ASTM F2807-13

(Specification)Standard Specification for Multilayer Polyethylene-Polyamide (PE-PA) Pipe for Pressure Piping Applications

Standard Specification for Multilayer Polyethylene-Polyamide (PE-PA) Pipe for Pressure Piping Applications

ABSTRACT

This specification establishes the requirements and test methods for 1/2 in. through 14 in. multilayer polyethylene-polyamide (PE-PA) pipe, which is a two-layer pipe (PE pipe layer bonded to an inner layer of PA). It covers the multilayer pipe for use in piping applications where the permeation and chemical resistance of PA compounds may be useful to protect the PE pipe layer, such as oil and gas producing applications that convey oil, dry or wet gas, and multiphase fluids. Electrofusion and mechanical joints are typically used for this multilayer pipe.

SCOPE

1.1 This specification covers requirements and test methods for 1/2 in. through 14 in. multilayer polyethylene-polyamide (PE-PA) pipe, which is a two-layer pipe (PE pipe layer bonded to an inner layer of PA). The multilayer pipe covered by this specification is intended for use in piping applications where the permeation and chemical resistance of polyamide (PA) compounds may be useful to protect the PE pipe layer, such as oil and gas producing applications that convey oil, dry or wet gas, and multiphase fluids.Note 1—Permeability and chemical resistance depends on the type of PA used. The PA layer delays but does not prevent liquid hydrocarbons effects. Therefore, the hydrocarbon chemical design factor for this multilayer pipe should be the same as for PE pipe layer—see X1.2.

1.2 Electrofusion and mechanical joints are typically used for this multilayer pipe.

1.3 Unless specified otherwise, all the pipe requirements in this standard are for the multilayer pipe.

1.4 The PA layer is not taken into consideration for the design pressure of multilayer pipe meeting this specification. Design pressure rating is determined from the PE pipe layer alone—see Appendix X1.

1.5 Units—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in figures and tables) shall not be considered as requirements of the standard.

1.7 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2807 −13 An American National Standard

Standard Specification for

Multilayer Polyethylene-Polyamide (PE-PA) Pipe for

Pressure Piping Applications

This standard is issued under the fixed designation F2807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope environmental practices and determine the applicability of

regulatory limitations prior to use.

1.1 This specification covers requirements and test methods

1.8 This international standard was developed in accor-

for ⁄2 in. through 14 in. multilayer polyethylene-polyamide

dance with internationally recognized principles on standard-

(PE-PA) pipe, which is a two-layer pipe (PE pipe layer bonded

ization established in the Decision on Principles for the

to an inner layer of PA). The multilayer pipe covered by this

Development of International Standards, Guides and Recom-

specification is intended for use in piping applications where

mendations issued by the World Trade Organization Technical

the permeation and chemical resistance of polyamide (PA)

Barriers to Trade (TBT) Committee.

compounds may be useful to protect the PE pipe layer, such as

oil and gas producing applications that convey oil, dry or wet

2. Referenced Documents

gas, and multiphase fluids.

NOTE 1—Permeability and chemical resistance depends on the type of

2.1 ASTM Standards:

PA used. The PA layer delays but does not prevent liquid hydrocarbons

D618 Practice for Conditioning Plastics for Testing

effects. Therefore, the hydrocarbon chemical design factor for this

D1598 Test Method for Time-to-Failure of Plastic Pipe

multilayer pipe should be the same as for PE pipe layer—see X1.2.

Under Constant Internal Pressure

1.2 Electrofusion and mechanical joints are typically used

D1599 Test Method for Resistance to Short-Time Hydraulic

for this multilayer pipe.

Pressure of Plastic Pipe, Tubing, and Fittings

1.3 Unless specified otherwise, all the pipe requirements in D1600 Terminology forAbbreviatedTerms Relating to Plas-

this standard are for the multilayer pipe. tics

D1603 Test Method for Carbon Black Content in Olefin

1.4 The PA layer is not taken into consideration for the

Plastics

design pressure of multilayer pipe meeting this specification.

D2122 Test Method for Determining Dimensions of Ther-

Design pressure rating is determined from the PE pipe layer

moplastic Pipe and Fittings

alone—see Appendix X1.

D2290 Test Method for Apparent Hoop Tensile Strength of

1.5 Units—The values stated in inch-pound units are to be

Plastic or Reinforced Plastic Pipe

regarded as the standard. The values given in parentheses are

D2837 Test Method for Obtaining Hydrostatic Design Basis

mathematical conversions to SI units that are provided for

forThermoplasticPipeMaterialsorPressureDesignBasis

information only and are not considered standard.

for Thermoplastic Pipe Products

1.6 The text of this standard references notes and footnotes D3350 Specification for Polyethylene Plastics Pipe and Fit-

tings Materials

which provide explanatory material. These notes and footnotes

(excluding those in figures and tables) shall not be considered D4218 Test Method for Determination of Carbon Black

Content in Polyethylene Compounds By the Muffle-

as requirements of the standard.

