ASTM E4-07

(Practice)Standard Practices for Force Verification of Testing Machines

Standard Practices for Force Verification of Testing Machines

SIGNIFICANCE AND USE

Testing machines that apply and indicate force are used in many industries, in many ways. They may be used in a research laboratory to measure material properties, and in a production line to qualify a product for shipment. No matter what the end use of the machine may be, it is necessary for users to know the amount of force that is applied and indicated, and that the accuracy of the force is traceable to the National Institute of Standards and Technology (NIST), formerly NBS. Practices E 4 provides a procedure to verify these machines, in order that the indicated forces may be traceable. A key element to this NIST traceability is that the devices used in the verification have known force characteristics, and have been calibrated in accordance with Practice E 74.

The procedures in Practices E 4 may be used by those using, manufacturing, and providing calibration service for testing machines and related instrumentation.

SCOPE

1.1 These practices cover procedures for the force verification, by means of standard calibration devices, of tension or compression, or both, static or quasi-static testing machines (which may, or may not, have force-indicating systems). These practices are not intended to be complete purchase specifications for testing machines. Testing machines may be verified by one of the three following methods or combination thereof:

1.1.1 Use of standard weights,

1.1.2 Use of equal-arm balances and standard weights, or

1.1.3 Use of elastic calibration devices. Note 1These practices do not cover the verification of all types of testing machines designed to measure forces, for example, the constant-rate-of-loading type which operates on the inclined-plane principle. This type of machine may be verified as directed in the applicable appendix of Specification D 76.

1.2 The procedures of apply to the verification of the force-indicating systems associated with the testing machine, such as a scale, dial, marked or unmarked recorder chart, digital display, etc. In all cases the buyer/owner/user must designate the force-indicating system(s) to be verified and included in the report.

1.3 Since conversion factors are not required in this practice, either inch-pound units, SI units, or metric values can be used as the standard.

1.4 Forces indicated on displays/printouts of testing machine data systems-be they instantaneous, delayed, stored, or retransmitted-which are verified with provisions of 1.1.1, 1.1.2, or 1.1.3, and are within the 1 % accuracy requirement, comply with Practices E 4.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

Designation:E4–07 Highway and Transportation Officials Standards

AASHTO No: T67

Standard Practices for

1

Force Verification of Testing Machines

This standard is issued under the fixed designation E 4; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2

1.1 These practices cover procedures for the force verifica- 2.1 ASTM Standards:

tion, by means of standard calibration devices, of tension or D76 SpecificationforTensileTestingMachinesforTextiles

compression, or both, static or quasi-static testing machines E74 Practice of Calibration of Force-Measuring Instru-

(which may, or may not, have force-indicating systems).These ments for Verifying the Force Indication of Testing Ma-

practices are not intended to be complete purchase specifica- chines

tionsfortestingmachines.Testingmachinesmaybeverifiedby E 467 Practice for Verification of Constant Amplitude Dy-

one of the three following methods or combination thereof: namic Forces in an Axial Fatigue Testing System

1.1.1 Use of standard weights,

3. Terminology

1.1.2 Use of equal-arm balances and standard weights, or

3.1 Definitions:

1.1.3 Use of elastic calibration devices.

3.1.1 testing machine (force-measuring type)—a mechani-

NOTE 1—These practices do not cover the verification of all types of

cal device for applying a force to a specimen.

testing machines designed to measure forces, for example, the constant-

3.1.1.1 portable testing machine (force-measuring type)—a

rate-of-loading type which operates on the inclined-plane principle. This

device specifically designed to be moved from place to place

type of machine may be verified as directed in the applicable appendix of

SpecificationD76.

and for applying a force (load) to a specimen.

3.1.2 tension testing machine, CRT (constant-rate-

1.2 Theproceduresof1.1.1-1.1.3applytotheverificationof

oftraverse)—amechanicaldeviceforapplyingaload(force)to

the force-indicating systems associated with the testing ma-

a specimen and in which the force is measured by means of a

chine,suchasascale,dial,markedorunmarkedrecorderchart,

pendulum.

digital display, etc. In all cases the buyer/owner/user must

3.1.3 force—in the case of testing machines, a force mea-

designate the force-indicating system(s) to be verified and

sured in units such as pound-force, newton, or kilogram-force.

included in the report.

