ASTM A240/A240M-15

(Specification)Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications

Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications

ABSTRACT

This specification covers chromium, chromium-nickel, and chromium-manganese-nickel stainless steel plate, sheet, and strip for pressure vessels and for general applications. The steel shall conform to the requirements as to chemical composition specified. The material shall conform to the mechanical properties specified.

SCOPE

1.1 This specification2 covers chromium, chromium-nickel, and chromium-manganese-nickel stainless steel plate, sheet, and strip for pressure vessels and for general applications.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished in inch-pound units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A240/A240M −15

StandardSpecification for

Chromium and Chromium-Nickel Stainless Steel Plate,

Sheet, and Strip for Pressure Vessels and for General

Applications

This standard is issued under the fixed designationA240/A240M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* A923 Test Methods for Detecting Detrimental Intermetallic

2 Phase in Duplex Austenitic/Ferritic Stainless Steels

1.1 This specification covers chromium, chromium-nickel,

E112 Test Methods for Determining Average Grain Size

and chromium-manganese-nickel stainless steel plate, sheet,

E527 Practice for Numbering Metals and Alloys in the

and strip for pressure vessels and for general applications.

Unified Numbering System (UNS)

1.2 The values stated in either SI units or inch-pound units

2.2 SAE Standard:

are to be regarded separately as standard. The values stated in

J 1086 Practice for Numbering Metals and Alloys (UNS)

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

3. General Requirements

values from the two systems may result in non-conformance

with the standard. 3.1 The following requirements for orders for material

furnished under this specification shall conform to the appli-

1.3 This specification is expressed in both inch-pound and

cable requirements of the current edition of Specification

SI units. However, unless the order specifies the applicable

A480/A480M.

“M” specification designation (SI units), the material shall be

3.1.1 Definitions;

furnished in inch-pound units.

3.1.2 General requirements for delivery;

1.4 This standard does not purport to address all of the

3.1.3 Ordering information;

safety concerns, if any, associated with its use. It is the

3.1.4 Process;

responsibility of the user of this standard to establish appro-

3.1.5 Special tests;

priate safety and health practices and determine the applica-

3.1.6 Heat treatment;

bility of regulatory limitations prior to use.

3.1.7 Dimensions and permissible variations;

3.1.8 Workmanship, finish and appearance;

2. Referenced Documents

3.1.9 Number of tests/test methods;

2.1 ASTM Standards:

3.1.10 Specimen preparation;

A370 Test Methods and Definitions for Mechanical Testing

3.1.11 Retreatment;

of Steel Products

3.1.12 Inspection;

A480/A480M Specification for General Requirements for

3.1.13 Rejection and rehearing;

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

3.1.14 Material test report;

Sheet, and Strip

3.1.15 Certification; and

3.1.16 Packaging, marking, and loading.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

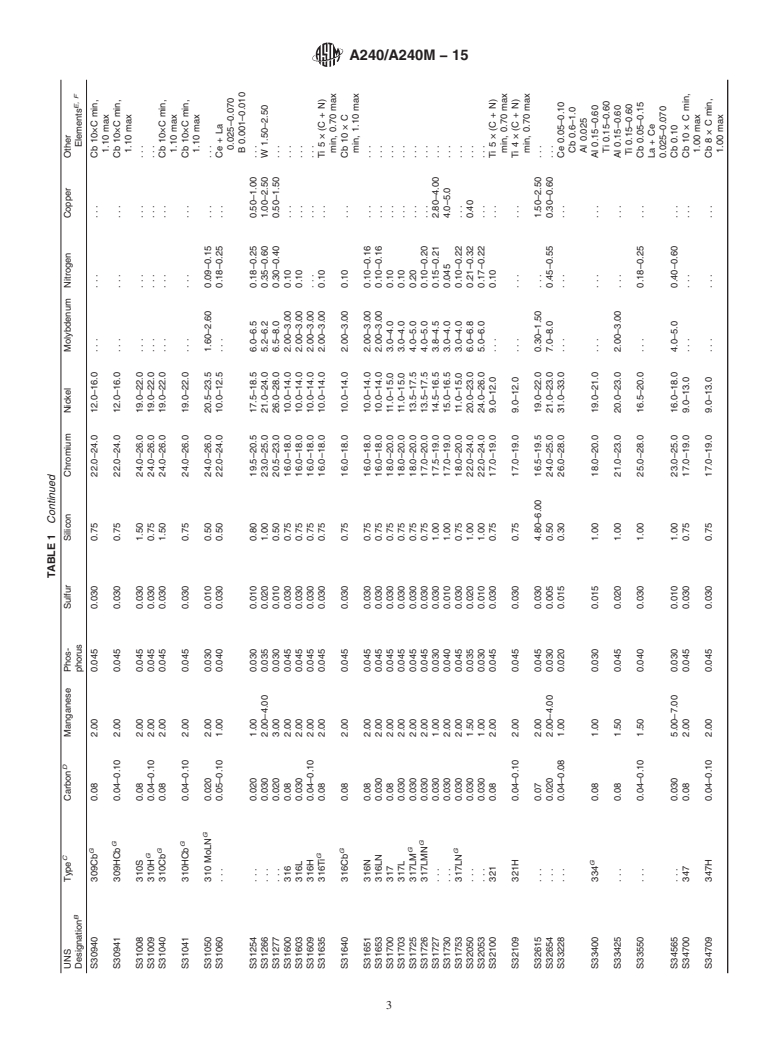

4. Chemical Composition

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

4.1 The steel shall conform to the requirements as to

A01.17 on Flat-Rolled and Wrought Stainless Steel.

