ASTM C1421-15

(Test Method)Standard Test Methods for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature

Standard Test Methods for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature

SIGNIFICANCE AND USE

5.1 Fracture toughness, KIc, is a measure of the resistance to crack extension in a brittle material. These test methods may be used for material development, material comparison, quality assessment, and characterization.

5.2 The pb and the vb fracture toughness values provide information on the fracture resistance of advanced ceramics containing large sharp cracks, while the sc fracture toughness value provides this information for small cracks comparable in size to natural fracture sources. Cracks of different sizes may be used for the sc method. If the fracture toughness values vary as a function of the crack size it can be expected that KIsc will differ from KIpb and KIvb. Table 1 tabulates advantages, disadvantages, and applicability of each method.

SCOPE

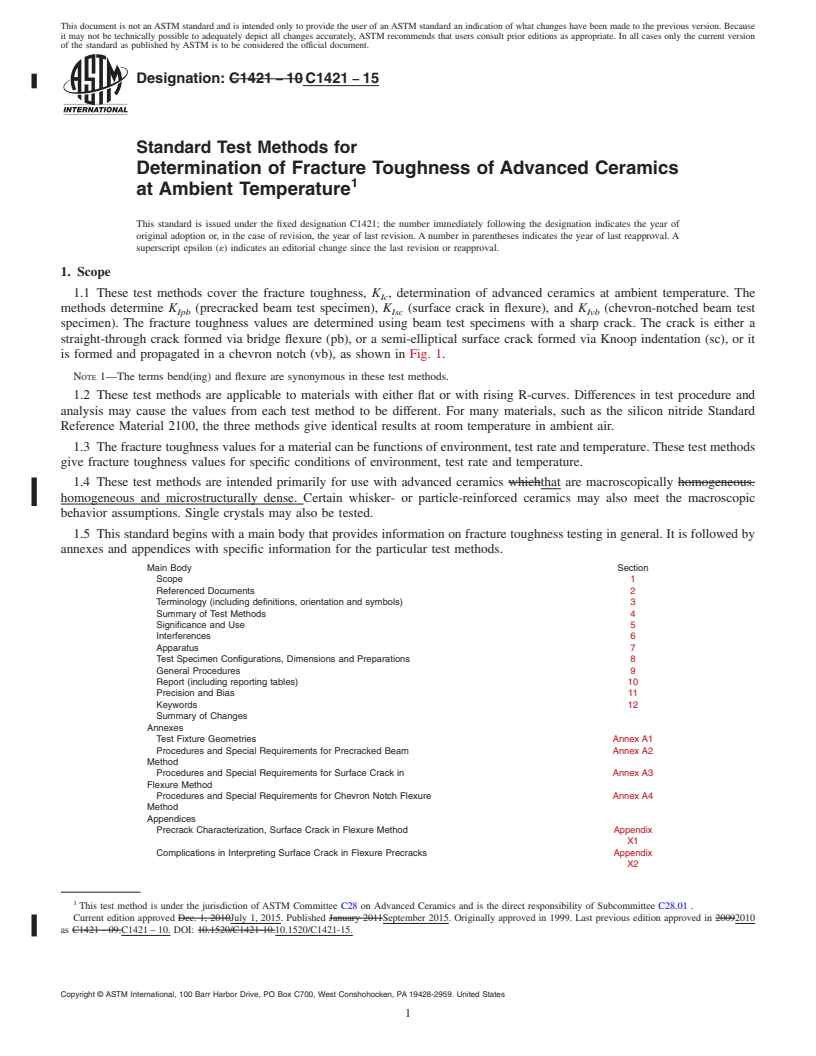

1.1 These test methods cover the fracture toughness, KIc, determination of advanced ceramics at ambient temperature. The methods determine KIpb (precracked beam test specimen), KIsc (surface crack in flexure), and KIvb (chevron-notched beam test specimen). The fracture toughness values are determined using beam test specimens with a sharp crack. The crack is either a straight-through crack formed via bridge flexure (pb), or a semi-elliptical surface crack formed via Knoop indentation (sc), or it is formed and propagated in a chevron notch (vb), as shown in Fig. 1.

