ASTM G123-00(2015)

(Test Method)Standard Test Method for Evaluating Stress-Corrosion Cracking of Stainless Alloys with Different Nickel Content in Boiling Acidified Sodium Chloride Solution

Standard Test Method for Evaluating Stress-Corrosion Cracking of Stainless Alloys with Different Nickel Content in Boiling Acidified Sodium Chloride Solution

SIGNIFICANCE AND USE

5.1 This test method is designed to compare alloys and may be used as one method of screening materials prior to service. In general, this test method is more useful for stainless steels than the boiling magnesium chloride test of Practice G36. The boiling magnesium chloride test cracks materials with the nickel levels found in relatively resistant austenitic and duplex stainless steels, thus making comparisons and evaluations for many service environments difficult.

5.2 This test method is intended to simulate cracking in water, especially cooling waters that contain chloride. It is not intended to simulate cracking that occurs at high temperatures (greater than 200°C or 390°F) with chloride or hydroxide.

Note 1: The degree of cracking resistance found in full-immersion tests may not be indicative of that for some service conditions comprising exposure to the water-line or in the vapor phase where chlorides may concentrate.

5.3 Correlation with service experience should be obtained when possible. Different chloride environments may rank materials in a different order.

5.4 In interlaboratory testing, this test method cracked annealed UNS S30400 and S31600 but not more resistant materials, such as annealed duplex stainless steels or higher nickel alloys, for example, UNS N08020 (for example 20Cb-34 stainless). These more resistant materials are expected to crack when exposed to Practice G36 as U-bends. Materials which withstand this sodium chloride test for a longer period than UNS S30400 or S31600 may be candidates for more severe service applications.

5.5 The repeatability and reproducibility data from Section 12 and Appendix X1 must be considered prior to use. Interlaboratory variation in results may be expected as occurs with many corrosion tests. Acceptance criteria are not part of this test method and if needed are to be negotiated by the user and the producer.

SCOPE

1.1 This test method covers a procedure for conducting stress-corrosion cracking tests in an acidified boiling sodium chloride solution. This test method is performed in 25 % (by mass) sodium chloride acidified to pH 1.5 with phosphoric acid. This test method is concerned primarily with the test solution and glassware, although a specific style of U-bend test specimen is suggested.

1.2 This test method is designed to provide better correlation with chemical process industry experience for stainless steels than the more severe boiling magnesium chloride test of Practice G36. Some stainless steels which have provided satisfactory service in many environments readily crack in Practice G36, but have not cracked during interlaboratory testing (see Section 12) using this sodium chloride test method.

1.3 This boiling sodium chloride test method was used in an interlaboratory test program to evaluate wrought stainless steels, including duplex (ferrite-austenite) stainless and an alloy with up to about 33 % nickel. It may also be employed to evaluate these types of materials in the cast or welded conditions.

1.4 This test method detects major effects of composition, heat treatment, microstructure, and stress on the susceptibility of materials to chloride stress-corrosion cracking. Small differences between samples such as heat-to-heat variations of the same grade are not likely to be detected.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G123 −00 (Reapproved 2015)

Standard Test Method for

Evaluating Stress-Corrosion Cracking of Stainless Alloys

with Different Nickel Content in Boiling Acidified Sodium

1

Chloride Solution

This standard is issued under the fixed designation G123; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope bility of regulatory limitations prior to use. For specific hazard

statements, see Section 8.

1.1 This test method covers a procedure for conducting

stress-corrosion cracking tests in an acidified boiling sodium

2. Referenced Documents

chloride solution. This test method is performed in 25% (by

2

2.1 ASTM Standards:

mass) sodium chloride acidified to pH 1.5 with phosphoric

D1193Specification for Reagent Water

acid. This test method is concerned primarily with the test

E8Test Methods for Tension Testing of Metallic Materials

solutionandglassware,althoughaspecificstyleofU-bendtest

E691Practice for Conducting an Interlaboratory Study to

specimen is suggested.

