ASTM D823-17

(Practice)Standard Practices for Producing Films of Uniform Thickness of Paint, Varnish, and Related Products on Test Panels

Standard Practices for Producing Films of Uniform Thickness of Paint, Varnish, and Related Products on Test Panels

SIGNIFICANCE AND USE

4.1 These practices should be used for those coatings that are designed for spray applications of objects in the factory or in the field. It is particularly important that it be used in the evaluation of metallic coatings for appearance properties, such as gloss and color.

4.2 Coatings applied by this test method may exhibit a slight orange-peel or spray wave.

SCOPE

1.1 Five practices are given for preparing films of uniform thickness of coatings on test panels. These practices are:

Practice A—Automatic Spray Machine Application

Practice B—Motor-Driven Dip Coater Application

Practice C—Motor-Driven Blade Film Application

Practice D—Hand-Held Spray Gun Application

Practice E—Hand-Held Blade Film Application

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D823 − 17

Standard Practices for

Producing Films of Uniform Thickness of Paint, Varnish,

1

and Related Products on Test Panels

This standard is issued under the fixed designation D823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D1186 Test Methods for Nondestructive Measurement of

Dry Film Thickness of Nonmagnetic Coatings Applied to

1.1 Five practices are given for preparing films of uniform

3

a Ferrous Base (Withdrawn 2006)

thickness of coatings on test panels. These practices are:

D1212 Test Methods for Measurement of Wet Film Thick-

Practice A—Automatic Spray Machine Application

ness of Organic Coatings

Practice B—Motor-Driven Dip Coater Application

D1400 TestMethodforNondestructiveMeasurementofDry

Practice C—Motor-Driven Blade Film Application

Film Thickness of Nonconductive Coatings Applied to a

Practice D—Hand-Held Spray Gun Application

3

Nonferrous Metal Base (Withdrawn 2006)

Practice E—Hand-Held Blade Film Application

D3924 Specification for Standard Environment for Condi-

1.2 The values stated in SI units are to be regarded as the

tioning and Testing Paint, Varnish, Lacquer, and Related

3

standard. The values given in parentheses are for information

Materials (Withdrawn 2016)

only.

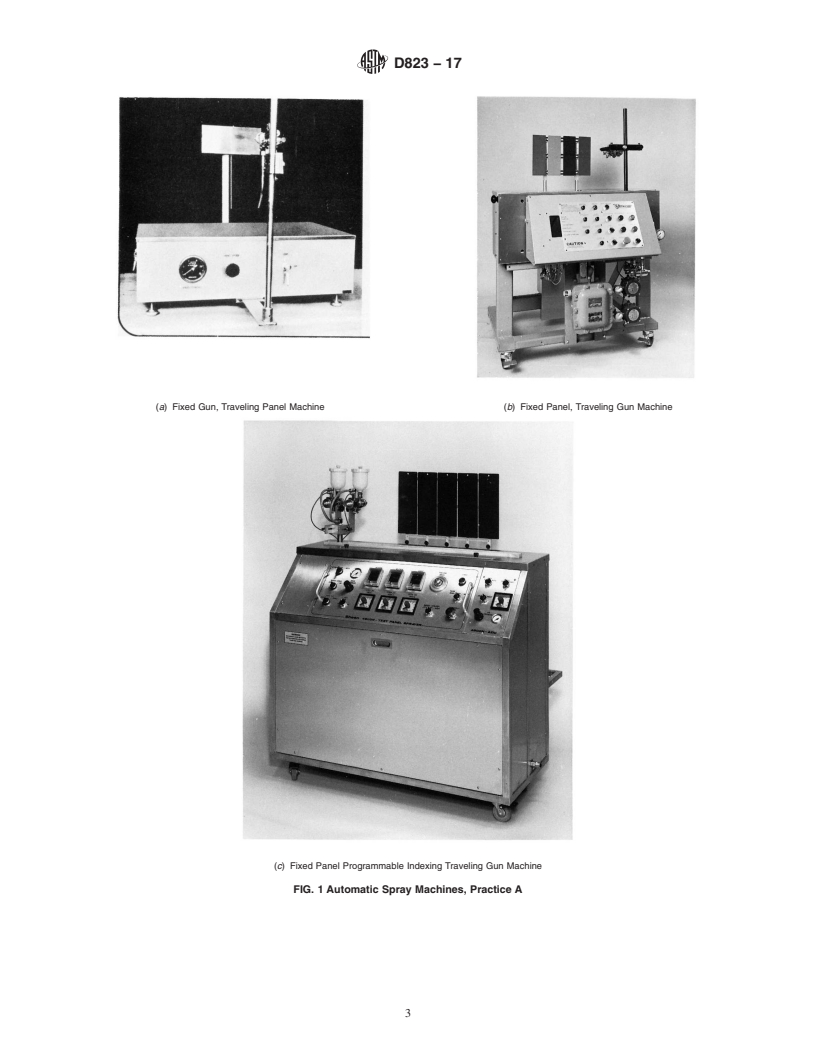

PRACTICE A—AUTOMATIC SPRAY MACHINE

1.3 This standard does not purport to address all of the

APPLICATION

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Summary of Practices

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.1 A liquid material is applied to a test panel by means of