Note 1: The figures on the right show the test specimen cross sections and crack types. Four-point loading may be used with all three methods. Three-point may be used with the pb and vb specimens.

Note 1: The terms bend(ing) and flexure are synonymous in these test methods.

1.2 These test methods are applicable to materials with either flat or with rising R-curves. Differences in test procedure and analysis may cause the values from each test method to be different. For many materials, such as the silicon nitride Standard Reference Material 2100, the three methods give identical results at room temperature in ambient air.

1.3 The fracture toughness values for a material can be functions of environment, test rate and temperature. These test methods give fracture toughness values for specific conditions of environment, test rate and temperature.

1.4 These test methods are intended primarily for use with advanced ceramics that are macroscopically homogeneous and microstructurally dense. Certain whisker- or particle-reinforced ceramics may also meet the macroscopic behavior assumptions. Single crystals may also be tested.

1.5 This standard begins with a main body that provides information on fracture toughness testing in general. It is followed by annexes and appendices with specific information for the particular test methods.

Main Body

Section

Scope

1

Referenced Documents

2

Terminology (including definitions, orientation and symbols)

3

Summary of Test Methods

4

Significance and Use

5

Interferences

6

Apparatus

7

Test Specimen Configurations, Dimensions and Preparations

8

General Procedures

9

Report (including reporting tables)

10

Precision and Bias

11

Keywords

12

Summary of Changes

Annexes

Test Fixture Geometries

Annex A1

Procedures and Special Requirements for Precracked Beam Method

Annex A2

Procedures and Special Requirements for Surface Crack in Flexure Method

Annex A3

Procedures and Special Requirements for Chevron Notch Flexure Method

Annex A4

Appendices

Precrack Characterization, Surface Crack in Flexure Method

Appendix X1

Complications in Interpreting Surface Crack in Flexure Precracks

Appendix X2

Alternative Precracking Procedure, Surface Crack in Flexure Method

Appendix X3

Chamfer Correction Factors, Surface Crack in Flexure Method Only

Appendix X4

Crack Orientation

Appendix X5

1.6 Values expressed in these test methods are in accordance with the...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1421 − 15

StandardTest Methods for

Determination of Fracture Toughness of Advanced Ceramics

1

at Ambient Temperature

This standard is issued under the fixed designation C1421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard begins with a main body that provides

information on fracture toughness testing in general. It is

1.1 These test methods cover the fracture toughness, K ,

Ic

followed by annexes and appendices with specific information

determination of advanced ceramics at ambient temperature.

for the particular test methods.

The methods determine K (precracked beam test specimen),

Ipb

Main Body Section

K (surfacecrackinflexure),and K (chevron-notchedbeam

Isc Ivb

Scope 1

test specimen). The fracture toughness values are determined

Referenced Documents 2

using beam test specimens with a sharp crack. The crack is

Terminology (including definitions, orientation and symbols) 3

Summary of Test Methods 4

either a straight-through crack formed via bridge flexure (pb),

Significance and Use 5

orasemi-ellipticalsurfacecrackformedviaKnoopindentation

Interferences 6

(sc), or it is formed and propagated in a chevron notch (vb), as

Apparatus 7

Test Specimen Configurations, Dimensions and Preparations 8

shown in Fig. 1.

General Procedures 9

Report (including reporting tables) 10

NOTE 1—The terms bend(ing) and flexure are synonymous in these test

Precision and Bias 11

methods.

Keywords 12

1.2 These test methods are applicable to materials with Summary of Changes

Annexes

eitherflatorwithrisingR-curves.Differencesintestprocedure

Test Fixture Geometries Annex A1

and analysis may cause the values from each test method to be

Procedures and Special Requirements for Precracked Beam Annex A2

Method

different. For many materials, such as the silicon nitride

Procedures and Special Requirements for Surface Crack in Annex A3

Standard Reference Material 2100, the three methods give

Flexure Method

identical results at room temperature in ambient air.

Procedures and Special Requirements for Chevron Notch Flexure Annex A4

Method

1.3 The fracture toughness values for a material can be

Appendices

functions of environment, test rate and temperature. These test

Precrack Characterization, Surface Crack in Flexure Method Appendix

X1

methods give fracture toughness values for specific conditions

Complications in Interpreting Surface Crack in Flexure Precracks Appendix

of environment, test rate and temperature.

