ASTM A376/A376M-12

(Specification)Standard Specification for Seamless Austenitic Steel Pipe for High-Temperature Central-Station Service

Standard Specification for Seamless Austenitic Steel Pipe for High-Temperature Central-Station Service

ABSTRACT

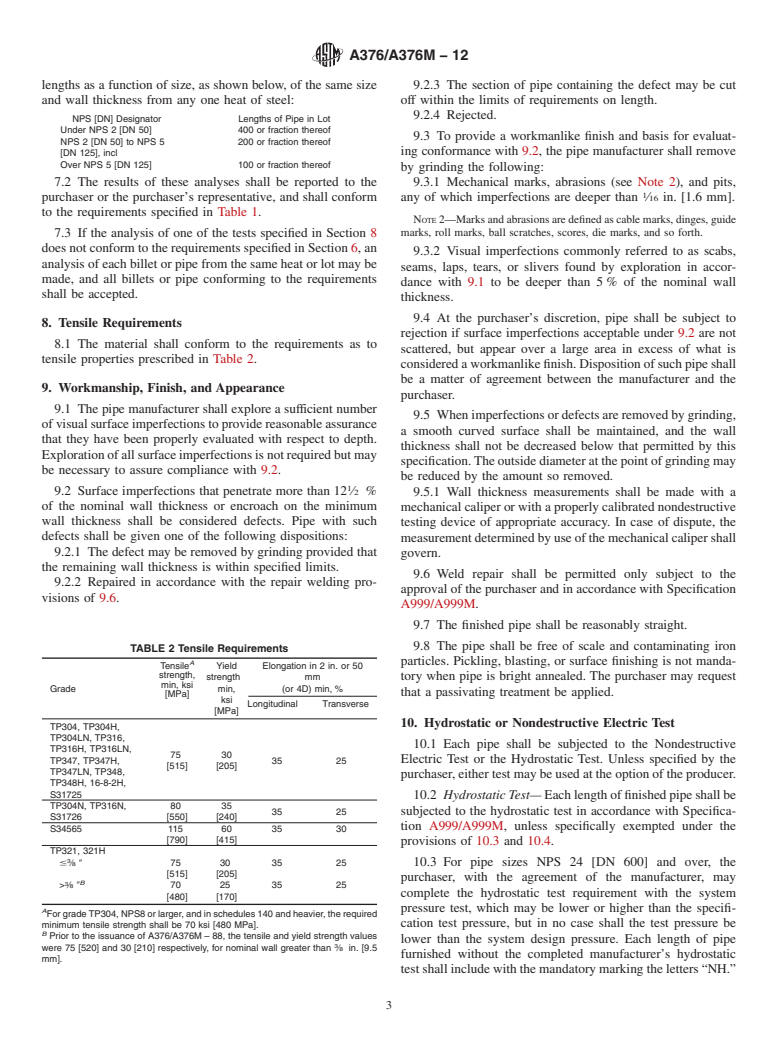

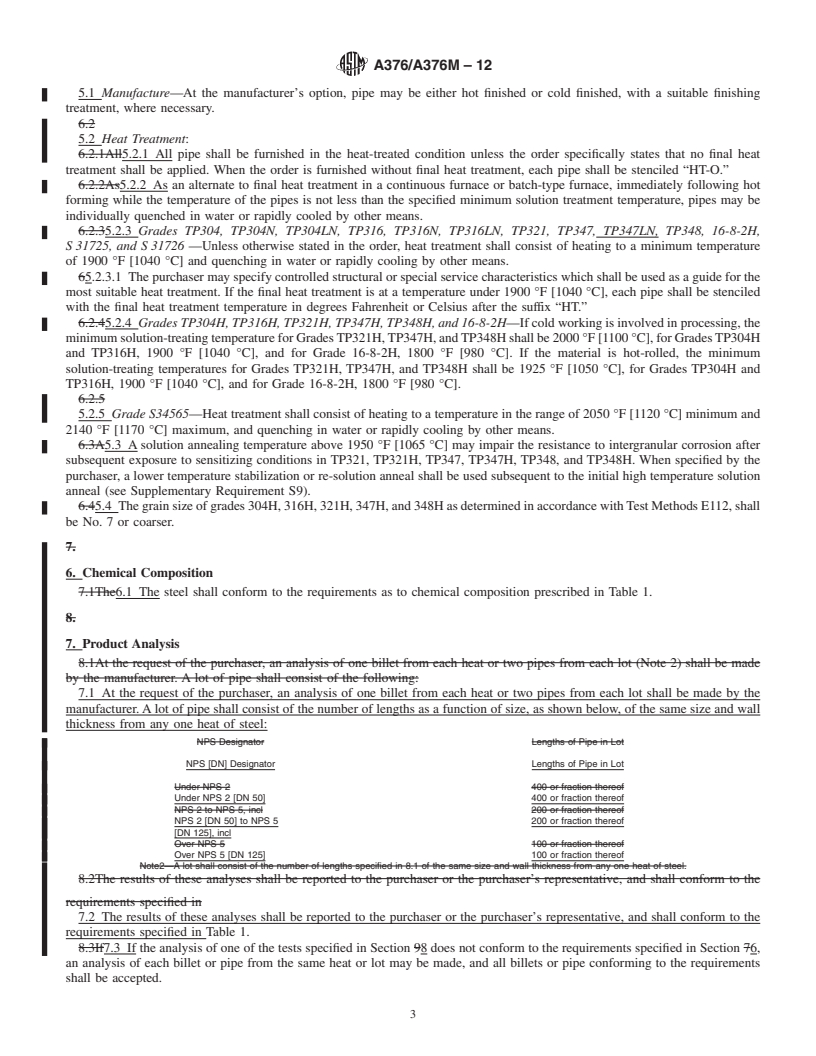

This specification covers seamless austenitic steel pipe intended for high-temperature central-station service. The grades covered are five H grades and two nitrogen grades. Pipe may be either hot finished or cold finished, with a suitable finishing treatment. All pipes shall be furnished in the heat-treated condition unless the order specifically states that no final heat treatment shall be applied. Tensile tests, hydrostatic test, nondestructive electric tests, ultrasonic tests, eddy-current tests, tension tests, and flattening tests shall be made to conform to the requirements specified.

SCOPE

1.1 This specification covers seamless austenitic steel pipe intended for high-temperature central-station service. Among the grades covered are H grades and nitrogen grades that are specifically intended for high-temperature service.

1.2 Optional supplementary requirements (S1 through S10) are provided. These supplementary requirements specify additional tests that will be made only when stated in the order, together with the number of such tests required.

1.3 Grades TP321 and TP321H have lower strength requirements for nominal wall thicknesses greater than 3/8 in. [9.5 mm].

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

Note 1—The dimensionless designators NPS (nominal pipe size) and DN (Diametre Nominel) have been substituted in this standard for such traditional terms as “nominal diameter,” “size,” and “nominal size.”

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A376/A376M −12 Usedin USDOE-NE standards

Standard Specification for

Seamless Austenitic Steel Pipe for High-Temperature

1

Central-Station Service