Current edition approved Jan. 1, 2015. Published January 2015. Originally

chemical composition specified in Table 1 and shall conform to

approved in 1940. Last previous edition approved in 2014 as A240/A240M – 14.

applicable requirements specified in Specification A480/

DOI: 10.1520/A0240_A0240M-15.

2 A480M.

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SA-240 in Section II of that Code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A240/A240M−15

A

TABLE 1 Chemical Composition Requirements,%

C D

UNS Type Carbon Manganese Phos- Sulfur Silicon Chromium Nickel Molybdenum Nitrogen Copper Other

B E, F

Designation phorus Elements

Austenitic (Chromium-Nickel) (Chromium-Manganese-Nickel)

N08020 . . . 0.07 2.00 0.045 0.035 1.00 19.0–21.0 32.0–38.0 2.00–3.00 . . . 3.00–4.00 Cb 8×C min,

1.00 max

N08367 . . . 0.030 2.00 0.040 0.030 1.00 20.0–22.0 23.5–25.5 6.0–7.0 0.18–0.25 0.75 . . .

N08700 . . . 0.04 2.00 0.040 0.030 1.00 19.0–23.0 24.0–26.0 4.3–5.0 . . . 0.50 Cb 8×C min

0.40 max

G H

N08800 800 0.10 1.50 0.045 0.015 1.00 19.0–23.0 30.0–35.0 . . . . . . 0.75 Fe 39.5 min

Al 0.15–0.60

Ti 0.15–0.60

G H

N08810 800H 0.05–0.10 1.50 0.045 0.015 1.00 19.0–23.0 30.0–35.0 . . . . . . 0.75 Fe 39.5 min

Al 0.15–0.60

Ti 0.15–0.60

H

N08811 . . . 0.06–0.10 1.50 0.040 0.015 1.00 19.0–23.0 30.0–35.0 . . . . . . 0.75 Fe 39.5 min

I

Ti 0.25–0.60

I

Al 0.25–0.60

G

N08904 904L 0.020 2.00 0.045 0.035 1.00 19.0–23.0 23.0–28.0 4.00–5.00 0.10 1.00–2.00 . . .

N08925 . . . 0.020 1.00 0.045 0.030 0.50 19.0–21.0 24.0–26.0 6.00–7.00 0.10–0.20 0.80–1.50 . . .

N08926 . . . 0.020 2.00 0.030 0.010 0.50 19.0–21.0 24.0–26.0 6.00–7.00 0.15–0.25 0.50–1.50 . . .

S20100 201 0.15 5.50–7.50 0.060 0.030 1.00 16.0–18.0 3.5–5.5 . . . 0.25 . . . . . .

S20103 . . . 0.03 5.50–7.50 0.045 0.030 0.75 16.0–18.0 3.5–5.5 . . . 0.25 . . . . . .

S20153 . . . 0.03 6.40–7.50 0.045 0.015 0.75 16.0–17.5 4.0–5.0 . . . 0.10–0.25 1.00 . . .

S20161 . . . 0.15 4.00–6.00 0.040 0.040 3.00–4.00 15.0–18.0 4.0–6.0 . . . 0.08–0.20 . . . . . .

S20200 202 0.15 7.50–10.00 0.060 0.030 1.00 17.0–19.0 4.0–6.0 . . . 0.25 . . . . . .

S20400 . . . 0.030 7.00–9.00 0.040 0.030 1.00 15.0–17.0 1.50–3.00 . . . 0.15–0.30 . . . . . .

S20431 . . . 0.12 5.00–7.00 0.045 0.030 1.00 17.0–18.0 2.0–4.0 . . . 0.10–0.25 1.50–3.50 . . .

S20432 . . . 0.08 3.00–5.00 0.045 0.030 1.00 17.0–18.0 4.0–6.0 . . . 0.05–0.20 2.00–3.00 . . .

S20433 . . . 0.08 5.50–7.50 0.045 0.030 1.00 17.0–18.0 3.5–5.5 . . . 0.10–0.25 1.50–3.50 . . .

J

S20910 XM-19 0.06 4.00–6.00 0.040 0.030 0.75 20.5–23.5 11.5–13.5 1.50–3.00 0.20–0.40 . . . Cb 0.10–0.30

V 0.10–0.30

J

S21400 XM-31 0.12 14.00–16.00 0.045 0.030 0.30–1.00 17.0–18.5 1.00 . . . 0.35 min . . . . . .

J

S21600 XM-17 0.08 7.50–9.00 0.045 0.030 0.75 17.5–22.0 5.0–7.0 2.00–3.00 0.25–0.50 . . . . . .

J

S21603 XM-18 0.03 7.50–9.00 0.045 0.030 0.75 17.5–22.0 5.0–7.0 2.00–3.00 0.25–0.50 . . . . . .

S21640 . . . 0.08 3.50–6.50 0.060 0.030 1.00 17.5–19.5 4.0–6.5 0.50–2.00 0.08–0.30 . . . Cb 0.10–1.00

S21800 . . . 0.10 7.00–9.00 0.060 0.030 3.5–4.5 16.0–18.0 8.0–9.0 . . . 0.08–0.18 . . . . . .

J

S21904 XM-11 0.04 8.00–10.00 0.060 0.030 0.75 19.0–21.5 5.5–7.5 . . . 0.15–0.40 . . . . . .

J

S24000 XM-29 0.08 11.50–14.50 0.060 0.030 0.75 17.0–19.0 2.3–3.7 . . . 0.20–0.40 . . . . . .

S30100 301 0.15 2.00 0.045 0.030 1.00 16.0–18.0 6.0–8.0 . . . 0.10 . . . . . .

G

S30103 301L 0.03 2.00 0.045 0.030 1.00 16.0–18.0 6.0–8.0 . . . 0.20 . . . . . .

