ASTM D1907-97

(Test Method)Standard Test Method for Linear Density of Yarn (Yarn Number) by the Skein Method

Standard Test Method for Linear Density of Yarn (Yarn Number) by the Skein Method

SCOPE

1.1 This test method covers the determination of the linear density of all types of yarn in package form, subject to the limitations of size and stretch given in 1.2 and 1.3. Provision is made for expressing yarn linear density in all the traditional yarn numbering systems.

1.2 This method is applicable to yarns that stretch less than 5 % when tension on the yarn is increased from 0.25 to 0.75 cN/tex (0.25 to 0.75 gf/tex). By mutual agreement, and use of a lower than specified reeling tension, this method may also be adapted to measure the linear density of yarns that stretch more than 5 %, under the above force.

1.3 This method is applicable to yarns finer than 2000 tex. However, it may be also adapted to coarser yarns by the use of skeins of shorter than specified lengths, and alternate reeling conditions, agreeable to the interested parties.

1.4 Depending on the procedure used to calculate the moisture content of the yarn being tested, and its actual moisture content, or finish content, or both, one or more of the following options may be utilized.

1.4.1 Unscoured Yarn:

Option 1—Yarn at equilibrium with the standard atmosphere for testing textiles.

Option 2—Oven-dried yarn.

Option 3—Oven-dried yarn, plus commercial moisture regain.

1.4.2 Scoured Yarn:

Option 4—Scoured yarn at equilibrium with the standard atmosphere for testing textiles.

Option 5—Oven-dried, scoured yarn.

Option 6—Oven-dried, scoured yarn, plus commercial moisture regain.

Option 7—Oven-dried, scoured yarn, plus commercial allowance (commercial moisture regain, plus an allowance for finish).

1.5 Specimens used to determine yarn linear density may also be used to determine the skein breaking strength of the yarn. Hence, this method provides the sequence of steps to be followed, to determine both these yarn properties.

Note 1—The linear density of yarns produced with jute, or glass, may also be determined by the following approved methods: Specifications D 541, D 578, and D 681. The linear density of short yarn segments, raveled from fabrics, may be determined by Test Method D 1059.

1.6 The values stated in SI units are to be regarded as standard. The values shown in parentheses are approximate conversions to U.S. customary unit equivalents.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1907 – 97

Standard Test Method for

Linear Density of Yarn (Yarn Number) by the Skein Method

This standard is issued under the fixed designation D 1907; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

also be determined by the following approved methods: Specifications

1. Scope

D 541, D 578, and D 681. The linear density of short yarn segments,

1.1 This test method covers the determination of the linear

raveled from fabrics, may be determined by Test Method D 1059.

density of all types of yarn in package form, subject to the

1.6 The values stated in SI units are to be regarded as

limitations of size and stretch given in 1.2 and 1.3. Provision is

standard. The values shown in parentheses are approximate

made for expressing yarn linear density in all the traditional

conversions to U.S. customary unit equivalents.

yarn numbering systems.

1.7 This standard does not purport to address all of the

1.2 This method is applicable to yarns that stretch less than

safety concerns, if any, associated with its use. It is the

5 % when tension on the yarn is increased from 0.25 to 0.75

responsibility of the user of this standard to establish appro-

cN/tex (0.25 to 0.75 gf/tex). By mutual agreement, and use of

priate safety and health practices and determine the applica-

a lower than specified reeling tension, this method may also be

bility of regulatory limitations prior to use.

adapted to measure the linear density of yarns that stretch more

than 5 %, under the above force.

2. Referenced Documents

1.3 This method is applicable to yarns finer than 2000 tex.

2.1 ASTM Standards:

However, it may be also adapted to coarser yarns by the use of

D 123 Terminology Relating to Textiles

skeins of shorter than specified lengths, and alternate reeling

D 541 Specification for Single Jute Yarn

conditions, agreeable to the interested parties.

D 578 Specification for Glass Fiber Strands

1.4 Depending on the procedure used to calculate the

D 681 Specification for Jute Rove and Plied Yarn for

moisture content of the yarn being tested, and its actual

Electrical and Packing Purposes

moisture content, or finish content, or both, one or more of the

D 1059 Test Method for Yarn Number Based on Short-

following options may be utilized.

Length Specimens

1.4.1 Unscoured Yarn:

D 1578 Test Method for Breaking Strength of Skeins

Option 1—Yarn at equilibrium with the standard atmosphere

D 1776 Practice for Conditioning Textiles for Testing

for testing textiles.

D 1909 Table of Commercial Moisture Regains for Textile

Option 2—Oven-dried yarn.

