ASTM C839-82(2020)

(Test Method)Standard Test Method for Compressive Stress of Porcelain Enamels by Loaded-Beam Method

Standard Test Method for Compressive Stress of Porcelain Enamels by Loaded-Beam Method

SIGNIFICANCE AND USE

4.1 All porcelain enamel coatings or glass coatings are by necessity under some degree of compression at room temperature. The desired degree of compression or stress depends upon the type of ware and the end use of the item. Some method of determining relative compressive stress of enamels is necessary to establish the suitability of an enamel for a proposed application.

SCOPE

1.1 This test method covers the measurement of the compressive stresses (Note 1) developed by fired porcelain enamels using the loaded-beam method.

Note 1: Although some may interpret the calculations that are used in this test method as indicating compressive load, it is commonly referred to as compressive stress within the porcelain enamel industry.

1.2 This test method is limited to the use of the loaded-beam method. However, this method includes charts (Fig. 1 and Fig. 2) that provide for conversion of loaded-beam test results to warp and ring stress values.

FIG. 2 Conversion Chart for Loaded-Beam Stress to Ring Stress

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C839 − 82 (Reapproved 2020)

Standard Test Method for

Compressive Stress of Porcelain Enamels by Loaded-Beam

Method

This standard is issued under the fixed designation C839; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Manymethodsandtestshavebeenusedintheindustrytodeterminetherelativecompressivestress

of porcelain enamel ground coats and cover coats. Three methods have been most commonly used.

Theyareloaded-beam,warp,andsplit-ringmethods.Intheloaded-beammethodthemeasureofstress

is the load required to bring a specimen back to a plane after it has been bowed by controlled

application of the enamel under test to one side of the specimen. The degree of the deflection of a

specimen from a plane caused by controlled application of enamel to one side is the indicating

measure of stress in the warp test. The indicating measurement in the split-ring test is the force

required to just open a split ring after controlled application of test enamel to the outside surface of

a ring.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method covers the measurement of the com-

ization established in the Decision on Principles for the

pressivestresses(Note1)developedbyfiredporcelainenamels

Development of International Standards, Guides and Recom-

using the loaded-beam method.

mendations issued by the World Trade Organization Technical

NOTE 1—Although some may interpret the calculations that are used in

Barriers to Trade (TBT) Committee.

thistestmethodasindicatingcompressiveload,itiscommonlyreferredto

as compressive stress within the porcelain enamel industry.

2. Referenced Documents

1.2 Thistestmethodislimitedtotheuseoftheloaded-beam

2.1 ASTM Standards:

method. However, this method includes charts (Fig. 1 and Fig.

A424SpecificationforSteel,Sheet,forPorcelainEnameling

2) that provide for conversion of loaded-beam test results to

warp and ring stress values.

3. Terminology

1.3 The values stated in inch-pound units are to be regarded

3.1 Description of Term Specific to This Standard

as standard. The values given in parentheses are mathematical

3.2 compressive stress or stress—a term used to designate

conversions to SI units that are provided for information only

the degree of compression that exists in a porcelain enamel on

and are not considered standard.

steel after processing.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 All porcelain enamel coatings or glass coatings are by

priate safety, health, and environmental practices and deter-

necessity under some degree of compression at room tempera-

mine the applicability of regulatory limitations prior to use.

ture.Thedesireddegreeofcompressionorstressdependsupon

the type of ware and the end use of the item. Some method of

determining relative compressive stress of enamels is neces-

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic

sary to establish the suitability of an enamel for a proposed

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.12 on

application.

Materials for Porcelain Enamel and Ceramic-Metal Systems.

This test method was developed at the National Bureau of Standards under the

sponsorship of the Porcelain Enamel Institute, Inc., and was published as PEI

Technical Publication No. T-30 (1973). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2020. Published December 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approvedin1976.Lastpreviouseditionapprovedin2015asC839–82(2015).DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0839-82R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C839 − 82 (2020)

Metric Equivalents

in. mm in. mm

0.02 0.51 0.10 2.54

0.04 1.02 0.12 3.05

0.06 1.52 0.14 3.56

0.08 2.03

FIG. 1 Conversion Chart for Loaded-Beam Stress to Warp Stress

FIG. 2 Conversion Chart for Loaded-Beam Stress to Ring Stress

C839 − 82 (2020)