G

S30153 301LN 0.03 2.00 0.045 0.030 1.00 16.0–18.0 6.0–8.0 . . . 0.07–0.20 . . . . . .

S30200 302 0.15 2.00 0.045 0.030 0.75 17.0–19.0 8.0–10.0 . . . 0.10 . . . . . .

S30400 304 0.07 2.00 0.045 0.030 0.75 17.5–19.5 8.0–10.5 . . . 0.10 . . . . . .

S30403 304L 0.030 2.00 0.045 0.030 0.75 17.5–19.5 8.0–12.0 . . . 0.10 . . . . . .

S30409 304H 0.04–0.10 2.00 0.045 0.030 0.75 18.0–20.0 8.0–10.5 . . . . . . . . . . . .

S30415 . . . 0.04–0.06 0.80 0.045 0.030 1.00–2.00 18.0–19.0 9.0–10.0 . . . 0.12–0.18 . . . Ce 0.03–0.08

S30435 . . . 0.08 2.00 0.045 0.030 1.00 16.0–18.0 7.0–9.0 . . . . . . 1.50–3.00 . . .

S30441 . . . 0.08 2.00 0.045 0.030 1.0–2.0 17.5–19.5 8.0–10.5 . . . 0.10 1.5–2.5 Cb 0.1–0.5

W 0.2–0.8

S30451 304N 0.08 2.00 0.045 0.030 0.75 18.0–20.0 8.0–10.5 . . . 0.10–0.16 . . . . . .

J

S30452 XM-21 0.08 2.00 0.045 0.030 0.75 18.0–20.0 8.0–10.5 . . . 0.16–0.30 . . . . . .

S30453 304LN 0.030 2.00 0.045 0.030 0.75 18.0–20.0 8.0–12.0 . . . 0.10–0.16 . . . . . .

S30500 305 0.12 2.00 0.045 0.030 0.75 17.0–19.0 10.5–13.0 . . . . . . . . . . . .

S30530 . . . 0.08 2.00 0.045 0.030 0.50–2.50 17.0–20.5 8.5–11.5 0.75–1.50 . . . 0.75–3.50 . . .

S30600 . . . 0.018 2.00 0.020 0.020 3.7–4.3 17.0–18.5 14.0–15.5 0.20 . . . 0.50 . . .

S30601 . . . 0.015 0.50–0.80 0.030 0.013 5.0–5.6 17.0–18.0 17.0–18.0 0.20 0.05 0.35 . . .

S30615 . . . 0.16–0.24 2.00 0.030 0.030 3.2–4.0 17.0–19.5 13.5–16.0 . . . . . . . . . Al 0.80–1.50

S30815 . . . 0.05–0.10 0.80 0.040 0.030 1.40–2.00 20.0–22.0 10.0–12.0 . . . 0.14–0.20 . . . Ce 0.03–0.08

S30908 309S 0.08 2.00 0.045 0.030 0.75 22.0–24.0 12.0–15.0 . . . . . . . . . . . .

G

S30909 309H 0.04–0.10 2.00 0.045 0.030 0.75 22.0–24.0 12.0–15.0 . . . . . . . . . . . .

A240/A240M−15

TABLE1 Continued

C D

UNS Type Carbon Manganese Phos- Sulfur Silicon Chromium Nickel Molybdenum Nitrogen Copper Other

B E, F

Designation phorus Elements

G

S30940 309Cb 0.08 2.00 0.045 0.030 0.75 22.0–24.0 12.0–16.0 . . . . . . . . . Cb 10×C min,

1.10 max

G

S30941 309HCb 0.04–0.10 2.00 0.045 0.030 0.75 22.0–24.0 12.0–16.0 . . . . . . . . . Cb 10×C min,

1.10 max

S31008 310S 0.08 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . . . . . . . .

G

S31009 310H 0.04–0.10 2.00 0.045 0.030 0.75 24.0–26.0 19.0–22.0 . . . . . . . . . . . .

G

S31040 310Cb 0.08 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . . . . . Cb 10×C min,

1.10 max

G

S31041 310HCb 0.04–0.10 2.00 0.045 0.030 0.75 24.0–26.0 19.0–22.0 . . . . . . . . . Cb 10×C min,

1.10 max

G

S31050 310 MoLN 0.020 2.00 0.030 0.010 0.50 24.0–26.0 20.5–23.5 1.60–2.60 0.09–0.15 . . . . . .

S31060 . . . 0.05–0.10 1.00 0.040 0.030 0.50 22.0–24.0 10.0–12.5 . . . 0.18–0.25 . . . Ce + La

0.025–0.070

B 0.001–0.010

S31254 . . . 0.020 1.00 0.030 0.010 0.80 19.5–20.5 17.5–18.5 6.0–6.5 0.18–0.25 0.50–1.00 . . .

S31266 . . . 0.030 2.00–4.00 0.035 0.020 1.00 23.0–25.0 21.0–24.0 5.2–6.2 0.35–0.60 1.00–2.50 W 1.50–2.50

S31277 . . . 0.020 3.00 0.030 0.010 0.50 20.5–23.0 26.0–28.0 6.5–8.0 0.30–0.40 0.50–1.50 . . .

S31600 316 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10 . . . . . .

S31603 316L 0.030 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10 . . . . . .

S31609 316H 0.04–0.10 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 . . . . . . . . .

G

S31635 316Ti 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10 . . . Ti 5 × (C + N)

min, 0.70 max

G

S31640 316Cb 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10 . . . Cb 10 × C

min, 1.10 max

S31651 316N 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10–0.16 . . . . . .

S31653 316LN 0.030 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10–0.16 . . . . . .

S31700 317 0.08 2.00 0.045 0.030 0.75 18.0–20.0 11.0–15.0 3.0–4.0 0.10 . . . . . .

