ASTM D6039/D6039M-96

(Specification)Standard Specification for Crates, Wood, Open and Covered

Standard Specification for Crates, Wood, Open and Covered

SCOPE

1.1 This specification covers five types and two styles of open and one type, and one style of covered wood crates designed for net loads not exceeding 4000lb [1800kg]. Open crates are suitable for shipment of items which are not readily susceptible to damage from outside forces and which require only limited protection against the elements.

1.2 If environmental protection is necessary, use of a shroud or a covered crate should be considered. With the exception of Type III, Style B crates, the crates included in this specification are for use in domestic and overseas shipment of net loads not over 4000lb [1800kg]. Use shall be confined to items falling within the dimensions and weight limitations of the types and grades specified in Table 1.

1.3 In general, Style A crates have heavier components and are to withstand rather severe handling and multiple shipment (heavy-duty), while Style B crates should be confined to handling and shipping that impose only light to moderate hazards on the container (light duty). Types I, IV, and V crates are general purpose types; Type II crates are designed for items such as ladders, tubing, extrusions, or wallboard which do not require blocking, bracing, or cushioning; and Type III, Style B crates are designed for such self-supporting material as channels, angles, or other structural members where the container serves only as a means for more convenient stacking and handling.

1.4 The values stated in either inch-pound units or SI units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5.1 Safety- Materials used for the crates shall present no environmental or toxicological hazards as defined by current industry standard or applicable federal or state laws or regulations.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6039/D6039M – 96

Standard Specification for

Crates, Wood, Open and Covered

This standard is issued under the fixed designation D 6039/D6039M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope industry standard or applicable federal or state laws or regula-

tions.

1.1 This specification covers five types and two styles of

open and one type, and one style of covered wood crates

2. Referenced Documents

designed for net loads not exceeding 4000 lb [1800 kg]. Open

2.1 ASTM Standards:

crates are suitable for shipment of items which are not readily

D 996 Terminology of Packaging and Distribution Environ-

susceptible to damage from outside forces and which require

ments

only limited protection against the elements.

D 3951 Practice for Commercial Packaging

1.2 If environmental protection is necessary, use of a shroud

D 3953 Specification for Strapping, Flat Steel and Seals

or a covered crate should be considered. With the exception of

D 4442 Test Methods for Direct Moisture Content of Wood

Type III, Style B crates, the crates included in this specification

and Wood-Base Materials

are for use in domestic and overseas shipment of net loads not

D 4444 Test Methods for Use and Calibration of Hand-Held

over 4000 lb [1800 kg]. Use shall be confined to items falling

Moisture Meters

within the dimensions and weight limitations of the types and

D 4675 Guide for Selection and Use of Flat Strapping

grades specified in Table 1.

Materials

1.3 In general, Style A crates have heavier components and

F 1667 Specification for Driven Fasteners: Nails, Staples

are to withstand rather severe handling and multiple shipment

and Spikes

(heavy-duty), while Style B crates should be confined to

2.2 ASME/ANSI Standards:

handling and shipping that impose only light to moderate

A208.1 Mat-Formed Wood Particleboard

hazards on the container (light-duty). Types I, IV, and V crates

B18.2.1 Square and Hex Bolts and Screws Inch Series

are general purpose types; Type II crates are designed for items

B18.5 Round Head Bolts (Inch Series)

such as ladders, tubing, extrusions, or wallboard which do not

2.3 APA Standard:

require blocking, bracing, or cushioning; and Type III, Style B

PRP-108 Performance Standards and Policies for

crates are designed for such self-supporting material as chan-

Structural-Use Panels

nels, angles, or other structural members where the container

2.4 National Motor Freight Traffıc Association Standard:

serves only as a means for more convenient stacking and

National Motor Freight Classification

handling.

2.5 Uniform Classification Committee Standard:

1.4 The values stated in either inch-pound or SI units shall

Uniform Freight Classification

be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system

3. Terminology

must be used independently of the other, without combining

3.1 General definitions for packaging and distribution envi-

values in any way.

ronments are found in Terminology D 996.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

Annual Book of ASTM Standards, Vol 15.09.

