ASTM E2995-14

(Specification)Standard Specification for ASTM Thermohydrometers with Integral Low-Hazard Thermometers

Standard Specification for ASTM Thermohydrometers with Integral Low-Hazard Thermometers

SCOPE

1.1 This specification covers glass thermohydrometers of various scale graduation systems, intended for use in a variety of ASTM Test Methods.

1.2 The thermohydrometers presented in this standard are not exact replacements for the thermohydrometers in Specification E100; the thermometers have larger maximum permissible scale errors than do their Hg-filled counterparts. The user should decide if these thermohydrometers are appropriate for use in his or her application.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2995 −14

StandardSpecification for

ASTM Thermohydrometers with Integral Low-Hazard

Thermometers

This standard is issued under the fixed designation E2995; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions—The definitions given inTerminology E344

1.1 This specification covers glass thermohydrometers of

apply.

various scale graduation systems, intended for use in a variety

of ASTM Test Methods.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 ledger paper, n—a paper characterized by strength,

1.2 The thermohydrometers presented in this standard are

high tearing resistance, eraseability, water resistance, ink

not exact replacements for the thermohydrometers in Specifi-

receptivity, uniformity of surface, and smoothness.

cation E100; the thermometers have larger maximum permis-

3.2.1.1 Discussion—Originally, ledger paper was used espe-

sible scale errors than do their Hg-filled counterparts. The user

cially for pen and ink records. Most ledger papers are surface

should decide if these thermohydrometers are appropriate for

sized, frequently subjected to appreciable wear, and must have

use in his or her application.

a high degree of permanence and durability.

1.3 This standard does not purport to address all of the

3.2.2 length of the scale, n—length of the nominal range in

safety concerns, if any, associated with its use. It is the

the stem, not including graduations extending above and below

responsibility of the user of this standard to establish appro-

the nominal limits.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 3.2.3 thermohydrometer, n—glass hydrometer having an

integral thermometer.

2. Referenced Documents

3.2.4 top of the thermohydrometer, n—top of the finished

instrument.

2.1 ASTM Standards:

D287 Test Method for API Gravity of Crude Petroleum and

3.2.5 total length, n—overall length of the finished thermo-

Petroleum Products (Hydrometer Method) hydrometer.

D1250 Guide for Use of the Petroleum Measurement Tables

4. Specifications

D3290 Specification for Bond and Ledger Papers for Perma-

nent Records (Withdrawn 2010) 4.1 Thermohydrometers shall conform to the detailed speci-

fications in Table 1 and to the general requirements specified in

E77 Test Method for Inspection and Verification of Ther-

mometers Sections5–15.

E100 Specification for ASTM Hydrometers

4.2 Thermohydrometers shall conform to the inspection

E126 Test Method for Inspection, Calibration, and Verifica-

criteria found in Section 16 and the calibration and verification

tion of ASTM Hydrometers

criteria found in Section 14.

E344 Terminology Relating to Thermometry and Hydrom-

4.3 Thermohydrometers manufactured to previous revisions

etry

of this specification shall retain the sameASTM status as those

meeting current specifications.

4.4 At time of purchase, scale errors shall not exceed the

This specification is under the jurisdiction of ASTM Committee E20 on

maximum permissible scale error found in Table 1.

Temperature Measurement and is the direct responsibility of Subcommittee E20.05

on Liquid-in-Glass Thermometers and Hydrometers.

NOTE 1—Caution—Users should be aware that both temperature and

Current edition approved Dec. 1, 2014. Published December 2014. DOI:

density indications of thermohydrometers may change with rough

10.1520/E2995-14

2 handling, shock, exposure to aggressive liquids, and thermal cycling,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

among other factors. Consequently, test results and performance obtained

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

at the time of manufacture may not necessarily apply throughout an

Standards volume information, refer to the standard’s Document Summary page on

extended period of use. Periodic calibration or verification of these

the ASTM website.