Fibers

Option 3—Oven-dried yarn, plus commercial moisture re-

D 2257 Test Method for Extractable Matter in Textiles

gain.

D 2258 Practice for Sampling Yarn for Testing

1.4.2 Scoured Yarn:

D 2494 Test Method for Commercial Mass of a Shipment of

Option 4—Scoured yarn at equilibrium with the standard

Yarn or Man-Made Staple Fiber, or Tow

atmosphere for testing textiles.

2.2 ISO Standards:

Option 5—Oven-dried, scoured yarn.

2060 Textiles—Yarn from Packages—Determination of lin-

Option 6—Oven-dried, scoured yarn, plus commercial mois-

ear density (mass per unit length) by the skein method.

ture regain.

Option 7—Oven-dried, scoured yarn, plus commercial al-

3. Terminology

lowance (commercial moisture regain, plus an allowance for

3.1 Definitions:

finish).

3.1.1 commercial allowance, (CA) n—an arbitrary value,

1.5 Specimens used to determine yarn linear density may

equal to the commercial moisture regain, plus a specific

also be used to determine the skein breaking strength of the

allowance for finish, used with the mass of scoured, oven-dried

yarn. Hence, this method provides the sequence of steps to be

yarn, to compute (1) yarn linear density, (2) the commercial or

followed, to determine both these yarn properties.

legal mass of a shipment or delivery of any specific textile

NOTE 1—The linear density of yarns produced with jute, or glass, may

material (see also commercial moisture regain), or (3) the mass

of a specific component in the analysis of fiber blends.

This test method is under the jurisdiction of ASTM Committee D-13 on

3.1.2 commercial moisture regain, (CMR) n—a formally

Textiles, and is the direct responsibility of Subcommittee D13.58 on Yarn Test

adopted, arbitrary value, to be used with the oven-dried mass of

Methods, General.

Current edition approved Jan. 10, 1997. Published August 1997. Originally

published as D 1907 – 61 T. Last previous edition D 1907 – 96. Annual Book of ASTM Standards, Vol. 07.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 1907

textile fibers, when calculating the commercial mass of a skeins will need to be tested (as compared to the number of

shipment or delivery. skeins to be tested for the determination of the average yarn

3.1.3 direct yarn numbering system, n—a system that ex- linear density alone).

presses yarn linear density (number) in mass per unit length. 5.3 This test method includes seven options, depending on

(See also denier, spyndle number, and tex.)

whether the yarn is scoured before weighing, weighed in the

3.1.4 indirect yarn numbering system, n—a system that conditioned or oven-dried state, or whether or not the results

expresses yarn linear density (number) in length per unit mass.

obtained are adjusted for commercial moisture regain, or a

(See also cotton count, metric count, worsted count, cut, and commercial allowance. Option 1 (unscoured, conditioned yarn)

run.)

is generally used for yarns spun on the cotton system, while

3.1.5 skein, n—a continuous strand of yarn, wound on a Options 6 and 7 (scoured, oven dried yarn, plus commercial

hand or motorized reel.

moisture regain, or allowance are generally used for filament

3.1.6 yarn linear density, n—the mass per unit length of a yarns, or yarns containing wool fibers. The specific options to

yarn. (See also yarn number.)

be used in any instance shall be agreed upon by the parties, or

3.1.7 yarn number, n—a measure of the linear density of a as prescribed in test methods or tolerances, for filament yarns,

yarn, expressed as “mass per unit length”, or “length per unit

or for yarns spun from specific fibers.

mass”, depending on the yarn numbering system used. (See 5.4 In Options 2, 3, 5, 6, and 7, an oven-dried sample is

also yarn linear density.)

obtained by exposing the yarn in an oven with a supply of air

3.1.8 yarn numbering system, n—a system expressing the at standard textile testing conditions, as described in 6.3.

size of a yarn as a relationship between its length and

associated mass. (See also yarn linear density, yarn number,

6. Apparatus and Reagents

direct yarn numbering system, indirect yarn numbering system,

6.1 Reel:

and Appendix X1.)

