ASTM D1970-00

(Specification)Standard Specification for Self-Adhering Polymer Modified Bituminous Sheet Materials Used as Steep Roofing Underlayment for Ice Dam Protection

Standard Specification for Self-Adhering Polymer Modified Bituminous Sheet Materials Used as Steep Roofing Underlayment for Ice Dam Protection

SCOPE

1.1 This specification covers polymer modified bituminous sheet materials intended for use as underlayment on roof eaves, or valleys, or both, to prevent leakage of shingle, tile, or metal roofs from water back-up due to ice dams.

1.2 These underlayment sheets have a sticky adhesive layer which is exposed by removal of a protective sheet. The top surface is suitable to work on during the application of the exposed roofing.

1.3 The values stated in SI units are to be regarded as standard.

1.4 The following safety hazards caveat pertains to the test methods portion, Section 7, of this standard. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1970 – 00

Standard Specification for

Self-Adhering Polymer Modified Bituminous Sheet Materials

Used as Steep Roofing Underlayment for Ice Dam

Protection

This standard is issued under the fixed designation D 1970; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Bituminous Sheet Material

E 96 Test Methods for Water Vapor Transmission of Mate-

1.1 This specification covers polymer modified bituminous

rials

sheet materials intended for use as underlayment on roof eaves,

or valleys, or both, to prevent leakage of shingle, tile, or metal

3. Terminology

roofs from water back-up due to ice dams.

3.1 Definitions—For definitions of terms used in this speci-

1.2 These underlayment sheets have a sticky adhesive layer

fication, refer to Terminology D 1079.

which is exposed by removal of a protective sheet. The top

3.2 Definitions of Terms Specific to This Standard:

surface is suitable to work on during the application of the

3.2.1 lot—for the purpose of sampling, a lot shall consist of

exposed roofing.

all material manufactured in one production run (not to exceed

1.3 The values stated in SI units are to be regarded as

24 h) using the same source of raw materials.

standard.

1.4 The following safety hazards caveat pertains to the test

4. Workmanship, Finish, and Appearance

methods portion, Section 7, of this standard. This standard

4.1 The underlayment sheet shall be supplied in roll form.

does not purport to address all of the safety concerns, if any,

4.2 The underlayment sheet shall be substantially uniform

associated with its use. It is the responsibility of the user of this

in thickness and appearance. It shall be free of visible defects

standard to establish appropriate safety and health practices

such as holes, ragged or untrue edges, breaks, cracks, tears,

and determine the applicability of regulatory limitations prior

protuberances, and indentations, except for those perforations

to use.

or protuberances which are intentional.

4.3 The surface of the underlayment sheet shall be designed

2. Referenced Documents

to provide traction and slip resistance to the applicator.

2.1 ASTM Standards:

D 228 Test Methods for Asphalt Roll Roofing, Cap Sheets,

NOTE 1—The intent of 4.3 is to recognize that surface slipperiness is

and Shingles important when working on a roof and, while no test method is specified

in this standard, several methods for assessing the relative slipperiness of

D 903 Test Method for Peel or Stripping Strength of Adhe-

surfaces are available. It is the further intent of this paragraph to ensure

sive Bonds

that, whatever method is used, the friction coefficient or resistance to

D 1079 Terminology Relating to Roofing, Waterproofing,

slipping of the surface of these products should be at least as great as

and Bituminous Materials

asphalt-saturated felt shingle underlayment tested under the same condi-

D 1204 Test Method for Linear Dimensional Changes of

tions of temperature and wetness as agreed between purchaser and seller.

Nonrigid Thermoplastic Sheeting or Film at Elevated

4.4 Sheet sections shall be suitable for joining by the

Temperature

manufacturer’s recommended procedure. The entire lower

D 2523 Practice for Testing Load-Strain Properties of Roof-

surface of the underlayment sheet shall be capable of being

ing Membranes

fully adhered to the roof deck.

D 4073 Test Method for Tensile-Tear Strength of Bitumi-

nous Roofing Membranes

5. Physical Requirements

D 5147 Test Methods for Sampling and Testing Modified

5.1 The underlayment sheet shall conform to the physical

requirements prescribed in Table 1.

5.2 The underlayment sheet shall not crack nor be so sticky

This specification is under the jurisdiction of ASTM Committee D-8 on

Roofing, Waterproofing, and Bituminous Materials and is the direct responsibility of

as to cause tearing or other damage upon being unrolled at

Subcommittee D08.02 on Prepared Roofings, Shingles, and Siding Materials.

material temperatures between 4.4 and 60°C (40 and 140°F).