S31703 317L 0.030 2.00 0.045 0.030 0.75 18.0–20.0 11.0–15.0 3.0–4.0 0.10 . . . . . .

G

S31725 317LM 0.030 2.00 0.045 0.030 0.75 18.0–20.0 13.5–17.5 4.0–5.0 0.20 . . . . . .

G

S31726 317LMN 0.030 2.00 0.045 0.030 0.75 17.0–20.0 13.5–17.5 4.0–5.0 0.10–0.20 . . . . . .

S31727 . . . 0.030 1.00 0.030 0.030 1.00 17.5–19.0 14.5–16.5 3.8–4.5 0.15–0.21 2.80–4.00 . . .

S31730 . . . 0.030 2.00 0.040 0.010 1.00 17.0–19.0 15.0–16.5 3.0–4.0 0.045 4.0–5.0 . . .

G

S31753 317LN 0.030 2.00 0.045 0.030 0.75 18.0–20.0 11.0–15.0 3.0–4.0 0.10–0.22 . . . . . .

S32050 . . . 0.030 1.50 0.035 0.020 1.00 22.0–24.0 20.0–23.0 6.0–6.8 0.21–0.32 0.40 . . .

S32053 . . . 0.030 1.00 0.030 0.010 1.00 22.0–24.0 24.0–26.0 5.0–6.0 0.17–0.22 . . . . . .

S32100 321 0.08 2.00 0.045 0.030 0.75 17.0–19.0 9.0–12.0 . . . 0.10 . . . Ti 5 × (C + N)

min, 0.70 max

S32109 321H 0.04–0.10 2.00 0.045 0.030 0.75 17.0–19.0 9.0–12.0 . . . . . . . . . Ti 4 × (C + N)

min, 0.70 max

S32615 . . . 0.07 2.00 0.045 0.030 4.80–6.00 16.5–19.5 19.0–22.0 0.30–1.50 . . . 1.50–2.50 . . .

S32654 . . . 0.020 2.00–4.00 0.030 0.005 0.50 24.0–25.0 21.0–23.0 7.0–8.0 0.45–0.55 0.30–0.60 . . .

S33228 . . . 0.04–0.08 1.00 0.020 0.015 0.30 26.0–28.0 31.0–33.0 . . . . . . . . . Ce 0.05–0.10

Cb 0.6–1.0

Al 0.025

G

S33400 334 0.08 1.00 0.030 0.015 1.00 18.0–20.0 19.0–21.0 . . . . . . . . . Al 0.15–0.60

Ti 0.15–0.60

S33425 . . . 0.08 1.50 0.045 0.020 1.00 21.0–23.0 20.0–23.0 2.00–3.00 . . . . . . Al 0.15–0.60

Ti 0.15–0.60

S33550 . . . 0.04–0.10 1.50 0.040 0.030 1.00 25.0–28.0 16.5–20.0 . . . 0.18–0.25 . . . Cb 0.05–0.15

La+Ce

0.025–0.070

S34565 . . . 0.030 5.00–7.00 0.030 0.010 1.00 23.0–25.0 16.0–18.0 4.0–5.0 0.40–0.60 . . . Cb 0.10

S34700 347 0.08 2.00 0.045 0.030 0.75 17.0–19.0 9.0–13.0 . . . . . . . . . Cb 10×Cmin,

1.00 max

S34709 347H 0.04–0.10 2.00 0.045 0.030 0.75 17.0–19.0 9.0–13.0 . . . . . . . . . Cb8×Cmin,

1.00 max

A240/A240M−15

TABLE1 Continued

C D

UNS Type Carbon Manganese Phos- Sulfur Silicon Chromium Nickel Molybdenum Nitrogen Copper Other

B E, F

Designation phorus Elements

S34751 347LN 0.005–0.020 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . 0.06–0.10 . . . Cb 0.20–0.50,

15×Cmin

S34800 348 0.08 2.00 0.045 0.030 0.75 17.0–19.0 9.0–13.0 . . . . . . . . . (Cb + Ta) 10×C

min, 1.00 max

Ta 0.10

Co 0.20

S34809 348H 0.04–0.10 2.00 0.045 0.030 0.75 17.0–19.0 9.0–13.0 . . . . . . . . . (Cb + Ta) 8×C

min, 1.00 max

Ta 0.10

Co 0.20

S35045 . . . 0.06–0.10 1.50 0.045 0.015 1.00 25.0–29.0 32.0–37.0 . . . . . . 0.75 Al 0.15–0.60

Ti 0.15–0.60

S35115 . . . 0.030 1.00 0.045 0.015 0.50–1.50 23.0–25.0 19.0–22.0 1.50–2.50 0.20–0.30 . . . . . .

S35125 . . . 0.10 1.00–1.50 0.045 0.015 0.50 20.0–23.0 31.0–35.0 2.00–3.00 . . . . . . Cb 0.25–0.60

S35135 . . . 0.08 1.00 0.045 0.015 0.60–1.00 20.0–25.0 30.0–38.0 4.0–4.8 . . . 0.75 Ti 0.40–1.00

S35140 . . . 0.10 1.00–3.00 0.045 0.030 0.75 20.0–22.0 25.0–27.0 1.00–2.00 0.08–0.20 . . . Cb 0.25–0.75

S35315 . . . 0.04–0.08 2.00 0.040 0.030 1.20–2.00 24.0–26.0 34.0–36.0 . . . 0.12–0.18 . . . Ce 0.03–0.10

J

S38100 XM-15 0.08 2.00 0.030 0.030 1.50–2.50 17.0–19.0 17.5–18.5 . . . . . . . . . . . .

