ASTM E11-13

(Specification)Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves

Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves

ABSTRACT

This specification covers the requirements for design and construction of testing sieves using a medium of woven wire cloth mounted in a frame for use in testing for the classification of materials according to designated particle size and wire cloth meeting the specifications specified, to be designated test grade wire cloth. Frames for wire cloth sieves shall be constructed in such a manner as to be rigid. The wire cloth shall be mounted on the frame without distortion, looseness or waviness. To prevent the material being sieved from catching in the joint between the wire cloth and the frame, the joint shall be filled smoothly or constructed so that the material will not be trapped. Standard frames for the sieve frames shall be circular with specific nominal diameters. The dimensions shall conform to the specified requirements. These frames shall be made from non corrosive material such as brass or stainless steel and be of seamless construction. The nonstandard frames for sieve frames may be either square, rectangular, or circular. The frame may have the sieve cloth permanently installed, or may be designed to permit replacement. Pans and covers for use with sieves shall be made so as to nest with the sieves. Pans with extended rims (�stacking skirts�) shall be furnished when specified. The pans and covers shall conform to the specified dimensions.

SCOPE

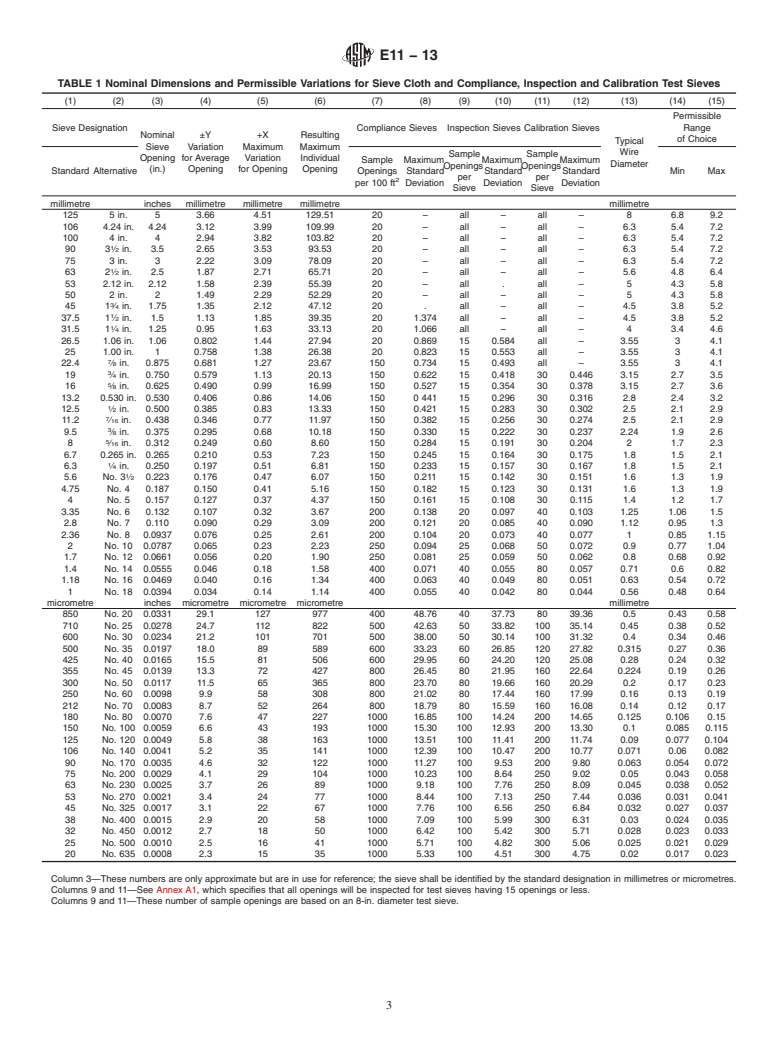

1.1 This document specifies the technical requirements for; the woven wire test sieve cloth (sieve cloth) used in test sieves, the construction of test sieves, standard and non-standard test sieve frame sizes, and test procedures used to inspect sieve cloth and the test sieves. This Specification applies to test sieves manufactured with sieve cloth having a nominal aperture size ranging from 125 millimetres (mm) down to 20 micrometres (μm).

1.2 Additional reference information can be found in Specifications E161, E323, E2016, and in Test Methods C430 and E2427.

