ASTM A1011/A1011M-00

(Specification)Standard Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy with Improved Formability

Standard Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy with Improved Formability

SCOPE

1.1 This specification covers hot-rolled structural, high strength-low alloy, and high-strength low-alloy with improved formability steel sheet and strip, in coils and cut lengths.

1.2 Hot rolled steel sheet and strip is available in the designations as listed in 4.1.

1.3 This specification is not applicable to the steel covered by Specification A635/A635M.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 1011/A 1011M – 00

Standard Specification for

Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-

Strength Low-Alloy and High-Strength Low-Alloy with

Improved Formability

This standard is issued under the fixed designation A 1011/A 1011M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 aging—loss of ductility with an increase in hardness,

1.1 This specification covers hot-rolled structural, high

yield strength, and tensile strength that occurs when steel,

strength-low alloy, and high-strength low-alloy with improved

which has been slightly cold worked (such as by temper

formability steel sheet and strip, in coils and cut lengths.

rolling) is stored for some time.

1.2 Hot rolled steel sheet and strip is available in the

3.2.1.1 Discussion—Aging also increases the tendency to-

designations as listed in 4.1.

ward stretcher strains and fluting.

1.3 This specification is not applicable to the steel covered

3.2.2 stabilization—the addition of one or more nitride or

by Specification A 635/A 635M.

carbide forming elements, or both, such as titanium and

1.4 The values stated in either inch-pound units or SI units

columbium, to control the level of the interstitial elements

are to be regarded separately as standard. Within the text, the

carbon and nitrogen in the steel.

SI units are shown in brackets. The values stated in each

3.2.2.1 Discussion—Stabilization improves formability and

system are not exact equivalents; therefore, each system must

increases resistance to aging.

be used independently of the other.

3.2.3 vacuum degassing—a process of refining liquid steel

2. Referenced Documents

in which the liquid is exposed to a vacuum as part of a special

technique for removing impurities or for decarburizing the

2.1 ASTM Standards:

steel.

A 370 Test Methods and Definitions for Mechanical Testing

of Steel Products

4. Classification

A 568/A 568M Specification for Steel Sheet, Carbon, and

4.1 Hot Rolled steel sheet and steel strip is available in the

High-Strength, Low-Alloy, Hot Rolled and Cold Rolled,

following designations:

General Requirements for

4.1.1 Commercial Steel (CS Types A, B, and C),

A 569/A 569M Specification for Steel, Carbon (0.15 Maxi-

4.1.2 Drawing Steel (DS Types A and B),

mum, Percent), Hot Rolled Sheet and Strip Commercial

A 622/A 622M Specification for Drawing Steel (DS), Sheet

NOTE 1—CS Type B and DS Type B describe the most common

and Strip, Carbon, Hot-Rolled

product previously included, respectively, in Specifications A 569/

A 569M and A 622/A 622M.

A 635/A 635M Specification for Steel, Sheet and Strip,

Heavy-Thickness Coils, Carbon, Hot Rolled

4.1.3 Structural Steel (SS grades 30[205], 33[230], 36[250]

A 749/A 749M Specification for Steel Strip, Carbon and

Types 1 and 2, 40[275], 45[310], 50[340], and 55[380]),

High-Strength, Low-Alloy, Hot Rolled, General Require-

4.1.4 High-Strength Low-Alloy Steel (HSLAS, classes 1

ments for

and 2, in grades 45[310], 50[340], 55[380], 60[410], 65[450],

A 941 Terminology Relating to Steel, Stainless Steel, Re-

and 70[480].

lated Alloys and Ferroalloys

4.1.5 High-Strength Low-Alloy Steel with Improved Form-

ability (HSLAS-F grades 50[340], 60[410], 70[480], and

3. Terminology

80[550]).

3.1 Definitions—For definitions of other terms used in this

4.1.5.1 HSLAS-F steel has improved formability when

specification refer to Terminology A 941.

compared to HSLAS. The steel is fully deoxidized, made to a

fine grain practice, and includes microalloying elements such

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

as columbium, vanadium, and zirconium. The steel may be

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

treated to achieve inclusion control.

A01.19 on Steel Sheet and Strip.

Current edition approved Aug. 10, 2000. Published October 2000.

5. Ordering Information

Annual Book of ASTM Standards, Vol 01.03.