S38815 . . . 0.030 2.00 0.040 0.020 5.50–6.50 13.0–15.0 13.0–17.0 0.75–1.50 . . . 0.75–1.50 Al 0.30

Duplex (Austenitic-Ferritic)

S31200 . . . 0.030 2.00 0.045 0.030 1.00 24.0–26.0 5.5–6.5 1.20–2.00 0.14–0.20 . . . . . .

S31260 . . . 0.03 1.00 0.030 0.030 0.75 24.0–26.0 5.5–7.5 2.5–3.5 0.10–0.30 0.20–0.80 W 0.10–0.50

S31803 . . . 0.030 2.00 0.030 0.020 1.00 21.0–23.0 4.5–6.5 2.5–3.5 0.08–0.20 . . . . . .

S32001 . . . 0.030 4.00–6.00 0.040 0.030 1.00 19.5–21.5 1.00–3.00 0.60 0.05–0.17 1.00 . . .

S32003 . . . 0.030 2.00 0.030 0.020 1.00 19.5–22.5 3.0–4.0 1.50–2.00 0.14–0.20 . . . . . .

S32101 . . . 0.040 4.00–6.00 0.040 0.030 1.00 21.0–22.0 1.35–1.70 0.10–0.80 0.20–0.25 0.10–0.80 . . .

S32202 . . . 0.030 2.00

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A240/A240M − 14 A240/A240M − 15

Standard Specification for

Chromium and Chromium-Nickel Stainless Steel Plate,

Sheet, and Strip for Pressure Vessels and for General

Applications

This standard is issued under the fixed designation A240/A240M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers chromium, chromium-nickel, and chromium-manganese-nickel stainless steel plate, sheet, and

strip for pressure vessels and for general applications.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable “M”

specification designation (SI units), the material shall be furnished in inch-pound units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A480/A480M Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip

A923 Test Methods for Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless Steels

E112 Test Methods for Determining Average Grain Size

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

2.2 SAE Standard:

J 1086 Practice for Numbering Metals and Alloys (UNS)

3. General Requirements

3.1 The following requirements for orders for material furnished under this specification shall conform to the applicable

requirements of the current edition of Specification A480/A480M.

3.1.1 Definitions;

3.1.2 General requirements for delivery;

3.1.3 Ordering information;

3.1.4 Process;

3.1.5 Special tests;

3.1.6 Heat treatment;

3.1.7 Dimensions and permissible variations;

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.17

on Flat-Rolled and Wrought Stainless Steel.

Current edition approved May 1, 2014Jan. 1, 2015. Published May 2014January 2015. Originally approved in 1940. Last previous edition approved in 20132014 as

A240/A240M – 13c.A240/A240M – 14. DOI: 10.1520/A0240_A0240M-14.10.1520/A0240_A0240M-15.

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-240 in Section II of that Code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A240/A240M − 15

3.1.8 Workmanship, finish and appearance;

3.1.9 Number of tests/test methods;

3.1.10 Specimen preparation;

3.1.11 Retreatment;

3.1.12 Inspection;

3.1.13 Rejection and rehearing;

3.1.14 Material test report;

3.1.15 Certification; and

3.1.16 Packaging, marking, and loading.

4. Chemical Composition

4.1 The steel shall conform to the requirements as to chemical composition specified in Table 1 and shall conform to applicable

requirements specified in Specification A480/A480M.

5. Mechanical Properties

5.1 The material shall conform to the mechanical properties specified in Table 2.

5.2 When specified by the purchaser, Charpy impact tests shall be performed in accordance with Supplementary Requirement

S1.

6. Materials for High-Temperature Service

6.1 The austenitic H Types shall conform to an average grain size of ASTM No. 7 or coarser as measured by Test Methods E112.

6.2 Supplementary Requirement S2 shall be invoked when non-H grade austenitic stainless steels are ordered for ASME Code

applications for service above 1000°F [540°C].

6.3 Grade S31060, unless otherwise specified in the purchase order, shall conform to an average grain size of ASTM No. 7 or

coarser, as measured by Test Methods E112.

7. Keywords

7.1 chromium; chromium-nickel stainless steel; chromium-manganese-nickel stainless steel; pressure vessels