X2

Alternative Precracking Procedure, Surface Crack in Flexure Appendix

1.4 These test methods are intended primarily for use with

Method X3

advanced ceramics that are macroscopically homogeneous and

Chamfer Correction Factors, Surface Crack in Flexure Method Only Appendix

X4

microstructurally dense. Certain whisker- or particle-

Crack Orientation Appendix

reinforced ceramics may also meet the macroscopic behavior

X5

assumptions. Single crystals may also be tested.

1.6 Valuesexpressedinthesetestmethodsareinaccordance

with the International System of Units (SI) and Practice

1 IEEE/ASTM SI10.

This test method is under the jurisdiction of ASTM Committee C28 on

Advanced Ceramics and is the direct responsibility of Subcommittee C28.01 .

1.7 The values stated in SI units are to be regarded as

Current edition approved July 1, 2015. Published September 2015. Originally

standard. No other units of measurement are included in this

approved in 1999. Last previous edition approved in 2010 as C1421–10. DOI:

10.1520/C1421-15. standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1421 − 15

NOTE 1—The figures on the right show the test specimen cross sections and crack types. Four-point loading may be used with all three methods.

Three-point may be used with the pb and vb specimens.

FIG. 1 The Three Test Methods

1.8 This standard does not purport to address all of the 3.1.4 slow crack growth (SCG)—sub critical crack growth

safety concerns, if any, associated with its use. It is the (extension)whichmayresultfrom,butisnotrestrictedto,such

responsibility of the user of this standard to establish appro- mechanisms as environmentally-assisted stress corrosion or

priate safety and health practices and determine the applica- diffusive crack growth.

bility of regulatory limitations prior to use.

-3/2

3.1.5 stress-intensity factor, K [FL ]—the magnitude of

the ideal-crack-tip stress field (stress field singularity) for a

2. Referenced Documents

particular mode in a homogeneous, linear-elastic bod

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1421 − 10 C1421 − 15

Standard Test Methods for

Determination of Fracture Toughness of Advanced Ceramics

1

at Ambient Temperature

This standard is issued under the fixed designation C1421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

