices and determine the applica-

3.1.2 used oil, n—any oil that has been in a piece of

bility of regulatory limitations prior to use. For specific

equipment (for example, an engine, gearbox, transformer, or

precautionary statement, see 6.4, 7.1, and 9.3.

turbine) whether operated or not. D 4175

3.1.2.1 Discussion—In this test method, used oil is from a

2. Referenced Documents

gasoline engine.

2.1 ASTM Standards:

D 235 Specification for Mineral Spirits (Petroleum Spirits)

4. Summary of Test Method

Hydrocarbon Dry Cleaning Solvents

4.1 The sample, mixed with water, is placed in a glass still

D 3525 Test Method for Gasoline Diluent in Used Gasoline

provided with a reflux condenser discharging into a graduated

Engine Oils by Gas Chromatography

trap connected to the still. Heat is applied, and the contents of

D 4057 Practice for Manual Sampling of Petroleum and

the still are brought to boiling. The diluent in the sample is

Petroleum Products

vaporized with the water and then liquefied in the condenser.

The diluent collects at the top of the trap, and the excess water

runs back to the still where it is again vaporized, carrying over

This test method is under the jurisdiction of ASTM Committee D02 on

an additional quantity of diluent. The boiling is continued until

PetroleumProductsand LubricantsandisthedirectresponsibilityofSubcommittee

D02.06 on Analysis of Lubricants.

all the diluent has been boiled out and recovered in the trap.

This test method was adopted as a jointASTM-IPstandard in 1964. In the IP, this

The volume is recorded.

method is under the jurisdiction of the Standardization Committee.

Current edition approved Dec. 10, 2002. Published March 2003. Originally

approved in 1930. Last previous edition approved in 1997 as D 322 – 97.

2 4

Annual Book of ASTM Standards, Vol 06.04. Available from the Institute of Petroleum, 61 New Cavendish St., London,

Annual Book of ASTM Standards, Vol 05.02. W1G 7AR.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D322–97 (2002)

5. Significance and Use possible of the contents of the cylinder by pouring it into the

flask. Wash the graduated cylinder with successive portions of

5.1 Some fuel dilution of the engine oil may take place

hot water until only a negligible amount of oil is left in the

duringnormaloperation.However,excessivefueldilutionisof

cylinder. Add additional water to the flask to make a total of

concern in terms of possible performance problems.

approximately 500 mL of water. Fill the trap with cold water

6. Apparatus

and add 1 6 0.1 mL of denatured ethanol to the water in the

6.1 Flask, round-bottom type (see Fig. 1 and A1.1).

trap.

6.2 Condenser, Liebig straight-tube type (see A1.2).

9.2 Assemble the apparatus as shown in Fig. 1, so that the

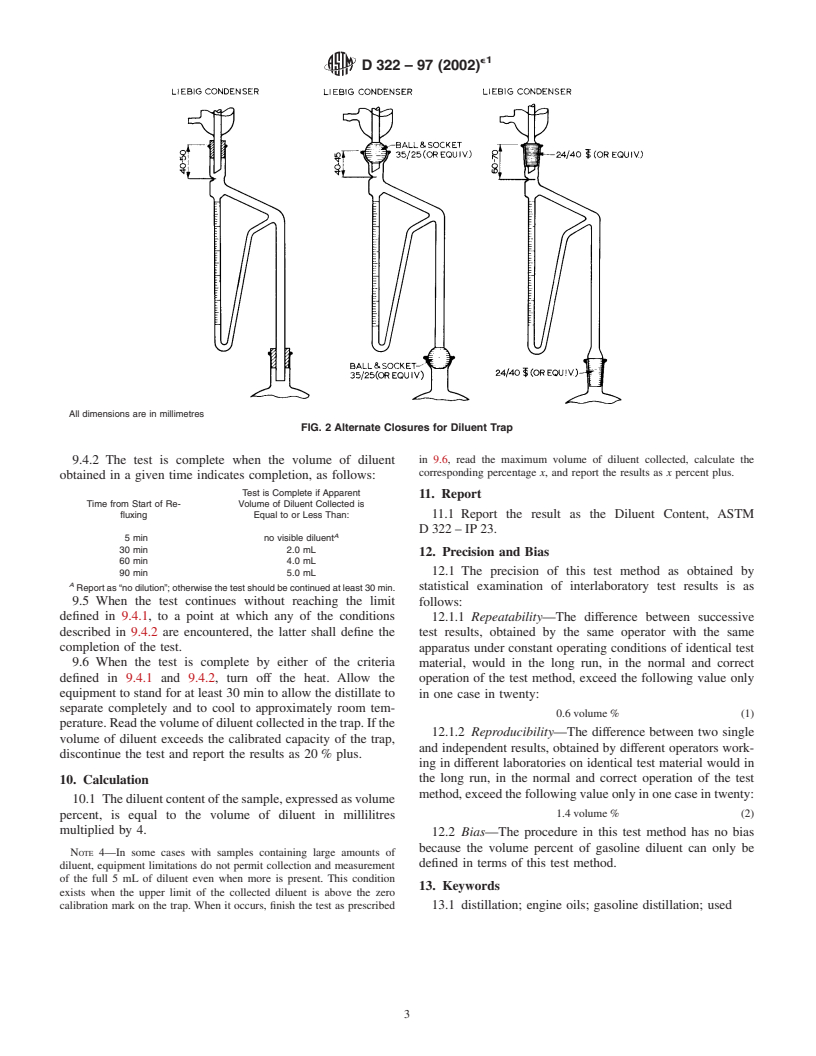

6.3 Trap, 5 mL, graduated in 0.1-mL increments (see Fig. 1

tip of the condenser is directly over the indentation in the trap.

and Fig. 2 and A1.3).

9.3 Apply heat to the flask at such a rate that refluxing starts

6.4 Heater—Any suitable gas burner or electric heater may

within 7 to 10 min after heat is applied, with the water and

be used with the glass flask. (Warning—Hot exposed surface.

sample being at 21 to 38°C prior to application of heat. After

Avoid contact by wearing protective equipment as required.)

boiling and condensation has commenced, adjust the rate of

7. Reagents and Materials

boiling so that condensed distillate is discharged from the

condenser at a rate of 1 to 3 drops per s. (Warning—Hot

7.1 Ethanol, Denatured , conforming to either Formula No.

exposed surface. Avoid contact by wearing protective equip-

30 or 3A of the US Bureau of Internal Revenue. (Warning—

Flammable. Denatured. Cannot be made non-toxic.) ment as required.)

7.2 Mineral Spirits (Petroleum Spirits), conforming to

NOTE 3—Bumping with a tendency to froth over is often experienced

Specification D 235.

with dirty oils. The use of boiling stones, steel wool, or about 5 mL of

NOTE 2—In Annex A1.3, the use of reagent grade heptane may be the concentrated hydrochloric acid (HCl) in the flask is often helpful in

preferred solvent because the use of commerical grade h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.