A240/A240M − 15

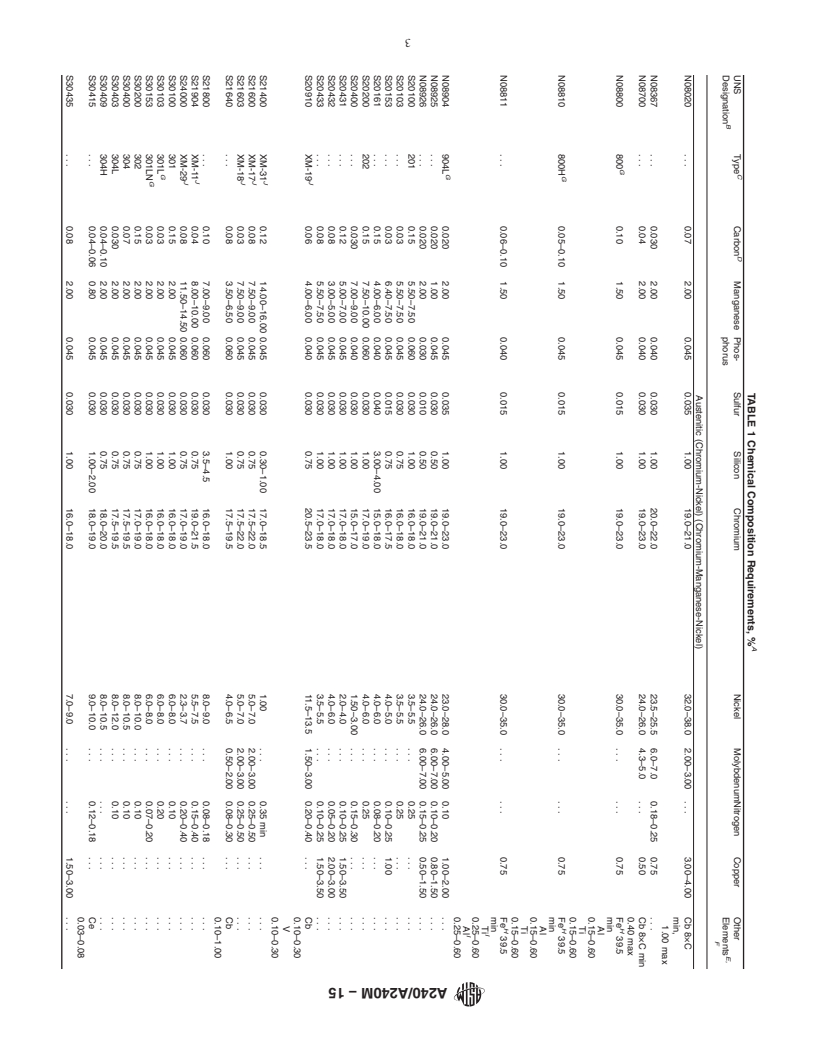

A

TABLE 1 Chemical Composition Requirements, %

C D

UNS Type Carbon Manganese Phos- Sulfur Silicon Chromium Nickel MolybdenumNitrogen Copper Other

B E,

Designation phorus Elements

F

Austenitic (Chromium-Nickel) (Chromium-Manganese-Nickel)

N08020 . . . 0.07 2.00 0.045 0.035 1.00 19.0–21.0 32.0–38.0 2.00–3.00 . . . 3.00–4.00 Cb 8×C

min,

1.00 max

N08367 . . . 0.030 2.00 0.040 0.030 1.00 20.0–22.0 23.5–25.5 6.0–7.0 0.18–0.25 0.75 . . .

N08700 . . . 0.04 2.00 0.040 0.030 1.00 19.0–23.0 24.0–26.0 4.3–5.0 . . . 0.50 Cb 8×C min

0.40 max

G H

N08800 800 0.10 1.50 0.045 0.015 1.00 19.0–23.0 30.0–35.0 . . . . . . 0.75 Fe 39.5

min

Al

0.15–0.60

Ti

0.15–0.60

G H

N08810 800H 0.05–0.10 1.50 0.045 0.015 1.00 19.0–23.0 30.0–35.0 . . . . . . 0.75 Fe 39.5

min

Al

0.15–0.60

Ti

0.15–0.60

H

N08811 . . . 0.06–0.10 1.50 0.040 0.015 1.00 19.0–23.0 30.0–35.0 . . . . . . 0.75 Fe 39.5

min

I

Ti

0.25–0.60

I

Al

0.25–0.60

G

N08904 904L 0.020 2.00 0.045 0.035 1.00 19.0–23.0 23.0–28.0 4.00–5.00 0.10 1.00–2.00 . . .

N08925 . . . 0.020 1.00 0.045 0.030 0.50 19.0–21.0 24.0–26.0 6.00–7.00 0.10–0.20 0.80–1.50 . . .

N08926 . . . 0.020 2.00 0.030 0.010 0.50 19.0–21.0 24.0–26.0 6.00–7.00 0.15–0.25 0.50–1.50 . . .

S20100 201 0.15 5.50–7.50 0.060 0.030 1.00 16.0–18.0 3.5–5.5 . . . 0.25 . . . . . .

S20103 . . . 0.03 5.50–7.50 0.045 0.030 0.75 16.0–18.0 3.5–5.5 . . . 0.25 . . . . . .

S20153 . . . 0.03 6.40–7.50 0.045 0.015 0.75 16.0–17.5 4.0–5.0 . . . 0.10–0.25 1.00 . . .

S20161 . . . 0.15 4.00–6.00 0.040 0.040 3.00–4.00 15.0–18.0 4.0–6.0 . . . 0.08–0.20 . . . . . .

S20200 202 0.15 7.50–10.00 0.060 0.030 1.00 17.0–19.0 4.0–6.0 . . . 0.25 . . . . . .

S20400 . . . 0.030 7.00–9.00 0.040 0.030 1.00 15.0–17.0 1.50–3.00 . . . 0.15–0.30 . . . . . .

S20431 . . . 0.12 5.00–7.00 0.045 0.030 1.00 17.0–18.0 2.0–4.0 . . . 0.10–0.25 1.50–3.50 . . .

S20432 . . . 0.08 3.00–5.00 0.045 0.030 1.00 17.0–18.0 4.0–6.0 . . . 0.05–0.20 2.00–3.00 . . .

S20433 . . . 0.08 5.50–7.50 0.045 0.030 1.00 17.0–18.0 3.5–5.5 . . . 0.10–0.25 1.50–3.50 . . .

J

S20910 XM-19 0.06 4.00–6.00 0.040 0.030 0.75 20.5–23.5 11.5–13.5 1.50–3.00 0.20–0.40 . . . Cb

0.10–0.30

V

0.10–0.30

J

S21400 XM-31 0.12 14.00–16.00 0.045 0.030 0.30–1.00 17.0–18.5 1.00 . . . 0.35 min . . . . . .

J

S21600 XM-17 0.08 7.50–9.00 0.045 0.030 0.75 17.5–22.0 5.0–7.0 2.00–3.00 0.25–0.50 . . . . . .

J

S21603 XM-18 0.03 7.50–9.00 0.045 0.030 0.75 17.5–22.0 5.0–7.0 2.00–3.00 0.25–0.50 . . . . . .

