ASTM F1160-14

(Test Method)Standard Test Method for Shear and Bending Fatigue Testing of Calcium Phosphate and Metallic Medical and Composite Calcium Phosphate/Metallic Coatings

Standard Test Method for Shear and Bending Fatigue Testing of Calcium Phosphate and Metallic Medical and Composite Calcium Phosphate/Metallic Coatings

SIGNIFICANCE AND USE

5.1 The shear and bending fatigue tests are used to determine the effect of variations in material, geometry, surface condition, stress, and so forth, on the fatigue resistance of coated metallic materials subjected to direct stress for up to 107 cycles. These tests may be used as a relative guide to the selection of coated materials for service under condition of repeated stress.

5.2 In order that such basic fatigue data be comparable, reproducible, and can be correlated among laboratories, it is essential that uniform fatigue practices be established.

5.3 The results of the fatigue test may be used for basic material property design. Actual components should not be tested using these test methods.

SCOPE

1.1 This test method covers the procedure for determining the shear and bending fatigue performance of calcium phosphate coatings and of porous and nonporous metallic coatings and for determining the bending fatigue performance of metallic coatings over sprayed with calcium phosphate. This test method has been established based on plasma-sprayed titanium and plasma-sprayed hydroxylapatite coatings. The efficacy of this test method for other coatings has not been established. In the shear fatigue mode, this test method evaluates the adhesive and cohesive properties of the coating on a metallic substrate. In the bending fatigue mode, this test method evaluates both the adhesion of the coating as well as the effects that the coating may have on the substrate material. These methods are limited to testing in air at ambient temperature. These test methods are not intended for application in fatigue tests of components or devices; however, the test method which most closely replicates the actual loading configuration is preferred.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1160 − 14

Standard Test Method for

Shear and Bending Fatigue Testing of Calcium Phosphate

and Metallic Medical and Composite Calcium Phosphate/

1

Metallic Coatings

This standard is issued under the fixed designation F1160; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers the procedure for determining 2.1 ASTM Standards:

the shear and bending fatigue performance of calcium phos- E6 Terminology Relating to Methods of Mechanical Testing

phate coatings and of porous and nonporous metallic coatings E466 Practice for Conducting Force Controlled Constant

and for determining the bending fatigue performance of Amplitude Axial Fatigue Tests of Metallic Materials

metallic coatings over sprayed with calcium phosphate. This E467 Practice for Verification of Constant Amplitude Dy-

test method has been established based on plasma-sprayed namic Forces in an Axial Fatigue Testing System

titanium and plasma-sprayed hydroxylapatite coatings. The E468 Practice for Presentation of Constant Amplitude Fa-

efficacy of this test method for other coatings has not been tigue Test Results for Metallic Materials

established. In the shear fatigue mode, this test method E1012 Practice for Verification of Testing Frame and Speci-

evaluates the adhesive and cohesive properties of the coating men Alignment Under Tensile and Compressive Axial

on a metallic substrate. In the bending fatigue mode, this test Force Application

method evaluates both the adhesion of the coating as well as E1832 Practice for Describing and Specifying a Direct

the effects that the coating may have on the substrate material. Current Plasma Atomic Emission Spectrometer

These methods are limited to testing in air at ambient tempera-

3. Terminology

ture. These test methods are not intended for application in

3.1 The definitions of terms relating to shear and fatigue

fatigue tests of components or devices; however, the test

method which most closely replicates the actual loading testing appearing in Terminology E6 shall be considered as

configuration is preferred. applying to the terms used in this test method.

3.2 loading points, n—objects in contact with the test beam

1.2 The values stated in either SI units or inch-pound units

or bar used to apply force to the beam or bar, usually radiused

are to be regarded separately as standard. The values stated in

to con concentrate the force to a point or a line.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

4. Summary of Test Method

values from the two systems may result in non-conformance

4.1 Shear Fatigue Testing:

with the standard.

4.1.1 The intent of the shear fatigue test is to determine the

1.3 This standard does not purport to address all of the

adhesive or cohesive strength, or both, of the coating.

safety concerns, if any, associated with its use. It is the

4.1.2 This test method is designed to allow the coating to

responsibility of the user of this standard to establish appro-

fail at either the coating/substrate interface, within the coating,

priate safety and health practices and determine the applica-

or at the interface between the coating and the adhesive

bility of regulatory limitations prior to use.

bonding agent used to transmit the force to the coating.

