ASTM B1-01(2007)

(Specification)Standard Specification for Hard-Drawn Copper Wire

Standard Specification for Hard-Drawn Copper Wire

ABSTRACT

This specification covers hard-drawn round copper wire for electrical purposes. The wire shall be tested and shall conform to the requirements as to tensile strength, elongation, and electrical resistivity. No joints shall be made in the completed wire. Joints in the wire and rod made prior to final drawing shall be in accordance with the best commercial practice.

SCOPE

1.1 This specification covers hard-drawn round copper wire for electrical purposes.

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification. For conductor sizes designated by AWG or kcmil sizes, the requirements in SI units are numerically converted from the corresponding requirements in inch-pound units. For conductor sizes designation by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B1 −01(Reapproved 2007)

Standard Specification for

Hard-Drawn Copper Wire

This standard is issued under the fixed designation B1; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Ordering Information

3.1 Orders for material under this specification shall include

1.1 This specification covers hard-drawn round copper wire

the following information:

for electrical purposes.

3.1.1 Quantity of each size,

1.2 The values stated in inch-pound or SI units are to be

3.1.2 Wire size: diameter in inches (5.4 and Table 1),

regarded separately as standard. Each system shall be used

3.1.3 Type of copper, if special (Section 4),

independently of the other. Combining values from the two

3.1.4 Whether certification of resistivity of rod stock is

systems may result in non-conformance with the specification.

acceptable instead of resistivity tests on the finished wire (6.2),

For conductor sizes designated by AWG or kcmil sizes, the

3.1.5 Package size (8.1),

requirements in SI units are numerically converted from the

3.1.6 Special package marking, if required, and

correspondingrequirementsininch-poundunits.Forconductor

3.1.7 Place of inspection (7.1).

sizes designation by AWG or kcmil, the requirements in SI

4. Materials and Manufacture

units have been numerically converted from corresponding

values stated or derived in inch-pound units. For conductor

4.1 The material shall be copper of such quality and purity

sizesdesignatedbySIunitsonly,therequirementsarestatedor

that the finished product shall have the properties and charac-

derived in SI units.

teristics prescribed in this specification.

1.2.1 For density, resistivity and temperature, the values

NOTE 1—Specification B49 defines the materials suitable for use.

stated in SI units are to be regarded as standard.

