ASTM B911/B911M-12

(Specification)Standard Specification for ACSR Twisted Pair Conductor (ACSR/TP)

Standard Specification for ACSR Twisted Pair Conductor (ACSR/TP)

ABSTRACT

This specification covers ACSR twisted pair conductor for use as overhead electric conductors. The conductors shall conform to the required values of equivalent size AWG, outer dimensions, nominal mass, rated strength, resistance and shall conform to the required component composition of aluminum and steel. . Tests for the electrical and mechanical properties shall be made on the component conductors.

SCOPE

1.1 This specification covers ACSR Twisted Pair Conductor (ACSR/TP) for use as overhead electric conductors (see Notes 1 and 2).

Note 1—The conductor is fabricated from two component ACSR conductors of the same size twisted helically around each other. This conductor is identified by the code name of the component ACSR conductor followed by /TP or the size and type of the component ACSR conductor followed by /TP.

Note 2—There are registered trademark symbols that are also used to identify the twisted pair notation. Consult cable manufacturers for additional details.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.2.1 For conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units. For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B911/B911M −12

StandardSpecification for

1

ACSR Twisted Pair Conductor (ACSR/TP)

This standard is issued under the fixed designation B911/B911M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

2

1. Scope 2.2 ASTM Standards:

B232/B232M Specification for Concentric-Lay-Stranded

1.1 ThisspecificationcoversACSRTwistedPairConductor

Aluminum Conductors, Coated-Steel Reinforced (ACSR)

(ACSR/TP) for use as overhead electric conductors (see Notes

1 and 2).

3. Terminology

NOTE 1—The conductor is fabricated from two component ACSR

3.1 Definitions of Terms Specific to This Standard:

conductors of the same size twisted helically around each other. This

3.1.1 component conductors—thetwoconductorstwistedto

conductor is identified by the code name of the component ACSR

fabricate the finished ACSR/TP.

conductor followed by /TP or the size and type of the component ACSR

conductor followed by /TP.

4. Ordering Information

NOTE 2—There are registered trademark symbols that are also used to

identify the twisted pair notation. Consult cable manufacturers for

4.1 Ordersformaterialunderthisspecificationshallinclude

additional details.

the following information:

1.2 The values stated in either SI units or inch-pound units 4.1.1 Quantity of each size,

are to be regarded separately as standard. The values stated in 4.1.1.1 Conductor Size—kcmil area of the fabricated

ACSR/TP (2 × kcmil area of one of the component

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining conductors),

4.1.2 Conductor type and the number of wires of the

values from the two systems may result in non-conformance

with the standard. component conductors,

4.1.3 The type of steel core wire and type of coating,

1.2.1 For conductor sizes designated byAWG or kcmil, the

4.1.4 Place of inspection,

requirementsinSIunitshavebeennumericallyconvertedfrom

4.1.5 Package size and type,

correspondingvaluesstatedorderivedininch-poundunits.For

4.1.6 Special package markings, if required, and

conductor sizes designated by SI units only, the requirements

4.1.7 Heavy wood lagging, if required.

are stated or derived in SI units. For density, resistivity, and

temperature, the values stated in SI units are to be regarded as

5. Requirements for Component Conductors

standard.

5.1 Before twisting, the component conductors shall con-

1.3 This standard does not purport to address all of the

form to the requirements of Specification B232/B232M.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

6. Twist

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 6.1 The component conductors shall be twisted about them-

selveswithacompletetwistevery9ft 61ft.Thistwistlength

shall be measured between the twisting machine and the

2. Referenced Documents

take-up reel with normal take-up tension on the ACSR/TP.

2.1 The following documents of the issue in effect on the

NOTE 3—The twist length can be altered as theACSR/TPis wound up

dateofmaterialpurchaseformapartofthisspecificationtothe

onto the take-up reel. It may not have the same twist length as when the

extent referenced herein:

TP is removed from the reel.