Determine the Precision of a Test Method

1.2 This test method is designed to provide better correla-

G15TerminologyRelatingtoCorrosionandCorrosionTest-

tion with chemical process industry experience for stainless

3

ing (Withdrawn 2010)

steels than the more severe boiling magnesium chloride test of

G16Guide for Applying Statistics to Analysis of Corrosion

Practice G36. Some stainless steels which have provided

Data

satisfactory service in many environments readily crack in

G30 Practice for Making and Using U-Bend Stress-

Practice G36, but have not cracked during interlaboratory

Corrosion Test Specimens

testing(seeSection12)usingthissodiumchloridetestmethod.

G36Practice for Evaluating Stress-Corrosion-Cracking Re-

1.3 Thisboilingsodiumchloridetestmethodwasusedinan

sistance of Metals and Alloys in a Boiling Magnesium

interlaboratory test program to evaluate wrought stainless

Chloride Solution

steels, including duplex (ferrite-austenite) stainless and an

G49Practice for Preparation and Use of Direct Tension

alloywithuptoabout33%nickel.Itmayalsobeemployedto

Stress-Corrosion Test Specimens

evaluate these types of materials in the cast or welded

G107Guide for Formats for Collection and Compilation of

conditions.

Corrosion Data for Metals for Computerized Database

Input

1.4 This test method detects major effects of composition,

heat treatment, microstructure, and stress on the susceptibility

3. Terminology

of materials to chloride stress-corrosion cracking. Small dif-

ferencesbetweensamplessuchasheat-to-heatvariationsofthe

3.1 Definitions—For definitions of corrosion-related terms

same grade are not likely to be detected.

used in this test method, see Terminology G15.

