ASTM D4438-24

(Test Method)Standard Test Method for Particle Size Distribution of Catalysts and Catalyst Carriers by Electronic Counting

Standard Test Method for Particle Size Distribution of Catalysts and Catalyst Carriers by Electronic Counting

SIGNIFICANCE AND USE

4.1 This test method can be used to determine particle size distributions for material specifications, manufacturing control, and research and development work in the particle size range usually encountered in fluidizable cracking catalysts.

SCOPE

1.1 This test method covers the determination of particle size distribution of catalyst and catalyst carrier (see Terminology D3766) particles using an electroconductive sensing method and is one of several valuable methods for the measurement of particle size.

1.2 The range of particle sizes investigated was 20 μm to 150 μm (see IEEE/ASTM SI 10) equivalent spherical diameter. The technique is capable of measuring particles above and below this range. The instrument used for this method is an electric current path of small dimensions that is modulated by individual particle passage through an aperture, and produces individual pulses of amplitude proportional to the particle volume.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4438 − 24

Standard Test Method for

Particle Size Distribution of Catalysts and Catalyst Carriers

1

by Electronic Counting

This standard is issued under the fixed designation D4438; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E122 Practice for Calculating Sample Size to Estimate, With

Specified Precision, the Average for a Characteristic of a

1.1 This test method covers the determination of particle

Lot or Process

size distribution of catalyst and catalyst carrier (see Terminol-

E177 Practice for Use of the Terms Precision and Bias in

ogy D3766) particles using an electroconductive sensing

ASTM Test Methods

method and is one of several valuable methods for the

E456 Terminology Relating to Quality and Statistics

measurement of particle size.

E691 Practice for Conducting an Interlaboratory Study to

1.2 The range of particle sizes investigated was 20 μm to

Determine the Precision of a Test Method

150 μm (see IEEE/ASTM SI 10) equivalent spherical diameter.

E1272 Specification for Laboratory Glass Graduated Cylin-

The technique is capable of measuring particles above and

ders

below this range. The instrument used for this method is an

IEEE/ASTM SI 10 Standard for Use of the International

electric current path of small dimensions that is modulated by

System of Units (SI): The Modern Metric System

individual particle passage through an aperture, and produces

individual pulses of amplitude proportional to the particle

3. Summary of Test Method

volume.

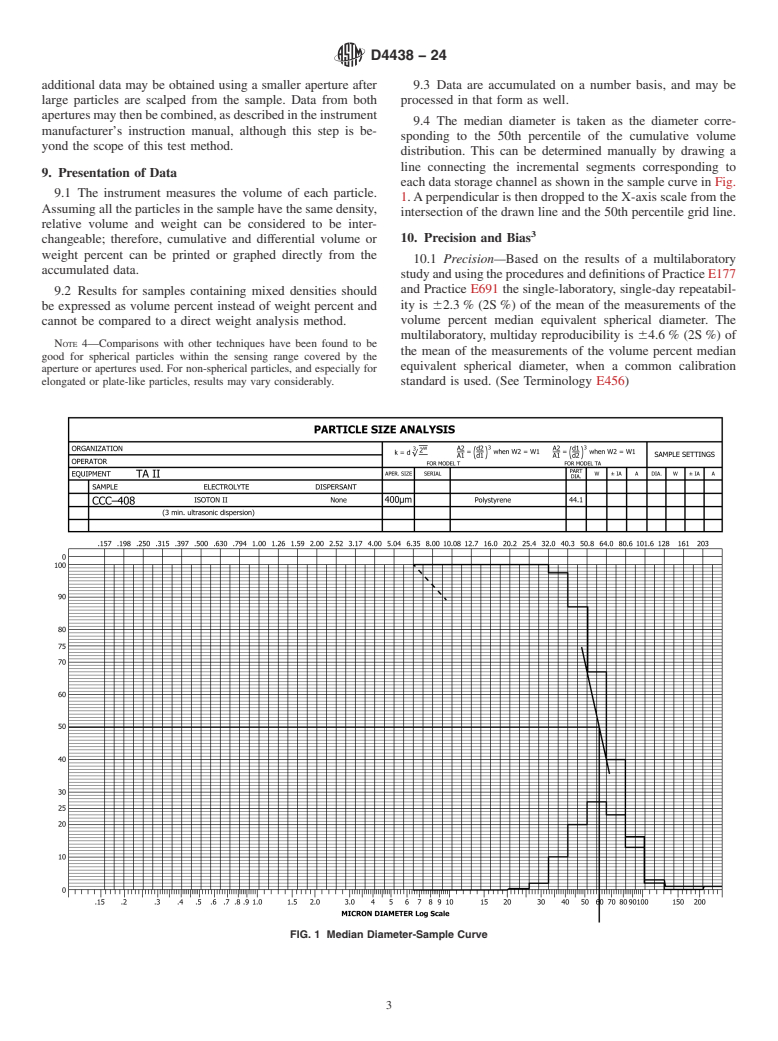

3.1 A carefully dispersed, dilute suspension of the represen-

1.3 This standard does not purport to address all of the

tative sample in a beaker filled with an electrolyte is placed in

safety concerns, if any, associated with its use. It is the

the counting position on the instrument sample stand. The

responsibility of the user of this standard to establish appro-

suspension is forced through a restricting aperture. Each

priate safety, health, and environmental practices and deter-

passing particle is recorded on an electronic counter, and the

mine the applicability of regulatory limitations prior to use.