1.5.1 Safety—Materials used for the crates shall present no

Annual Book of ASTM Standards, Vol 04.10.

environmental or toxicological hazards as defined by current Annual Book of ASTM Standards, Vol 15.08.

Available from the American Society of Mechanical Engineers, United Engi-

neering Center, 345 East 47th St., New York, NY 10017.

Available from the Engineered Wood Assoc., P.O. Box 11700, Tacoma, WA

98411-0700.

1 7

This specification is under the jurisdiction of ASTM Committee D-10 on Available from the American Trucking Association, Inc., Traffic Department,

Packaging and is the direct responsibility of Subcommittee D10.26 on Wooden 2200 Mill Rd., Alexandria, VA 22314.

Crates, Pallets, and Skids. Available from the Uniform Classification Committee, Tariff Publishing Of-

Current edition approved Oct. 10, 1996. Published December 1996. ficer, Room 1106, 222 South Riverside Plaza, Chicago, IL 60606.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6039/D6039M

TABLE 1 Crate Classification

Style A, Heavy Duty Style B, Light Duty

Type Inside Dimensions, max Inside Dimensions, max

Maximum Net Maximum Net

Load (lb/kg) Load (lb/kg)

Length (ft/mm) Width (ft/mm) Height (ft/mm) Length (ft/mm) Width (ft/mm) Height (ft/mm)

I 250 [113] 4 [1200] 3 [900] 3 [900] 200 [90] 4 [1200] 3 [900] 3 [900]

A

II 1000 [450] 12 [3600] 4 [900] 2 [450] No Style B

III No Style A No load or size restriction except as limited by handling methods

IV 1000 [450] 6 [1800] 4 [900] 4 [900] No Style B

B

V 2500 [1125] 12 [3600] 6 [1800] 6 [1800] 4000 [1800] 32 [9600] 6 [1800] 10 [3000]

A

Items such as ladders, tubing, and extrusions weighing less than 200 lb [90 kg] and not exceeding 20 ft [6000 mm] long, 3 ft [900 mm] wide and 2 ft [600 mm] high

may be packed in Type II crates.

B

Type V, Styles A and B crates shall be further classified as being either nondemountable or demountable. Type V, Style B crates may be open or covered.

4. Classification 6.5 Nails—Nails shall be steel and shall be coolers, sinkers,

corkers, or common in accordance with Specification F 1667.

4.1 Crates covered by this specification shall be of the types

6.6 Bolts and Nuts—Bolts and nuts including lag bolts shall

and styles shown in Table 1 for maximum net loads and

conform to ASME/ANSI B18.2.1 and ASME/ANSI B18.5.

maximum dimensions.

6.7 Washers—Washers shall be round carbon steel general

5. Ordering Information

purpose washers.

6.8 Metal Strapping—Strapping used to reinforce crates

5.1 Purchasers should select the preferred options permitted

shall conform to Specification D 3953 Type 1, 2, or 3 as

herein, and include the following information in procurement

applicable. Strapping finish shall be as specified herein.

documents:

