ASTM F1345-10a(2023)

(Specification)Standard Specification for Zinc-5 % Aluminum-Mischmetal Alloy-Coated Steel Chain-Link Fence Fabric

Standard Specification for Zinc-5 % Aluminum-Mischmetal Alloy-Coated Steel Chain-Link Fence Fabric

ABSTRACT

This specification covers the physical requirements for zinc-5 % aluminum-mischmetal (Zn-5Al-MM) alloy-coated steel chain-link fence fabric before weaving. The physical properties to which the fabric should conform are weave form, size of mesh, size of wire, height of fabric, selvage, weight of coating, workmanship, and standard length of rolls.

SCOPE

1.1 This specification covers zinc-5 % aluminum-mischmetal (Zn-5A1-MM) alloy-coated steel chain-link fence fabric, Zn-5A1-MM alloy-coated, before weaving.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1345 − 10a (Reapproved 2023)

Standard Specification for

Zinc-5 % Aluminum-Mischmetal Alloy-Coated Steel Chain-

Link Fence Fabric

This standard is issued under the fixed designation F1345; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification covers zinc-5 % aluminum- 3.1 Definitions of Terms Specific to This Standard:

mischmetal (Zn-5A1-MM) alloy-coated steel chain-link fence 3.1.1 chain link fence fabric, n—a fencing material made

fabric, Zn-5A1-MM alloy-coated, before weaving. from steel wire helically wound and interwoven in such a

manner as to provide a continuous mesh without knots or ties

1.2 The values stated in inch-pound units are to be regarded

except in the form of knuckling, or of twisting the ends of the

as the standard.

wires to form the selvage of the fabric.

1.3 This international standard was developed in accor-

3.1.2 diamond count, n—the number of diamond openings

dance with internationally recognized principles on standard-

from one edge of the fabric to the other. The diamond count of

ization established in the Decision on Principles for the

a given fabric shall begin at the first completed diamond at one

Development of International Standards, Guides and Recom-

edge and continue to the unfinished half or full opening at the

mendations issued by the World Trade Organization Technical

other edge.

Barriers to Trade (TBT) Committee.

3.1.3 knuckling, v—a term used to describe the type of

2. Referenced Documents selvage obtained by interlocking adjacent pairs of wire ends

and then bending the wire ends back into a loop. The loop shall

2.1 ASTM Standards:

be closed or nearly closed to a measurement less than the

A90/A90M Test Method for Weight [Mass] of Coating on

diameter of the wire.

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

3.1.4 twisting, v—a term used to describe the type of selvage

A491 Specification for Aluminum-Coated Steel Chain-Link

Fence Fabric obtained by twisting adjacent pairs of wire ends together in a

close helix of 1 ⁄2 machine turns, which is equivalent to three

A700 Guide for Packaging, Marking, and Loading Methods

full twists, and cutting the wire ends at an angle. The wire ends

for Steel Products for Shipment

beyond the twist shall be at least ⁄4 in. (6.4 mm) long. This

A817 Specification for Metallic-Coated Steel Wire for

type of selvage is not used on fabric with a mesh size of less

Chain-Link Fence Fabric and Marcelled Tension Wire

than 2 in. (50.8 mm).

2.2 Federal Standard:

Fed. Std. No. 123 Marking for Shipment, Civil Agencies

4. Ordering Information

2.3 Military Standards:

4.1 Orders for chain-link fence fabric purchased to this

MIL-STD-129 Marking for Shipment and Storage

specification shall include the following information:

MIL-STD-163 Steel Mill Products, Preparation for Ship-

4.1.1 Quantity (Section 13),

ment and Storage

4.1.2 Size of mesh (Section 7),

4.1.3 Size of wire (Section 8),

4.1.4 Height of fabric (Section 9),

This specification is under the jurisdiction of ASTM Committee F14 on Fences

4.1.5 Diamond count, if specified (Section 6),

and is the direct responsibility of Subcommittee F14.40 on Chain Link Fence and

Wire Accessories.

