ASTM D1434-23

(Test Method)Standard Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting

Standard Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting

SIGNIFICANCE AND USE

5.1 These measurements give semiquantitative estimates for the gas transmission of single pure gases through film and sheeting. Correlation of measured values with any given use, such as packaged contents protection, must be determined by experience. The gas transmission rate is affected by conditions not specifically provided for in these tests, such as moisture content (Note 2), plasticizer content, and nonhomogeneities. These tests do not include any provision for testing seals that may be involved in packaging applications.

Note 2: The tests are run using gas with 0 % moisture changes.

5.2 The historic Interlaboratory testing has revealed that permeances measured by these procedures exhibit a strong dependence on the procedure being used, as well as on the laboratory performing the testing. The historic method relied upon manual calibrations of Hg capillary columns and manual data readings of pressure. The references and use of Hg and capillary columns have been removed from this standard as current D1434 instruments rely upon readily calibrated vacuum gauges and automated recording of data. It is planned that the next revision of this standard includes an updated ILS with modern instrumentation. Additionally, it has been noted that an agreement with other gas transmission rate methods is sometimes poor and may be material-dependent. The materials being tested often affect the between-laboratory precision. The causes of these variations are not precisely known at this time, but is likely due to the fact that this method analyzes ALL gasses from the sample and not just the Test gas. This includes pre-absorbed water vapor within the sample and any free solvents remaining within the specimen. The 48 hr desiccator drying period outlined within the method may not be long enough for all materials. Additionally, other gas transmission rate methods (as those used for oxygen transmission rate, water vapor transmission rate and carbon dioxide transmission rate) often...

SCOPE

1.1 This test method utilizes a manometric method to determine the steady-state rate of transmission of a gas through plastics in the form of film, sheeting, laminates, and plastic-coated papers or fabrics. This test method provides for the determination of (1) gas transmission rate (GTR), (2) permeance, and, in the case of homogeneous materials, (3) permeability.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1434 − 23

Standard Test Method for

Determining Gas Permeability Characteristics of Plastic Film

1

and Sheeting

This standard is issued under the fixed designation D1434; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 gas transmission rate, GTR, n—the quantity of a given

gas passing through a unit of the parallel surfaces of a plastic

1.1 This test method utilizes a manometric method to

film in unit time under the conditions of test. The SI unit of

determine the steady-state rate of transmission of a gas through

2

GTR is mol/(m ·s). The test conditions, including temperature

plastics in the form of film, sheeting, laminates, and plastic-

and partial pressure of the gas on both sides of the film, must

coated papers or fabrics. This test method provides for the

be stated. Other factors, such as relative humidity and hydro-

determination of (1) gas transmission rate (GTR), (2)

static pressure, that influence the transport of the gas must also

permeance, and, in the case of homogeneous materials, (3)

2

be stated. A commonly used unit of GTR is mL (STP)/(m ·d)

permeability.

at a pressure differential of one atmosphere.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 3.1.2 permeance, P, n—the ratio of the gas transmission rate

standard. to the difference in partial pressure of the gas on the two sides

2

of the film. The SI unit of permeance is mol/ (m ·s·Pa). The test

1.3 This standard does not purport to address all of the

conditions (see 5.1) must be stated.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.3 permeability, P’, n—the product of the permeance and

priate safety, health, and environmental practices and deter-

the thickness of a film. The permeability is meaningful only for

mine the applicability of regulatory limitations prior to use.

homogeneous materials, in which it is a property characteristic

1.4 This international standard was developed in accor-

of the bulk material. This quantity should not be used unless

dance with internationally recognized principles on standard-

the constancy of the permeability has been verified using

ization established in the Decision on Principles for the

several different thicknesses of the material. The SI unit of P is

Development of International Standards, Guides and Recom- 2

(mol·m)/(m ·s·Pa) = mol ⁄(m·s·Pa). The test conditions (see 5.1)

mendations issued by the World Trade Organization Technical

must be stated.

Barriers to Trade (TBT) Committee.

NOTE 1—One milliliter (STP) is 44.62 μmol, one atmosphere is 0.1013

3

2. Referenced Documents

MPa, and one day is 86.4 × 10 s. GTR in SI units is obtained by

−10

multiplying the value in inch-pound units by 5.160 × 10 . Additional

2

2.1 ASTM Standards:

units and conversions are shown in Appendix X1.