This standard is issued under the fixed designationA376/A376M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E112 Test Methods for Determining Average Grain Size

2 E213 Practice for Ultrasonic Testing of Metal Pipe and

1.1 This specification covers seamless austenitic steel pipe

Tubing

intended for high-temperature central-station service. Among

E381 Method of Macroetch Testing Steel Bars, Billets,

the grades covered are H grades and nitrogen grades that are

Blooms, and Forgings

specifically intended for high-temperature service.

E426 PracticeforElectromagnetic(Eddy-Current)Examina-

1.2 Optional supplementary requirements (S1 through S10)

tion of Seamless and Welded Tubular Products,Austenitic

are provided. These supplementary requirements specify addi-

Stainless Steel and Similar Alloys

tional tests that will be made only when stated in the order,

2.2 Other Standards:

together with the number of such tests required.

SNT-TC-1A Personnel Qualification and Certification in

4

1.3 GradesTP321 andTP321H have lower strength require- Nondestructive Testing

3

ments for nominal wall thicknesses greater than ⁄8 in. [9.5

3. Ordering Information

mm].

3.1 Orders for material to this specification should include

1.4 The values stated in either inch-pound units or SI units

the following, as required to describe the desired material

are to be regarded separately as standard. Within the text, the

adequately:

SI units are shown in brackets. The values stated in each

3.1.1 Quantity (feet, centimetres, or number of lengths),

system may not be exact equivalents; therefore, each system

3.1.2 Name of material (seamless austenitic steel pipe),

shall be used independently of the other. Combining values

3.1.3 Grade (Table 1),

from the two systems may result in non-conformance with the

3.1.4 Size (nominal size, or outside diameter and schedule

standard. The inch-pound units shall apply unless the “M”

number or average wall thickness),

designation of this specification is specified in the order.