4.2 Bending Fatigue Testing:

1

This test method is under the jurisdiction ofASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

2

F04.15 on Material Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2014.PublishedJuly2014.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ε

in 1991. Last previous edition approved in 2011 as F1160 – 05 (2011) . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1160-14. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1160 − 14

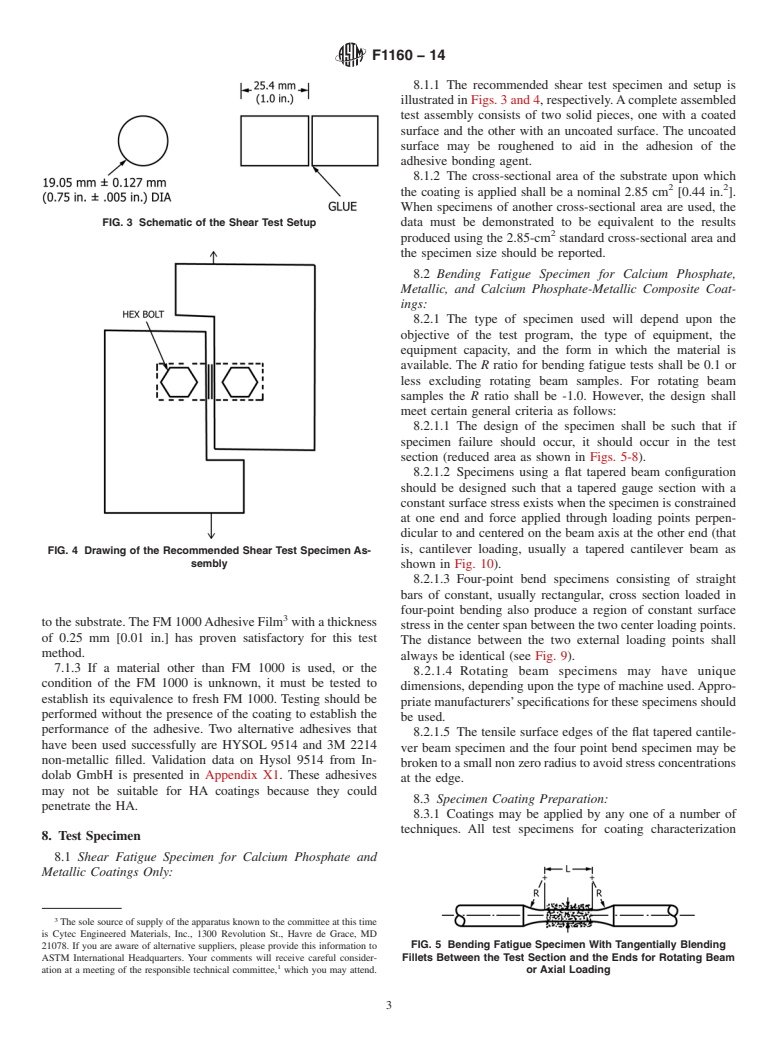

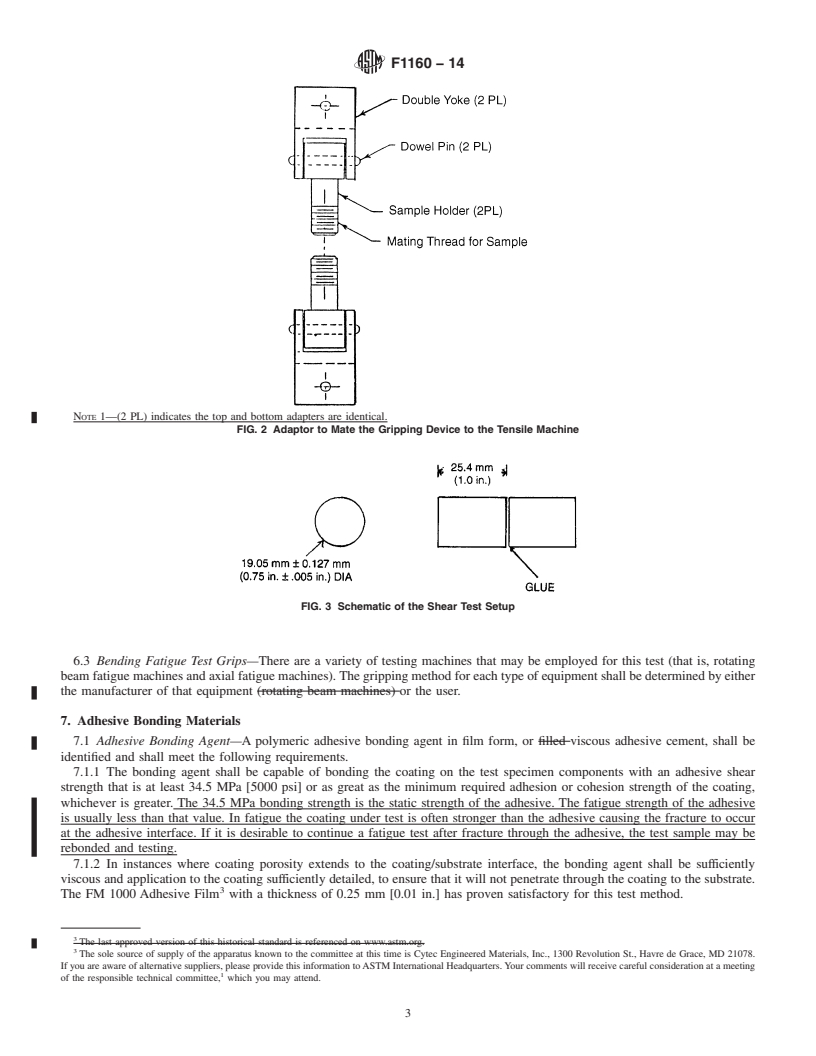

4.2.1 The primary intent of the bending fatigue test is to 6.2.3 Fig. 2 shows a drawing of the adaptor to mate the

quantify the effect that the coating has on the substrate it is shear fixture to the tensile machine

applied to. Secondarily, it may be used to provide a subjective

6.2.4 Figs. 3 and 4 show schematics of the test setup.

evaluation of coating adhesion, (that is, spalling resistance,

6.3 Bending

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F1160 − 05 (Reapproved 2011) F1160 − 14

Standard Test Method for

Shear and Bending Fatigue Testing of Calcium Phosphate

and Metallic Medical and Composite Calcium Phosphate/

1

Metallic Coatings

This standard is issued under the fixed designation F1160; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Units information was editorially corrected in January 2012.

1. Scope

1.1 This test method covers the procedure for determining the shear and bending fatigue performance of calcium phosphate

coatings and of porous and nonporous metallic coatings and for determining the bending fatigue performance of metallic coatings

oversprayed over sprayed with calcium phosphate. This test method has been established based on plasma-sprayed titanium and

plasma-sprayed hydroxylapatite coatings. The efficacy of this test method for other coatings has not been established. In the shear

fatigue mode, this test method evaluates the adhesive and cohesive properties of the coating on a metallic substrate. In the bending