The last approved version of this historical standard is referenced on instruments, in accordance with procedures set forth in Standard Test

www.astm.org. Method E126, is recommended

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2995−14

TABLE 1 Specifications for ASTM Thermohydrometers

API Gravity Thermohydrometers

for Petroleum Products and Other Liquids of Similar Surface Tensions (33 dynes/cm or less)

Thermometer Scale in Body

ASTM Thermohydrometer No. Nominal API Gravity Range, deg

S550HL-14 -6 to +6

S551HL-14 -1 to 11

S552HL-14 9to21

S553HL-14 19 to 31

S554HL-14 29 to 41

S555HL-14 39 to 51

S556HL-14 49 to 61

S557HL-14 59 to 71

S558HL-14 69 to 81

S559HL-14 79 to 91

S560HL-14 89 to 101

S561HL-14 37 to 49

S562HL-14 64 to 76

Thermohydrometer Dimensions

Total length, mm 374 to 387

Body diameter, mm 18 to 25

Stem diameter, min, mm 4.0

Hydrometer Scale

Standard temperature, °F 60

Subdivisions, °API 0.1

Intermediate lines at, °API 0.5

Main (numbered) lines at, °API 1.0

Scale error at any point not to exceed, °API 0.1

Length of nominal scale, mm 125 to 145

Thermometer Scale

Range, °F 0to150

Immersion total

Subdivisions, °F 2

Intermediate lines at, °F 10

Main (numbered) lines at, °F 20

Scale error at any point not to exceed, °F 2

Scale length, mm 80 to 110

Density Thermohydrometers

for Petroleum Products and Other Liquids of Similar Surface Tensions (33 dynes/cm or less)

Thermometer Scale in Body

ASTM Thermohydrometer No. Nominal Range, kg/m at 15°C

S500HL-14 600 to 650

S501HL-14 650 to 700

S502HL-14 700 to 750

S503HL-14 750 to 800

S504HL-14 800 to 850

S505HL-14 850 to 900

S506HL-14 900 to 950

S507HL-14 950 to 1000

S508HL-14 1000 to 1050

S509HL-14 1050 to 1100

S510HL-14 775 to 825

Thermohydrometer Dimensions

Total length, mm 374 to 387

Body diameter, mm 18 to 25

Stem diameter, min, mm 4.0

Hydrometer Scale

Standardization temperature, °C 15

Subdivisions, kg/m at 15°C 0.5

Intermediate lines, kg/m at 15°C 1.0

Number lines, kg/m at 15°C 5

Main (numbered) lines, kg/m at 15°C 10

Scale error at any point not to exceed, kg/m at 15°C 0.5

Length of nominal scale, mm 125 to 145

Thermometer Scale

Range, °C -20to65

Immersion total

Subdivisions, °C 1

Intermediate lines at, °C 5

Main (numbered) lines at, °C 10

Scale error at any point not to exceed, °C 1

Scale length, mm 80 to 110

E2995−14

5. Type 5.6 The API thermohydrometers are intended for use in

conjunction withTest Method D287, with hydrometer readings

5.1 Thermohydrometers shall be of the constant mass,

being corrected in accordance with Guide D1250, IP 200.

variable displacement type. Thermohydrometers shall be made

Therefore, these thermohydrometers shall be made of glass

of glass, except for the scale, ballast, cement, and the thermo-

having a cubical coefficient of expansion of approximately

metric liquid of the thermometer.

0.000023/1°C or 0.0000128/1°F.

