ASTM D4445-10(2019)

(Test Method)Standard Test Method for Fungicides for Controlling Sapstain and Mold on Unseasoned Lumber (Laboratory Method)

Standard Test Method for Fungicides for Controlling Sapstain and Mold on Unseasoned Lumber (Laboratory Method)

SIGNIFICANCE AND USE

5.1 This test method is useful as a screening procedure for selecting fungicides or formulations for more rigorous field evaluation.

SCOPE

1.1 This (laboratory) test method is used for determining the minimum concentration of fungicide, or formulation of fungicides, that is effective in preventing biodeterioration by sapstain fungi and molds in selected species of wood under optimum laboratory conditions.

Note 1: From the results of this test, commercial treating solution concentrations cannot be estimated without further field tests.

1.2 The requirements for test materials and procedures are discussed in the following order:

Section

Summary of Test Method

4

Apparatus

6

Reagents

7

Wood

8

Test Fungi

9

Culture Media

10

Preparation of Inoculum

11

Preparation of Test Chambers

12

Treatment of Samples

13

Inoculation and Incubation

14

Evaluation of the Test

15

Report

16

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4445 − 10 (Reapproved 2019)

Standard Test Method for

Fungicides for Controlling Sapstain and Mold on

1

Unseasoned Lumber (Laboratory Method)

This standard is issued under the fixed designation D4445; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This (laboratory) test method is used for determining the 2.1 ASTM Standards:

D9 Terminology Relating to Wood and Wood-Based Prod-

minimum concentration of fungicide, or formulation of

fungicides, that is effective in preventing biodeterioration by ucts

D1165 Nomenclature of Commercial Hardwoods and Soft-

sapstain fungi and molds in selected species of wood under

optimum laboratory conditions. woods

D1193 Specification for Reagent Water

NOTE 1—From the results of this test, commercial treating solution

concentrations cannot be estimated without further field tests.

3. Terminology

1.2 The requirements for test materials and procedures are

3.1 Definitions—For definitions of terms used in this test

discussed in the following order:

method, refer to Terminologies D9 and D1165.

Section

Summary of Test Method 4

Apparatus 6 4. Summary of Test Method

Reagents 7

4.1 Unseasoned sapwood specimens are treated either by

Wood 8

Test Fungi 9 spraying with, or by immersing in, solutions or dispersions of

Culture Media 10

a fungicide formulation prepared at five or more concentration

Preparation of Inoculum 11

levels. The specimens are exposed to sapstain fungi and molds.

Preparation of Test Chambers 12

Treatment of Samples 13

Options for testing the toxicity of fungicides include testing

Inoculation and Incubation 14

against individual fungi or against several fungi by using a

Evaluation of the Test 15

mixed spore suspension for the inoculation of the specimens.

Report 16

4.2 The intensity of surface fungal growth is estimated after

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this incubation and the results used to determine the minimum

chemical treatment concentration giving zero growth (CGo).

standard.

1.4 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 This test method is useful as a screening procedure for

responsibility of the user of this standard to establish appro-

selecting fungicides or formulations for more rigorous field

priate safety, health, and environmental practices and deter-

evaluation.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

6. Apparatus

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

6.1 Incubation Room (or Incubation Cabinet), maintained at

Development of International Standards, Guides and Recom-

a temperature of 25 6 1°C, and relative humidity between 70

mendations issued by the World Trade Organization Technical

and 80 %.

Barriers to Trade (TBT) Committee.

6.2 Steam Sterilizer.

6.3 Containers:

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood

and is the direct responsibility of Subcommittee D07.06 on Treatments for Wood

2

Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2019. Published August 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1984. Last previous edition approved in 2015 as D4445–10(2015). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D4445-10R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4445 − 10 (2019)

