ASTM D7270-07(2021)

(Guide)Standard Guide for Environmental and Performance Verification of Factory-Applied Liquid Coatings

Standard Guide for Environmental and Performance Verification of Factory-Applied Liquid Coatings

SIGNIFICANCE AND USE

3.1 The primary objective of this verification guide is to determine the “air pollution-prevention potential” (possible reduction in VOC or HAP emissions) of factory-applied liquid coatings.

3.2 The overall objective of this guide is to verify the above pollution-prevention characteristics and basic performance characteristics of liquid coating technologies. Use of this guide can increase acceptance of more environmentally friendly technologies for product finishing with an accompanying reduction in emissions to the atmosphere. The specific objectives of this guide are to (1) quantify the VOC and HAP content of liquid coatings and (2) verify the basic quality and durability performance of these coatings.

3.3 The primary criteria for verification of liquid coatings will be:

3.3.1 Confirm that use of the coating will significantly reduce VOC and HAP content or emissions (or both) during application or cure, or both.

3.3.2 Confirm that the coating can provide an acceptable finish (appearance, hardness, flexibility, etc.) for the intended end use.

3.4 The test results from this guide can provide to potential users the best data available to determine whether the coating will provide a pollution-prevention benefit while meeting the finish quality requirements for its intended use. This guide intends to supply end users with unbiased technical data to assist them in this decision-making process.

3.5 The quantitative air pollution-prevention potential depends on a multitude of factors; therefore, the liquid coatings are to be applied in accordance with the coating vendor’s instructions and the resulting verification data reflect only the specific conditions of the test. To quantify the environmental benefit (air pollution-prevention potential), a test to quantify the VOC or HAP emissions from the new liquid coatings will be conducted and compared to data for existing coatings typically used in the target industry.

SCOPE

1.1 This guide provides a generic testing procedure to verify the air pollution-prevention characteristics and basic properties of liquid coatings applied to metal, plastic, wood, or composite substrates in a factory/manufacturing environment. Thus it may be used to evaluate these liquid coatings to verify their volatile organic compound (VOC) and organic hazardous air pollutant (HAP) content as well as basic performance properties.

1.2 This guide is adapted from a procedure used by the US Environmental Protection Agency (EPA) to establish third party verification of the physical properties and performance of coatings that have potential to reduce air emissions. The data from the verification testing is available on the internet at the EPA’s Environmental Technology Verification (ETV) Program website (http://www.epa.gov/etv/centers/center6.html) under the “P2 Innovative Coatings and Coating Equipment Pilot.”

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D7270 −07 (Reapproved 2021)

Standard Guide for

Environmental and Performance Verification of Factory-

Applied Liquid Coatings

This standard is issued under the fixed designation D7270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 Thisguideprovidesagenerictestingproceduretoverify

2.1 ASTM Standards:

the air pollution-prevention characteristics and basic properties

B117 Practice for Operating Salt Spray (Fog) Apparatus

of liquid coatings applied to metal, plastic, wood, or composite

B499 Test Method for Measurement of Coating Thicknesses

substrates in a factory/manufacturing environment. Thus it

by the Magnetic Method: Nonmagnetic Coatings on

may be used to evaluate these liquid coatings to verify their

Magnetic Basis Metals

volatile organic compound (VOC) and organic hazardous air

D522 Test Methods for Mandrel Bend Test of Attached

pollutant (HAP) content as well as basic performance proper-

Organic Coatings

ties.

D523 Test Method for Specular Gloss

1.2 This guide is adapted from a procedure used by the US

D1729 Practice for Visual Appraisal of Colors and Color

Environmental Protection Agency (EPA) to establish third

Differences of Diffusely-Illuminated Opaque Materials

partyverificationofthephysicalpropertiesandperformanceof

D1735 Practice for Testing Water Resistance of Coatings

coatings that have potential to reduce air emissions. The data

Using Water Fog Apparatus

from the verification testing is available on the internet at the

D2244 Practice for Calculation of Color Tolerances and

EPA’s Environmental Technology Verification (ETV) Program

Color Differences from Instrumentally Measured Color

website (http://www.epa.gov/etv/centers/center6.html) under

Coordinates

the “P2 Innovative Coatings and Coating Equipment Pilot.”

