ASTM A799/A799M-10

(Practice)Standard Practice for Steel Castings, Stainless, Instrument Calibration, for Estimating Ferrite Content

Standard Practice for Steel Castings, Stainless, Instrument Calibration, for Estimating Ferrite Content

SIGNIFICANCE AND USE

The amount of ferrite present in an austenitic stainless steel has been shown to influence the strength, toughness and corrosion resistance of this type of cast alloy. The amount of ferrite present tends to correlate well with the magnetic permeability of the steel. The methods described in this standard cover calibration practice for estimating ferrite by the magnetic permeability of the steel. The practice is inexpensive to use over large areas of the cast part and is non-destructive.

This practice has been used for research, alloy development, quality control, and manufacturing control.

Many instruments are available having different designs, and different principles of operation. When the probe is placed on the material being investigated, a closed magnetic circuit is formed allowing measurement of the magnetic permeability. When calibrated with standards having known ferrite content, this permeability indicates the ferrite content of the material being analyzed. The estimated ferrite content is read from a calibrated dial or from a digital-readout dial. Follow the manufacturer's instructions for proper calibration of the instrument.

Since this practice measures magnetic attraction and not ferrite directly, it is subject to all of the variables that affect magnetic permeability, such as the shape, size, orientation, and composition of the ferrite phase. These in turn are affected by thermal history. Ferrite measurements by magnetic methods have also been found to be affected by the surface finish of the material being analyzed.

Magnetic methods should not be used for arbitration of conflicts on ferrite content except when agreed upon between manufacturer and purchaser.

SCOPE

1.1 This practice covers the procedure for calibration of instruments to be used for estimating the ferrite content of the microstructure of cast stainless steels by magnetic response or measurement of permeability. This procedure covers both primary and secondary instruments.

1.1.1 A primary instrument is one that has been calibrated using National Institute of Standards and Technology-Standard Reference Material (NIST-SRM) thickness coating standards. It is a laboratory tool to be used with test specimens. Some primary instruments may be used to directly measure the ferrite content of castings.

1.1.2 A secondary instrument is one that has been calibrated by the use of secondary standards that have been measured by a calibrated primary instrument. Secondary instruments are to be used to directly measure the ferrite content of castings.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.2.1 Within the text, the SI units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A799/A799M − 10

StandardPractice for

Steel Castings, Stainless, Instrument Calibration, for

1

Estimating Ferrite Content

This standard is issued under the fixed designationA799/A799M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Alloys, and Ferroalloys

B499 Test Method for Measurement of Coating Thicknesses

1.1 This practice covers the procedure for calibration of

by the Magnetic Method: Nonmagnetic Coatings on

instruments to be used for estimating the ferrite content of the

Magnetic Basis Metals

microstructure of cast stainless steels by magnetic response or

E562 Test Method for Determining Volume Fraction by

measurement of permeability. This procedure covers both

Systematic Manual Point Count

primary and secondary instruments.

2.2 NIST Standard:

1.1.1 A primary instrument is one that has been calibrated

NIST-SRM Coating Thickness Standards

using National Institute of Standards andTechnology-Standard

Reference Material (NIST-SRM) thickness coating standards.

NOTE 1—The specific coating thickness standards previously refer-

enced in this practice are no longer available. Similar ones are now

It is a laboratory tool to be used with test specimens. Some

available from NIST.

primaryinstrumentsmaybeusedtodirectlymeasuretheferrite

content of castings.

3. Terminology

1.1.2 Asecondary instrument is one that has been calibrated

3.1 Definitions—The definitions in Terminology A941 are

by the use of secondary standards that have been measured by

applicable to this standard.

a calibrated primary instrument. Secondary instruments are to

be used to directly measure the ferrite content of castings.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 ferrite, n—the body-centered cubic microconstituent

1.2 The values stated in either SI units or inch-pound units

in stainless steel.

are to be regarded separately as standard. The values stated in

3.2.2 ferrite percentage, n—a value designating the ferrite

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining content of stainless steels.

values from the two systems may result in non-conformance 3.2.2.1 Discussion—The Steel Founders’ Society of

with the standard. America (SFSA) has assigned ferrite percentages to the series

3

1.2.1 Within the text, the SI units are shown in brackets. of NIST coating thickness standards . This assignment was

based on the magnetic attraction for a standard magnet by the

1.3 This standard does not purport to address all of the

coating standards when compared with the magnetic attraction

safety concerns, if any, associated with its use. It is the

of the same magnet by a series of cast stainless steels whose

responsibility of the user of this standard to establish appro-

ferrite content had been determined by an accurate metallo-

priate safety and health practices and determine the applica-

graphic point count. A similar assignment based on magnetic

bility of regulatory limitations prior to use.