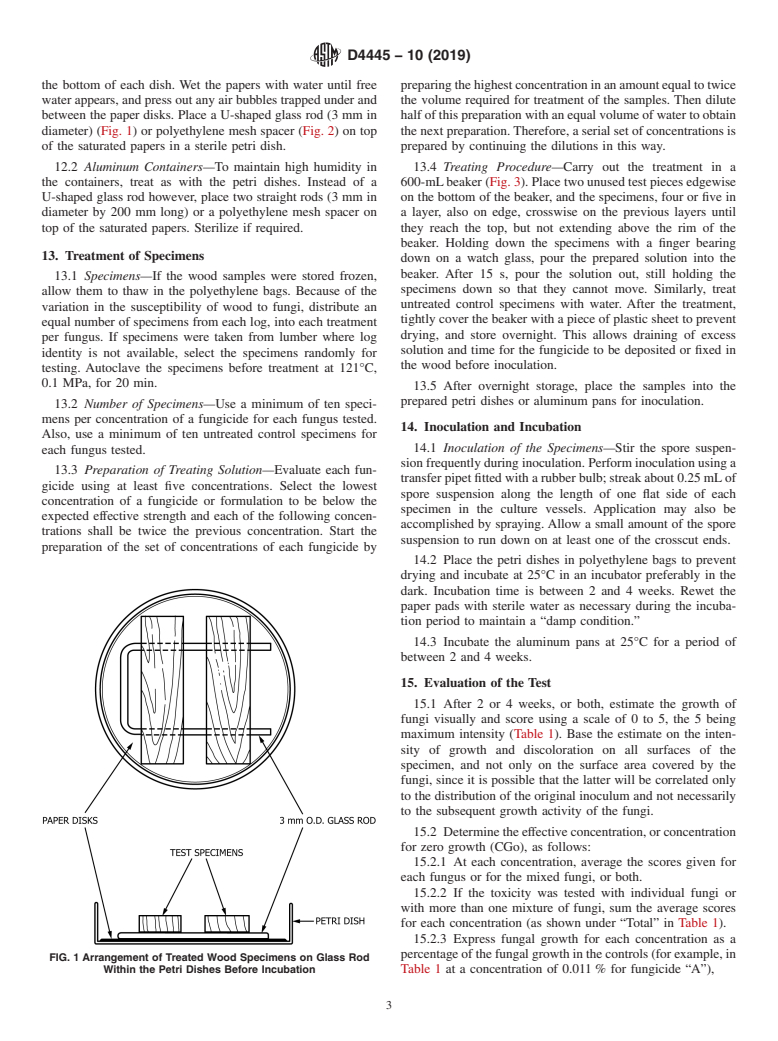

6.3.1 Sterile Petri Dishes, with minimum size of 140 9.2.1 Sapstain Fungi:

(diameter) by 20 mm (height) with lid or, 9.2.1.1 Diplodia natalensis P. Evans (ATCC 34643).

6.3.2 Aluminum Pans, with minimum size of 240 by 100 by 9.2.1.2 Ceratocystis pilifera (Fr.) C. Moreau (ATCC

20 mm (height) with aluminum foil cover. 15457).

9.2.1.3 Aureobasidium pullulans (d By) Arnaud (ATCC

6.4 Spacers:

16624).

6.4.1 U-Shaped Glass Rod, with 3 mm diameter or,

9.2.2 Mold Fungi:

6.4.2 Polyethylene Mesh, cut to cover the bottom of the

9.2.2.1 Trichoderma pseudokoningii (Rifai) (ATCC 26801).

selected container(s).

9.2.2.2 Cephaloascus fragrans Hanawa (ATCC 12091).

9.2.2.3 Gliocladium roseum (Link) Bainier (ATCC 10521).

7. Reagents

9.3 General Consideratio

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4445 − 10 (Reapproved 2015) D4445 − 10 (Reapproved 2019)

Standard Test Method for

Fungicides for Controlling Sapstain and Mold on

1

Unseasoned Lumber (Laboratory Method)

This standard is issued under the fixed designation D4445; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This (laboratory) test method is used for determining the minimum concentration of fungicide, or formulation of fungicides,

that is effective in preventing biodeterioration by sapstain fungi and molds in selected species of wood under optimum laboratory

conditions.

NOTE 1—From the results of this test, commercial treating solution concentrations cannot be estimated without further field tests.

1.2 The requirements for test materials and procedures are discussed in the following order:

Section

Summary of Test Method 4

Apparatus 6

Reagents 7

Wood 8

Test Fungi 9

Culture Media 10

Preparation of Inoculum 11

Preparation of Test Chambers 12

Treatment of Samples 13

Inoculation and Incubation 14

Evaluation of the Test 15

Report 16

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D9 Terminology Relating to Wood and Wood-Based Products

D1165 Nomenclature of Commercial Hardwoods and Softwoods

D1193 Specification for Reagent Water

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminologies D9 and D1165.

4. Summary of Test Method

4.1 Unseasoned sapwood specimens are treated either by spraying with, or by immersing in, solutions or dispersions of a

fungicide formulation prepared at five or more concentration levels. The specimens are exposed to sapstain fungi and molds.

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood and is the direct responsibility of Subcommittee D07.06 on Treatments for Wood Products.

Current edition approved Nov. 1, 2015July 1, 2019. Published December 2015August 2019. Originally approved in 1984. Last previous edition approved in 20102015

as D4445 – 10.D4445–10(2015). DOI: 10.1520/D4445-10R15.10.1520/D4445-10R19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4445 − 10 (2019)

Options for testing the toxicity of fungicides include testing against individual fungi or against several fungi by using a mixed spore

suspension for the inoculation of the specimens.

4.2 The intensity of surface fungal growth is estimated after incubation and the results used to determine the minimum chemical

treatment concentration giving zero growth (CGo).

5. Significance and Use

5.1 This test method is useful as a screening procedure for selecting fungicides or formulations for more rigorous field

evaluation.

6. Apparatus

6.1 Incubation Room (or Incubation Cabinet), maintained at a temperature of 25 6 1°C, and relative humidity between 70 and

80 %.

6.2 Steam Sterilizer.

6.3 Containers:

6.3.1 Sterile Petri Dishes, with minimum size of 140 (diameter) by 20 mm (height) with lid or,

6.3.2 Aluminum Pans, with minimum size of 240 by 100 by 20 mm (height) with aluminum foil cover.

6.4 Spacers:

6.4.1 U-Shaped Glass Rod, with 3 mm diameter or,

6.4.2 Polyethylene Mesh, cut to cover the bottom of the selected container(s).

7. Reagents

7.1 Purity of Water—Reference to water s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.