3.1.5 Lengths (specific or random), (Permissible Variations

NOTE 1—The dimensionless designators NPS (nominal pipe size) and

in Length Section of Specification A999/A999M),

DN (Diametre Nominel) have been substituted in this standard for such

3.1.6 End finish (Ends Section of Specification A999/

traditional terms as “nominal diameter,” “size,” and “nominal size.”

A999M),

3.1.7 Optional requirements (Section 8) (see Hydrostatic

2. Referenced Documents

Test Requirements Section and the Permissible Variation in

3

2.1 ASTM Standards:

Weight for Seamless Pipe Section for weighing individual

A262 Practices for Detecting Susceptibility to Intergranular

lengths, of Specification A999/A999M), (see 9.6, repairing by

Attack in Austenitic Stainless Steels

welding; 13.3, die stamping),

A999/A999M Specification for General Requirements for

3.1.8 Test report required (Certification Section of Specifi-

Alloy and Stainless Steel Pipe

cation A999/A999M),

3.1.9 Specification designation, and

3.1.10 Special requirements or any supplementary require-

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

ments selected, or both.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products.

4. General Requirements

Current edition approved May 1, 2012. Published June 2012. Originally

approved in 1954. Last previous edition approved in 2006 as A376/A376M–06.

4.1 Material furnished to this specification shall conform to

DOI: 10.1520/A0376_A0376M-12.

2

the applicable requirements of the current edition of Specifi-

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SA-376 in Section II of that Code.

cation A999/A999M unless otherwise provided herein.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

the ASTM website. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A376/A376M−12

TABLE 1 Chemical Requirem

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Used in USDOE-NE standards

Designation:A376/A376M–06 (Reapproved 2011) Designation: A376/A376M – 12

Standard Specification for

Seamless Austenitic Steel Pipe for High-Temperature

1

Central-Station Service

This standard is issued under the fixed designationA376/A376M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers seamless austenitic steel pipe intended for high-temperature central-station service. Among the

grades covered are five H grades and two nitrogen grades (304N and 316N) that are specifically intended for high-temperature

service.

1.2 Optional supplementary requirements (S1 through S10) are provided. These supplementary requirements specify additional

tests that will be made only when stated in the order, together with the number of such tests required.

3

1.3 Grades TP321 and TP321H have lower strength requirements for nominal wall thicknesses greater than ⁄8 in. [9.5 mm].

1.4 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard. The

inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

NOTE 1—The dimensionless designators NPS (nominal pipe size) hasand DN (Diametre Nominel) have been substituted in this standard for such

traditional terms as “nominal diameter,” “size,” and “nominal size.”

2. Referenced Documents

3

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to IntergranularAttack inAustenitic Stainless SteelsA941Terminology Relating to

Steel, Stainless Steel, Re-

lated Alloys, and Ferroal-

loys

A999/A999M Specification for General Requirements for Alloy and Stainless Steel Pipe

E112 Test Methods for Determining Average Grain Size

E213 Practice for Ultrasonic Testing of Metal Pipe and Tubing

E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

E426 Practice for Electromagnetic (Eddy-Current) Examination of Seamless andWeldedTubular Products,Austenitic Stainless

Steel and Similar Alloys

2.2 Other Standards:

4

SNT-TC-1A Personnel Qualification and Certification in Nondestructive Testing

3. Terminology

3.1Definitions—For definitions of terms used in this specification, refer to Terminology A941.

4.Ordering Information

43.1 Orders for material to this specification should include the following, as required to describe the desired material

adequately:

43.1.1 Quantity (feet, centimetres, or number of lengths),

43.1.2 Name of material (seamless austenitic steel pipe),

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.10

on Stainless and Alloy Steel Tubular Products.

Current edition approved Oct.May 1, 2011.2012. Published MarchJune 2012. Originally approved in 1954. Last previous edition approved in 2006 as A376/A376M–06.

DOI: 10.1520/A0376_A0376M-06R11.10.1520/A0376_A0376M-12.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-376 in Section II of that Code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A376/A376M – 12

43.1.3 Grade (Table 1),

43.1.4 Size (nominal size, or outside diameter and schedule number or average wall thickness),

43.1.5 Lengths (specific or random), (Permissible Variations in Length Section of Specification A999/A999M),

4.1.6End3.1.6 End finish (Ends Section of Specification A999/A999M),

4.1.7Optional requirements (Section 9

3.1.7 Optional requirements (Section 8) (see HydrostaticTest Requiremen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.