1.3 The values stated in SI units shall be considered standard for the dimensions of the sieve cloth openings and the wire diameters used in the sieve cloth. The values stated in inch-pound units shall be considered standard with regard to the sieve frames, pans, and covers.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E11 −13

StandardSpecification for

1

Woven Wire Test Sieve Cloth and Test Sieves

This standard is issued under the fixed designation E11; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E2016 Specification for Industrial Woven Wire Cloth

E2427 Test Method for Acceptance by Performance Testing

1.1 This document specifies the technical requirements for;

for Sieves

thewovenwiretestsievecloth(sievecloth)usedintest sieves,

2.2 Federal Standard:

the construction of test sieves, standard and non-standard test

3

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

sieve frame sizes, and test procedures used to inspect sieve

2.3 Military Standard:

cloth and the test sieves. This Specification applies to test

3

MIL-STD-129 Marking for Shipment and Storage

sieves manufactured with sieve cloth having a nominal aper-

2.4 ISO Standard:

ture size ranging from 125 millimetres (mm) down to 20

ISO 3310-1 Test Sieves—Technical Requirements and Test-

micrometres (µm).

4

ing – Part 1: Test Sieves of Metal Wire Cloth

1.2 Additional reference information can be found in Speci-

fications E161, E323, E2016, and in Test Methods C430 and

3. Terminology

E2427.

3.1 Definitions:

1.3 The values stated in SI units shall be considered

3.1.1 aperture—the dimension defining an opening in a

standard for the dimensions of the sieve cloth openings and the

screening surface.

wire diameters used in the sieve cloth. The values stated in

3.1.2 crimp—the corrugation in the warp and shute wire, or

inch-pound units shall be considered standard with regard to

both. The crimp in the wires is formed either during the

the sieve frames, pans, and covers.

weavingprocess,orwithacrimpingmachinepriortoweaving.

1.4 This standard does not purport to address all of the

If formed during the weaving process, the tension existing

safety concerns, if any, associated with its use. It is the

between the warp and shute wires fundamentally determines

responsibility of the user of this standard to establish appro-

the respective amount or depth of crimp, which locks the wires

priate safety and health practices and determine the applica-

in place, and in part establishes the firmness of the sieve cloth.

bility of regulatory limitations prior to use.

3.1.3 firmness—a subjective term referring to the planar

rigidity of sieve cloth (as a roll good, not mounted in a test

2. Referenced Documents

sieveframe),establishedbythetensilestrengthofthematerial,

2

2.1 ASTM Standards:

the relationship of the mesh to wire diameters, the type of

C430 Test Method for Fineness of Hydraulic Cement by the

weave, and amount of crimp in the wires. The absence of

45-µm (No. 325) Sieve

firmness in sieve cloth is termed sleaziness.

E161 Specification for Precision Electroformed Sieves

3.1.4 matched test sieve—a test sieve that reproduces the

E323 Specification for Perforated-Plate Sieves for Testing

performance results of another test sieve within user defined

Purposes

limits for a designated material (for information only and may

E1638 Terminology Relating to Sieves, Sieving Methods,

not be in compliance with this Specification).

and Screening Media

3.1.5 mesh—thenumberofwiresoropeningsperlinearinch

(25.4 mm) counted from the center of any wire to a point

1

ThisspecificationisunderthejurisdictionofASTMCommitteeE29onParticle

exactly 1 in. (25.4 mm) distant, including the fractional

and Spray Characterization and is the direct responsibility of Subcommittee E29.01

distance between either thereof.

on Sieves, Sieving Methods, and Screening Media.

Current edition approved Oct. 1, 2013. Published October 2013. Originally

ε1

approved in 1925. Last previous edition approved in 2009 as E11 – 09 . DOI:

3

10.1520/E0011-13. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.dodssp.daps.mil.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E11−13

3.1.6 plain weave—sieve cloth in which the warp wires and 4.4 For U.S. Government purch

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E11 − 09 E11 − 13

Standard Specification for

1

Woven Wire Test Sieve Cloth and Test Sieves

This standard is issued under the fixed designation E11; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