5. General Requirements (see Section 8)

5.1 Tensile Strength and Elongation —The wire shall con-

2. Referenced Documents

form to the requirements as to tensile strength and elongation

2.1 ASTM Standards:

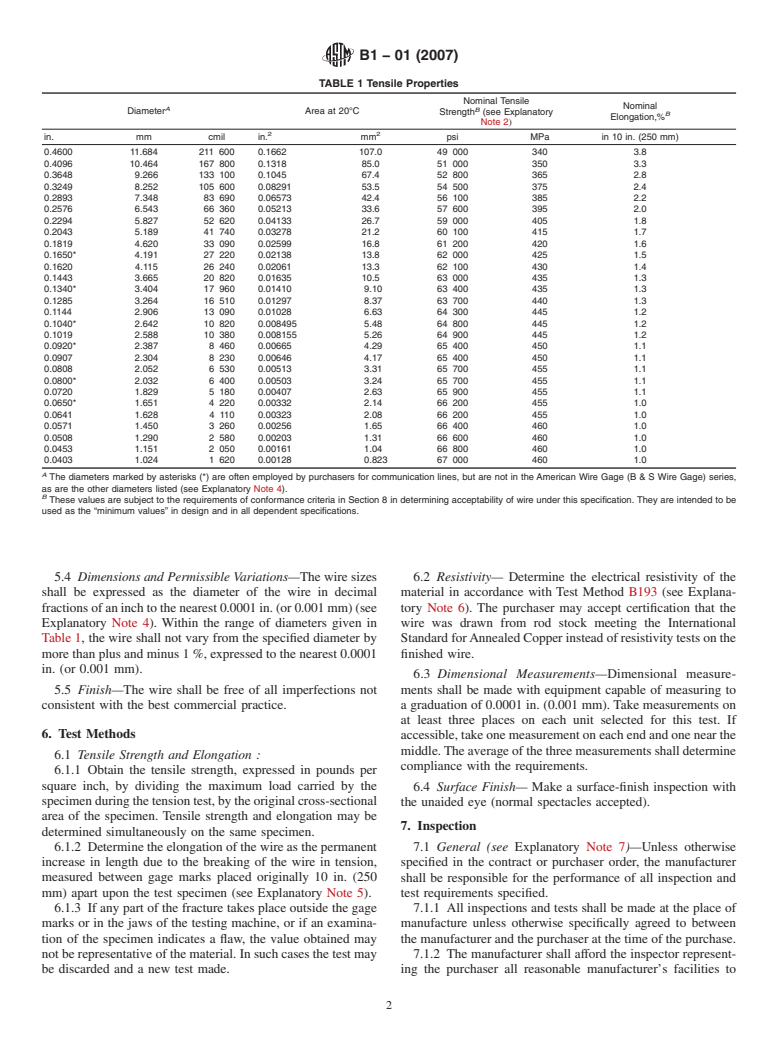

prescribed in Table 1 (see Explanatory Note 1 and Note 2). For

B49 Specification for Copper Rod Drawing Stock for Elec-

wire whose nominal diameter is more than 0.001 in. (1 mil)

trical Purposes

(0.025 mm) greater than a size listed in Table 1 and less than

B193 Test Method for Resistivity of Electrical Conductor

that of the next larger size, the requirements of the next larger

Materials

size shall apply.

B258 Specification for Nominal Diameters and Cross-

5.2 Joints—No joints shall be made in the completed wire

SectionalAreasofAWGSizesofSolidRoundWiresUsed

(see Explanatory Note 3). Joints in the wire and rods made

as Electrical Conductors

prior to final drawing shall be in accordance with the best

2.2 National Institute of Standards and Technology:

commercial practice. Tests on a specimen containing a joint

NBS Handbook 100 —Copper Wire Tables

shall show at least 95% of the tensile strength given in Table 1.

Elongation tests shall not be made on a specimen containing a

joint.

This specification is under the jurisdiction of ASTM Committee B01 on

5.3 Resistivity— The electrical resistivity at 20°C shall not

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

exceed the following values:

Conductors of Copper and Copper Alloys.

Current edition approved March 15, 2007. Published April 2007. Originally

Nominal Diameter, in. Resistivity at 20°C,

approved in 1909. Last previous edition approved in 2001 as B1 – 01. DOI:

Ω·lb/mile

10.1520/B0001-01R07. 0.460 to 0.325, incl 900.77

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Under 0.325 to 0.0403, incl 910.15

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Nominal Diameter, in. Resistivity at 20°C,

Standards volume information, refer to the standard’s Document Summary page on

Ω·g/m

the ASTM website.

11.68 to 8.25, incl 0.15775

Available from the National Technical Information Service, 5285 Port Royal

Under 8.25 to 1.02, incl 0.15940

Road, Springfield, VA 22161.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B1−01(Reapproved 2007)

B1−01 (2007)

TABLE 1 Tensile Properties

Nominal Tensile

Nominal

A

B

Diameter Area at 20°C Strength (see Explanatory

B

Elongation,%

Note 2)

2 2

in. mm cmil in. mm psi MPa in 10 in. (250 mm)

