ASTM A324-73(2000)

(Specification)Standard Specification for Ferrotitanium

Standard Specification for Ferrotitanium

SCOPE

1.1 This specification covers four grades of ferrotitanium, designated A, B, C, and D.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 324 – 73 (Reapproved 2000)

Standard Specification for

Ferrotitanium

This standard is issued under the fixed designation A 324; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

A

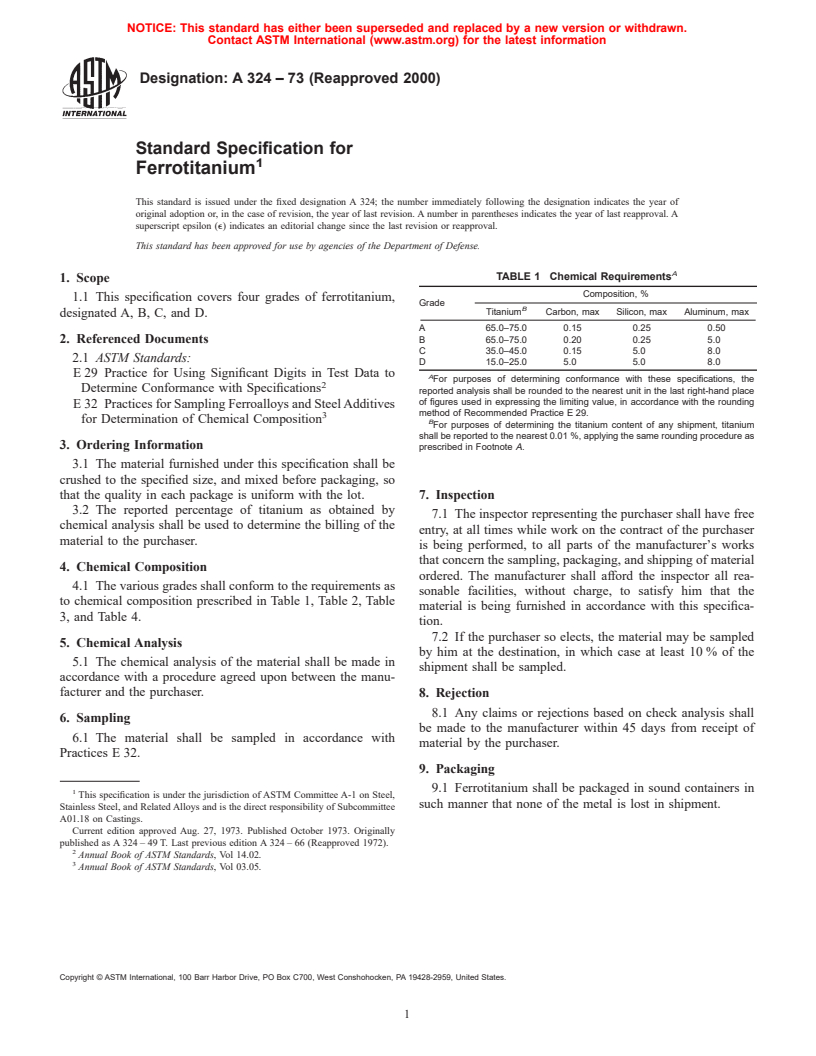

TABLE 1 Chemical Requirements

1. Scope

Composition, %

1.1 This specification covers four grades of ferrotitanium,

Grade

B

Titanium Carbon, max Silicon, max Aluminum, max

designated A, B, C, and D.

A 65.0–75.0 0.15 0.25 0.50

2. Referenced Documents

B 65.0–75.0 0.20 0.25 5.0

C 35.0–45.0 0.15 5.0 8.0

2.1 ASTM Standards:

D 15.0–25.0 5.0 5.0 8.0

E 29 Practice for Using Significant Digits in Test Data to

A

For purposes of determining conformance with these specifications, the

Determine Conformance with Specifications

reported analysis shall be rounded to the nearest unit in the last right-hand place

of figures used in expressing the limiting value, in accordance with the rounding

E 32 Practices for Sampling Ferroalloys and Steel Additives

method of Recommended Practice E 29.

for Determination of Chemical Composition

B

For purposes of determining the titanium content of any shipment, titanium

shall be reported to the nearest 0.01 %, applying the same rounding procedure as

3. Ordering Information

prescribed in Footnote A.

3.1 The material furnished under this specification shall be

crushed to the specified size, and mixed before packaging, so

that the quality in each package is uniform with the lot. 7. Inspection

3.2 The reported percentage of titanium as obtained by

7.1 The inspector representing the purchaser shall have free

chemical analysis shall be used to determine the billing of the

entry, at all times while work on the contract of the purchaser

material to the purchaser.

is being performed, to all parts of the manufacturer’s works

that concern the sampling, packaging, and shipping of material

4. Chemical Composition

ordered. The manufacturer shall afford the inspector all rea-

4.1 The various grades shall conform to the requirements as

sonable facilities, without charge, to satisfy him that the

to chemical composition prescribed in Table 1, Table 2, Table

material is being furnished in accordance with this specifica-

3, and Table 4.

tion.

7.2 If the purchaser so elects, the material may be sampled

5. Chemical Analysis

by him at the destination, in which case at least 10 % of the

5.1 The chemical analysis of the material shall be made in

shipment shall be sampled.

accordance with a procedure agreed upon between the manu-

facturer and the purchaser.

8. Rejection

8.1 Any claims or rejections based on check analysis shall

6. Sampling

be made to the manufacturer within 45 days from receipt of

6.1 The material shall be sampled in accordance with

material by the purchaser.

Practices E 32.

9. Packaging

9.1 Ferrotitanium shall be packaged in sound containers in

This specification is under the jurisdiction of ASTM Committee A-1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.