Discontinued; see 2000 Annual Book of ASTM Standards, Vol 01.03.

5.1 It is the purchaser’s responsibility to specify in the

Annual Book of ASTM Standards, Vol 01.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 1011/A 1011M

XX, hot rolled steel sheet, CS Type A, pickled and oiled, cut edge, 0.075

purchase order all ordering information necessary to describe

by 36 by 96 in., thickness tolerance Table 4 of Specification A 568/

the required material. Examples of such information include,

A 568M, 100 000 lb, for part no. 6310, for shelf bracket.

but are not limited to, the following:

or:

5.1.1 ASTM specification number and year of issue,

ASTM A 1011M-XX, hot rolled steel sheet, CS Type B, pickled and oiled,

5.1.2 Name of material and designation (hot rolled steel

cut edge, 3.7 by 117 mm by coil, ID 600 mm, OD 1500 mm, max weight

sheet) (include grade, type and class, as appropriate, for CS,

10 000 kg, thickness tolerance Table A1.1 of Specification A 568/A 568M,

DS, SS, HSLAS and HSLAS-F), (see 4.1), 50 000 kg, for upper control arm.

5.1.2.1 When a type is not specified for CS or DS, Type B

6. General Requirements for Delivery

will be furnished, (see 4.1),

6.1 Material furnished under this specification shall con-

5.1.2.2 When a class is not specified for HSLAS, Class 1

form to the applicable requirements of the current edition of

will be furnished, (see 4.1),

Specification A 568/A 568M for sheets and Specification

5.1.2.3 When a type is not specified for SS Grade 36, Type

A 749/A 749M for strip, unless otherwise provided for herein.

1 will be furnished, (see 4.1),

5.1.3 Finish (see 9.1)

7. Chemical Composition

5.1.4 Type of edge (see 9.3),

7.1 The heat analysis of the steel shall conform to the

5.1.5 Oiled or not oiled, as required (see 9.2),

chemical composition requirements of the appropriate desig-

5.1.6 Dimensions (thickness, thickness tolerance table (see

nation shown in Table 1 for CS and DS and Table 2 for SS,

5.1.6.1), width, and whether cut lengths or coils),

HSLAS, and HSLAS-F.

5.1.6.1 As agreed upon between the purchaser and the

7.2 Each of the elements listed in Tables 1 and 2 shall be

producer, material ordered to this specification will be supplied

included in the report of the heat analysis. When the amount of

to meet the appropriate thickness tolerance table shown in

copper, nickel, chromium, or molybdenum is less than 0.02 %,

Specifications A 568/A 568M for sheet and A 749/A 749M for

the analysis may be reported as < 0.02 %. When the amount of

strip.

vanadium, columbium, or titanium is less than 0.008 %, the

NOTE 2—Not all producers are capable of meeting all the limitations of

analysis may be reported as < 0.008 %.

the thickness tolerance tables in Specifications A 568/A 568M and A 749/

7.3 When the steel is used in welded applications, the

A 749M. The purchaser should contact the producer prior to placing an

welding procedure shall be suitable for the steel chemistry and

order.

the intended service.

5.1.7 Coil size (inside diameter, outside diameter, and maxi-

mum weight),

8. Mechanical Properties

5.1.8 Copper bearing steel (if required),

8.1 CS and DS:

5.1.9 Quantity,

8.1.1 Typical, nonmandatory mechanical properties for CS

5.1.10 Application (part identification and description),

and DS are found in Table 3.

5.1.11 Special requirements, (if required), or supplementary

8.1.2 The material shall be capable of being bent at room

requirement S1 for HSLAS, and

temperature in any direction through 180° flat on itself without

5.1.12 A report of heat analysis will be supplied, if re-

cracking on the outside of the bent portion (see the section on

quested, for CS and DS. For materials with required mechani-

bend test in Test Methods and Definitions A 370).

cal properties, SS, HSLAS, and HSLAS-F, a report is required

8.2 SS, HSLAS, and HSLAS-F:

of heat analysis and mechanical properties as determined by

8.2.1 The available grades and corresponding mechanical

the tension test.

properties for SS, HSLAS, and HSLAS-F are shown in Table

NOTE 3—A typical ordering description is as follows: ASTM A 1011- 4.