Current edition approved Jan. 10, 2000. Published March 2000. Originally

published as D 1970 – 90. Last previous edition D 1970 – 97.

Annual Book of ASTM Standards, Vol 04.04.

Annual Book of ASTM Standards, Vol 15.06.

4 5

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 04.06.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 1970

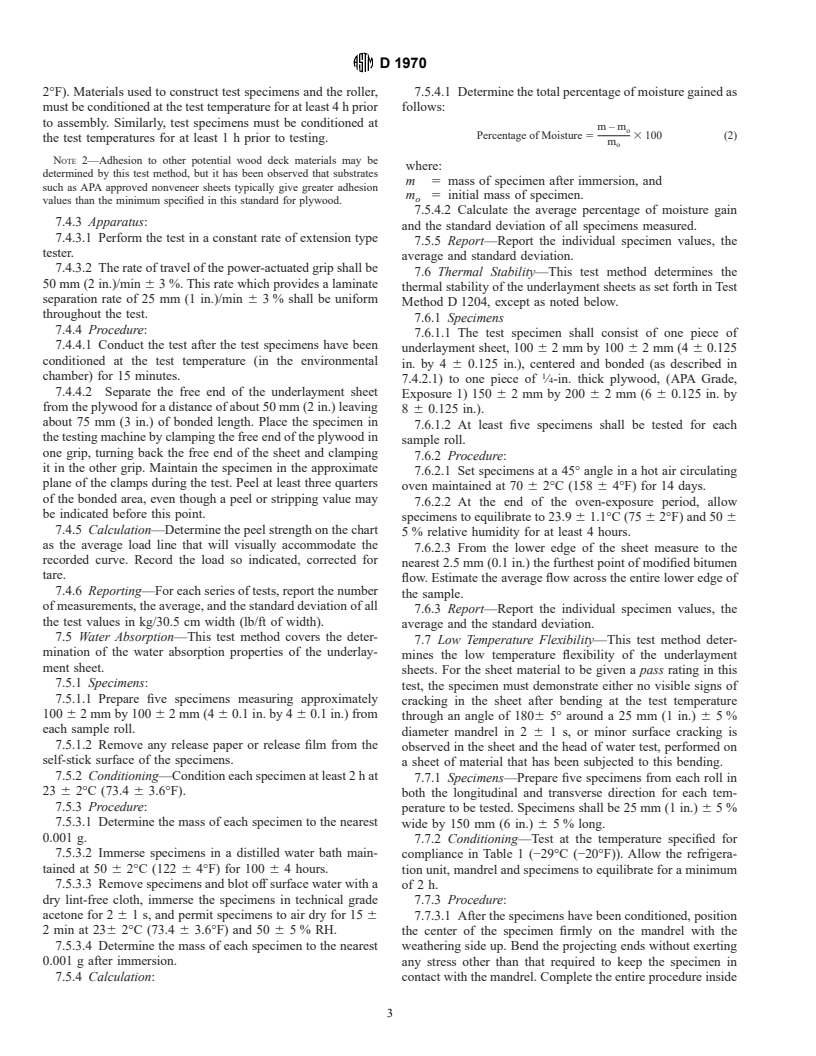

TABLE 1 Physical Requirements of Polymer Modified Bitumen

for sheets having an ultimate elongation of 75 % or less at

Sheets Used as Steep Roofing Underlayment

23.9°C (75°F) and 50 mm (2 in.) 6 5 % for sheets having an

Property Inch-Pound Metric

ultimate elongation greater than 75 % at 23.9°C (75°F).

Thickness, min 40 mils 1.0 mm

7.3.2.3 Maintain a rate of separation of 50 mm (2 in.)6 3%

Maximum load, min

per min.

Longitudinal 25 lbf/in. 4.4 kN/m

7.3.2.4 Record the percent elongation of each specimen at

Transverse 25 lbf/in. 4.4 kN/m

Elongation at break, min of modified 10 % the visual break of the modified bitumen portion using an

bitumen portion

extensiometer, or mark the extension at visual break of the

Adhesion to plywood, min at 40°F 2.0 lbf/ft width 0.92 kgf/30.5 cm

modified bitumen portion from the chart of the stress versus

Adhesion to plywood, min at 75°F 12.0 lbf/ft width 5.44 kgf/30.5 cm

Water absorption, max 0.1 %

time (knowing the speed of the chart drive and the jaw

Thermal stability, max 0.1 in. 3 mm

separation rate).

Flexibility temperature −20°F −29°C

7.3.2.5 Record the maximum load attained by each speci-

Tear resistance

Longitudinal, min 20 lbf 89 N

men.