5.1.1 Title, number, and date of this specification,

7. Construction

5.1.2 Type and style of crate required (see 4.1),

7.1 Nails and Nailing—For fastening covering materials to

5.1.3 Combination of end and side panels required (see

members, the length of nails shall not be less than 1 in. [25

7.7.2),

mm] and shall not exceed the sum of the thickness of the

5.1.4 When interior side battens shall be replaced by exte-

covering material and the member. Nail sizes specified for the

rior side cleats for forklift handling (see 7.7.4),

fabrication of the various crates are based on Groups I and II

5.1.5 Alternative method of assembly of demountable crate

wood. When Groups III and IV woods are used, nail sizes may

if required (see 7.10.6),

be onepenny size smaller than those specified. The patterns to

5.1.6 When demountability is required for Type V crates

be used for the nailing of two flat pieces of lumber shall

(see 7.10 and 7.11),

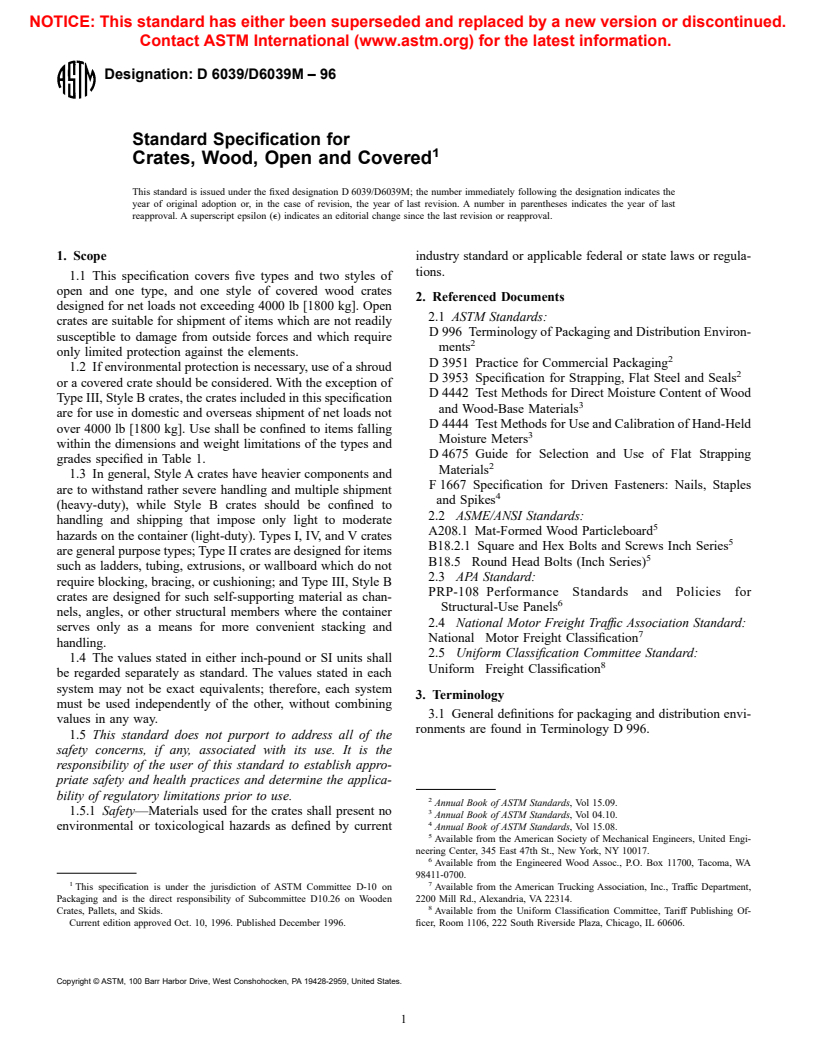

conform to the details shown in Fig. 1 or as specified herein.

5.1.7 Whether Type V, Style B crates shall be open or

Unless otherwise specified herein, the following requirements

covered (see 7.11),

shall determine size, placement, and quantity of nails:

5.1.8 Whether covering material shall be other than as

7.1.1 All adjacent crate members shall be fastened to each

specified (see 7.11.6),

other, either directly or by means of the covering.

5.1.9 When demountability is required for covered crates

7.1.2 All nails that are not to be clinched shall be cement

(see 7.11.7),

coated or mechanically deformed (helically or annularly

5.1.10 When assembly instructions shall be furnished (see

threaded).

7.12),

7.1.3 Nails shall be driven through the thinner member into

5.1.11 When the crates are to be furnished other than

the thicker member wherever possible.

knocked down (see 9.1), and

7.1.4 When the flat faces of lumber are nailed together and

5.1.12 When packaging (see 9.1) and marking (see 9.2) is

the combined thickness is 3 in. [75 mm] or less (except for the

other than as specified.

top joists and covering material), nails shall be long enough to

6. Materials

pass through both thicknesses and shall be clinched not less

1 3

6.1 Materials—Materials not specified shall be selected by than ⁄4in. [6 mm] nor more than ⁄8 in. [9 mm].

the contractor/crate builder and shall be subject to all the 7.1.5 When the flat faces of lumber are nailed together and

the combined thickness is more than 3 in. [75 mm] or when the

provisions of this specification. Materials shall be free of

defects which adversely affect performance or serviceability of flat face of one or more pieces is nailed to the edge or end face

of another, nails shall not be clinched. The portion of the nail

the finished product.