Furnace Technique

1.7 The following precautionary caveat pertains only to the

D6779 Classification System for and Basis of Specification

test method portion, Section 6, of this specification.This

for Polyamide Molding and Extrusion Materials (PA)

standard does not purport to address all of the safety concerns,

F412 Terminology Relating to Plastic Piping Systems

if any, associated with its use. It is the responsibility of the user

F1290 PracticeforElectrofusionJoiningPolyolefinPipeand

of this standard to establish appropriate safety, health, and

Fittings

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.68 on Energy For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 1, 2013. Published December 2013. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2807-13. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2807 − 13

2.2 Federal Specifications: 4. Compound Requirements

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

4.1 PE Compound Requirements—The PE compound used

2.3 ISO Standards: to make the PE pipe layer shall be virgin compound and shall

ISO 1167 Thermoplastics pipes for the conveyance of have a Plastics Pipe Institute (PPI) hydrostatic design basis

fluids—Resistance to internal pressure (HDB) rating in accordance with PPI TR-3 using Test Method

ISO 3126 Plastic piping systems—Plastic piping D2837.ThePEcompoundusedforthePEpipelayershallhave

components—Measurement and determination of dimen- apipematerialdesignationcodeofPE4710inaccordancewith

sions PPI TR-3 Section F.7 and shall be listed in PPI TR-4, and shall

ISO 6259 Thermoplastics pipes—Determination of tensile meet Specification D3350 requirements, with a minimum cell

properties class of 444474C.

ISO 8510-2 Adhesives—Peel test for a flexible-to-rigid 4.1.1 Additive Classes—PE compounds shall be Code C as

specimen assembly—180° peel defined in Specification D3350. Code C compound shall

5 contain 2.0 to 3.0 percent carbon black as measured by Test

2.4 Plastic Pipe Institute:

Method D1603 or D4218. The pipe manufacturer shall mea-

PPI TR-3 Policies and Procedures for Developing Hydro-

sure carbon black content of the compound once per week.

static Design Basis (HDB), Pressure Design Basis (PDB),

4.1.2 Chemical Resistance—Testing shall be conducted per

Strength Design Basis (SDB), and Minimum Required

6.10 on specimens of PE compound from compression molded

Strength (MRS) Ratings for Thermoplastic Piping Mate-

plaques or from a ring specimen prepared from pipe.

rials or Pipe

PPI TR-4 PPI Listing of Hydrostatic Design Basis (HDB),

NOTE 2—This test is only an indication of what may happen as a result

of short-term exposure to these chemicals. Contact the manufacturer for

Strength Design Basis (SDB), Pressure Design Basis

specific chemical resistance information for this product.

(PDB) and Minimum Required Strength (MRS) Ratings

for Thermoplastic Piping Materials or Pipe 4.1.3 Elevated Temperature—The PE 4710 compound shall

PPI TR-9 Recommended Design Factors and Design Coef- have an HDB at 140°F (60°C) of at least 1000 psi listed in PPI

ficients for Thermoplastic Pressure Pipe TR-4.

PPI TR-23 Guidelines for Establishing the Pressure Rating

4.2 PA Compound Requirements—The PA compound shall

for Multilayer and Co-extruded Plastic Pipes

be a non-reinforced PA with the three-digit cell class (group,

2.5 Other Documents: class, grade) in accordance with Classification D6779 per

SAE J 2260 Nonmetallic Fuel System Tubing with One or Table 1.

More Layers 4.2.1 Chemical Resistance—Based on the intended applica-

EN 14125 Thermoplastic and flexible metal pipework for tion and the corresponding need for chemical resistance, the

underground installation at petrol filling stations

multilayer pipe manufacturer shall provide chemical resistance

properties for the type of PAcompound used in the PAlayer of

3. Terminology this multilayer pipe.

4.2.2 Color—The PAlayer shall have a different color from

3.1 Definitions:

theblackPEpipelayersothatitcanbeeasilyrecognized,such

3.1.1 Definitions are in accordance with Terminology F412,

as the APWA color coding system of yellow for gas and oil

and abbreviations are in accordance with Terminology D1600,

lines.

unless otherwise specified.