1.5 The values stated in SI units are to be regarded as the

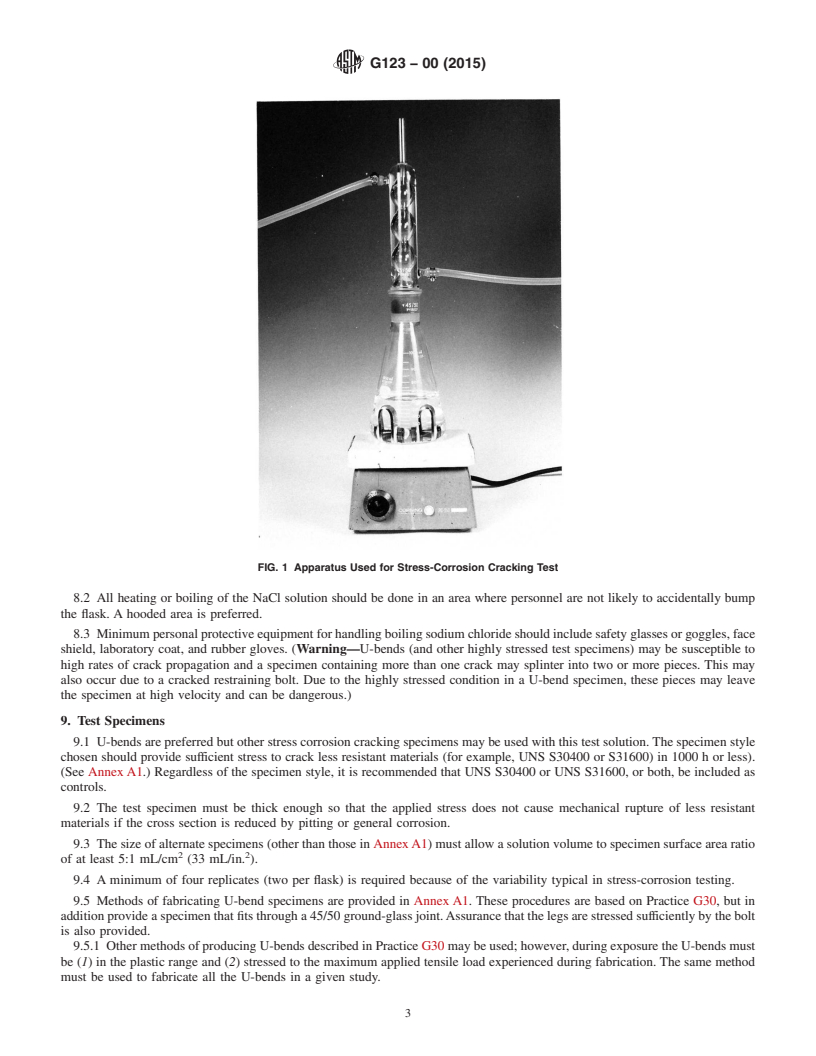

4. Summary of Test Method

standard. The values given in parentheses are for information

only. 4.1 Asolutionof25%sodiumchloride(by mass)inreagent

water is mixed, and the pH is adjusted to 1.5 with phosphoric

1.6 This standard does not purport to address all of the

acid. The solution is boiled and U-bends (or other stressed

safety concerns, if any, associated with its use. It is the

specimens) are exposed in fresh solution for successive one-

responsibility of the user of this standard to establish appro-

week periods.

priate safety and health practices and determine the applica-

1 2

This test method is under the jurisdiction of ASTM Committee G01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Environmentally Assisted Cracking. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2015. Published December 2015. Originally the ASTM website.

3

approved in 1994. Last previous edition approved in 2011 as G123–00(2011). DOI: The last approved version of this historical standard is referenced on

10.1520/G0123-00R15. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G123−00 (2015)

4.2 The test may be continued for as many weeks as

necessary, but six weeks (about 1000 h) or less are expected to

be sufficient to crack susceptible materials. Longer exposures

provide greater assurance of resistance for those materials

which do not crack.

4.3 It is recommended that samples of a susceptible

material, for example, UNS S30400 or S31600 (Type 304 or

Type316stainless,respectively)

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G123 − 00 (Reapproved 2011) G123 − 00 (Reapproved 2015)

Standard Test Method for

Evaluating Stress-Corrosion Cracking of Stainless Alloys

with Different Nickel Content in Boiling Acidified Sodium

1

Chloride Solution

This standard is issued under the fixed designation G123; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for conducting stress-corrosion cracking tests in an acidified boiling sodium chloride

solution. This test method is performed in 25 % (by mass) sodium chloride acidified to pH 1.5 with phosphoric acid. This test

method is concerned primarily with the test solution and glassware, although a specific style of U-bend test specimen is suggested.

1.2 This test method is designed to provide better correlation with chemical process industry experience for stainless steels than

the more severe boiling magnesium chloride test of Practice G36. Some stainless steels which have provided satisfactory service

in many environments readily crack in Practice G36, but have not cracked during interlaboratory testing (see Section 12) using

this sodium chloride test method.

1.3 This boiling sodium chloride test method was used in an interlaboratory test program to evaluate wrought stainless steels,

including duplex (ferrite-austenite) stainless and an alloy with up to about 33 % nickel. It may also be employed to evaluate these

types of materials in the cast or welded conditions.

1.4 This test method detects major effects of composition, heat treatment, microstructure, and stress on the susceptibility of

materials to chloride stress-corrosion cracking. Small differences between samples such as heat-to-heat variations of the same

grade are not likely to be detected.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 8.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

E8 Test Methods for Tension Testing of Metallic Materials

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

G15 Terminology Relating to Corrosion and Corrosion Testing (Withdrawn 2010)

G16 Guide for Applying Statistics to Analysis of Corrosion Data

G30 Practice for Making and Using U-Bend Stress-Corrosion Test Specimens

G36 Practice for Evaluating Stress-Corrosion-Cracking Resistance of Metals and Alloys in a Boiling Magnesium Chloride

Solution

G49 Practice for Preparation and Use of Direct Tension Stress-Corrosion Test Specimens

G107 Guide for Formats for Collection and Compilation of Corrosion Data for Metals for Computerized Database Input

3. Terminology

3.1 Definitions—For definitions of corrosion-related terms used in this test method, see Terminology G15.

1

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on Environmentally

Assisted Cracking.

Current edition approved March 1, 2011Nov. 1, 2015. Published April 2011December 2015. Originally approved in 1994. Last previous edition approved in 20052011

as G123–00(2005).G123–00(2011). DOI: 10.1520/G0123-00R11.10.1520/G0123-00R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G123 − 00 (2015)

4. Summary of Test Method

4.1 A solution of 25 % sodium chloride (by mass) in reagent water is mixed, and the pH is adjusted to 1.5 with phosphoric acid.

The solution is boiled and U-bends (or other stressed specimens) are exposed in fresh soluti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.