permeability was also established. Algebraic equations have

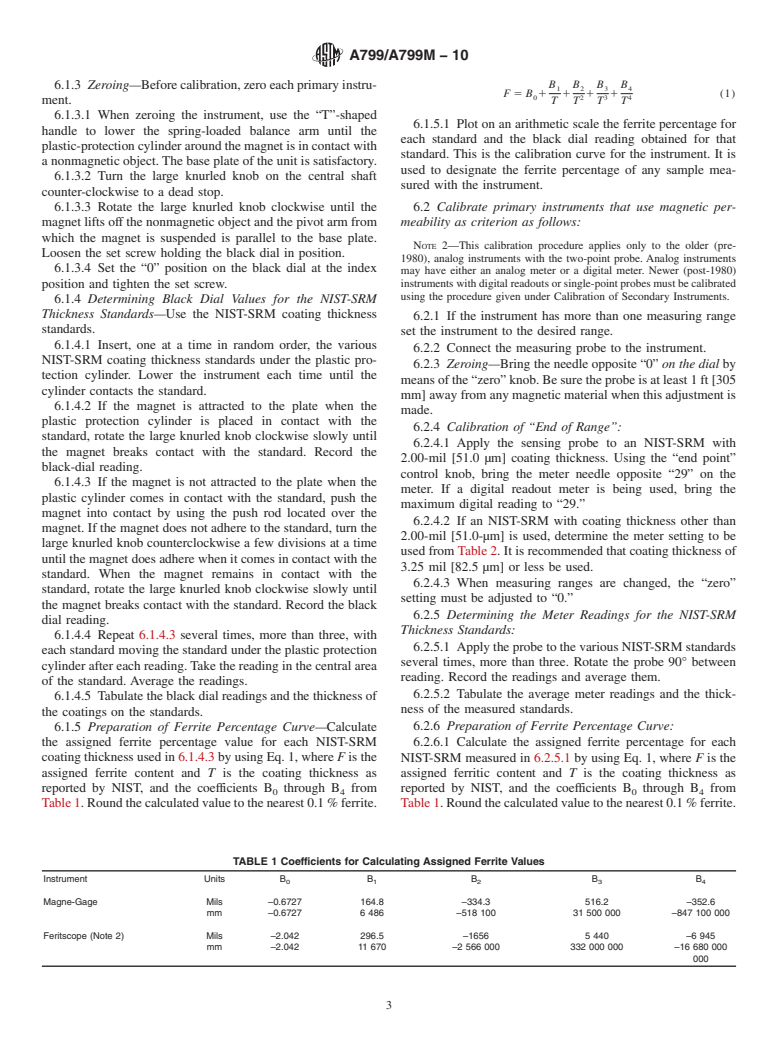

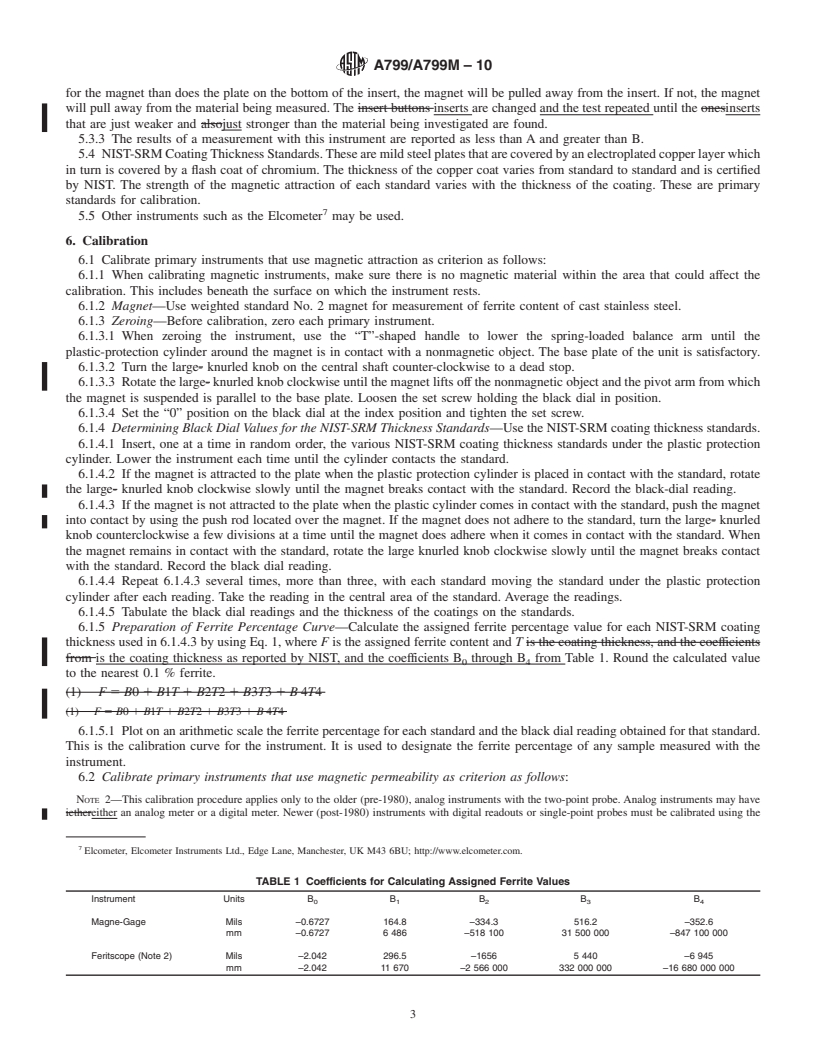

now been derived from a plot of the thickness of these

2. Referenced Documents

standards and the assigned ferrite percentages. By the use of

2

2.1 ASTM Standards:

these equations, any primary instrument will have its calibra-

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

tiontraceabletotheSFSA’sinstrumentsoranyothercalibrated

instrument and thus afford comparable reproducible ferrite

1 percentages. It also allows traceability to NIST.

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

3.2.3 secondary standards, n—a piece of cast stainless steel

A01.18 on Castings.

whose ferrite percentage has been determined by a calibrated

Current edition approved April 1, 2010. Published April 2010. Originally

primary instrument.

approved in 1982. Last previous edition approved in 2009 as A799/A799M – 04

(2009).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Aubrey, L.S., Weiser, P.F., Pollard, W.J., and Schoefer, E.A., “ Ferrite

Standards volume information, refer to the standard’s Document Summary page on MeasurementandControlinCastDuplexStainlessSteels,” Stainless Steel Castings,

the ASTM website. DOI: 10.1520/A0799_A0799M-04R09. ASTM STP 756, ASTM, 1982, p 126.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West C

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A799/A799M–04 (Reapproved 2009) Designation: A799/A799M – 10

Standard Practice for

Steel Castings, Stainless, Instrument Calibration, for

1

Estimating Ferrite Content

This standard is issued under the fixed designationA799/A799M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers the procedure for calibration of instruments to be used for estimating the ferrite content of the

microstructure of cast stainless steels by magnetic response or measurement of permeability. This procedure covers both primary

and secondary instruments.

1.1.1 A primary instrument is one that has been calibrated using National Institute of Standards and Technology-Standard

Reference Material (NIST-SRM) thickness coating standards. It is a laboratory tool to be used with test specimens. Some primary

instruments may be used to directly measure the ferrite content of castings.