6.2 The direction of the twist shall be left hand.

1

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

2

Conductors of Light Metals. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2012. Published May 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2000. Last previous edition approved in 2005 as B911/B911M–05. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/B0911_B0911M-12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B911/B911M−12

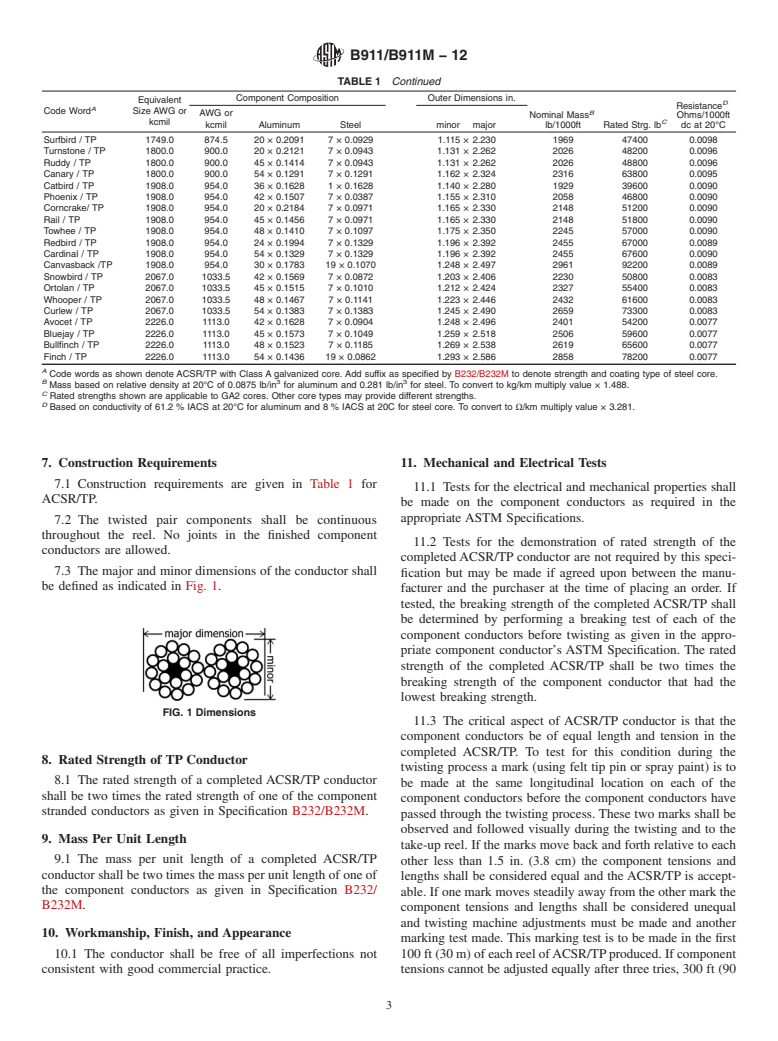

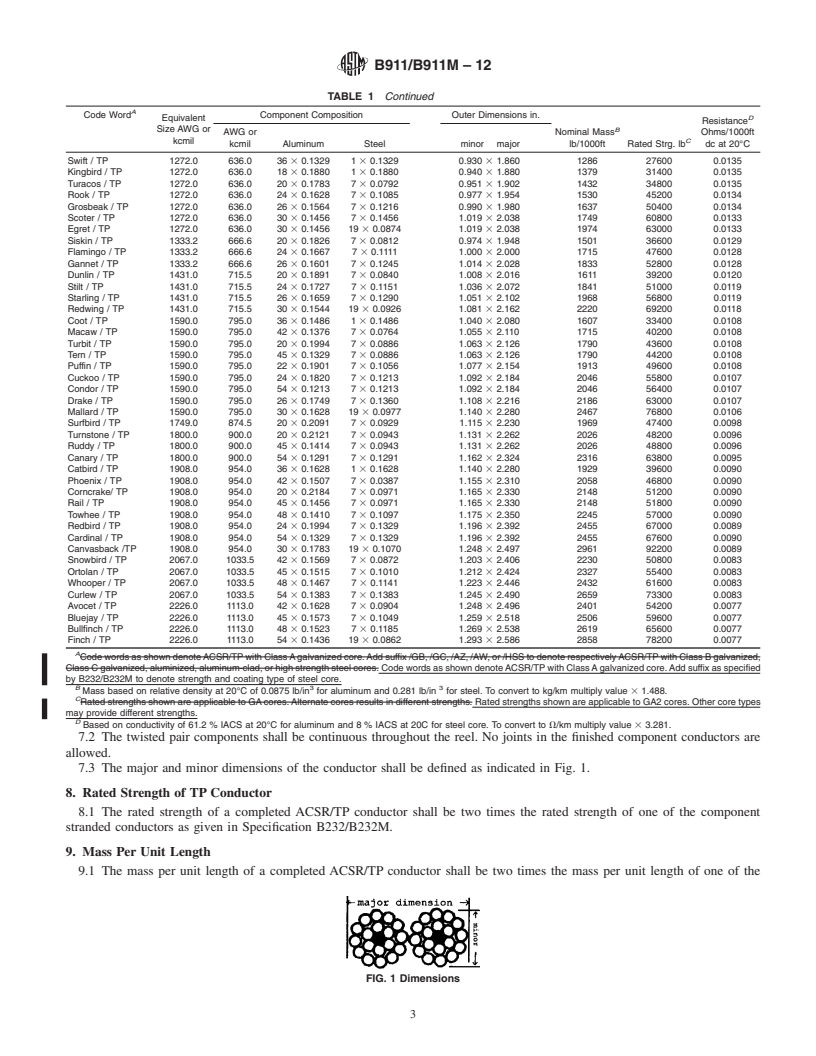

TABLE 1 Construction Requirements for TP Type Conductor Using Aluminum Conductor, Steel Reinforced (ACSR)

Component Composition Outer Dimensions in.

Equivalent

D

Resistance

A

Code Word Size AWG or B

AWG or

Nominal Mass Ohms/1000ft

C

kcmil

kcmil Aluminum Steel minor major lb/1000ft Rated Strg. lb dc at 20°C

Swan / TP 1 4 6 × 0.0834 1 × 0.0834 0.250 × 0.500 115 3700 0.2016

Swanate / TP 1 4 7 × 0.0772 1 × 0.1029 0.257 × 0.514 115 4720 0.1994

Swallow / TP 1/0 3 6 × 0.0937 1 ×

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B911/B911M–05 Designation: B911/B911M – 12

Standard Specification for

1

ACSR Twisted Pair Conductor (ACSR/TP)

This standard is issued under the fixed designation B911/B911M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers ACSR Twisted Pair Conductor (ACSR/TP) for use as overhead electric conductors (see Notes 1

and 2).

NOTE 1—The conductor is fabricated from two component ACSR conductors of the same size twisted helically around each other. This conductor is

identified by the code name of the component ACSR conductor followed by /TP or the size and type of the component ACSR conductor followed by

/TP.

NOTE 2—There are registered trademark symbols that are also used to identify the twisted pair notation. Consult cable manufacturers for additional

details.

1.2 The values stated in inch-pound either SI units or SIinch-pound units are to be regarded separately as standard. Each The

values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other.

Combining values from the two systems may result in non-conformance with the specification. Forstandard.