0.4600 11.684 211 600 0.1662 107.0 49 000 340 3.8

0.4096 10.464 167 800 0.1318 85.0 51 000 350 3.3

0.3648 9.266 133 100 0.1045 67.4 52 800 365 2.8

0.3249 8.252 105 600 0.08291 53.5 54 500 375 2.4

0.2893 7.348 83 690 0.06573 42.4 56 100 385 2.2

0.2576 6.543 66 360 0.05213 33.6 57 600 395 2.0

0.2294 5.827 52 620 0.04133 26.7 59 000 405 1.8

0.2043 5.189 41 740 0.03278 21.2 60 100 415 1.7

0.1819 4.620 33 090 0.02599 16.8 61 200 420 1.6

0.1650* 4.191 27 220 0.02138 13.8 62 000 425 1.5

0.1620 4.115 26 240 0.02061 13.3 62 100 430 1.4

0.1443 3.665 20 820 0.01635 10.5 63 000 435 1.3

0.1340* 3.404 17 960 0.01410 9.10 63 400 435 1.3

0.1285 3.264 16 510 0.01297 8.37 63 700 440 1.3

0.1144 2.906 13 090 0.01028 6.63 64 300 445 1.2

0.1040* 2.642 10 820 0.008495 5.48 64 800 445 1.2

0.1019 2.588 10 380 0.008155 5.26 64 900 445 1.2

0.0920* 2.387 8 460 0.00665 4.29 65 400 450 1.1

0.0907 2.304 8 230 0.00646 4.17 65 400 450 1.1

0.0808 2.052 6 530 0.00513 3.31 65 700 455 1.1

0.0800* 2.032 6 400 0.00503 3.24 65 700 455 1.1

0.0720 1.829 5 180 0.00407 2.63 65 900 455 1.1

0.0650* 1.651 4 220 0.00332 2.14 66 200 455 1.0

0.0641 1.628 4 110 0.00323 2.08 66 200 455 1.0

0.0571 1.450 3 260 0.00256 1.65 66 400 460 1.0

0.0508 1.290 2 580 0.00203 1.31 66 600 460 1.0

0.0453 1.151 2 050 0.00161 1.04 66 800 460 1.0

0.0403 1.024 1 620 0.00128 0.823 67 000 460 1.0

A

The diameters marked by asterisks (*) are often employed by purchasers for communication lines, but are not in the American Wire Gage (B&SWire Gage) series,

as are the other diameters listed (see Explanatory Note 4).

B

These values are subject to the requirements of conformance criteria in Section 8 in determining acceptability of wire under this specification. They are intended to be

used as the “minimum values” in design and in all dependent specifications.

5.4 Dimensions and Permissible Variations—The wire sizes 6.2 Resistivity— Determine the electrical resistivity of the

shall be expressed as the diameter of the wire in decimal material in accordance with Test Method B193 (see Explana-

fractionsofaninchtothenearest0.0001in.(or0.001mm)(see tory Note 6). The purchaser may accept certification that the

Explanatory Note 4). Within the range of diameters given in wire was drawn from rod stock meeting the International

Table 1, the wire shall not vary from the specified diameter by Standard forAnnealed Copper instead of resistivity tests on the

more than plus and minus 1 %, expressed to the nearest 0.0001 finished wire.

in. (or 0.001 mm).

6.3 Dimensional Measurements—Dimensional measure-

5.5 Finish—The wire shall be free of all imperfections not ments shall be made with equipment capable of measuring to

consistent with the best commercial practice. a graduation of 0.0001 in. (0.001 mm). Take measurements on

at least three places on each unit selected for this test. If

6. Test Methods

accessible,takeonemeasurementoneachendandonenearthe

middle.Theaverageofthethreemeasurementsshalldetermine

6.1 Tensile Strength and Elongation :

compliance with the requirements.

6.1.1 Obtain the tensile strength, expressed in pounds per

square inch, by dividing the maximum load carried by the

6.4 Surface Finish— Make a surface-finish inspection with

specimenduringthetensiontest,bytheoriginalcross-sectional

the unaided eye (normal spectacles accepted).

area of the specimen. Tensile strength and elongation may be

7. Inspection

determined simultaneously on the same specimen.

6.1.2 Determine the elongation of the wire as the permanent 7.1 General (see Explanatory Note 7)—Unless otherwise

increase in length due to the breaking of the wire in tension, specified in the contract or purchaser order, the manufacturer

measured between gage marks placed originally 10 in. (250 shall be responsible for the performance of all inspection and

mm) apart upon the test specimen (see Explanatory Note 5). test requirements specified.

6.1.3 If any part of the fracture takes place outside the gage 7.1.1 All inspections and tests shall be made at the place of

marks or in the jaws of the testing machine, or if an examina- manufacture unless otherwise specifically agreed to between

tion of the specimen indicates a flaw, the value obtained may the manufacturer and the purchaser at the time of the purchase.

not be representative of the material. In such cases the test may 7.1.2 The manufacturer shall afford the inspector represent-

be discarded and a new test made. ing the purchaser all reasonable manufacturer’s facilities to

B1−01 (2007)

TABLE 3 Sampling for Surface Finish and Packaging Inspection

satisfy him that the material is being furnished in accordance

with this specification. Number of Units Number of Units in Allowable Number

in Lot Sample, n of Defective

7.1.3 Unless otherwise agreed upon between the purchaser

Units, c

and the manufacturer, conformance of the wire to the various

1 to 30, incl all 0

requirementslistedinSection5shallbedeterminedonsamples

31 to 50, incl 30 0

51 to 100, incl 37 0

taken from each lot of wire presented for acceptance.

101 to 200, incl 40 0

7.1.4 The manufacturer shall, if requested prior to

201 to 300, incl 70 1

inspection, certify that all wire in the lot was made under such

301 to 500, incl 100 2

501 to 800, incl 130 3

conditions that the product as a whole conforms to the

Over 800 155 4

requirements of this specification as determined by regularly

made and recorded tests.