4.3 Rework Compound—To prevent possible contamination

3.1.2 multilayer pipe, n—plastic pipe comprised of more

between PE and PA, rework (regrind) shall not be used for the

than one layer.

polyethylene and polyamide layers.

3.1.3 re-rounding equipment, n—tooling used to reform the

4.4 Documentation—A documentation system to allow for

pipe and permanently reduce ovality to 5% or less.

traceability of compounds used in the manufacture of the

3.1.4 rounding equipment, n—tooling, devices, clamps, and

multilayer pipe product meeting the requirements of this

so forth, used to temporarily hold the pipe round while a

specification shall exist and be supplied to the purchaser, if

joining procedure (heat fusion, electrofusion, or mechanical) is

requested.

performed.

5. Multilayer Pipe Requirements

5.1 General—Multilayer pipe shall be supplied in either

coils or straight lengths. Pipe that will be supplied in coils shall

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

meet the minimum test values required by this standard after

www.access.gpo.gov.

Available from International Organization for Standardization (ISO), 1, ch. de

la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

TABLE 1 Polyamide Type and Cell Class

Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

Polyamide (PA) Type PA Cell Class

Irving, TX 75062, http://www.plasticpipe.org.

Available from National Fire Protection Association (NFPA), 1 Batterymarch

PA 6 214

Park, Quincy, MA 02169-7471, http://www.nfpa.org.

PA 11 322

Available from European Committee for Standardization (CEN), Avenue PA 12 423

Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

F2807 − 13

5 % was chosen as the limit for the amount contributed by manufacturing,

being bent to minimum radius used for coiling and then

packing, in-plant storage, and shipping. Before or during installation,

uncoiled or straightened prior to testing.

coiled multilayer pipe larger than 3 in. IPS (89 mm) should be processed

5.1.1 The multilayer pipe shall meet all the performance

by the installer through re-rounding equipment that corrects ovality to 5%

requirements of this standard. There shall be no delamination

or less.

of the bonded PA layer during coiling, shipping, handling or

NOTE 4—Ovality is a packaging condition that occurs when roundable

pipe is wound into a coil—the pipe flattens out as it is coiled. Ovality is

operation of the multilayer pipe.

corrected when joining equipment is applied to roundable pipe, or by field

5.2 Workmanship—The multilayer pipe shall be homoge-

processing roundable pipe through re-rounding and straightening equip-

neous throughout each layer. The multilayer pipe shall be free

ment during installation.

of visible cracks, holes, foreign inclusion, blisters, and dents,

5.3.3.1 Length—The multilayer pipe shall be supplied in

or other injurious defects. Each respective layer of the multi-

straight lengths or coils as agreed upon between the manufac-

layer pipe shall be as uniform as commercially practicable in

turer and the purchaser. The length shall not be less than the

color, opacity, density, and other physical properties.

minimum length agreed upon when corrected to 73°F (23°C).

5.3 Multilayer Pipe Dimensions and Tolerances:

5.4 Sustained Pressure—To assure slow crack growth resis-

5.3.1 PE Pipe Layer Dimensions—The PE dimensions shall

tance of the multilayer pipe construction, the multilayer pipe

be specified by wall thickness and outside diameter.

