ASTM D3134-15(2019)

(Practice)Standard Practice for Establishing Color and Gloss Tolerances

Standard Practice for Establishing Color and Gloss Tolerances

SIGNIFICANCE AND USE

5.1 Color specifications are centered around exact positions in color space. Correspondingly, gloss specifications are centered around an exact position on the gloss scale. Because it is difficult to achieve these exact positions repeatedly, it is necessary to specify tolerances that are acceptable to both the buyer and the seller. This practice details the procedure for accomplishing this goal.

SCOPE

1.1 This practice describes a procedure for establishing tolerances and evaluating the color and gloss of specimens with respect to specified standards. This practice is appropriate for nonfluorescent opaque specimens.

1.2 This practice does not indicate the extent of tolerances, but gives guidance on how they can be set. For product specification, the tolerances between specimens and the specified standard should be agreed upon between the purchaser and the seller.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3134 − 15 (Reapproved 2019)

Standard Practice for

Establishing Color and Gloss Tolerances

This standard is issued under the fixed designation D3134; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Permissible color and gloss deviations from a standard are generally dependent upon the color

discrimination of the observer, on the lighting and surround in which the material is viewed, and on

special considerations related to the design, manufacture, and practical usage of the colored material

or object. The tolerances, therefore, may be influenced by economic, technical, psychological, and

practical requirements. In many circumstances, acceptability of color and gloss deviations from a

standard may differ appreciably from perceptibility for many reasons. With proper allowances,

perceptibility data can be used as an aid to develop permissible tolerances. Finally, these consider-

ations should result in a specification acceptable to both buyer and seller.

1. Scope 2. Referenced Documents

1.1 This practice describes a procedure for establishing 2.1 ASTM Standards:

tolerancesandevaluatingthecolorandglossofspecimenswith D523 Test Method for Specular Gloss

respect to specified standards. This practice is appropriate for D1535 Practice for Specifying Color by the Munsell System

nonfluorescent opaque specimens. D1729 Practice for Visual Appraisal of Colors and Color

Differences of Diffusely-Illuminated Opaque Materials

1.2 This practice does not indicate the extent of tolerances,

D2244 Practice for Calculation of Color Tolerances and

but gives guidance on how they can be set. For product

Color Differences from Instrumentally Measured Color

specification, the tolerances between specimens and the speci-

Coordinates

fiedstandardshouldbeagreeduponbetweenthepurchaserand

D3964 Practice for Selection of Coating Specimens for

the seller.

Appearance Measurements

1.3 This standard does not purport to address all of the

D4449 Test Method for Visual Evaluation of Gloss Differ-

safety concerns, if any, associated with its use. It is the

ences Between Surfaces of Similar Appearance

responsibility of the user of this standard to establish appro-

D5531 GuideforPreparation,Maintenance,andDistribution

priate safety, health, and environmental practices and deter-

of Physical Product Standards for Color and Geometric

mine the applicability of regulatory limitations prior to use.

Appearance of Coatings

1.4 This international standard was developed in accor-

E284 Terminology of Appearance

dance with internationally recognized principles on standard-

E308 PracticeforComputingtheColorsofObjectsbyUsing

ization established in the Decision on Principles for the

the CIE System

Development of International Standards, Guides and Recom-

E312 Practice for Description and Selection of Conditions

mendations issued by the World Trade Organization Technical

for Photographing Specimens Using Analog (Film) Cam-

Barriers to Trade (TBT) Committee. 3

eras and Digital Still Cameras (DSC) (Withdrawn 2017)

1 2

This practice is under the jurisdiction of ASTM Committee E12 on Color and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Appearance and is the direct responsibility of Subcommittee E12.11 on Visual contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2019. Published November 2019. Originally the ASTM website.

approved in 1972. Last previous edition approved in 2015 as D3134 – 15. DOI: The last approved version of this historical standard is referenced on

10.1520/D3134-15R19. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3134 − 15 (2019)