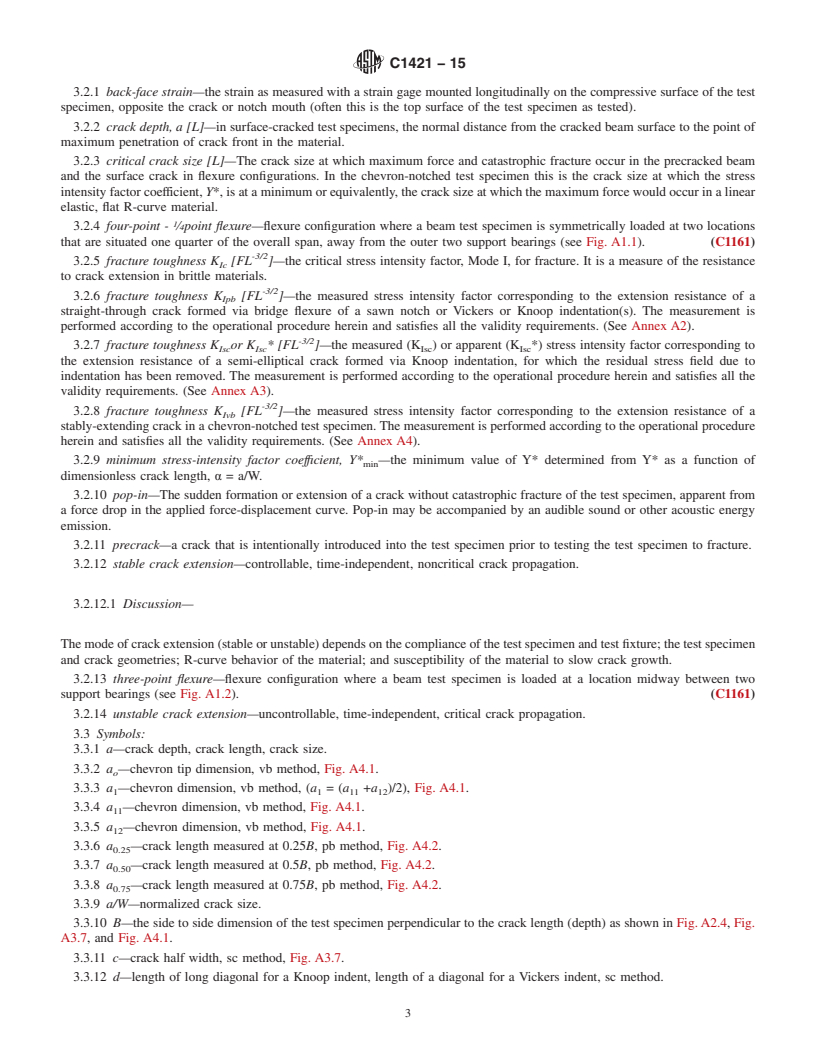

1.1 These test methods cover the fracture toughness, K , determination of advanced ceramics at ambient temperature. The

Ic

methods determine K (precracked beam test specimen), K (surface crack in flexure), and K (chevron-notched beam test

Ipb Isc Ivb

specimen). The fracture toughness values are determined using beam test specimens with a sharp crack. The crack is either a

straight-through crack formed via bridge flexure (pb), or a semi-elliptical surface crack formed via Knoop indentation (sc), or it

is formed and propagated in a chevron notch (vb), as shown in Fig. 1.

NOTE 1—The terms bend(ing) and flexure are synonymous in these test methods.

1.2 These test methods are applicable to materials with either flat or with rising R-curves. Differences in test procedure and

analysis may cause the values from each test method to be different. For many materials, such as the silicon nitride Standard

Reference Material 2100, the three methods give identical results at room temperature in ambient air.

1.3 The fracture toughness values for a material can be functions of environment, test rate and temperature. These test methods

give fracture toughness values for specific conditions of environment, test rate and temperature.

1.4 These test methods are intended primarily for use with advanced ceramics whichthat are macroscopically homogeneous.

homogeneous and microstructurally dense. Certain whisker- or particle-reinforced ceramics may also meet the macroscopic

behavior assumptions. Single crystals may also be tested.

1.5 This standard begins with a main body that provides information on fracture toughness testing in general. It is followed by

annexes and appendices with specific information for the particular test methods.

Main Body Section

Scope 1

Referenced Documents 2

Terminology (including definitions, orientation and symbols) 3

Summary of Test Methods 4

Significance and Use 5

Interferences 6

Apparatus 7

Test Specimen Configurations, Dimensions and Preparations 8

General Procedures 9

Report (including reporting tables) 10

Precision and Bias 11

Keywords 12

Summary of Changes

Annexes

Test Fixture Geometries Annex A1

Procedures and Special Requirements for Precracked Beam Annex A2

Method

Procedures and Special Requirements for Surface Crack in Annex A3

Flexure Method

Procedures and Special Requirements for Chevron Notch Flexure Annex A4

Method

Appendices

Precrack Characterization, Surface Crack in Flexure Method Appendix

X1

Complications in Interpreting Surface Crack in Flexure Precracks Appendix

X2

1

This test method is under the jurisdiction of ASTM Committee C28 on Advanced Ceramics and is the direct responsibility of Subcommittee C28.01 .

Current edition approved Dec. 1, 2010July 1, 2015. Published January 2011September 2015. Originally approved in 1999. Last previous edition approved in 20092010

as C1421 – 09.C1421 – 10. DOI: 10.1520/C1421-10.10.1520/C1421-15.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1421 − 15

NOTE 1—The figures on the right show the test specimen cross sections and crack types. Four-point loading may be used with all three methods.

Three-point may be used with the pb and vb specimens.

FIG. 1 The Three Test Methods

Alternative Precracking Procedure, Surface Crack in Flexure Appendix

Method X3

Chamfer Correction Factors, Surface Crack in Flexure Method Only Appendix

X4

Crack Orientation Appendix

X5

1.6 Values expressed in these test methods are in accordance with the International System of Units (SI) and Practice

IEEE/ASTM SI 10.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.