A

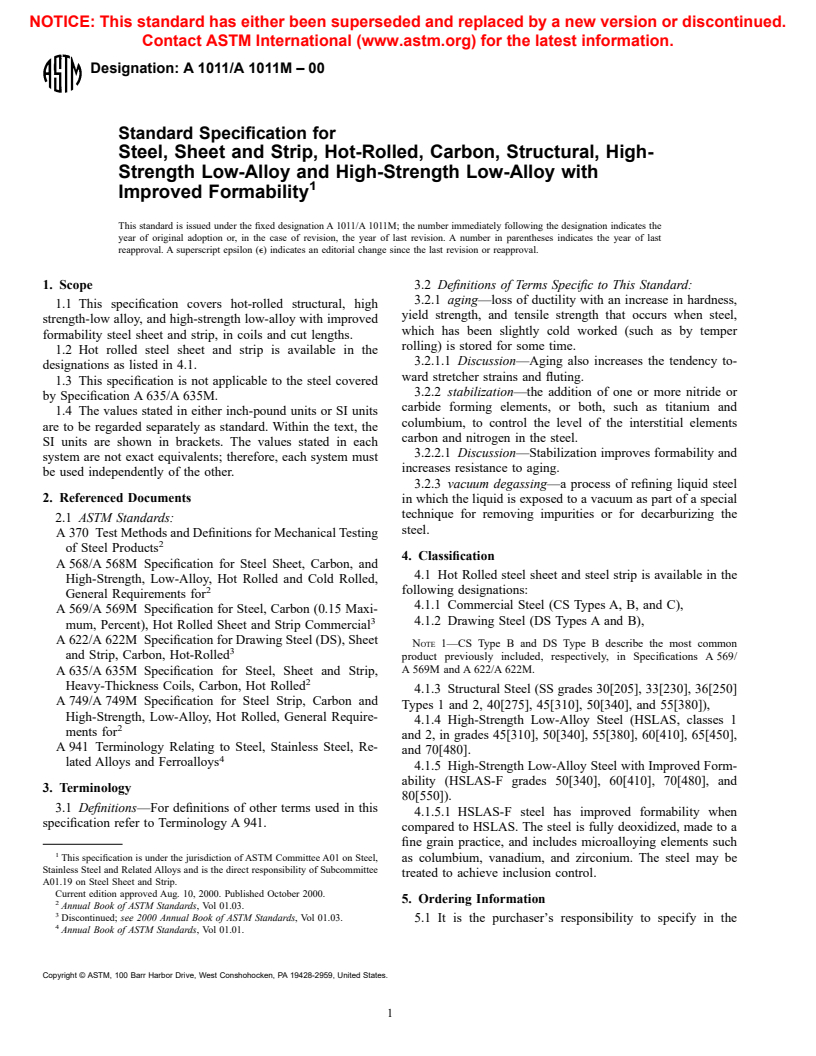

TABLE 1 Chemical Composition

For Hot Rolled Steel Sheet and Strip Designations CS and DS

Composition, % Heat Analysis

Element Maximum unless otherwise shown

B B B,C B D

CMn P S Al SiCu Ni Cr Mo VCb Ti N

E,F,G,H I

CS Type A 0.10 0.60 0.030 0.035 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 0.008 . . .

G I

CS Type B 0.02 to 0.15 0.60 0.030 0.035 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 0.008 . . .

E,F,G,H I

CS Type C 0.08 0.60 0.10 0.035 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 0.008 . . .

E,F,H

DS Type A 0.08 0.50 0.020 0.030 0.01 min . . . 0.20 0.20 0.15 0.06 0.008 0.008 0.008 . . .

DS Type B 0.02 to 0.08 0.50 0.020 0.030 0.01 min . . . 0.20 0.20 0.15 0.06 0.008 0.008 0.008 . . .

A

Where an ellipsis (.) appears in the table, there is no requirement, but the analysis shall be reported.

B

The sum of copper, nickel, chromium, and molybdenum shall not exceed 0.50 % of heat analysis. When one or more of these elements is specified by the purchaser,

the sum does not apply, in which case, only the individual limits on the remaining elements shall apply.

C

Chromium is permitted, at the producer’s option, to 0.25 % maximum when the carbon content is less than or equal to 0.05 %. In such case the limit on the sum of

the four elements in Footnote B does not apply.