E805 Practice for Identification of Instrumental Methods of 7. Procedure

Color or Color-Difference Measurement of Materials

7.1 Selection and Specification of Color and Gloss Stan-

E1164 PracticeforObtainingSpectrometricDataforObject-

dard:

Color Evaluation

7.1.1 Select a standard in accordance with Practice D3964

E1331 Test Method for Reflectance Factor and Color by

that is preferably the same type of material as the specimens to

Spectrophotometry Using Hemispherical Geometry

be evaluated for color or gloss, or both. Prepare, in sufficient

E1345 Practice for Reducing the Effect of Variability of

quantity,secondarystandardsinaccordancewithGuideD5531

Color Measurement by Use of Multiple Measurements

that are representative of the desired color and gloss, in the

E1349 Test Method for Reflectance Factor and Color by

permanent material. Standards should have the same spectral

Spectrophotometry Using Bidirectional (45°:0° or 0°:45°)

characteristics as the manufactured product. This is usually

Geometry

accomplished by use of the same colorant composition, incor-

E1360 Practice for Specifying Color by Using the Optical

porated in the same manner into the same material. The

Society of America Uniform Color Scales System

standard should have the same texture as the manufactured

E1499 Guide for Selection, Evaluation, and Training of

product.

Observers

7.1.1.1 In order to obtain a permanent record, use Practice

E1541 Practice for Specifying and Matching Color Using

E805 and either Test Method E1331 or Test Method E1349 to

the Colorcurve System (Withdrawn 2007)

correctly identify the instrumental measurement method. Mea-

2.2 CIE Publication:

sure the color in accordance with Practices E1164 and E805.

CIE Publication 015 Colorimetry

Report the color as described in Practice E308. Do this even if

2.3 ISO Standard:

the standard is textured. (If the standard is textured, note the

ISO 15930 Graphic Technology – Part 4: Complete ex-

texture orientation during measurement.) The variability of the

changeofCMYKandspotcolourprintingdatausingPDF

measurements due to texture may be reduced by following the

1.4 (PDF/X-la)

recommendations outlined in Practice E1345.

7.1.1.2 Visual Color Assessment—Use Guide E1499 to se-

3. Terminology

lect an observer for the assessment. Assess and specify the

3.1 Definitions—For definitions of terms related to this

color in terms of a color system described in Practices D1535,

practice see Terminology E284.

E1360,or E1541.

7.1.1.3 Measure the gloss in accordance with Test Method

4. Summary of Practice

D523, or evaluate it in accordance with Test Method D4449.

4.1 This practice consists of recommendations for the se-

7.1.1.4 Employ photography for permanently recording the

lection of a standard, the necessary physical measurements to

appearance of the surface texture (see Practice E312). While

assess the permanence of the standard to reproduce it when

Practice D3134 does not deal with texture tolerances or

needed, and to establish tolerances.

specifications, it should be recognized that significant differ-

ences in surface texture between standard and test specimens

4.2 Recommendationsaregivenforthedeterminationofthe

conformance of a specimen to preestablished color and gloss significantly affect both color and gloss, whether examined

visually or instrumentally. In the case of visual evaluation of

tolerances by instrumental or visual means.

the effect of color and gloss, differences can be minimized by

5. Significance and Use

strict adherence to recommended illuminating and viewing

geometry (see Practice D1729).

5.1 Color specifications are centered around exact positions

in color space. Correspondingly, gloss specifications are cen-

7.2 Selection and Specification of Color Tolerances:

tered around an exact position on the gloss scale. Because it is

7.2.1 The purchaser and the seller shall agree on color

difficult to achieve these exact positions repeatedly, it is

toleranceswithrespecttoapreviouslyselectedstandardandon

necessary to specify tolerances that are acceptable to both the

the color scales in which they are expressed. Selection of the

buyer and the seller. This practice details the procedure for

magnitude and direction of color tolerances shall be based on

accomplishing this goal.