1.1.2 A secondary instrument is one that has been calibrated by the use of secondary standards that have been measured by a

calibrated primary instrument. Secondary instruments are to be used to directly measure the ferrite content of castings.

1.2 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

mustshall be used independently of the other. Combining values from the two systems may result in non-conformance with the

specification. standard.

1.2.1 Within the text, the SI units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

B499 Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic

Basis Metals

E562 Test Method for Determining Volume Fraction by Systematic Manual Point Count

2.2 NIST Standard:

NIST-SRM Coating Thickness Standards

NOTE 1—The specific coating thickness standards previously referenced in this practice are no longer available. Similar ones are now available from

NIST.

3. Terminology

3.1 Definitions: The definitions in Terminology A941 are applicable to this standard.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 ferrite, n—the body-centered cubic microconstituent in stainless steel.

3.2.2 ferrite percentage, n—a value designating the ferrite content of stainless steels.

3.2.2.1 Discussion—The Steel Founders’ Society of America (SFSA) has assigned ferrite percentages to the series of NIST

3

coating thickness standards .This assignment was based on the magnetic attraction for a standard magnet by the coating standards

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.18

on Castings.

Current edition approved Oct.April 1, 2009.2010. Published JanuaryApril 2010. Originally approved in 1982. Last previous edition approved in 20042009 as

A799/A799M – 04 (2009).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website. DOI: 10.1520/A0799_A0799M-04R09.

3

Aubrey, L.S., Weiser, P.F., Pollard, W.J., and Schoefer, E.A., “ Ferrite Measurement and Control in Cast Duplex Stainless Steels,” Stainless Steel Castings, ASTM STP

756, ASTM, 1982, p 126.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A799/A799M – 10

when compared with the magnetic attraction of the same magnet by a series of cast stainless steels whose ferrite content had been

determined by an accurate metallographic point count.Asimilar assignment base

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.