ASTM D6887-03(2008)

(Test Method)Standard Test Method for Testing Alkyd Compatibility with Resin or Resin Solutions

Standard Test Method for Testing Alkyd Compatibility with Resin or Resin Solutions

SIGNIFICANCE AND USE

p>Incompatibility of the system can lead to loss of gloss, decreased color strength, rheological problems and grind issues in the flush or pigment base.

This method is used in the lithographic industry, especially in pigment wetting applications, where the alkyd may or may not be totally compatible with the resin selected for the application.

SCOPE

1.1 This test method covers the procedure for determining the degree of compatibility of an alkyd with a specific resin or resin solution.

1.2 The most common use of this method is to test alkyd compatibility with a hydrocarbon resin or a solution of the resin in an aliphatic solvent, for lithographic ink vehicle applications.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6887 − 03 (Reapproved2008)

Standard Test Method for

1

Testing Alkyd Compatibility with Resin or Resin Solutions

This standard is issued under the fixed designation D6887; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 The solution is placed into pre-labeled jars and cooled.

1.1 This test method covers the procedure for determining 4.3 Degree of compatibility is reported at 30 min and 24 h

the degree of compatibility of an alkyd with a specific resin or after cooling to room temperature.

resin solution.

5. Significance and Use

1.2 The most common use of this method is to test alkyd

5.1 Incompatibility of the system can lead to loss of gloss,

compatibility with a hydrocarbon resin or a solution of the

decreasedcolorstrength,rheologicalproblemsandgrindissues

resin in an aliphatic solvent, for lithographic ink vehicle

in the flush or pigment base.

applications.

5.2 This method is used in the lithographic industry, espe-

1.3 The values stated in SI units are to be regarded as

cially in pigment wetting applications, where the alkyd may or

standard. No other units of measurement are included in this

may not be totally compatible with the resin selected for the

standard.

application.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

6. Apparatus

responsibility of the user of this standard to establish appro-

6.1 Beakers, 150 mL (4).

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 6.2 Jars, with lids, 4 oz (4).

6.3 Balance, capacity of at least 200 g, accurate to 60.1 g.

2. Referenced Documents

2 6.4 Hot Plate, capable of heating to a minimum of 200°C.

2.1 ASTM Standards:

6.5 Thermometer, 0 to 200°C, 61°C.

D6038 Test Methods for Determining the Compatibility of

Resin/Solvent Mixtures by Precipitation Temperature

6.6 Spatula, or stirrer rods.

(Cloud Point)

7. Test Samples

3. Terminology

7.1 Alkyd to be tested.

3.1 Definitions:

7.2 Resin or resin solution.

3.1.1 compatibility, n—resin and solvent mixture forms a

clear, homogenous, and stable solution. D6038

8. Procedure

3.1.2 incompatibility, n—resin and solvent mixture does not

8.1 Label each jar and beaker with the resin, alkyd and ratio

form a clear, homogenous, and stable solution.

being tested.

4. Summary of Test Method

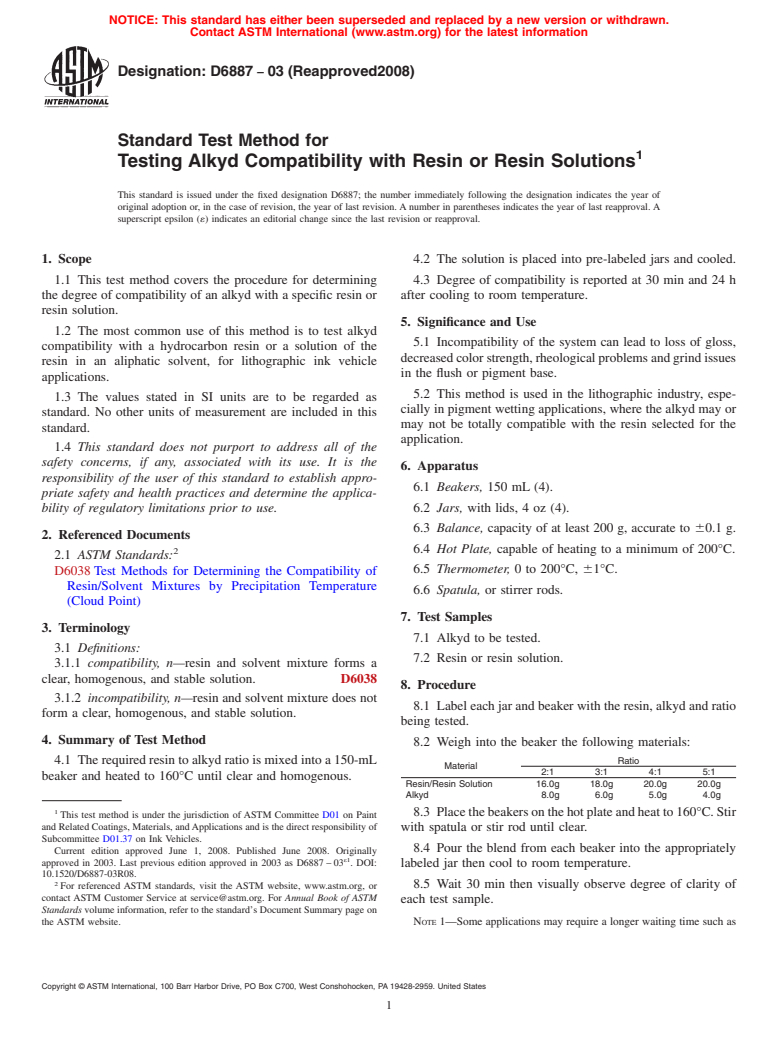

8.2 Weigh into the beaker the following materials:

4.1 The required resin to alkyd ratio is mixed into a 150-mL Ratio

Material

2:1 3:1 4:1 5:1

beaker and heated to 160°C until clear and homogenous.

Resin/Resin Solution 16.0g 18.0g 20.0g 20.0g

Alkyd 8.0g 6.0g 5.0g 4.0g

1

8.3 Placethebeakersonthehotplateandheatto160°C.Stir

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

with spatula or stir rod until clear.

Subcommittee D01.37 on Ink Vehicles.

8.4 Pour the blend from each beaker into t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.