data are accumulated according to selected particle size inter-

1.4 This international standard was developed in accor-

vals for subsequent processing.

dance with internationally recognized principles on standard-

3.2 The instrument response is proportional to liquid dis-

ization established in the Decision on Principles for the

placement by the particle volume. Equivalent spherical diam-

Development of International Standards, Guides and Recom-

eter is commonly used to express the particle size.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Significance and Use

2. Referenced Documents 4.1 This test method can be used to determine particle size

distributions for material specifications, manufacturing control,

2

2.1 ASTM Standards:

and research and development work in the particle size range

B215 Practices for Sampling Metal Powders

usually encountered in fluidizable cracking catalysts.

D1193 Specification for Reagent Water

D3766 Terminology Relating to Catalysts and Catalysis

3

5. Apparatus

E105 Guide for Probability Sampling of Materials

5.1 Electronic Particle Counter, with sample stand and

stirring motor.

1

This test method is under the jurisdiction of ASTM Committee D32 on

5.2 Aperture Tubes, with varying diameters. The diameter

Catalysts and is the direct responsibility of Subcommittee D32.02 on Physical-

required is dependent upon the particle size distribution of the

Mechanical Properties.

Current edition approved March 15, 2024. Published March 2024. Originally

sample. Generally, any given tube will cover a particle size

ɛ1

approved in 1985. Last previous edition approved in 2018 as D4438 – 13 (2018) .

range from 2 % to 40 % of its aperture diameter.

DOI: 10.1520/D4438-24.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Supporting data have been filed at ASTM International Headquarters and may

the ASTM website. be obtained by requesting Research Report RR:D32-1011.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4438 − 24

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D4438 − 13 (Reapproved 2018) D4438 − 24

Standard Test Method for

Particle Size Distribution of Catalysts and Catalyst Carriers

1

by Electronic Counting

This standard is issued under the fixed designation D4438; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Keywords revised editorially in May 2018.

1. Scope

1.1 This test method covers the determination of particle size distribution of catalyst and catalyst carrier (see Terminology D3766)

particles using an electroconductive sensing method and is one of several valuable methods for the measurement of particle size.

1.2 The range of particle sizes investigated was 20 to 150 μm 20 μm to 150 μm (see IEEE/ASTM SI 10) equivalent spherical

diameter. The technique is capable of measuring particles above and below this range. The instrument used for this method is an

electric current path of small dimensions that is modulated by individual particle passage through an aperture, and produces

individual pulses of amplitude proportional to the particle volume.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B215 Practices for Sampling Metal Powders

D1193 Specification for Reagent Water

D3766 Terminology Relating to Catalysts and Catalysis

E105 Guide for Probability Sampling of Materials

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1272 Specification for Laboratory Glass Graduated Cylinders

IEEE/ASTM SI 10 Standard for Use of the International System of Units (SI): The Modern Metric System

1

This test method is under the jurisdiction of ASTM Committee D32 on Catalysts and is the direct responsibility of Subcommittee D32.02 on Physical-Mechanical

Properties.

Current edition approved May 1, 2018March 15, 2024. Published June 2018March 2024. Originally approved in 1985. Last previous edition approved in 20132018 as

ɛ1

D4438 – 13.D4438 – 13 (2018) . DOI: 10.1520/D4438-13R18E01.10.1520/D4438-24.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4438 − 24

3. Summary of Test Method

3.1 A carefully dispersed, dilute suspension of the representative sample in a beaker filled with an electrolyte is placed in the

counting position on the instrument sample stand. The suspension is forced through a restricting aperture. Each passing particle

is recorded on an electronic counter, and the data are accumulated according to selected particle size intervals for subsequent

processing.

3.2 The instrument response is proportional to liquid displacement by the particle volume. Equivalent spherical diameter is

commonly used to express the particle size.

4. Significance and Use

4.1 This test method can be used to determine particle size distributions for material specifications, manufacturing control, and

research and development work in the particle size range usually encountered in fluidizable cracking catalysts.

3

5. Apparatus

5.1 Electronic Particle Counter, with sample stand and stirring motor.

5.2 Aperture Tubes, with varying diameters. The diameter required is dependent upon the particle size distribu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.