Transverse, min 20 lbf 89 N

7.3.3 Calculation:

Moisture vapor permeability, max 0.1 U.S. Perms 5.7 ng/Pa.S.M.

7.3.3.1 Determine the percent elongation at break of the

Sealability around nail pass

Waterproof integrity after low temperature pass

modified bitumen portion obtained from the extensiometer in

flexibility

accordance with the manufacturer’s instructions, or read di-

Waterproof integrity of lap seam pass

rectly. Calculate the percent elongation from the chart as

Slip resistance Greater than asphalt saturated felt

when tested under the same

follows:

conditions of temperature and

wetness (see Note 1) a

% Elongation 5 3 100 % (1)

b

where:

6. Sampling

a 5 extension at modified bitumen break (extension at

6.1 From each lot of underlayment sheet, select sample rolls break on chart 3 jaw separation rate divided by chart

in accordance with Test Methods D 228. speed), and

b 5 initial jaw separation.

6.2 The rolls so selected shall constitute the representative

sample used for all subsequent observations and tests pertain- 7.3.3.2 Determine the average percent elongation at break

ing to the lot of material being examined. of the modified bitumen portion in each direction.

7.3.3.3 Calculate the average maximum load in each direc-

7. Test Methods

tion.

7.1 Conditioning—Unless otherwise specified, condition 7.3.4 Report—For each set of five specimens in each

direction report the individual measurements, the average and

test specimens for at least4hat23 6 2°C (73.4 6 3.6°F) and

50 6 5 % relative humidity prior to testing. standard deviation for the size of specimen (initial length

between jaws), maximum load in kN/m (lbf/in.), percent

7.2 Thickness:

7.2.1 Measure the thickness of the shingle underlayment in elongation at modified bitumen break, and method of deter-

mining elongation.

accordance with Test Methods D 5147.

7.2.2 Report the number of measurements, the average and 7.4 Adhesion to Plywood—This test method covers the

determination of the adhesive properties of the underlayment

standard deviation across the sheet.

7.3 Maximum Load and Elongation at Break—This test sheets to plywood, as set forth in Test Method D 903 except as

noted below.

method covers the determination of the maximum load and

elongation at break of the underlayment sheets, as set forth in 7.4.1 Specimen Preparation:

7.4.1.1 The test specimen shall consist of one piece of

Practice D 2523 except as noted below.

7.3.1 Specimens: underlayment sheet, 75 6 2by200 6 2mm(3 6 0.125 by 8

6 0.125 in.), bonded for 15 in. (75 3 125 mm) (3 by 5 in.) to

7.3.1.1 Prepare five specimens from each sample roll in

both the longitudinal and transverse directions. Specimens one piece of 6 mm ( ⁄4 in.) minimum thick plywood, APA

Grade, Exposure 1, 75 by 150 mm (3 by 6 in.). The plywood

shall be 25 mm (1 in.) 6 5 % wide by a minimum of 150 mm

(6 in.) 6 5 % long. For materials with high elongation the must not be reused for testing.

length of the sample may be reduced to 100 mm (4 in.) 6 5% 7.4.1.2 Roll test specimen three times back and forth with a

if necessary to avoid limitations imposed by dimensions of the roller which has a mass of 11.8 kg (26 lb) 6 0.5 %, diameter

test machine. of 125 mm (5 in.) 6 5 %, and width of 125 mm (5 in.) 6 5%

7.3.2 Procedure: (2 to 3 s per cycle).

7.3.2.1 Condition each specimen at least2hat23 6 2°C 7.4.1.3 At least five specimens shall be tested for each test

(73.4 6 3.6°F). temperature.

7.3.2.2 Use a constant rate of elongation (CRE) tension 7.4.1.4 It is recommended that specimens be assembled

testing machine, preferably with automatic load and strain individually. Cutting specimens to size after assembly may

recording equipment and clamps that permit a uniform clamp- influence the test results.

ing pressure on the specimen without slipping. The initial 7.4.2 Conditioning—Testing is to be performed at two

clamp separation shall be a minimum of 75 mm (3 in.)6 5% temperatures, 23.9 6 1.1°C (756 2°F) and 4.4 6 1.1°C (40 6

D 1970

2°F). Materials used to construct test specimens and the roller, 7.5.4.1 Determine the total percentage of moisture gained as

must be conditioned at the test temperature for at least 4 h prior follows:

to assembly. Similarly, test specimens must be conditioned at

m–m

o

Percentage of Moisture 5 3 100 (2)

the test temperatures for at least 1 h prior to testing.

m

o

NOTE 2—Adhesion to other potential wood deck materials may be

where:

determined by this test method, but it has been observed that substrates

m 5 mass of specimen after immersion, and

such as APA approved nonveneer sheets typically give greater adhesion

m 5 initial mass of specimen.

o

values than the minimum specified in this standard for plywood.