6.1.1 General—A hand reel or motor driven reel having a

3.2 For definitions of other textile terms used in this method,

perimeter of 1.000 m or 1.500 yd. with a tolerance of 60.25 %

refer to Terminology D 123.

is recommended. By prior agreement, reels having a perimeter

of between 1.0 and 2.5 m (1.5 and 3.0 yd) may be used. The

4. Summary of Test Method

reel shall be fitted with a traversing mechanism that will avoid

4.1 Specified lengths of yarn are wound on reels as skeins,

bunching successive wraps of yarn, and with an indicator of the

and weighed. The linear density of the yarn is computed from

length wound. A warning bell that rings at a specified length, is

the mass and length of the skein. In some options, the skein is

also recommended. And, it is advisable that one arm of the reel

scoured before weighing, and, depending on the option chosen,

be collapsible, to allow for easy removal of the wound skeins.

the mass of the skein may be determined after oven drying, or

6.1.2 Reel Perimeter—Determine the actual perimeter of

after conditioning.

the reel by winding a 0.6 cm. (0.25 in.) wide steel measuring

tape around the reel. Tension the tape prior to directly reading

5. Significance and Use

the circumference of the reel, by attaching a 0.5 kg (1.0 lb)

5.1 Test Method D 1907 is considered satisfactory for

weight to the end of the tape. Repeat this measurement near

acceptance testing of commercial shipments, since it has been

each end of the bars of the reel, and in the center. If the

used extensively in the trade for that purpose.

circumference at any of these areas is outside the limits of

5.1.1 In case of dispute arising from differences in reported

1.000 6 2.5 mm (1.500 + 0.1 in.), adjust the fly wheel to bring

test results when using Test Method D 1907 for acceptance

the measurement(s) within the limits.

testing of commercial shipments, the purchaser and the sup-

6.1.3 Yarn Tensioning—The reel shall be fitted with either a

plier should conduct comparative tests to determine if there is

positive fee system at a controlled tension of 0.5 cN/tex (0.05

a statistical bias between their laboratories.

gf/ tex) or with an adjustable tension device. The length of the

5.1.2 Competent statistical assistance is recommended for

skeins should be checked, and variations in length not be

the determination of such a bias. As a minimum, the two parties

allowed to exceed 60.25 % (See Annex A1).

should take a group of test specimens that are as homogeneous

6.2 Balance—For the determination of average yarn linear

as possible, and that are from the same lot of the material in

density, a balance of suitable capacity, graduated in grams or

question. The test specimens should then be randomly assigned

grains, with a sensitivity of 1 part in 1000 should be used. If

in equal numbers to each laboratory for testing. The average

single skeins are weighed, a balance graduated directly in yarn

results from the two laboratories should be compared using

linear density may be used.

statistical analysis for unpaired data, and an acceptable prob-

ability level chosen by the parties before testing begins. If a NOTE 2—The 1:1000 balance sensitivity is needed to ascertain the

completion of conditioning, or oven drying. For subsequent weighings of

bias is found, either its cause must be identified and corrected,

skeins, a 1:500 sensitivity has been found to be sufficient.

or the purchaser and supplier must agree to interpret future test

NOTE 3—For the calculation of the variation of yarn linear density, a

results with consideration to the known bias.

1:100 balance sensitivity is sufficient to weigh individual skeins, after the

5.2 This test method is intended primarily for the determi-

skeins are conditioned, or oven-dried.

nation of the average linear density of yarns. However, the

variations identified by the results may also provide useful 6.3 Drying Oven—An oven, ventilated and capable of being

information. If the coefficient of variation is to be calculated, controlled in a temperature range of 105 6 3°C (221 6 5°F),

each skein must be weighed separately, and a larger number of is required to dry the skeins. The oven should be of sufficient

D 1907

design to facilitate the free passage of air through the speci- 7.3.1 An exception to the information provided in Note 5

mens, and should be supplied with a current of air sufficient to may occur in packages of filament yarns; consistent differences

change the air in the oven once every 4 min. The specimens in yarn linear density are sometimes present between yarn on

shall be protected from any direct heat, radiating from the the outside of the package, as compared to yarn on the inside.

heating units of the oven. Air supplied to the oven shall be at If such differences are suspected, test more than one skein from

the standard atmosphere for testing textiles. The oven may be each package, without reducing the number of packages

provided with facilities to shut off the air current and weigh the sampled for testing, taking skeins at intervals throughout the

specimens, without removing them from the oven. packages.

6.4 Facilities for Scouring (Options 4, 5, 6, and 7), as

8. Conditioning

indicated in X2.2, or in Sections 6.1 and 6.3 of Test Method

D 2494.

8.1 Before reeling test skeins, condition yarn in skein form

6.5 Weighing Cans, with tight fitting lids, and of sufficient

in the standard atmosphere for testing textiles for a minimum

size to hold all skeins, or groups of skeins (Options 2, 3, 5, 6,

of 1 h, and yarn on packages for a minimum of 3 h.

and 7), if the weighing is to be done outside the oven. Weighing

Additionally, prior to testing, preconditioning of the test skeins

bottles with ground-glass stoppers may also be used.

may be required for Option 1, but is not necessary for Options

6.6 Auxiliary Facilities, suited to the specimens and options 2 through 7.

used, such as sample supports, tared wire gauze baskets of

NOTE 6—For Options 2 through 7, where the yarn is scoured or

corrosion resistant metal, dessicators of sufficient size to hold

oven-dried after reeling, the conditioning prior to reeling is required to

the weighing cans or bottles, and an efficient dessicant.

ensure a correct skein length.