fatigue mode, this test method evaluates both the adhesion of the coating as well as the effects that the coating may have on the

substrate material. These methods are limited to testing in air at ambient temperature. These test methods are not intended for

application in fatigue tests of components or devices; however, the test method which most closely replicates the actual loading

configuration is preferred.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E6 Terminology Relating to Methods of Mechanical Testing

E206 Definitions of Terms Relating to Fatigue Testing and the Statistical Analysis of Fatigue Data; Replaced by E 1150

3

(Withdrawn 1988)

E466 Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

E467 Practice for Verification of Constant Amplitude Dynamic Forces in an Axial Fatigue Testing System

E468 Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials

E1012 Practice for Verification of Testing Frame and Specimen Alignment Under Tensile and Compressive Axial Force

Application

E1832 Practice for Describing and Specifying a Direct Current Plasma Atomic Emission Spectrometer

3. Definitions

3.1 The definitions of terms relating to shear and fatigue testing appearing in Terminology E6 shall be considered as applying

to the terms used in this test method.

1

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved Oct. 1, 2011June 1, 2014. Published January 2012July 2014. Originally approved in 1991. Last previous edition approved in 20052011 as

ε

F1160 – 05.F1160 – 05 (2011) . DOI: 10.1520/F1160-05R11E01.10.1520/F1160-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1160 − 14

3. Terminology

3.1 The definitions of terms relating to shear and fatigue testing appearing in Terminology E6 shall be considered as applying

to the terms used in this test method.

3.2 loading points, n—objects in contact with the test beam or bar used to apply force to the beam or bar, usually radiused to

con concentrate the force to a point or a line.

4. Summary of Test Method

4.1 Shear Fatigue Testing:

4.1.1 The intent of the shear

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.