7.5.4.2 Calculate the average percentage of moisture gain

7.4.3 Apparatus:

and the standard deviation of all specimens measured.

7.4.3.1 Perform the test in a constant rate of extension type

7.5.5 Report—Report the individual specimen values, the

tester.

average and standard deviation.

7.4.3.2 The rate of travel of the power-actuated grip shall be

7.6 Thermal Stability—This test method determines the

50 mm (2 in.)/min 6 3 %. This rate which provides a laminate

thermal stability of the underlayment sheets as set forth in Test

separation rate of 25 mm (1 in.)/min 6 3 % shall be uniform

Method D 1204, except as noted below.

throughout the test.

7.6.1 Specimens

7.4.4 Procedure:

7.6.1.1 The test specimen shall consist of one piece of

7.4.4.1 Conduct the test after the test specimens have been

underlayment sheet, 100 6 2mmby100 6 2mm(4 6 0.125

conditioned at the test temperature (in the environmental

in. by 4 6 0.125 in.), centered and bonded (as described in

chamber) for 15 minutes. 1

7.4.2.1) to one piece of ⁄4-in. thick plywood, (APA Grade,

7.4.4.2 Separate the free end of the underlayment sheet

Exposure 1) 150 6 2mmby200 6 2mm(6 6 0.125 in. by

from the plywood for a distance of about 50 mm (2 in.) leaving

8 6 0.125 in.).

about 75 mm (3 in.) of bonded length. Place the specimen in

7.6.1.2 At least five specimens shall be tested for each

the testing machine by clamping the free end of the plywood in

sample roll.

one grip, turning back the free end of the sheet and clamping

7.6.2 Procedure:

it in the other grip. Maintain the specimen in the approximate

7.6.2.1 Set specimens at a 45° angle in a hot air circulating

plane of the clamps during the test. Peel at least three quarters

oven maintained at 70 6 2°C (158 6 4°F) for 14 days.

of the bonded area, even though a peel or stripping value may

7.6.2.2 At the end of the oven-exposure period, allow

be indicated before this point.

specimens to equilibrate to 23.9 6 1.1°C (75 6 2°F) and 50 6

7.4.5 Calculation—Determine the peel strength on the chart

5 % relative humidity for at least 4 hours.

as the average load line that will visually accommodate the

7.6.2.3 From the lower edge of the sheet measure to the

recorded curve. Record the load so indicated, corrected for

nearest 2.5 mm (0.1 in.) the furthest point of modified bitumen

tare.

flow. Estimate the average flow across the entire lower edge of

7.4.6 Reporting—For each series of tests, report the number

the sample.

of measurements, the average, and the standard deviation of all

7.6.3 Report—Report the individual specimen values, the

the test values in kg/30.5 cm width (lb/ft of width).

average and the standard deviation.

7.5 Water Absorption—This test method covers the deter-

7.7 Low Temperature Flexibility—This test method deter-

mination of the water absorption properties of the underlay-

mines the low temperature flexibility of the underlayment

ment sheet.

sheets. For the sheet material to be given a pass rating in this

7.5.1 Specimens:

test, the specimen must demonstrate either no visible signs of

7.5.1.1 Prepare five specimens measuring approximately

cracking in the sheet after bending at the test temperature

100 6 2mmby100 6 2mm(4 6 0.1 in. by 4 6 0.1 in.) from

through an angle of 1806 5° around a 25 mm (1 in.) 6 5%

each sample roll.

diameter mandrel in 2 6 1 s, or minor surface cracking is

7.5.1.2 Remove any release paper or release film from the

observed in the sheet and the head of water test, performed on

self-stick surface of the specimens.

a sheet of material that has been subjected to this bending.

7.5.2 Conditioning—Condition each specimen at least2hat

7.7.1 Specimens—Prepare five specimens from each roll in

23 6 2°C (73.4 6 3.6°F).

both the longitudinal and transverse direction for each tem-

7.5.3 Procedure:

perature to be tested. Specimens shall be 25 mm (1 in.) 6 5%

7.5.3.1 Determine the mass of each specimen to the nearest

wide by 150 mm (6 in.) 6 5 % long.

0.001 g.

7.7.2 Conditioning—Test at the temperature specified for

7.5.3.2 Immerse specimens in a distilled water bath main-

compliance in Table 1 (−29°C (−20°F)). Allow the refrigera-

tained at 50 6 2°C (122 6 4°F) for 100 6 4 hours.

tion unit,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.