1.4 This international standard was developed in accor- an automatic spray machine consisting of a mounted spray gun

dance with internationally recognized principles on standard-

and a panel holder. This machine can (1) move the panel

ization established in the Decision on Principles for the holder, with test panel, at a uniform speed through the

Development of International Standards, Guides and Recom-

atomized spray produced by a fixed spray gun, or (2)itcan

mendations issued by the World Trade Organization Technical

move the gun, with atomized spray, at a uniform speed past the

Barriers to Trade (TBT) Committee.

test panel mounted on a fixed panel holder. A machine

equipped with a programmable system can index the spray gun

2. Referenced Documents vertically for multiple passes and for multiple coats with

2

selective time delay.

2.1 ASTM Standards:

D609 Practice for Preparation of Cold-Rolled Steel Panels 3.2 The thickness of coating applied is controlled by the

for Testing Paint, Varnish, Conversion Coatings, and

traverse speed of the panel or gun, the fluid delivery rate of the

Related Coating Products gun, the viscosity of the material, and the amount of nonvola-

D1005 Test Method for Measurement of Dry-Film Thick-

tile matter in the material.

ness of Organic Coatings Using Micrometers

4. Significance and Use

4.1 These practices should be used for those coatings that

1

These practices are under the jurisdiction of ASTM Committee D01 on Paint

are designed for spray applications of objects in the factory or

and Related Coatings, Materials, and Applications and are the direct responsibility

in the field. It is particularly important that it be used in the

of Subcommittee D01.23 on Physical Properties of Applied Paint Films.

evaluation of metallic coatings for appearance properties, such

Current edition approved Dec. 1, 2017. Published December 2017. Originally

ε1

approved in 1945. Last previous edition approved in 2012 as D823 – 95 (2012) . as gloss and color.

DOI: 10.1520/D0823-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D823 − 17

4.2 Coatingsappliedbythistestmethodmayexhibitaslight desired pattern and uniformity are obtained. Further refine-

orange-peel or spray wave. ments may be made in the spray pattern by modifying the air

pressure, the type of thinning agent, and the consistency of the

5. Apparatus

material.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D823 − 95 (Reapproved 2012) D823 − 17

Standard Practices for

Producing Films of Uniform Thickness of Paint, Varnish,

1

and Related Products on Test Panels

This standard is issued under the fixed designation D823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Figure 3 was replaced and Section 18 was editorially corrected in November 2012.

1. Scope

1.1 Five practices are given for preparing films of uniform thickness of coatings on test panels. These practices are:

Practice A—Automatic Spray Machine Application

Practice B—Motor-Driven Dip Coater Application

Practice C—Motor-Driven Blade Film Application

Practice D—Hand-Held Spray Gun Application

Practice E—Hand-Held Blade Film Application

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D609 Practice for Preparation of Cold-Rolled Steel Panels for Testing Paint, Varnish, Conversion Coatings, and Related Coating

Products

D1005 Test Method for Measurement of Dry-Film Thickness of Organic Coatings Using Micrometers

D1186 Test Methods for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to a Ferrous

3

Base (Withdrawn 2006)

D1212 Test Methods for Measurement of Wet Film Thickness of Organic Coatings

D1400 Test Method for Nondestructive Measurement of Dry Film Thickness of Nonconductive Coatings Applied to a

3

Nonferrous Metal Base (Withdrawn 2006)

D3924 Specification for Standard Environment for Conditioning and Testing Paint, Varnish, Lacquer, and Related Materials

3

(Withdrawn 2016)

PRACTICE A—AUTOMATIC SPRAY MACHINE APPLICATION

3. Summary of Practices

3.1 A liquid material is applied to a test panel by means of an automatic spray machine consisting of a mounted spray gun and

a panel holder. This machine can (1) move the panel holder, with test panel, at a uniform speed through the atomized spray

1

These practices are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved Nov. 1, 2012Dec. 1, 2017. Published November 2012December 2017. Originally approved in 1945. Last previous edition approved in 20072012

ε1

as D823 – 95 (2007).(2012) . DOI: 10.1520/D0823-95R12E01.10.1520/D0823-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D823 − 17

produced by a fixed spray gun, or (2) it can move the gun, with atomized spray, at a uniform speed past the test panel mounted

on a fixed panel holder. A machine equipped with a programmable system can index the spray gun vertically for multiple passes

and for multiple coats with selective time delay.

3.2 The thickness of coating applied is controlled by the traverse speed of the panel or gun, the fluid delivery rate of the gun,

the viscosity of the material, and the amount of nonvolatile matter in the material.

4. Significance and Use

4.1 These practices should be used for those coatings that are designed for spray applications of o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.