ASTM C694-90a(2000)

(Test Method)Standard Test Method for Weight Loss (Mass Loss) of Sheet Steel During Immersion in Sulfuric Acid Solution

Standard Test Method for Weight Loss (Mass Loss) of Sheet Steel During Immersion in Sulfuric Acid Solution

SCOPE

1.1 This test method covers the evaluation of the weight-loss (mass loss) characteristics of sheet steel in sulfuric acid solution.

1.2 This test method provides means of rating the effectiveness of in-plant pretreatment acid solutions in preparing steel surfaces for porcelain enameling.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C694–90a(Reapproved 2000)

Standard Test Method for

Weight Loss (Mass Loss) of Sheet Steel During Immersion

1

in Sulfuric Acid Solution

This standard is issued under the fixed designation C 694; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

In the manufacture of porcelain-enameled ware, formed steel articles are pretreated to ensure

enamel adherence. The pretreatment comprises, in part, of etching the steel surface with sulfuric acid

solution and in depositing nickel on the steel surface from a nickelous sulfate solution. Conditions are

maintained to provide a minimum amount of metal removal (weight loss) (mass loss) in the acid

solution and a minimum amount of nickel deposition. These minimums are particularly critical in

direct-on enameling in which the ground-coat enamel with its adherence-promoting oxides is omitted.

1. Scope ditioned by controlled solution of panels of the same sheet

steel. The specimens are rinsed, dried, and reweighed after the

1.1 This test method covers the evaluation of the weight-

timed exposure.

loss (mass loss) characteristics of sheet steel in sulfuric acid

3.2 Values of weight loss (mass loss) per unit area are

solution.

calculated for the four acid immersion periods and, if desired,

1.2 This test method provides means of rating the effective-

the rate of weight loss (mass loss) per unit area per unit time is

ness of in-plant pretreatment acid solutions in preparing steel

calculated.

surfaces for porcelain enameling.

1.3 The values stated in inch-pound units are to be regarded

4. Significance and Use

as the standard. The values in parentheses are for information

4.1 The results of this test method can be used to evaluate

only.

the pickle weight-loss (mass loss) characteristics of a given lot

1.4 This standard does not purport to address all of the

of sheet steel in dilute sulfuric acid solution, and may enable

safety concerns, if any, associated with its use. It is the

the enamel processor to select a pickling time that will provide

responsibility of the user of this standard to establish appro-

satisfactory porcelain enamel bond.

priate safety and health practices and determine the applica-

4.2 The results of this test method can be used to evaluate

bility of regulatory limitations prior to use.

the effectiveness of the enamel processor’s pretreatment sys-

2. Terminology tem in preparing the steel for porcelain enameling, and may aid

the processor in obtaining satisfactory porcelain enamel bond.

2.1 Definitions:

2.1.1 quarter lines—imaginarylinesparalleltothedirection

5. Apparatus

of rolling, positioned at a distance from the sheet mill edge

5.1 Analytical Balance, accurate to 0.01 g.

equal to one quarter of the sheet width.

5.2 Linear Measuring Device.

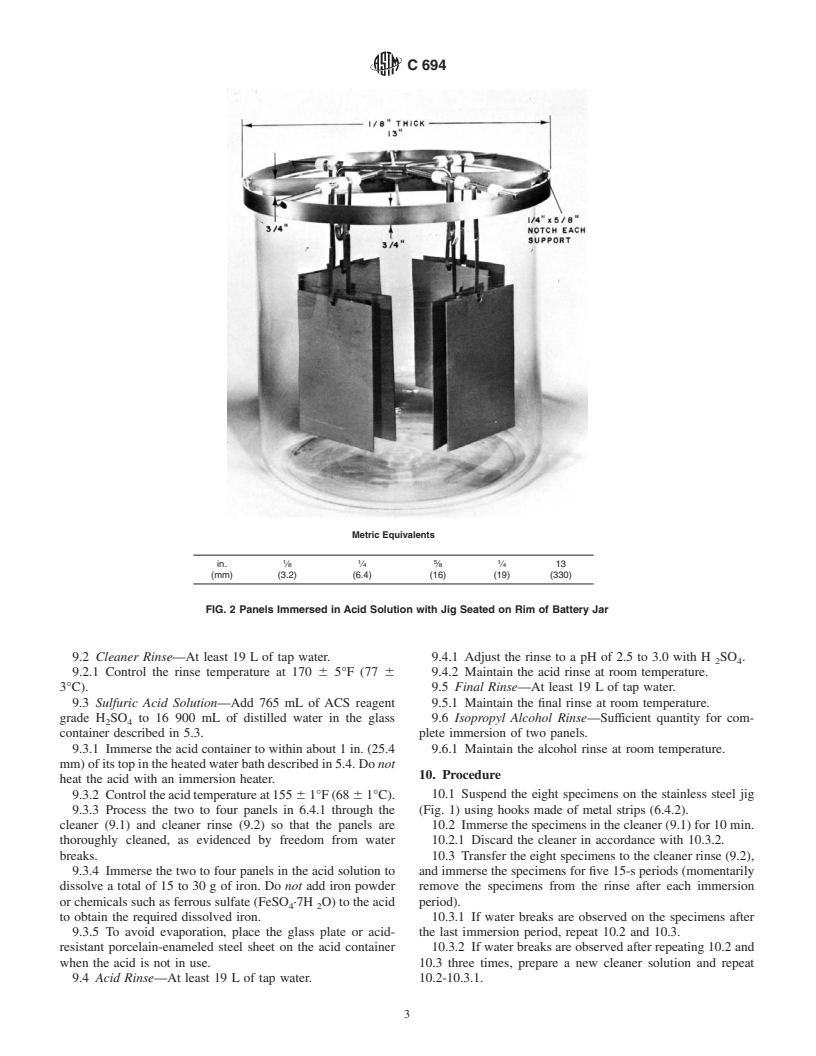

3. Summary of Test Method 5.3 Borosilicate Glass Container, having an inside diameter

1

of about 11 ⁄2 in. (290 mm) and an outside depth of about 11 in.