4.1.6 Type of selvage (Section 10),

Current edition approved Sept. 1, 2023. Published September 2023. Originally

4.1.7 Certification if required (Section 16),

approved in 1991. Last previous edition approved in 2019 as F1345 – 10a (2019).

4.1.8 Class of Coating (Section 11), and

DOI: 10.1520/F1345-10AR23.

4.1.9 ASTM designation and year of issue.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 All rolls of fencing accepted by the purchaser shall be

Standards volume information, refer to the standard’s Document Summary page on

billed on the basis of the original footage of the rolls before

the ASTM website.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

sampling, unless changed by contractual arrangement.

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

www.dodssp.daps.mil. NOTE 1—A typical ordering description is as follows: 25 rolls, 50 ft

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1345 − 10a (2023)

A

TABLE 1 Typical Diamond Count

NOTE 1—Other diamond counts are permitted (see 6.2).

NOTE 2—For fabric heights over 144 in., see 6.2.

NOTE 3—Variations to knuckled or twisted selvage may affect diamond count (see 6.2).

Nominal Di-

Height of Fence Fabric, in.

ameter Size of

Coated Mesh, in.

36 42 48 60 72 84 96 108 120 144

Wire, in.

1 1 1 1 1 1 1 1 1 1

0.192 2 10 ⁄2 12 ⁄2 13 ⁄2 17 ⁄2 20 ⁄2 24 ⁄2 27 ⁄2 31 ⁄2 34 ⁄2 41 ⁄2

1 1 1 1 1 1 1 1 1 1

0.148 2 10 ⁄2 12 ⁄2 13 ⁄2 17 ⁄2 20 ⁄2 24 ⁄2 27 ⁄2 31 ⁄2 34 ⁄2 41 ⁄2

0.148 1 ⁄4 . . 23 29 35 41 46 52 58 70

0.148 1 20 23 27 33 39 45 53 61 67 79

1 1 1 1 1 1

0.120 2 10 ⁄2 12 ⁄2 14 ⁄2 17 ⁄2 20 ⁄2 24 ⁄2

3 1 1 1 1

0.120 1 ⁄4 31 ⁄2 35 ⁄2 39 ⁄2 47 ⁄2

0.120 1 20 23 27 33 39 45 53 61 67 79

1 1 1 1 1 1

0.113 2 ⁄8 9 ⁄2 11 ⁄2 13 ⁄2 16 ⁄2 19 ⁄2

A

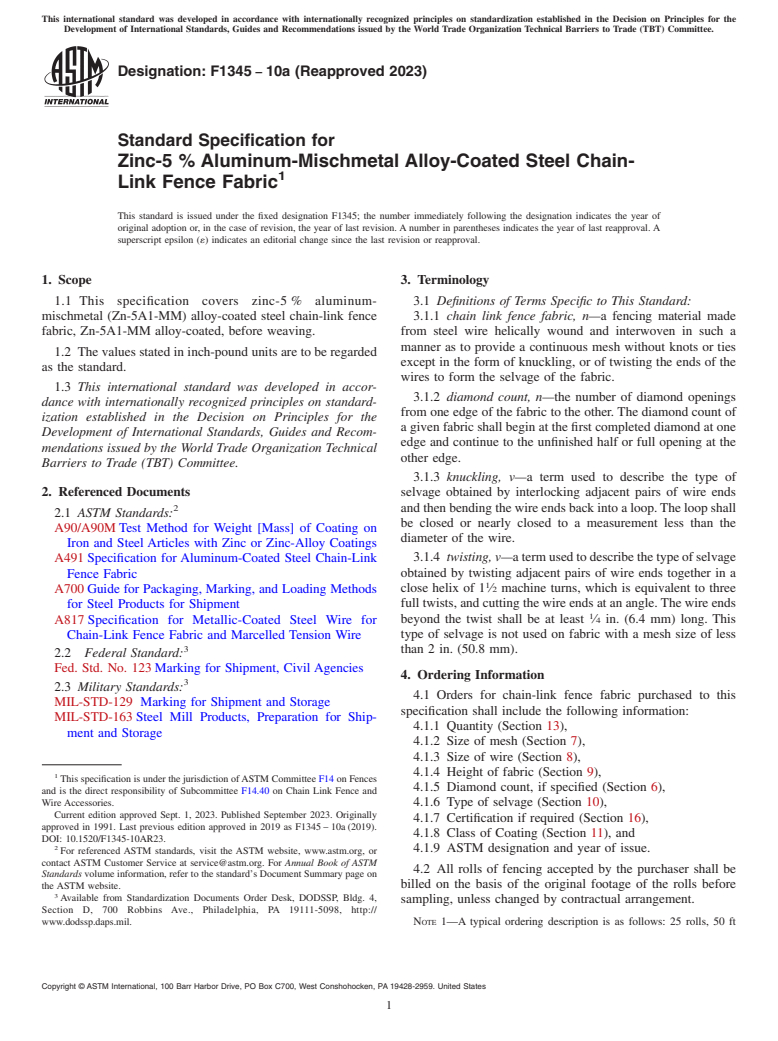

See Appendix X1 for SI equivalents and Fig. 1 for mesh sizes less than 1 in. (25.4 mm).

A

TABLE 2 Sizes of Wire and Mesh

each, chain-link fence fabric, Zn-5A1-MM alloy-coated, 2 in. mesh,

0.148 in. wire, 60 in. high, knuckled both selvages, class 2 coating to NOTE 1—For fabrics heights over 144 in., see 9.1.

Specification F1345.