careful consideration of all applicable factors. For example,

tolerances may be selected on the basis of perceptibility of the

6. Specimens

magnitude of color difference, rejection of or closer limits on

6.1 The exact method of preparation of the specimen shall

certain directions of color difference, and costs of controlling

be agreed upon between the purchaser and the seller. However,

the magnitude and direction of color difference. Recommen-

for the highest precision in instrumental measurements the

dations on color scales appear in CIE Publication No. CIE

specimens should be opaque, uniform in color, plane, and

Publication 015 and Practice E308.

uniform in texture. The specimens should be relatively

7.2.1.1 Express color differences between the specimen and

permanent, and capable of being cleaned. Preferred sizes of

the standard in terms of a set of three independent parameters.

specimens for visual evaluation are given in Practice D1729,

TheCIE1976L*a*b*(CIELAB)approximatelyuniformcolor

the specific size being governed by the use of the specimens.

space and color difference equations have been recommended

forusebytheInternationalCommissiononIllumination(CIE).

See Practice D2244 and Practice E308.While this color metric

Available from CIE (International Commission on Illumination), http://

www.techstreet.com. (CIELAB) is convenient for expressing color differences, it

D3134 − 15 (2019)

must be understood that a given calculated color difference in ances. To illustrate the principle recommended: (1) rate a

one region of color space may not represent the same visual number of specimens for acceptability, (2) plot them, and (3)

difference in other regions of color space.

prepare to draw the tolerance figure dictated by the data.

7.2.2 Glossdifferencescanaffectinstrumentalmeasurement

7.2.5.2 In such cases it is customary to plot the hue angle of

of color differences. Large gloss differences between visually

the standard by drawing a line from the origin (0, 0) through

identical colors can cause their color measurements to exhibit

the standard color on the a*b* plot. This line of constant hue

largercolordifferencesthaninfactexist.Whenusinghistorical

becomes the major axis. Similarly, a line perpendicular to the

data to establish color tolerances, exercise care to limit the

constant-hue line and passing through the standard color is a

specimens to those that have quite similar gloss values. When

line of constant chroma (or saturation) and becomes the minor

establishing gloss tolerances, be aware that changes in gloss

axis of the ellipse, if the data plot indicates the ellipse should

values may have an effect upon color measurements.

be symmetrical around the standard color. These lines assist in

7.2.3 Whencolordifferenceformulaeareusedinpractice,it

drawing the tolerance ellipse, Fig. 2(a).

is often desirable to identify the components of color

7.2.5.3 To determine lightness tolerances it is necessary to

difference, in terms of correlates of lightness, hue, and per-

plot the data for the same colors on a graph showing L* along

ceived chroma (saturation). It is also desirable to express color

with either a* and b*, and draw a tolerance ellipse as in Fig.

specificationsintermsofsuchcorrelates.TheCIEterminology

3(b). The choice between a* and b* is dictated by which of

appropriate to this usage is CIE 1976 lightness, CIE 1976

these attributes cover the greater range.