shall not fail as defined in Test Method D1598, when tested in

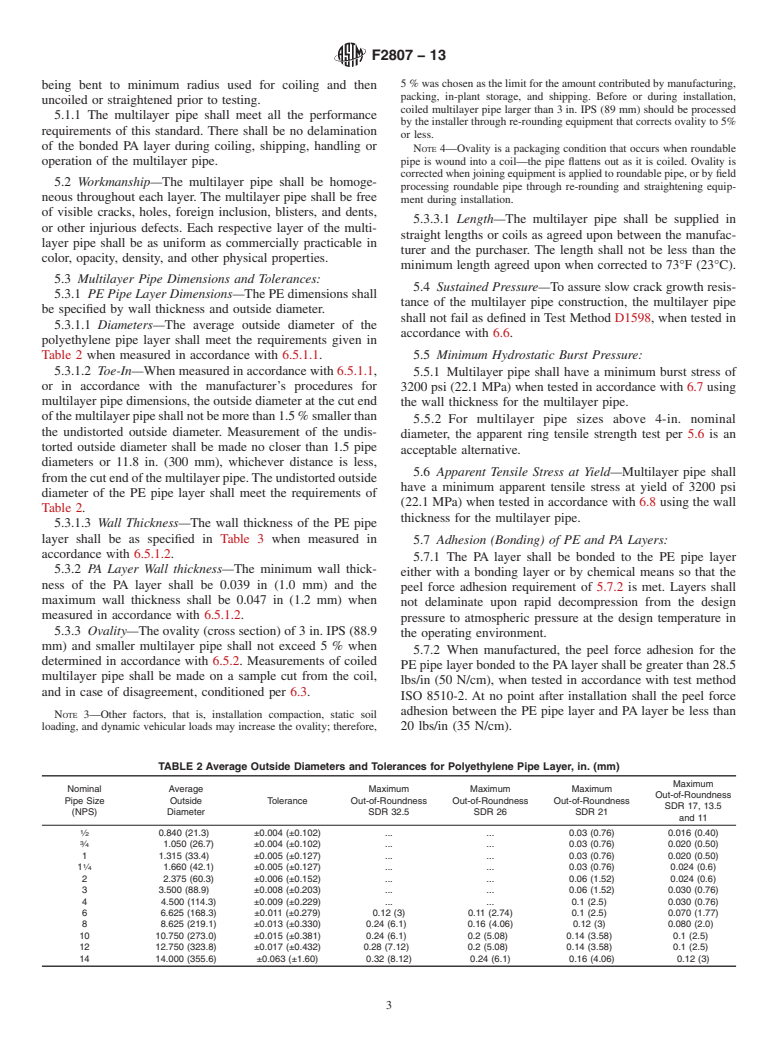

5.3.1.1 Diameters—The average outside diameter of the

accordance with 6.6.

polyethylene pipe layer shall meet the requirements given in

Table 2 when measured in accordance with 6.5.1.1. 5.5 Minimum Hydrostatic Burst Pressure:

5.3.1.2 Toe-In—When measured in accordance with 6.5.1.1,

5.5.1 Multilayer pipe shall have a minimum burst stress of

or in accordance with the manufacturer’s procedures for

3200 psi (22.1 MPa) when tested in accordance with 6.7 using

multilayer pipe dimensions, the outside diameter at the cut end

the wall thickness for the multilayer pipe.

ofthemultilayerpipeshallnotbemorethan1.5%smallerthan

5.5.2 For multilayer pipe sizes above 4-in. nominal

the undistorted outside diameter. Measurement of the undis-

diameter, the apparent ring tensile strength test per 5.6 is an

torted outside diameter shall be made no closer than 1.5 pipe

acceptable alternative.

diameters or 11.8 in. (300 mm), whichever distance is less,

5.6 Apparent Tensile Stress at Yield—Multilayer pipe shall

fromthecutendofthemultilayerpipe.Theundistortedoutside

have a minimum apparent tensile stress at yield of 3200 psi

diameter of the PE pipe layer shall meet the requirements of

(22.1 MPa) when tested in accordance with 6.8 using the wall

Table 2.

thickness for the multilayer pipe.

5.3.1.3 Wall Thickness—The wall thickness of the PE pipe

layer shall be as specified in Table 3 when measured in

5.7 Adhesion (Bonding) of PE and PA Layers:

accordance with 6.5.1.2.

5.7.1 The PA layer shall be bonded to the PE pipe layer

5.3.2 PA Layer Wall thickness—The minimum wall thick-

either with a bonding layer or by chemical means so that the

ness of the PA layer shall be 0.039 in (1.0 mm) and the

peel force adhesion requirement of 5.7.2 is met. Layers shall

maximum wall thickness shall be 0.047 in (1.2 mm) when

not delaminate upon rapid decompression from the design

measured in accordance with 6.5.1.2.

pressure to atmospheric pressure at the design temperature in

5.3.3 Ovality—The ovality (cross section) of 3 in. IPS (88.9

the operating environment.

mm) and smaller multilayer pipe shall not exceed 5 % when

5.7.2 When manufactured, the peel force adhesion for the

determined in accordance with 6.5.2. Measurements of coiled

PE pipe layer bonded to the PAlayer shall be greater than 28.5

multilayer pipe shall be made on a sample cut from the coil,

lbs/in (50 N/cm), when tested in accordance with test method

and in case of disagreement, conditioned per 6.3.

ISO 8510-2. At no point after installation shall the peel force

adhesion between the PE pipe layer and PA layer be less than

NOTE 3—Other factors, that is, installation compaction, static soil

loading, and dynamic vehicular loads may increase the ovality; therefore, 20 lbs/in (35 N/cm).

TABLE 2 Average Outside Diameters and Tolerances for Polyethylene Pipe Layer, in. (mm)

Maximum

Nominal Average Maximum Maximum Maximum

Out-of-Roundness

Pipe Size Outside Tolerance Out-of-Roundness Out-of-Roundness Out-of-Roundness

SDR 17, 13.5

(NPS) Diameter SDR 32.5 SDR 26 SD

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.