6.2 Lumber—Wood members shall be the industries’ com- in the thicker piece shall not be less than two times the length

monly accepted practice for nominal sizes and wood groups, of the nail in the thinner pieces for tenpenny nails and smaller,

unless otherwise specified. and not less than 1 ⁄2 in. [38 mm] for twelvepenny nails and

6.3 Plywood/Standard Use—All plywood shall be larger.

performance-rated paneling manufactured in accordance with 7.1.6 When splitting occurs with the use of diamond-point

APA PRP-108, or ANSI A208.1. nails, the nails shall be slightly blunted. When blunting does

6.4 Paper-Overlaid Veneer—Paper-overlaid veneer shall be not prevent the splitting, holes slightly smaller than the

of a type providing the maximum protection against the diameter of the nail shall be drilled for each nail.

hazards in shipment and storage. 7.1.7 Nails shall be driven so that neither the head nor the

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6039/D6039M

shank, even though the threaded portion may have a greater

diameter than the shank. The diameter of the lead hole for the

threaded part of the lag bolt shall be as in Table 2.

7.2.1 Lag bolts shall be placed by being turned in the holes

the full length of the bolt and shall not be driven in with a

hammer or by any similar means. If for any reason the thread

in the wood is stripped when the lag bolts are placed, the lag

bolt shall be removed and placed in a new hole near the old

position. A flat washer shall be used under the head of each lag

bolt and under the nut of each carriage bolt. After the nut is

placed, the thread of the carriage bolt projecting beyond the nut

shall be painted with a suitable metal primer or similar

material.

7.3 Staples—The crown of the staples used for fastening

covering materials to frame members shall not be less than

⁄8in. [9 mm]. The length of the staples shall not exceed the sum

of the thickness of the covering material and the frame

member; except that, staples shall never be less than 1 in. [25

mm] in length.

7.4 Splices—Splices and butt joints made in frame members

and skids of long crates shall be as shown in Fig. 2.

7.5 Type I Crates—Style A—The load and size limitations

shall be as specified in Table 1. Style A crates shall be used

only for items forming a Type I load and weighing not more

than 250 lb [113 kg].

7.5.1 Base—Skids shall be nominal 2 by 4 lumber. Diago-

nals shall be 1 by 4 in. [25 by 100 mm] in size. End floor

members shall be the same thickness and width as the skid,

except that when used as load-bearing members, their sizes

shall be as specified in Table 3. End floor members shall be

bolted to each skid with ⁄8-in. [9-mm] diameter carriage bolts

as specified in 7.2. Single-piece rubbing strips used on each

NOTE 1—All widths are nominal. skid shall be minimum 3 by 4 in. [75 by 100 mm] in size and

NOTE 2—Similar patterns shall be used when boards cross at angles

beveled at each end at an angle of 45° for at least one-half their

other 90°.

thickness. The rubbing strip length shall be less than the skid

FIG. 1 Nailing Patterns

length to allow open space at each end for sling and fork truck

handling. The open space shall not be less than 4 in. [100 mm]

point projects above the surface of the wood. Occasional

and not more than 10-in. [250-mm] long. On crates over 36-in.

overdriving will be permitted, but nails shall not be overdriven

[900-mm] long, the rubbing strip length shall be adjusted to

more than one eighth the thickness of the piece holding the

provide a distance of not more than 28 in. [700 mm] between

head.

end openings.

7.1.8 Nails shall be positioned not less than the thickness of

7.5.2 Side, End, and Top Panels—All members of the side,

the piece from the end nor less than one half the thickness of

end, and top panels shall be nominal 1 by 4 lumber. Nailing and

the piece from the side edge of the lumber whenever possible.

nailing patterns shall be as specified in 7.1 and as shown in Fig.

Nails driven into the side edge of lumber shall be centered on

1.

the side edge.