D2369 Test Method for Volatile Content of Coatings

D2794 Test Method for Resistance of Organic Coatings to

1.3 The values stated in SI units are to be regarded as the

the Effects of Rapid Deformation (Impact)

standard. The values given in parentheses are for information

only. D3359 Test Methods for Rating Adhesion by Tape Test

D3363 Test Method for Film Hardness by Pencil Test

1.4 This standard does not purport to address all of the

D3792 Test Method forWater Content of Coatings by Direct

safety concerns, if any, associated with its use. It is the

Injection Into a Gas Chromatograph

responsibility of the user of this standard to establish appro-

D3960 PracticeforDeterminingVolatileOrganicCompound

priate safety, health, and environmental practices and deter-

(VOC) Content of Paints and Related Coatings

mine the applicability of regulatory limitations prior to use.

D4017 Test Method for Water in Paints and Paint Materials

1.5 This international standard was developed in accor-

by Karl Fischer Method

dance with internationally recognized principles on standard-

D4060 Test Method for Abrasion Resistance of Organic

ization established in the Decision on Principles for the

Coatings by the Taber Abraser

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.55 on Factory Applied Coatings on Preformed Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2021. Published June 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2007. Last previous edition approved in 2013 as D7270 – 07 (2013). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D7270-07R21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7270−07 (2021)

D4457 Test Method for Determination of Dichloromethane 3.4 The test results from this guide can provide to potential

and 1,1,1-Trichloroethane in Paints and Coatings by users the best data available to determine whether the coating

Direct Injection into a Gas Chromatograph (Withdrawn will provide a pollution-prevention benefit while meeting the

2019) finish quality requirements for its intended use. This guide

D5402 Practice for Assessing the Solvent Resistance of intends to supply end users with unbiased technical data to

Organic Coatings Using Solvent Rubs assist them in this decision-making process.

D5767 Test Method for Instrumental Measurement of

3.5 The quantitative air pollution-prevention potential de-

Distinctness-of-Image (DOI) Gloss of Coated Surfaces

pends on a multitude of factors; therefore, the liquid coatings

D6133 Test Method for Acetone, p-Chlorobenzotrifluoride,

are to be applied in accordance with the coating vendor’s

Methyl Acetate or t-Butyl Acetate Content of Solvent-

instructions and the resulting verification data reflect only the

borne and Waterborne Paints, Coatings, Resins, and Raw

specific conditions of the test. To quantify the environmental

Materials by Direct Injection Into a Gas Chromatograph

benefit (air pollution-prevention potential), a test to quantify

D6438 Test Method for Acetone, Methyl Acetate, and

the VOC or HAP emissions from the new liquid coatings will

Parachlorobenzotrifluoride Content of Paints, and Coat-

be conducted and compared to data for existing coatings

ings by Solid Phase Microextraction-Gas Chromatogra-

typically used in the target industry.

phy

D6695 Practice for Xenon-Arc Exposures of Paint and

4. Testing Site

Related Coatings

4.1 To accelerate the transition of environmentally friendly

D6886 TestMethodforDeterminationoftheWeightPercent

processes to the manufacturing base, the test facility should

Individual Volatile Organic Compounds in Waterborne

offertheabilitytotestprocessesandproductsonrepresentative

Air-Dry Coatings by Gas Chromatography

commercial equipment. The coating application equipment in

2.2 EPA Methods:

the test facility should be available for the pilot-scale testing

EPAMethod 24 Surface Coatings (Determination ofVolatile

performed in this guide (for example, surface pretreatment,

Matter Content, Water Content, Density, Volume Solids,

powder coating, electrocoating, wet spray, and conventional

and Weight Solids of Surface Coatings)

forced-air and infrared ovens, as applicable). Layouts of an

EPAMethod 311 HAPS in Paints and Coatings (Analysis of

example of an approved test facility are shown in Appendix

Hazardous Air Pollutant Compounds in Paints and Coat-

X1,Figs.X1.1andX1.2,respectively.Examplesofthevarious

ings by Direct Injection Into a Gas Chromatograph)

testing laboratories and their representative equipment hold-

ings that are relevant to the approved test facility verification

3. Significance and Use

projects are listed in Table X1.1.