D618 Practice for Conditioning Plastics for Testing

3

3.1.4 steady state—the state attained when the amount of

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

gas absorbed in the film is in equilibrium with the flux of gas

3. Terminology through the film.

3.1 Definitions of Terms Specific to This Standard:

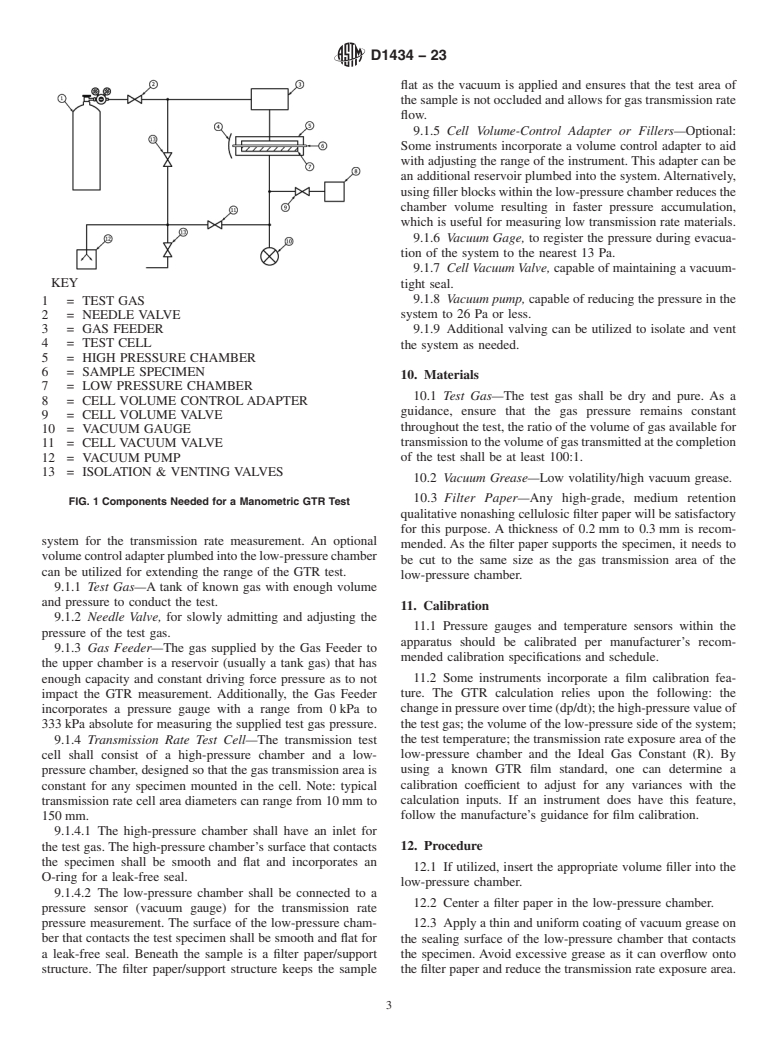

4. Summary of Test Method

4.1 The sample is mounted in a gas transmission cell so as

1

This test method is under the jurisdiction of ASTM Committee F02 on Primary

to form a sealed semi-barrier between two chambers. One

Barrier Packaging and is the direct responsibility of Subcommittee F02.10 on

chamber contains the test gas at a specific high pressure, and

Permeation.

Current edition approved May 1, 2023. Published June 2023. Originally the other chamber, at a lower pressure, receives the permeating

ɛ1

approved in 1956. Last previous edition approved in 2015 as D1434 – 82 (2015) .

gas.

DOI: 10.1520/D1434-23.

2

4.1.1 The lower pressure chamber is initially evacuated.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Following the evacuation, the low-pressure chamber is allowed

Standards volume information, refer to the standard’s Document Summary page on

to accumulate the permeating test gas. The transmission of the

the ASTM website.

3

gas through the test specimen is determined from monitoring

The last approved version of this historical standard is referenced on

www.astm.org. the slope of the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D1434 − 82 (Reapproved 2015) D1434 − 23

Standard Test Method for

Determining Gas Permeability Characteristics of Plastic Film

1

and Sheeting

This standard is issued under the fixed designation D1434; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial corrections were made in September 2015.

1. Scope

1.1 This test method covers the estimation of the utilizes a manometric method to determine the steady-state rate of transmission

of a gas through plastics in the form of film, sheeting, laminates, and plastic-coated papers or fabrics. This test method provides

for the determination of (1) gas transmission rate (GTR), (2) permeance, and, in the case of homogeneous materials, (3)

permeability.

1.2 Two procedures are provided:

1.2.1 Procedure M—Manometric.

1.2.2 Procedure V—Volumetric.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

3

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction of ASTM Committee F02 on FlexiblePrimary Barrier Packaging and is the direct responsibility of Subcommittee F02.10 on

Permeation.

Current edition approved June 1, 2015May 1, 2023. Published September 2015June 2023. Originally approved in 1956. Last previous edition approved in 20092015 as

ϵ1ɛ1

D1434 – 82 (2009)(2015) . DOI: 10.1520/D1434-82R15E01.10.1520/D1434-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1434 − 23

3.1.1 gas transmission rate, GTR—GTR, n—the quantity of a given gas passing through a unit of the parallel surfaces of a plastic

2

film in unit time under the conditions of test. The SI unit of GTR is 1 mol/(m ·s). The test conditions, including temperature and

partial pressure of the gas on both sides of the film, must be stated. Other factors, such as relative humidity and hydrostatic

pressure, that influence the transport of the gas must also be stated. The inch-pound unit of GTR, a A commonly used unit of

2

GTR,GTR is 1 mL (STP)/(m ·d) at a pressure differential of one atmosphere.

3.1.2 permeance, P—P, n—the ratio of the gas transmission rate to the difference in partial pressure of the gas on the two sides

2

of the film. The SI unit of permeance is 1 mol/ (m ·s·Pa). The test conditions (see 5.1) must be stated.

3.1.3 permeability, PP’,—n—the product of the permeance and the thickness of a film. The permeability is meaningful only for

homogeneous materials, in which it is a property characteristic of the bulk material. This quantity should not be used unless the

constancy of the permeability has been verified using several different thicknesses of the material. The SI unit of P is

2

1(mol·m)/(m ·s·Pa) = mol mol/(m·s·Pa). ⁄(m·s·Pa). The test conditions (see 3.15.1) must be stated.

3

NOTE 1—One millilitremilliliter (STP) is 44.62 μmol, one atmosphere is 0.1013 MPa, and one day is 86.4 × 10 s. GTR in SI units is obtained by

−10

multiplying the value in inch-pound units by 5.160 × 10 . Additional units and conversions are shown in Appendix

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.