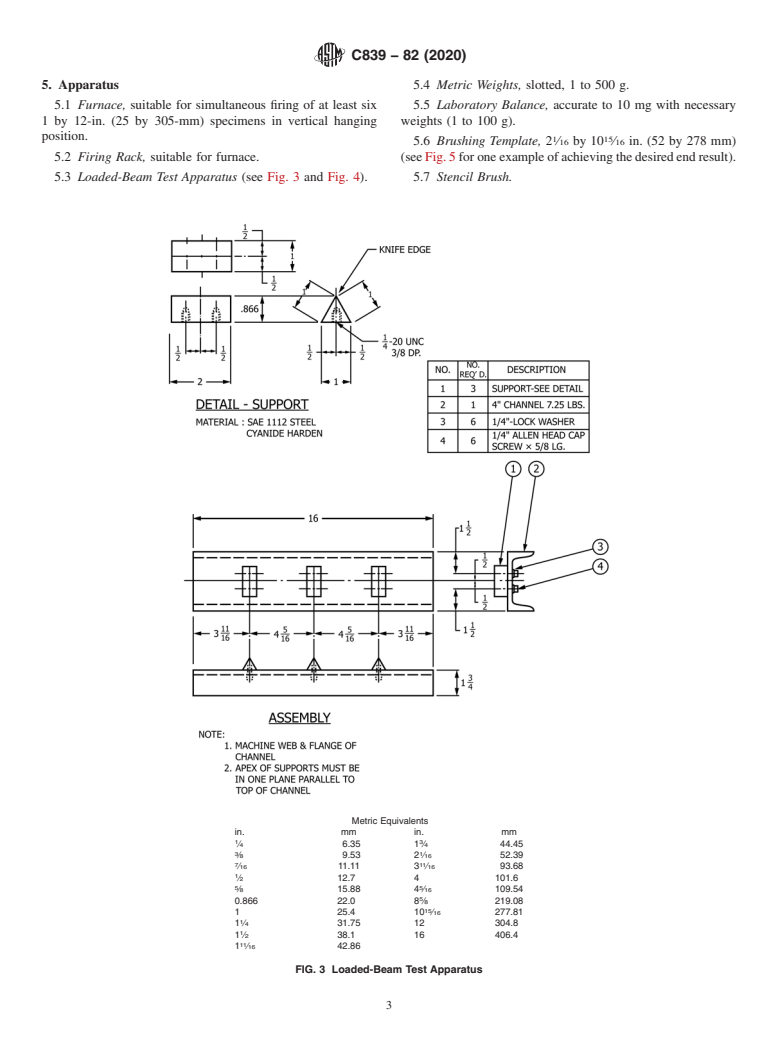

5. Apparatus 5.4 Metric Weights, slotted, 1 to 500 g.

5.1 Furnace, suitable for simultaneous firing of at least six 5.5 Laboratory Balance, accurate to 10 mg with necessary

1 by 12-in. (25 by 305-mm) specimens in vertical hanging weights (1 to 100 g).

position.

1 15

5.6 Brushing Template, 2 ⁄16 by 10 ⁄16 in. (52 by 278 mm)

5.2 Firing Rack, suitable for furnace. (seeFig.5foroneexampleofachievingthedesiredendresult).

5.3 Loaded-Beam Test Apparatus (see Fig. 3 and Fig. 4). 5.7 Stencil Brush.

Metric Equivalents

in. mm in. mm

1 3

⁄4 6.35 1 ⁄4 44.45

3 1

⁄8 9.53 2 ⁄16 52.39

7 11

⁄16 11.11 3 ⁄16 93.68

⁄2 12.7 4 101.6

5 5

⁄8 15.88 4 ⁄16 109.54

0.866 22.0 8 ⁄8 219.08

1 25.4 10 ⁄16 277.81

1 ⁄4 31.75 12 304.8

1 ⁄2 38.1 16 406.4

1 ⁄16 42.86

FIG. 3 Loaded-Beam Test Apparatus

C839 − 82 (2020)

FIG. 4 Loaded-Beam Test Apparatus

NOTE 1—See Fig. 3 for metric equivalents.

FIG. 5 Brushing Template

5.8 Fluorescent Light Fixture with diffusion panel and diameter hole should be punched in one end of the specimen

adjustable support. for hanging purposes during drying and firing. The center of

the hole should be on the center line ⁄16 in. (11 mm) from the

6. Test Specimens

end of the specimen. Specimens should be numbered for

identification during the testing procedure. They may be

6.1 Six specimens are required for each enamel tested.

permanently identified by metal stamping on the scribed side

6.2 Specimens 1 by 12 in. (25 by 305 mm) shall be cut by

while being supported on an anvil (see Fig. 6).

shearing from flat sheets of 20-gage Commercial QualityType

II enameling iron (see Specification A424) with thickness

7. Procedure

0.036 6 0.002 in. (0.91 6 0.05 mm). The 12-in. dimension

7.1 Application of Ground Coat to Test Strips:

should be cut perpendicular to the direction of rolling of sheet.

7.1.1 Subject the specimens to a pickle procedure normal

Care should be exercised to prevent formation of burrs during

for ground coat application. Pickle in a suspended vertical

shearing. Burrs that are formed may be removed by carefully

position to prevent distortion.

filing edges or by lightly touching edges to a sanding belt.

7.1.2 Measure and record metal thickness of the test speci-

Since opposing sides of the sheet may produce slightly

differentresults,onesideofthesheetshouldbescribedinsuch mens.

a manner that the scribe mark will appear about 1 in. from one 7.1.3 Apply a medium high-temperature ground coat (1520

end of the resulting strips after shearing. A ⁄4-in. (6.35-mm) to1540°F(825to840°C))byspraying.Withscribedsidesup,

C839 − 82 (2020)

NOTE 1—Wipe all bisque cover coat enamel from sides, ends, and back of ground coated test sample before firing cover coat.

NOTE 2—See Fig. 3 for metric equivalents.

FIG. 6 Detail of Test Specimen

first spray the back sides of strips to give 1.5 g dry weight per 7.3.2 Centrally load the strip with slotted weights over the

strip. Dr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.