7.2 Inspection and Testing Terms:

9. Conformance Criteria (see Explanatory Note 7)

7.2.1 Lot—Alot is any amount of wire of one type and size

9.1 Any lot of wire, the samples of which comply with the

presented for acceptance at one time, such amount, however,

conformance criteria of this section, shall be considered as

not to exceed 100 000 lb (45 000 kg) (see Explanatory Note

complying with the requirements of Section 5. Individual

8).

production units that fail to meet one or more of the require-

7.2.2 Sample—A sample is a quantity of production units

ments shall be rejected. Failure of a sample group from a lot to

(coils, reels, etc.) selected at random from the lot for the

meet one or more of the following criteria shall constitute

purpose of determining conformance of the lot to the require-

causeforrejectionofthelot.Theconformancecriteriaforeach

ments of this specification.

of the prescribed properties given in Section 5 are as follows:

7.2.3 Specimen—A specimen is a length of wire removed

9.1.1 Tensile Strength— The lot shall be considered con-

for test purposes from any individual production unit of the

forming if the average tensile strength of the four specimens is

sample.

not less than the appropriate tensile strength of Table 1 minus

7.3 Sample Size— The number of production units in a 400 psi (3 MPa); however, any individual production unit, the

sample (see Explanatory Note 7) shall be as follows:

specimen from which has a tensile strength less than the

appropriatetensilestrengthvalueinTable1minus1700psi(12

7.3.1 Fortension,elongation,andresistivitydeterminations,

the sample shall consist of four production units. From each MPa) shall be rejected.

unit,onetestspecimenofsufficientlengthshallberemovedfor 9.1.1.1 Thelotshallbeconsideredtohavefailedtomeetthe

the performance of the required tests. tensile conformance criterion if the average of the four

specimens is less than the tensile strength in Table 1 minus 400

7.3.2 For dimensional measurements, the sample shall con-

psi (3 MPa) and the tensile strength of any of the individual

sist of a quantity of production units shown in Table 2 under

specimens is less than the value in Table 1 minus 1700 psi (12

the heading “First Sample.”

MPa).

7.3.3 For surface-finish inspection and for packaging in-

9.1.1.2 If the average of the four specimens is less than the

spection(whenspecifiedbythepurchaseratthetimeofplacing

tensile strength in Table 1 minus 400 psi (3 MPa) and the

the order) the sample shall consist of a quantity of production

tensile strength of each of the individual specimens is equal to

units shown in Table 3.

or more than the value in Table 1 minus 1700 psi (12 MPa), six

additional specimens from six production units other than the

8. Packaging and Package Marking

four originally sampled shall be tested. The lot shall be

8.1 Package sizes shall be agreed upon between the manu-

considered conforming if the tensile strength of each of the ten

facturer and the purchaser in the placing of individual orders.

specimensisnotlessthantheappropriatetensilestrengthvalue

8.2 The wire shall be protected against damage in ordinary in Table 1 minus 1700 psi and the average of the ten specimens

handling and shipping. isnotlessthanthevalueinTable1minus400psi.Thelotshall

TABLE 2 Sampling for Dimensional Measurements

First Sample Second Sample

Number of Allowable Number Allowable

Number of Units in Lot

Units in Sample, of Defects in Number of Units Number of

n, plus n

n First Sample, c in Sample, n Defects in Both

1 1 2

Samples, c

1 to 14, incl all 0 . . .

15 to 50, incl 14 0 . . .

51 to 100, incl 19 0 23 42 1

101 to 200, incl 24 0 46 70 2

210 to 400, incl 29 0 76 105 3

401 to 800, incl 33 0 112 145 4

Over 800 34 0 116 150 4

B1−01 (2007)

be considered to have failed to meet the tensile strength Failure to meet this requirement shall constitute failure to meet

requirement if the tensile strength of any of the individual the resistivity conformance criterion.

specimens is less than the value in Table 1 minus 1700 psi or 9.1.4 Dimensions—The dimensions of the first sample

if the average of the ten specimens is less than the value in (Table 2) shall conform to the requirements of 5.4. If there are

Table 1 minus 400 psi. no failures, the lot conforms to this requirement. If there are

9.1.2 Elongation—Thelotshallbeconsideredconformingif failures but the number of these does not exceed the allowable

the average elongation of the four specimens is not less than defect number, c (Table 2), for the respective nu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.