5.2 The outer surface of the stem and body shall be

symmetrical about the vertical axis. There shall be no uneven

6. Body

or unnecessary thickening of the walls, and no abrupt changes

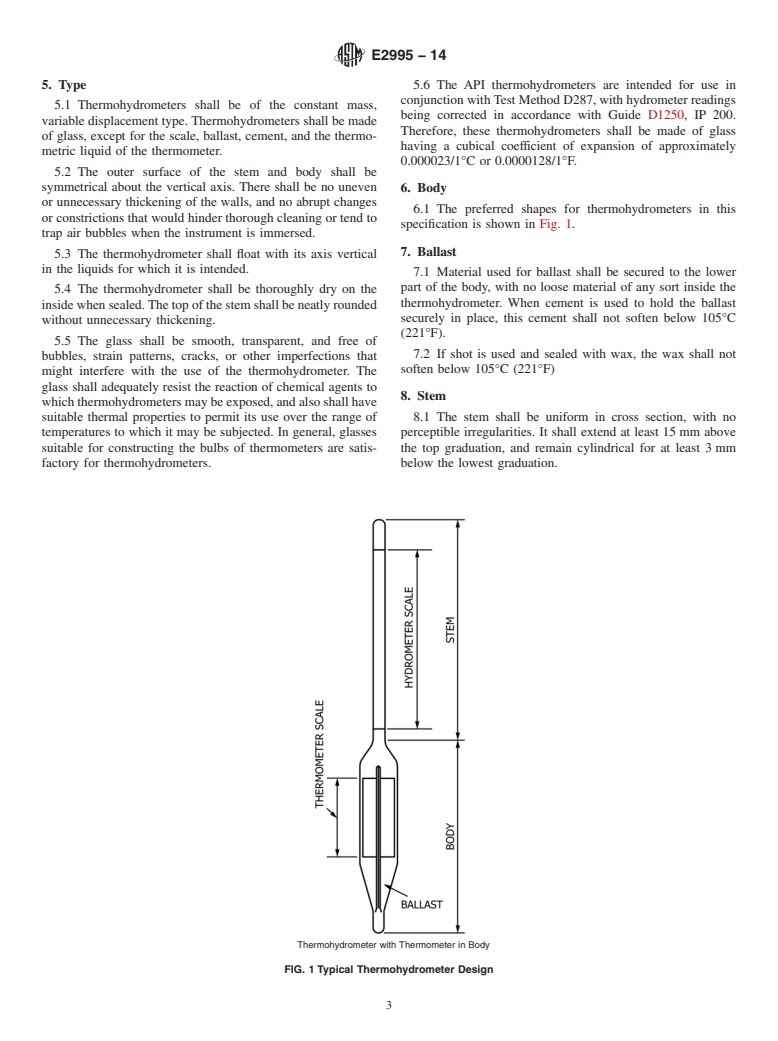

6.1 The preferred shapes for thermohydrometers in this

or constrictions that would hinder thorough cleaning or tend to

specification is shown in Fig. 1.

trap air bubbles when the instrument is immersed.

7. Ballast

5.3 The thermohydrometer shall float with its axis vertical

in the liquids for which it is intended.

7.1 Material used for ballast shall be secured to the lower

part of the body, with no loose material of any sort inside the

5.4 The thermohydrometer shall be thoroughly dry on the

thermohydrometer. When cement is used to hold the ballast

inside when sealed.The top of the stem shall be neatly rounded

securely in place, this cement shall not soften below 105°C

without unnecessary thickening.

(221°F).

5.5 The glass shall be smooth, transparent, and free of

7.2 If shot is used and sealed with wax, the wax shall not

bubbles, strain patterns, cracks, or other imperfections that

soften below 105°C (221°F)

might interfere with the use of the thermohydrometer. The

glass shall adequately resist the reaction of chemical agents to

8. Stem

which thermohydrometers may be exposed, and also shall have

suitable thermal properties to permit its use over the range of 8.1 The stem shall be uniform in cross section, with no

temperatures to which it may be subjected. In general, glasses perceptible irregularities. It shall extend at least 15 mm above

suitable for constructing the bulbs of thermometers are satis- the top graduation, and remain cylindrical for at least 3 mm

factory for thermohydrometers. below the lowest graduation.

Thermohydrometer with Thermometer in Bod

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.