3.1 Representative sheet-steel specimens are selected, mea-

(280 mm).

sured, cleaned, and weighed prior to immersion for measured

5.4 Water Bath, heated, of sufficient size to immerse the

periods in a bath of dilute sulfuric acid that has been precon-

glass container (5.3) to within about 1 in. (25 mm) of its top.

5.5 Glass Plate or Acid-Resistant Porcelain-Enameled Steel

1

This test method is under the jurisdiction ofASTM Committee B08 on Metallic

Sheet, sufficient to cover the container described in 5.3.

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.12 on

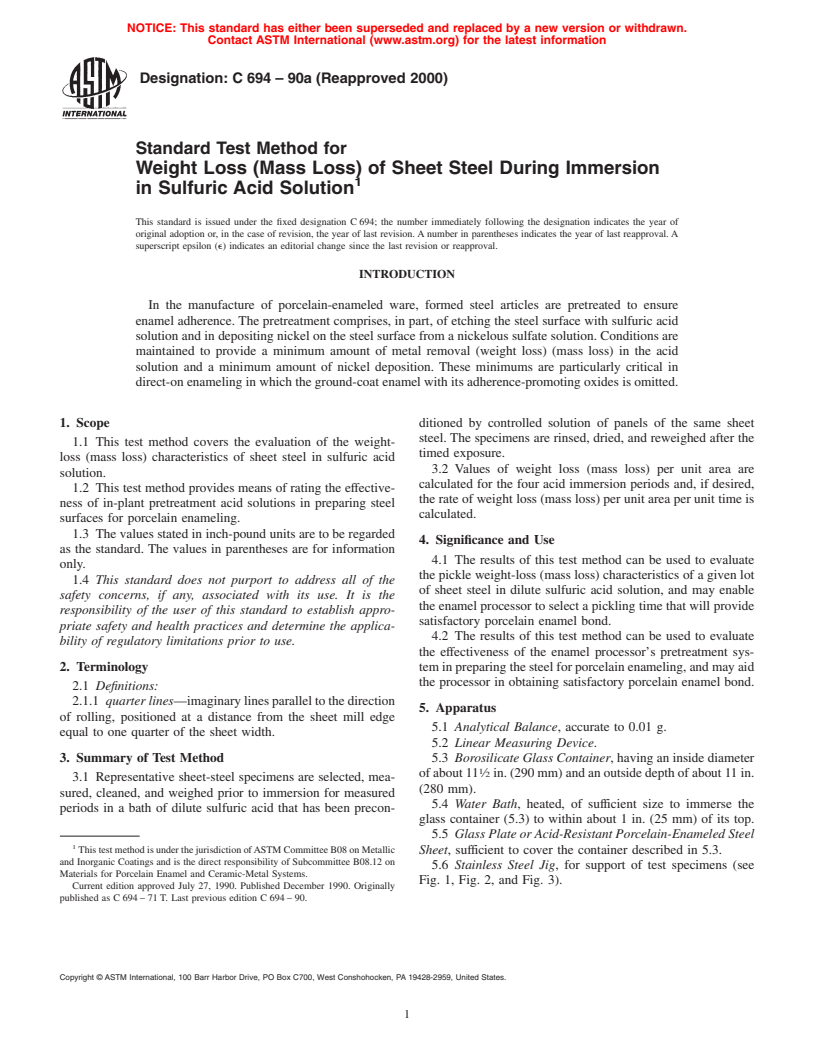

5.6 Stainless Steel Jig, for support of test specimens (see

Materials for Porcelain Enamel and Ceramic-Metal Systems.

Fig. 1, Fig. 2, and Fig. 3).

Current edition approved July 27, 1990. Published December 1990. Originally

published as C 694 – 71 T. Last previous edition C 694 – 90.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C694

Metric Equivalents

1

in. ⁄4 45 6

(mm) (6) (102) (127) (127)

NOTE 1—All materials are of Type 316 stainless steel.

FIG. 1 Specimens Suspended from Stainless-Steel Jig

6. Reagents and Materials 8. Test Specimens

6.1 Distilled Water. 8.1 File edges of the eight test specimens lightly to remove

6.2 Isopropyl Alcohol ((CH ) CHOH). shearing burrs.

3 2

6.3 Methyl Alcohol (CH OH). 8.1.1 Punch or drill a hole near one end, at the center of the

3

specimen width.

6.4 Steel Sheet, sufficient in size to provide the panels and

strips described in 6.4.1 and 6.4.2, and to provide the test 8.1.2 Determine the width, W, a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.