ASTM D4693-03

(Test Method)Standard Test Method for Low-Temperature Torque of Grease-Lubricated Wheel Bearings

Standard Test Method for Low-Temperature Torque of Grease-Lubricated Wheel Bearings

SIGNIFICANCE AND USE

This test method differentiates among greases having distinctly different low-temperature characteristics. This test is used for specification purposes and correlates with its precursor which has been used to predict the performance of greases in automotive wheel bearings in low-temperature service.4 It is the responsibility of the user to determine the correlation with other types of service.

SCOPE

1.1 This test method determines the extent to which a test grease retards the rotation of a specially-manufactured, spring-loaded, automotive-type wheel bearing assembly when subjected to low temperatures. Torque values, calculated from restraining-force determinations, are a measure of the viscous resistance of the grease. This test method was developed with greases giving torques of less than 35 Nm at -40°C.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4693 – 03

Standard Test Method for

Low-Temperature Torque of Grease-Lubricated Wheel

1

Bearings

This standard is issued under the fixed designation D4693; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* E230 Specification and Temperature-Electromotive Force

(EMF) Tables for Standardized Thermocouples

1.1 This test method determines the extent to which a test

E563 Practice for Preparation and Use of Freezing Point

grease retards the rotation of a specially-manufactured, spring-

Reference Baths

loaded, automotive-type wheel bearing assembly when sub-

E 585/E 585M Specification for Compacted Mineral-

jected to low temperatures. Torque values, calculated from

Insulated, Metal-Sheathed, Base-Metal Thermocouple

restraining-force determinations, are a measure of the viscous

Cable

resistance of the grease. This test method was developed with

E 608/E 608M Specification for Metal-Sheathed Base-

greases giving torques of less than 35 N·m at−40°C.

Metal Thermocouples

1.2 The values stated in SI units are to be regarded as the

3

2.2 Military Standard:

standard. The values in parentheses are for information only.

MIL-G-10924F Specification for Automotive and Artillery

1.3 This standard does not purport to address all of the

2.3 Other Standard:

safety concerns, if any, associated with its use. It is the

Anti-Friction Bearing ManufacturerAssoc. (AFBMA) Stan-

responsibility of the user of this standard to establish appro-

dard19, 1974 (ANSI B. 3.19-1975)

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Terminology

2. Referenced Documents 3.1 Definitions:

2

3.1.1 automotive wheel bearing grease, n—a lubricating

2.1 ASTM Standards:

grease specifically formulated to lubricate automotive wheel

D217 Test Methods for Cone Penetration of Lubricating

bearings at relatively high grease temperatures and bearing

Grease

speeds. D3527

D1403 Test Method for Cone Penetration of Lubricating

3.1.2 lubricant, n—any material interposed between two

Grease Using One-Quarter and One-Half Scale Cone

surfaces that reduces the friction or wear between them.

Equipment

D4175

D3527 Test Method for Life Performance of Automotive

3.1.3 lubricating grease, n—a semi-fluid to solid product of

Wheel Bearing Grease

a dispersion of a thickener in a liquid lubricant.

D 4175 Terminology Relating to Petroleum, Petroleum

3.1.3.1 Discussion—Thedispersionofthethickenerformsa

Products, and Lubricants

two-phase system and immobilizes the liquid lubricant by

E1 Specification for ASTM Thermometers

surfacetensionandotherphysicalforces.Otheringredientsare

E77 Test Method for Inspection and Verification of Ther-

commonly included to impact special properties. D217

mometers

3.1.4 thickener, n—in lubricating grease, a substance com-

E220 Test Method for Calibration of Thermocouples by

posed of finely-divided particles dispersed in a liquid lubricant

Comparison Techniques

to form the product’s structure.

3.1.4.1 Discussion—The solid thickener can be fibers (such

1

as various metallic soaps) or plates or spheres (such as certain

This test method is under the jurisdiction of Committee D02 on Petroleum

ProductsandLubricantsandisthedirectresponsibilityofSubcommitteeD02.G0on

non-soap thickeners) which are insoluble or, at the most, only

Lubricating Grease.

very slightly soluble in the liquid lubricant. The general

Current edition approved Dec. 1, 2003. Published January 2004. Originally

e1 requirements are that the solid particles be extremely small,

approved in 1987. Last previous edition approved in 2002 as D4693–97 (2002) .

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 4693 – 03

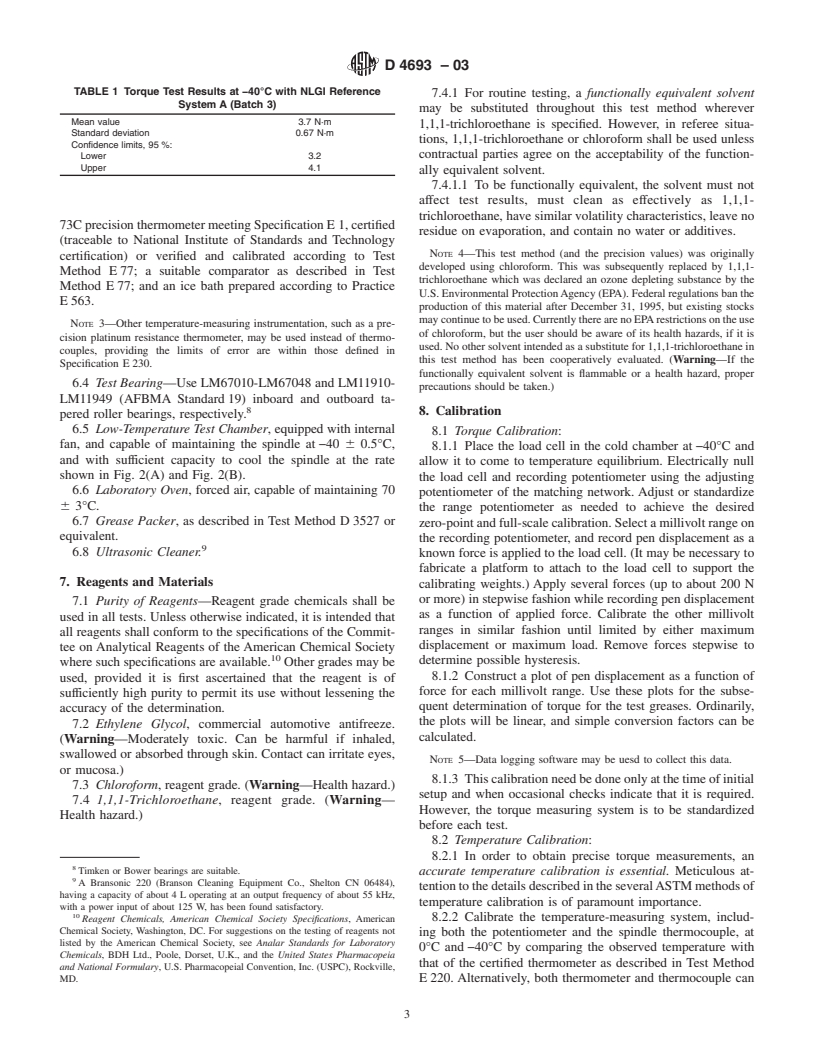

FIG. 1 Low-Temperature Torque Apparatus

which drive a specially-manufactured spindle-bearings-hub assembly

uniformly dispered, and capable of forming a relatively stable,

equipped with a spring-loading mechanism. For apparatus contained

gel-like structure with the liquid lubricant. D217

totally within the cold chamber, the drive sys

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.