3.1 The primary objective of this verification guide is to

4.2 A test plan, referred to as a Testing and Quality

determine the “air pollution-prevention potential” (possible

AssuranceProtocol(T/QAP),willbeestablishedtoprovidethe

reduction in VOC or HAPemissions) of factory-applied liquid

testing details that are dependent upon the specific liquid

coatings.

coating being tested. Some general guidelines and procedures

3.2 The overall objective of this guide is to verify the above

can be applied to each T/QAP. These include:

pollution-prevention characteristics and basic performance

4.2.1 A detailed description of each part of the test will be

characteristics of liquid coating technologies. Use of this guide

provided. The selection of tests to be performed, test details,

can increase acceptance of more environmentally friendly

evaluation methods and acceptance criteria are defined by the

technologies for product finishing with an accompanying

end use requirements of the coating. These details should be

reduction in emissions to the atmosphere. The specific objec-

incorporatedintoatestplanthatisuniquetoeachcoating.This

tivesofthisguideareto(1)quantifytheVOCandHAPcontent

will include a detailed design of experiments and a schematic

ofliquidcoatingsand(2)verifythebasicqualityanddurability

diagram of testing to be performed.

performance of these coatings.

4.2.2 Critical and noncritical factors will be listed. Noncriti-

3.3 The primary criteria for verification of liquid coatings

cal factors will remain constant throughout the testing. Critical

will be:

factors will be listed as control (process) factors or response

3.3.1 Confirm that use of the coating will significantly

(coating product quality) factors.

reduce VOC and HAP content or emissions (or both) during

4.2.3 The T/QAP will identify the testing site.

application or cure, or both.

4.2.4 Regardless of where the testing is performed, the

3.3.2 Confirm that the coating can provide an acceptable

approved test facility will ensure that the integrity of third-

finish (appearance, hardness, flexibility, etc.) for the intended

party testing is maintained.

end use.

4.2.5 Regardless of where the testing is performed, the

Quality Assurance (QA) portion of the guide will be strictly

adhered to.

The last approved version of this historical standard is referenced on

4.2.6 A statistically significant number of samples will be

www.astm.org.

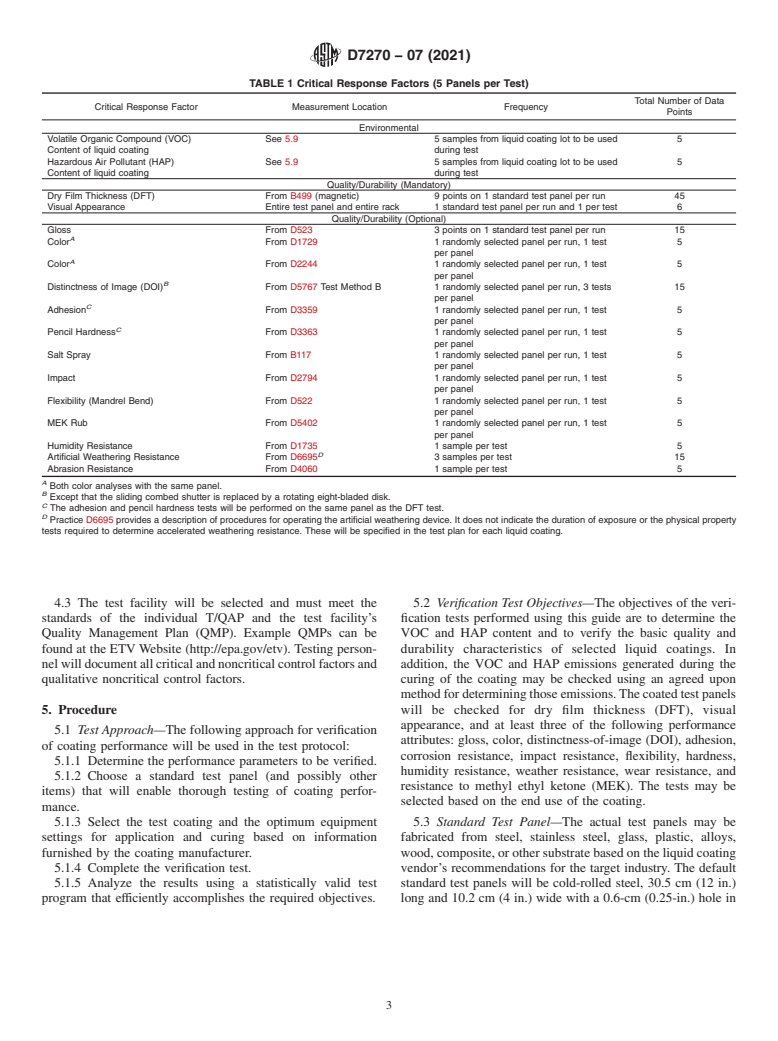

analyzed for each critical response factor (see Table 1).

US EPA, Office of Air Quality Planning and Standards (OAQPS), TTN EMC

Variances (or standard deviations) of each critical response

Webmaster (C304-03), Research Triangle Park, NC 27711 (website, www.epa.gov/

ttn/emc). factor will be reported for all results.