Specified

Size,

Diameter

Coated Size of

5. Materials

of Height of Fence Fabric, in.

Wire Mesh, in.

Coated

Gauge

5.1 The wire from which the fabric is woven shall conform

Wire, in.

to all requirements of Specification A817 for Type III coating,

0.192 6 2 36, 42, 48, 60, 72, 84, 96, 108, 120, 144

0.148 9 2 36, 42, 48, 60, 72, 84, 96, 108, 120, 144

in the class of coating specified (Class 1 or Class 2).

0.148 9 1 ⁄4 . . . . . . 48, 60, 72, 84, 96, 108, 120, 144

0.148 9 1 36, 42, 48, 60, 72, 84, 96, 108, 120, 144

6. Weave

0.148 9 ⁄2 36, 42, 48, 60, 72, 84, 96, 108, 120, 144

0.120 11 2 36, 42, 48, 60, 72, 84 . . . . . . . . . . . . . . .

6.1 The wire shall be woven throughout in the form of

0.120 11 1 ⁄4 . . . . . . . . . . . . . . . . . . 96, 108, 120, 144

approximately uniform square mesh, having parallel sides and

0.120 11 1 ⁄4 . . . . . . 48, 60, 72, 84, 96, 108, 120, 144

horizontal and vertical diagonals of approximately uniform

0.120 11 1 36, 42, 48, 60, 72, 84, 96, 108, 120, 144

0.120 11 ⁄8 36, 42, 48, 60, 72, 84, 96, 108, 120, 144

dimensions. The top and bottom of the fabric shall be knuckled

0.120 11 ⁄2 36, 42, 48, 60, 72, 84, 96, 108, 120, 144

or twisted as specified in Section 10.

0.120 11 ⁄8 36, 42, 48, 60, 72, 84, 96, 108, 120, 144

1 1

0.113 11 ⁄2 2 ⁄8 36, 42, 48, 60, 72 . . . . . . . . . . . . . . . . . .

6.2 Typical diamond count for each standard height is

A

See Appendix X1 for SI equivalents. See Fig. 1 for mesh dimensions for ⁄8 in.,

shown in Table 1. Other diamond counts are permissible

1 5

⁄2 in., and ⁄8 in. mesh.

provided that they are consistent within a lot. The purchaser

has the option to specify the diamond count (4.1.5).

7. Size of Mesh

permissible variation from the specified height shall be 61 in.

7.1 The size of mesh shall be as indicated in Table 2.

(625 mm) for standard selvage.

7.2 The permissible variation from the specified size of

mesh shall be 6 ⁄8 in. (63.2 mm) for all mesh sizes except

10. Selvage

1 in., and 6 ⁄16 in. (61.6 mm) for 1 in. mesh size and under.

10.1 Unless oth

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.