7.5.3 Assembly—Assembly of crates shall be as shown in

7.1.9 When two members having parallel grain are attached,

Fig. 3 and as specified herein. Nailing shall be as specified

the number of rows of nails shall be determined by the nominal

herein and in 7.1. The sides shall be fastened to the base by

width of surfaces in contact, one row for widths up to and

including 2 in. [50 mm], two rows for widths between 2 in. [50

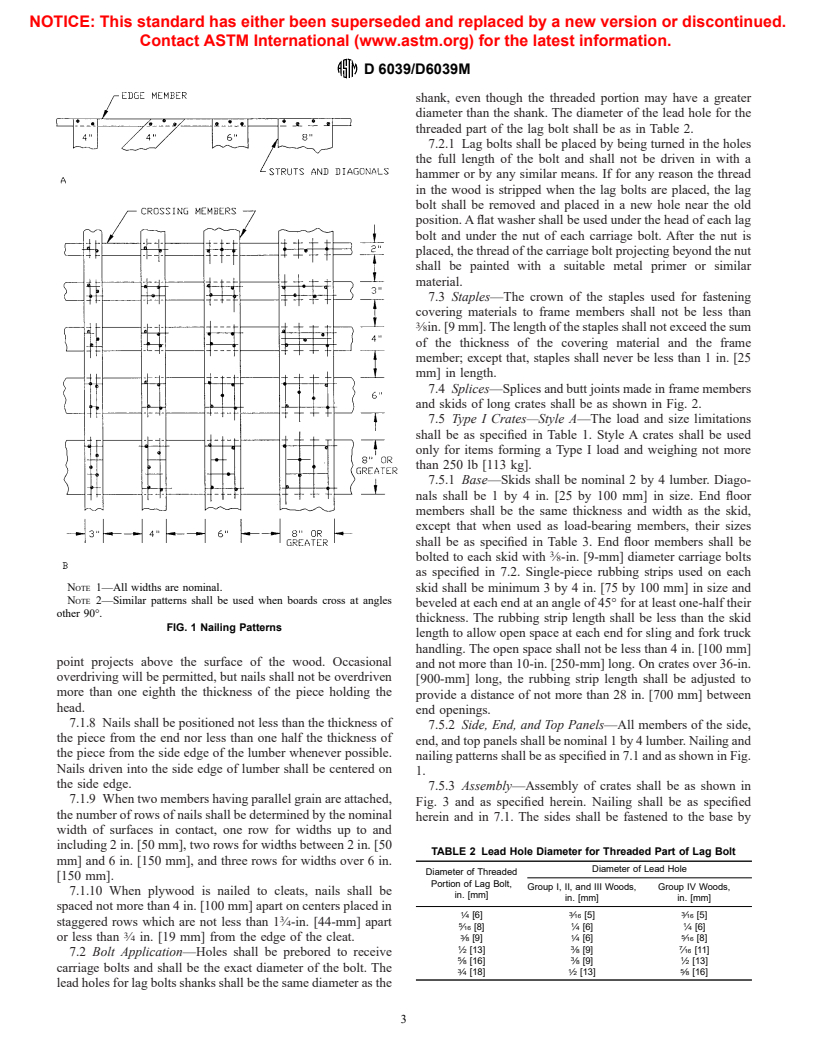

TABLE 2 Lead Hole Diameter for Threaded Part of Lag Bolt

mm] and 6 in. [150 mm], and three rows for widths over 6 in.

Diameter of Lead Hole

Diameter of Threaded

[150 mm].

Portion of Lag Bolt,

Group I, II, and III Woods, Group IV Woods,

7.1.10 When plywood is nailed to cleats, nails shall be

in. [mm]

in. [mm] in. [mm]

spaced not more than 4 in. [100 mm] apart on centers placed in

1 3 3

⁄4 [6] ⁄16 [5] ⁄16 [5]

staggered rows which are not less than 1 ⁄4-in. [44-mm] apart

5 1 1

⁄16 [8] ⁄4 [6] ⁄4 [6]

3 3 1 5

or less than ⁄4 in. [19 mm] from the edge of the cleat. ⁄8 [9] ⁄4 [6] ⁄16 [8]

1 3 7

⁄2 [13] ⁄8 [9] ⁄16 [11]

7.2 Bolt Application—Holes shall be prebored to receive

5 3 1

⁄8 [16] ⁄8 [9] ⁄2 [13]

carriage bolts and shall be the exact diameter of the bolt. The

3 1 5

⁄4 [18] ⁄2 [13] ⁄8 [16]

lead holes for lag bolts shanks shall be the same diameter as t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.