D7270−07 (2021)

TABLE 1 Critical Response Factors (5 Panels per Test)

Total Number of Data

Critical Response Factor Measurement Location Frequency

Points

Environmental

Volatile Organic Compound (VOC) See 5.9 5 samples from liquid coating lot to be used 5

Content of liquid coating during test

Hazardous Air Pollutant (HAP) See 5.9 5 samples from liquid coating lot to be used 5

Content of liquid coating during test

Quality/Durability (Mandatory)

Dry Film Thickness (DFT) From B499 (magnetic) 9 points on 1 standard test panel per run 45

Visual Appearance Entire test panel and entire rack 1 standard test panel per run and 1 per test 6

Quality/Durability (Optional)

Gloss From D523 3 points on 1 standard test panel per run 15

A

Color From D1729 1 randomly selected panel per run, 1 test 5

per panel

A

Color From D2244 1 randomly selected panel per run, 1 test 5

per panel

B

Distinctness of Image (DOI) From D5767 Test Method B 1 randomly selected panel per run, 3 tests 15

per panel

C

Adhesion From D3359 1 randomly selected panel per run, 1 test 5

per panel

C

Pencil Hardness From D3363 1 randomly selected panel per run, 1 test 5

per panel

Salt Spray From B117 1 randomly selected panel per run, 1 test 5

per panel

Impact From D2794 1 randomly selected panel per run, 1 test 5

per panel

Flexibility (Mandrel Bend) From D522 1 randomly selected panel per run, 1 test 5

per panel

MEK Rub From D5402 1 randomly selected panel per run, 1 test 5

per panel

Humidity Resistance From D1735 1 sample per test 5

D

Artificial Weathering Resistance From D6695 3 samples per test 15

Abrasion Resistance From D4060 1 sample per test 5

A

Both color analyses with the same panel.

B

Except that the sliding combed shutter is replaced by a rotating eight-bladed disk.

C

The adhesion and pencil hardness tests will be performed on the same panel as the DFT test.

D

Practice D6695 provides a description of procedures for operating the artificial weathering device. It does not indicate the duration of exposure or the physical property

tests required to determine accelerated weathering resistance. These will be specified in the test plan for each liquid coating.

4.3 The test facility will be selected and must meet the 5.2 Verification Test Objectives—The objectives of the veri-

standards of the individual T/QAP and the test facility’s fication tests performed using this guide are to determine the

Quality Management Plan (QMP). Example QMPs can be VOC and HAP content and to verify the basic quality and

found at the ETV Website (http://epa.gov/etv). Testing person- durability characteristics of selected liquid coatings. In

nelwilldocumentallcriticalandnoncriticalcontrolfactorsand addition, the VOC and HAP emissions generated during the

qualitative noncritical control factors. curing of the coating may be checked using an agreed upon

methodfordeterminingthoseemissions.Thecoatedtestpanels

5. Procedure will be checked for dry film thickness (DFT), visual

appearance, and at least three of the following performance

5.1 Test Approach—The following approach for verification

attributes: gloss, color, distinctness-of-image (DOI), adhesion,

of coating performance will be used in the test protocol:

corrosion resistance, impact resistance, flexibility, hardness,

5.1.1 Determine the performance parameters to be verified.

humidity resistance, weather resistance, wear resistance, and

5.1.2 Choose a standard test panel (and possibly other

resistance to methyl ethyl ketone (MEK). The tests may be

items) that will enable thorough testing of coating perfor-

selected based on the end use of the coating.

mance.

5.1.3 Select the test coating and the optimum equipment 5.3 Standard Test Panel—The actual test panels may be

settings for application and curing based on information fabricated from steel, stainless steel, glass, plastic, alloys,

furnished by the coating manufacturer. wood,composite,orothersubstratebasedontheliquidcoating

5.1.4 Complete the verification test. vendor’s recommendations for the target industry. The default

5.1.5 Analyze the results using a statistically valid test standard test panels will be cold-rolled steel, 30.5 cm (12 in.)

program that efficiently accomplishes the required objectives. long and 10.2 cm (4 in.) wide with a 0.6-cm (0.25-in.) hole in

D7270−07 (2021)

one end so that it may be suspended from a hook. Other shapes automatically sprayed using a specified vertical overlap of the

(parts) may be treated and tested as required to complete the spray pattern. The PLC will also trigger the pneumatic spray

verification. gun or a pneumatically actuated cylinder that compresses

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.