S21640 . . . 0.08 3.50–6.50 0.060 0.030 1.00 17.5–19.5 4.0–6.5 0.50–2.00 0.08–0.30 . . . Cb

0.10–1.00

S21800 . . . 0.10 7.00–9.00 0.060 0.030 3.5–4.5 16.0–18.0 8.0–9.0 . . . 0.08–0.18 . . . . . .

J

S21904 XM-11 0.04 8.00–10.00 0.060 0.030 0.75 19.0–21.5 5.5–7.5 . . . 0.15–0.40 . . . . . .

J

S24000 XM-29 0.08 11.50–14.50 0.060 0.030 0.75 17.0–19.0 2.3–3.7 . . . 0.20–0.40 . . . . . .

S30100 301 0.15 2.00 0.045 0.030 1.00 16.0–18.0 6.0–8.0 . . . 0.10 . . . . . .

G

S30103 301L 0.03 2.00 0.045 0.030 1.00 16.0–18.0 6.0–8.0 . . . 0.20 . . . . . .

G

S30153 301LN 0.03 2.00 0.045 0.030 1.00 16.0–18.0 6.0–8.0 . . . 0.07–0.20 . . . . . .

S30200 302 0.15 2.00 0.045 0.030 0.75 17.0–19.0 8.0–10.0 . . . 0.10 . . . . . .

S30400 304 0.07 2.00 0.045 0.030 0.75 17.5–19.5 8.0–10.5 . . . 0.10 . . . . . .

S30403 304L 0.030 2.00 0.045 0.030 0.75 17.5–19.5 8.0–12.0 . . . 0.10 . . . . . .

S30409 304H 0.04–0.10 2.00 0.045 0.030 0.75 18.0–20.0 8.0–10.5 . . . . . . . . . . . .

S30415 . . . 0.04–0.06 0.80 0.045 0.030 1.00–2.00 18.0–19.0 9.0–10.0 . . . 0.12–0.18 . . . Ce

0.03–0.08

S30435 . . . 0.08 2.00 0.045 0.030 1.00 16.0–18.0 7.0–9.0 . . . . . . 1.50–3.00 . . .

A240/A240M − 15

TABLE 1 Continued

C D

UNS Type Carbon Manganese Phos- Sulfur Silicon Chromium Nickel MolybdenumNitrogen Copper Other

B E,

Designation phorus Elements

F

S30441 . . . 0.08 2.00 0.045 0.030 1.0–2.0 17.5–19.5 8.0–10.5 . . . 0.10 1.5–2.5 Cb 0.1–0.5

W 0.2–0.8

S30451 304N 0.08 2.00 0.045 0.030 0.75 18.0–20.0 8.0–10.5 . . . 0.10–0.16 . . . . . .

J

S30452 XM-21 0.08 2.00 0.045 0.030 0.75 18.0–20.0 8.0–10.5 . . . 0.16–0.30 . . . . . .

S30453 304LN 0.030 2.00 0.045 0.030 0.75 18.0–20.0 8.0–12.0 . . . 0.10–0.16 . . . . . .

S30500 305 0.12 2.00 0.045 0.030 0.75 17.0–19.0 10.5–13.0 . . . . . . . . . . . .

S30530 . . . 0.08 2.00 0.045 0.030 0.50–2.50 17.0–20.5 8.5–11.5 0.75–1.50 . . . 0.75–3.50 . . .

S30600 . . . 0.018 2.00 0.020 0.020 3.7–4.3 17.0–18.5 14.0–15.5 0.20 . . . 0.50 . . .

S30601 . . . 0.015 0.50–0.80 0.030 0.013 5.0–5.6 17.0–18.0 17.0–18.0 0.20 0.05 0.35 . . .

S30615 . . . 0.16–0.24 2.00 0.030 0.030 3.2–4.0 17.0–19.5 13.5–16.0 . . . . . . . . . Al

0.80–1.50

S30815 . . . 0.05–0.10 0.80 0.040 0.030 1.40–2.00 20.0–22.0 10.0–12.0 . . . 0.14–0.20 . . . Ce

0.03–0.08

S30908 309S 0.08 2.00 0.045 0.030 0.75 22.0–24.0 12.0–15.0 . . . . . . . . . . . .

G

S30909 309H 0.04–0.10 2.00 0.045 0.030 0.75 22.0–24.0 12.0–15.0 . . . . . . . . . . . .

G

S30940 309Cb 0.08 2.00 0.045 0.030 0.75 22.0–24.0 12.0–16.0 . . . . . . . . . Cb 10×C

min,

1.10 max

G

S30941 309HCb 0.04–0.10 2.00 0.045 0.030 0.75 22.0–24.0 12.0–16.0 . . . . . . . . . Cb 10×C

min,

1.10 max

S31008 310S 0.08 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . . . . . . . .

G

S31009 310H 0.04–0.10 2.00 0.045 0.030 0.75 24.0–26.0 19.0–22.0 . . . . . . . . . . . .

G

S31040 310Cb 0.08 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . . . . . Cb 10×C

min,

1.10 max

G

S31041 310HCb 0.04–0.10 2.00 0.045 0.030 0.75 24.0–26.0 19.0–22.0 . . . . . . . . . Cb 10×C

min,

1.10 max

G

S31050 310 MoLN 0.020 2.00 0.030 0.010 0.50 24.0–26.0 20.5–23.5 1.60–2.60 0.09–0.15 . . . . . .

S31060 . . . 0.05–0.10 1.00 0.040 0.030 0.50 22.0–24.0 10.0–12.5 . . . 0.18–0.25 . . . Ce + La

0.025–0.070

B 0.001–0.010

S31254 . . . 0.020 1.00 0.030 0.010 0.80 19.5–20.5 17.5–18.5 6.0–6.5 0.18–0.25 0.50–1.00 . . .