7. Sampling 9. Procedure

9.1 General:

7.1 Lot Sample—As a lot sample for acceptance testing,

take at random the number of shipping units directed in an 9.1.1 The procedure used depends on the options selected;

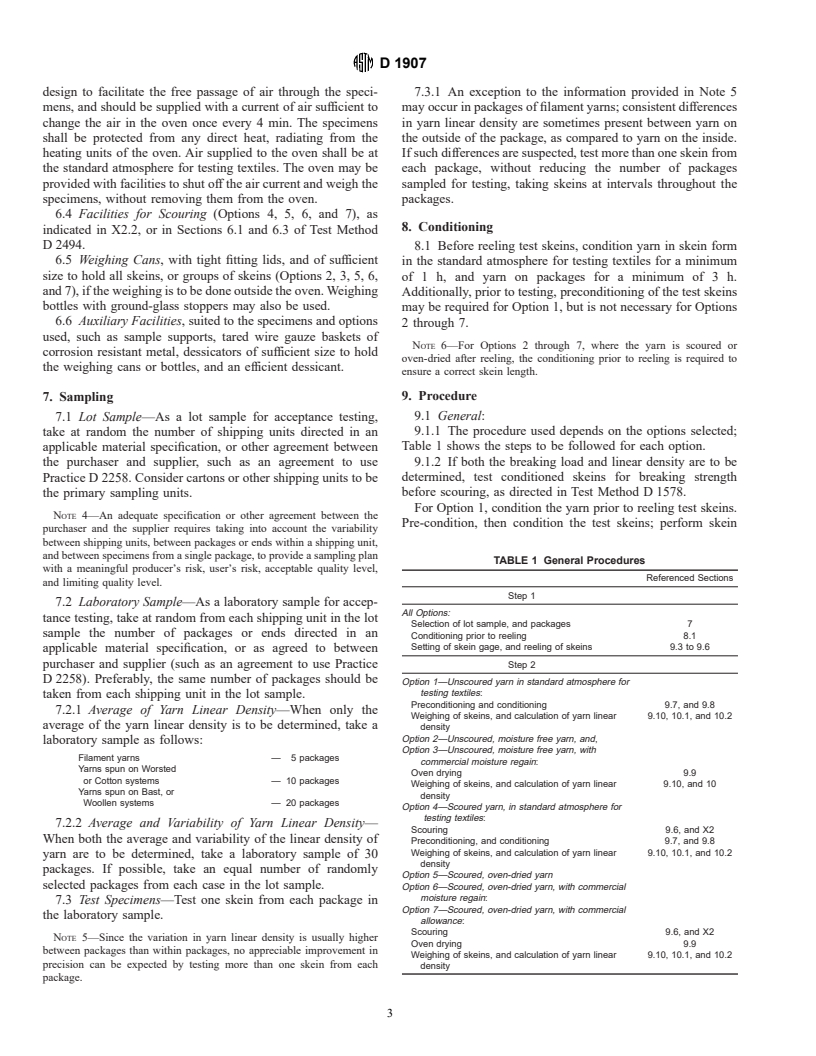

Table 1 shows the steps to be followed for each option.

applicable material specification, or other agreement between

the purchaser and supplier, such as an agreement to use 9.1.2 If both the breaking load and linear density are to be

determined, test conditioned skeins for breaking strength

Practice D 2258. Consider cartons or other shipping units to be

the primary sampling units. before scouring, as directed in Test Method D 1578.

For Option 1, condition the yarn prior to reeling test skeins.

NOTE 4—An adequate specification or other agreement between the

Pre-condition, then condition the test skeins; perform skein

purchaser and the supplier requires taking into account the variability

between shipping units, between packages or ends within a shipping unit,

and between specimens from a single package, to provide a sampling plan

TABLE 1 General Procedures

with a meaningful producer’s risk, user’s risk, acceptable quality level,

Referenced Sections

and limiting quality level.

Step 1

7.2 Laboratory Sample—As a laboratory sample for accep-

All Options:

tance testing, take at random from each shipping unit in the lot

Selection of lot sample, and packages 7

sample the number of packages or ends directed in an

Conditioning prior to reeling 8.1

Setting of skein gage, and reel

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.