1.2.1 For conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from

corresponding values stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are

stated or derived in SI units. 1.2.1ForFor density, resistivity, and temperature, the values stated in SI units are to be regarded as

standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B232/B232M Specification for Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Reinforced (ACSR)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 component conductors—the two conductors twisted to fabricate the finished ACSR/TP.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Quantity of each size,

4.1.1.1 Conductor Size—kcmil area of the fabricated ACSR/TP (2 3 kcmil area of one of the component conductors),

4.1.2 Conductor type and the number of wires of the component conductors,

4.1.3 The type of steel core wire and type of coating,

4.1.4 Place of inspection,

4.1.5 Package size and type,

4.1.6 Special package markings, if required, and

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Conductors

of Light Metals.

Current edition approved Oct.1, 2005. Published November 2005. Originally approved in 2000. Last previous edition approved in 2000 as B911/B911M–00. DOI:

10.1520/B0911_B0911M-05.

Current edition approved April 1, 2012. Published May 2012. Originally approved in 2000. Last previous edition approved in 2005 as B911/B911M – 05. DOI:

10.1520/B0911_B0911M-12.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B911/B911M – 12

4.1.7 Heavy wood lagging, if required.

5. Requirements for Component Conductors

5.1 Before twisting, the component conductors shall conform to the requirements of Specification B232/B232M.

6. Twist

6.1 The component conductors shall be twisted about themselves with a complete twist every 9 ft 6 1 ft.This twist length shall

be measured between the twisting machine and the take-up reel with normal take-up tension on the ACSR/TP.

NOTE 3—The twist length can be altered as the ACSR/TP is wound up onto the take-up reel. It may not have the sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.