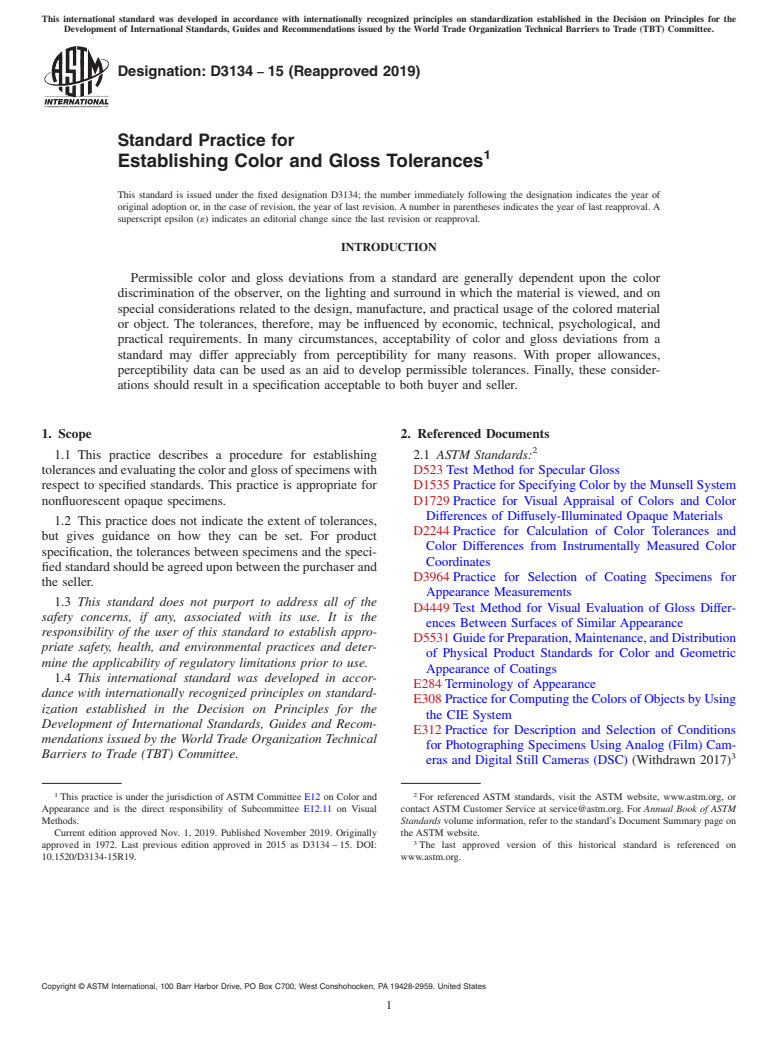

hue-angle, h , and CIE 1976 chroma, C* . Refer to Practice

ab ab

7.2.5.4 The scales on Fig. 2(a) and Fig. 3(b) are changed

D2244 and Practice E308 for equations and definitions. The

CIELAB 1976 hue-angle and chroma are illustrated in Fig. 1. from absolute values (L*, a*, b*) into color difference values

7.2.4 TheCIELABopponent-colorred-greencoordinate a*, (∆L*, ∆a*, ∆b*) as shown.

and the yellow-blue coordinate b* are defined in Practice

7.2.6 When tolerances for each color attribute (hue,

D2244 and Practice E308.

lightness,andsaturationorchroma)aresymmetricalintheplus

7.2.5 Graphical Interpretation of Historical Data:

and minus directions, the graphical representation is a regular

7.2.5.1 Color tolerances can be determined from a graphical

geometric figure that can be represented mathematically, as by

interpretation of historical data (batches accepted, rejected, or

the equation for an ellipse or an ellipsoid. It is also common to

considered borderline). Fig. 2 (a) and Fig. 3(b) show plots of

represent color tolerances by a set of six points: light and dark

specimensratedbymultipleobserverswithrespecttohowwell

limits, low and high saturation limits, and two adjacent hue

they match a standard, along with figures defining the toler-

limits. Such representation may involve some sacrifice in

accuracy of the tolerance specification and should be used with

care.

7.2.7 In general, color tolerances will not be symmetrically

located in all directions about the standard color in any color

space. (see Fig. 2(a) and Fig. 3(b)). However, in some

instances the asymmetry may be small enough that the color

tolerances may be represented by a single, overall color

difference (∆E) that represents the radius of a sphere about the

standard in color space.

7.2.8 Finally, there are many deviations from the regular

geometric figures described in 7.2.6 and depicted in Fig. 2(a)

and Fig. 3(b). For example, the tolerance figure may not be

regular; perhaps it will be an ovoid instead of an ellipse; its

major axis may deviate from the direction of constant hue; and

the standard color may be far from its center. Frequently when

it is necessary to set color tolerances, the amount of historical

accept-reject data will be too modest for this purpose. It is

therefore necessary to monitor tolerances, once set, to ensure

that they appropriately address the color quality control re-

quirement.

NOTE 1—Hue angle is measured in degrees starting with h =0 in

ab

7.2.9 When tolerance standards are prepared to illustrate the

the + a* (red) direction and increasing counterclockwise. Chroma is

measured as the length of the line from the neutral point (a*= b*=0)to

color in the hue, lightness, and saturation or chroma attributes

thesamplepoint.SamplePoint2hasalargervalueof h thanPoint1an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.