S31266 . . . 0.030 2.00–4.00 0.035 0.020 1.00 23.0–25.0 21.0–24.0 5.2–6.2 0.35–0.60 1.00–2.50 W

1.50–2.50

S31277 . . . 0.020 3.00 0.030 0.010 0.50 20.5–23.0 26.0–28.0 6.5–8.0 0.30–0.40 0.50–1.50 . . .

S31600 316 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10 . . . . . .

S31603 316L 0.030 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10 . . . . . .

S31609 316H 0.04–0.10 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 . . . . . . . . .

G

S31635 316Ti 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10 . . . Ti 5 × (C +

N)

min, 0.70

max

G

S31640 316Cb 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10 . . . Cb 10 × C

min, 1.10

max

S31651 316N 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10–0.16 . . . . . .

S31653 316LN 0.030 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 2.00–3.00 0.10–0.16 . . . . . .

S31700 317 0.08 2.00 0.045 0.030 0.75 18.0–20.0 11.0–15.0 3.0–4.0 0.10 . . . . . .

S31703 317L 0.030 2.00 0.045 0.030 0.75 18.0–20.0 11.0–15.0 3.0–4.0 0.10 . . . . . .

G

S31725 317LM 0.030 2.00 0.045 0.030 0.75 18.0–20.0 13.5–17.5 4.0–5.0 0.20 . . . . . .

G

S31726 317LMN 0.030 2.00 0.045 0.030 0.75 17.0–20.0 13.5–17.5 4.0–5.0 0.10–0.20 . . . . . .

S31727 . . . 0.030 1.00 0.030 0.030 1.00 17.5–19.0 14.5–16.5 3.8–4.5 0.15–0.21 2.80–4.00 . . .

S31730 . . . 0.030 2.00 0.040 0.010 1.00 17.0–19.0 15.0–16.5 3.0–4.0 0.045 4.0–5.0 . . .

G

S31753 317LN 0.030 2.00 0.045 0.030 0.75 18.0–20.0 11.0–15.0 3.0–4.0 0.10–0.22 . . . . . .

A240/A240M − 15

TABLE 1 Continued

C D

UNS Type Carbon Manganese Phos- Sulfur Silicon Chromium Nickel MolybdenumNitrogen Copper Other

B E,

Designation phorus Elements

F

S32050 . . . 0.030 1.50 0.035 0.020 1.00 22.0–24.0 20.0–23.0 6.0–6.8 0.21–0.32 0.40 . . .

S32053 . . . 0.030 1.00 0.030 0.010 1.00 22.0–24.0 24.0–26.0 5.0–6.0 0.17–0.22 . . . . . .

S32100 321 0.08 2.00 0.045 0.030 0.75 17.0–19.0 9.0–12.0 . . . 0.10 . . . Ti 5 × (C +

N) min,

0.70 max

S32109 321H 0.04–0.10 2.00 0.045 0.030 0.75 17.0–19.0 9.0–12.0 . . . . . . . . . Ti 4 × (C +

N) min,

0.70 max

S32615 . . . 0.07 2.00 0.045 0.030 4.80–6.00 16.5–19.5 19.0–22.0 0.30–1.50 . . . 1.50–2.50 . . .

S32654 . . . 0.020 2.00–4.00 0.030 0.005 0.50 24.0–25.0 21.0–23.0 7.0–8.0 0.45–0.55 0.30–0.60 . . .

S33228 . . . 0.04–0.08 1.00 0.020 0.015 0.30 26.0–28.0 31.0–33.0 . . . . . . . . . Ce

0.05–0.10

Cb 0.6–1.0

Al 0.025

G

S33400 334 0.08 1.00 0.030 0.015 1.00 18.0–20.0 19.0–21.0 . . . . . . . . . Al

0.15–0.60

Ti

0.15–0.60

S33425 . . . 0.08 1.50 0.045 0.020 1.00 21.0–23.0 20.0–23.0 2.00–3.00 . . . . . . Al

0.15–0.60

Ti

0.15–0.60

S33550 . . . 0.04–0.10 1.50 0.040 0.030 1.00 25.0–28.0 16.5–20.0 . . . 0.18–0.25 . . . Cb

0.05–0.15

La + Ce

0.025–0.070

S34565 . . . 0.030 5.00–7.00 0.030 0.010 1.00 23.0–25.0 16.0–18.0 4.0–5.0 0.40–0.60 . . . Cb 0.10

S34700 347 0.08 2.00 0.045 0.030 0.75 17.0–19.0 9.0–13.0 . . . . . . . . . Cb 10 × C

min, 1.00

max

S34709 347H 0.04–0.10 2.00 0.045 0.030 0.75 17.0–19.0 9.0–13.0 . . . . . . . . . Cb 8 × C

min, 1.00

max

S34751 347LN 0.005–0.020 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . 0.06–0.10 . . . Cb

0.20–0.50,

15 × C min

S34800 348 0.08 2.00 0.045 0.030 0.75 17.0–19.0 9.0–13.0 . . . . . . . . . (Cb + Ta)

10×C min,

1.00 max

Ta 0.10

Co 0.20

S34809 348H 0.04–0.10 2.00 0.045 0.030 0.75 17.0–19.0 9.0–13.0 . . . . . . . . . (Cb + Ta)

8×C min,

1.00 max

Ta 0.10

Co 0.20

S35045 . . . 0.06–0.10 1.50 0.045 0.015 1.00 25.0–29.0 32.0–37.0 . . . . . . 0.75 Al

0.15–0.60

Ti

0.15–0.60

S35115 . . .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.