3.1.3.1 Discussion—The pound-force is that force which

1.3 Since conversion factors are not required in this prac-

acting on a 1-lb mass will give to it an acceleration of 9.80665

tice, either inch-pound units, SI units, or metric values can be

2 2

m/s (32.1740 ft/s ). The newton is that force which acting on

used as the standard.

2

a 1-kg mass will give to it an acceleration of 1 m/s .

1.4 Forces indicated on displays/printouts of testing ma-

3.1.4 accuracy—the specified permissible variation from

chine data systems—be they instantaneous, delayed, stored, or

the correct value.Atesting machine is said to be accurate if the

retransmitted—which are verified with provisions of 1.1.1,

indicated force is within the specified permissible variation

1.1.2,or 1.1.3, and are within the 61 % accuracy requirement,

from the actual force.

comply with Practices E 4.

3.1.4.1 Discussion—In these methods the word “accurate”

1.5 This standard does not purport to address all of the

applied to a testing machine is used without numerical values,

safety concerns, if any, associated with its use. It is the

for example, “An accurate testing machine was used for the

responsibility of the user of this standard to establish appro-

investigation.”Theaccuracyofatestingmachineshouldnotbe

priate safety and health practices and determine the applica-

confused with sensitivity. For example, a testing machine

bility of regulatory limitations prior to use.

might be very sensitive; that is, it might indicate quickly and

1

These practices are under the jurisdiction of ASTM Committee E28 on

2

Mechanical Testing and is the direct responsibility of Subcommittee E28.01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Calibration of Mechanical Testing Machines and Apparatus. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Jan. 1, 2007. Published January 2007. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1923. Last previous edition approved in 2003 asE4–03. the ASTM website.

Copyright © ASTM International, 100 Ba

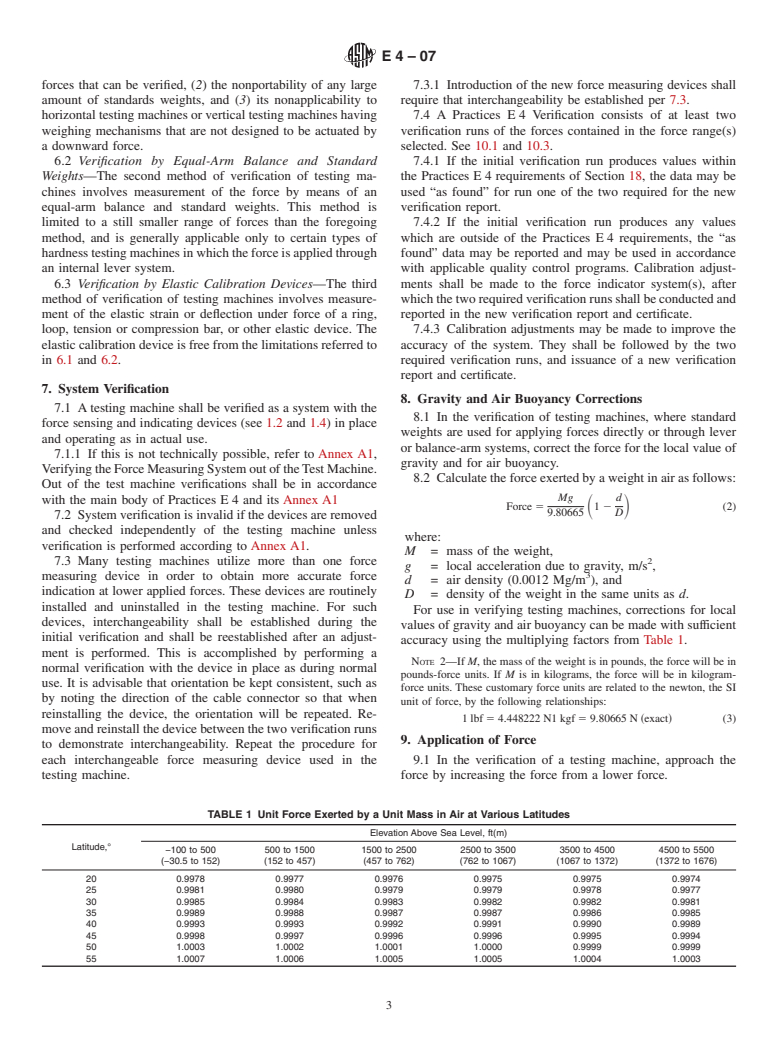

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.