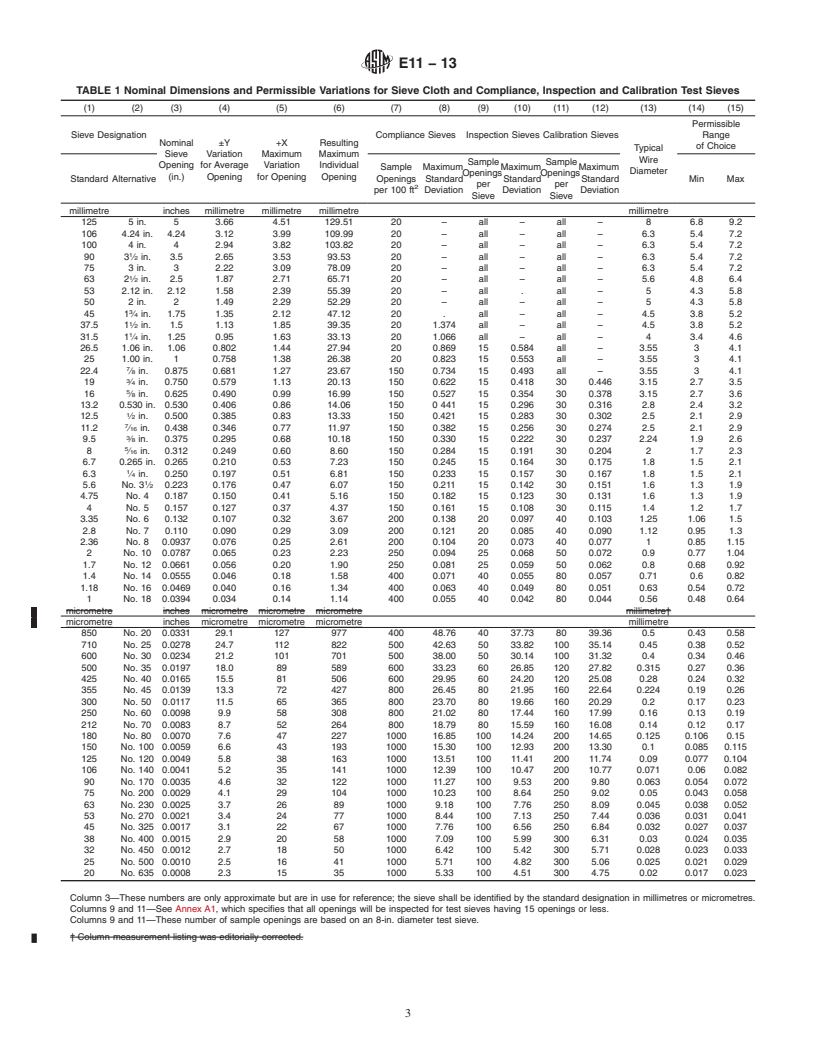

ε NOTE—Table 1 and Table 2 were editorially corrected in November 2010.

1. Scope

1.1 This document specifies the technical requirements for; the woven wire test sieve cloth (sieve cloth) used in test sieves, the

construction of test sieves, standard and non-standard test sieve frame sizes, and test procedures used to inspect sieve cloth and

the test sieves. This Specification applies to test sieves manufactured with sieve cloth having a nominal aperture size ranging from

125 millimetres (mm) down to 20 micrometres (μm).

1.2 Additional reference information can be found in Specifications E161, E323, E2016, and in Test Methods C430 and E2427.

1.3 The values stated in SI units shall be considered standard for the dimensions of the sieve cloth openings and the wire

diameters used in the sieve cloth. The values stated in inch-pound units shall be considered standard with regard to the sieve

frames, pans, and covers.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C430 Test Method for Fineness of Hydraulic Cement by the 45-μm (No. 325) Sieve

E161 Specification for Precision Electroformed Sieves

E323 Specification for Perforated-Plate Sieves for Testing Purposes

E1638 Terminology Relating to Sieves, Sieving Methods, and Screening Media

E2016 Specification for Industrial Woven Wire Cloth

E2427 Test Method for Acceptance by Performance Testing for Sieves

2.2 Federal Standard:

3

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2.3 Military Standard:

3

MIL-STD-129 Marking for Shipment and Storage

2.4 ISO Standard:

4

ISO 3310-1 Test Sieves—Technical Requirements and Testing – Part 1: Test Sieves of Metal Wire Cloth

3. Terminology

3.1 Definitions:

3.1.1 aperture—the dimension defining an opening in a screening surface.

1

This specification is under the jurisdiction of ASTM Committee E29 on Particle and Spray Characterization and is the direct responsibility of Subcommittee E29.01 on

Sieves, Sieving Methods, and Screening Media.

Current edition approved May 1, 2009Oct. 1, 2013. Published June 2009October 2013. Originally approved in 1925. Last previous edition approved in 20042009 as

ε1

E11 – 04.E11 – 09 . DOI: 10.1520/E0011-09E01.10.1520/E0011-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E11 − 13

3.1.2 crimp—the corrugation in the warp and shute wire, or both. The crimp in the wires is formed either during the weaving

process, or with a crimping machine prior to weaving. If formed during the weaving process, the tension existing between the warp

and shute wires fundamentally determines the respective amount or depth of crimp, which locks the wires in place, and in part

establishes the firmness of the sieve cloth.

3.1.3 firmness—a subjective term referring to the planar rigidity of sieve cloth (as a roll good, not mounted in a test sieve frame),

established by the tensile strength of the material, the relationship of the mesh to wire diameters, the type of weave, and amount

of crimp in the wires. The absence of firmness in sieve cloth is termed sleaziness.

3.1.4 matched test sieve—a test sieve that reproduces the perfo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.