D

Titanium is permitted, at producer’s option, to 0.025 % provided the ratio of % titanium to % nitrogen does not exceed 3.4.

E

Specify Type B to avoid carbon levels below 0.02 %.

F

For carbon levels less than or equal to 0.02 %, columbium or titanium, or both, may be used as stabilizing elements at the producer’s option. In such case, the limits

for these elements are 0.10 % for columbium and 0.15 % for titanium.

G

When an aluminum deoxidized steel is required, it may be ordered to a minimum of 0.01 % total aluminum.

H

May be furnished as a vacuum degassed or chemically stabilized steel, or both, at producer’s option.

I

When copper steel is specified, the copper limit is a minimum requirement. When copper steel is not specified, the copper limit is a maximum requirement.

A 1011/A 1011M

A

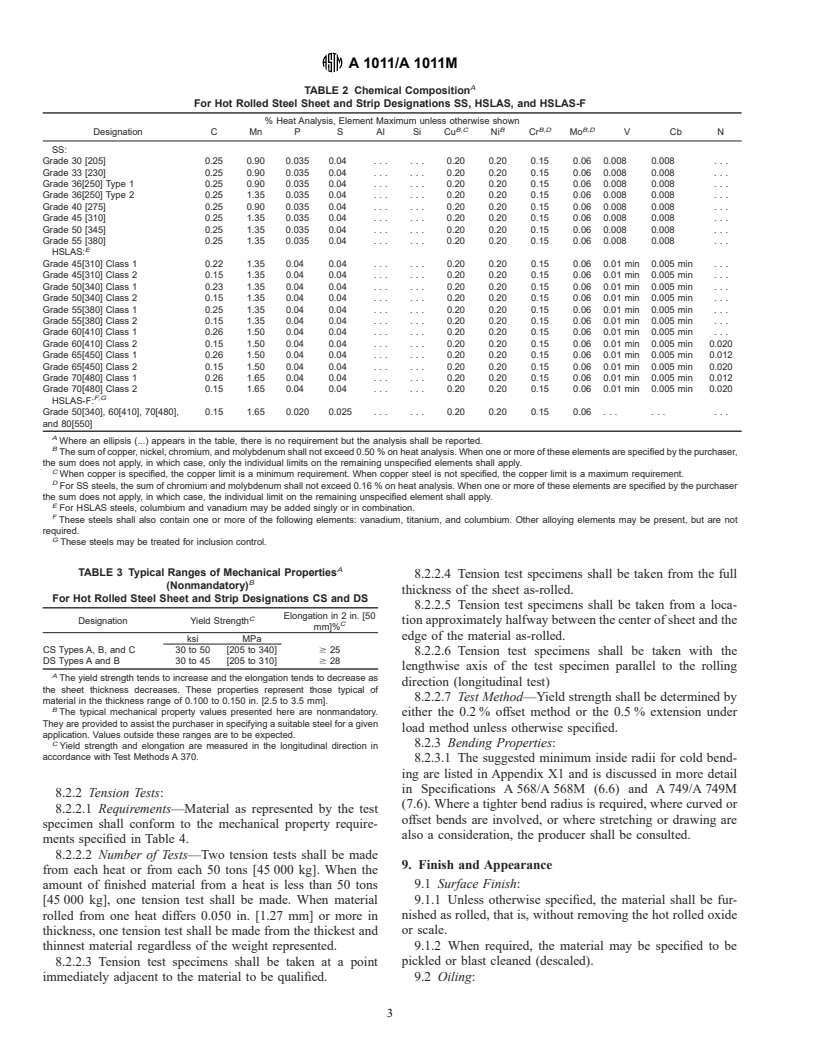

TABLE 2 Chemical Composition

For Hot Rolled Steel Sheet and Strip Designations SS, HSLAS, and HSLAS-F

% Heat Analysis, Element Maximum unless otherwise shown

B,C B B,D B,D

Designation C Mn P S Al Si Cu Ni Cr Mo VCb N

SS:

Grade 30 [205] 0.25 0.90 0.035 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 . . .

Grade 33 [230] 0.25 0.90 0.035 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 . . .

Grade 36[250] Type 1 0.25 0.90 0.035 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 . . .

Grade 36[250] Type 2 0.25 1.35 0.035 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 . . .

Grade 40 [275] 0.25 0.90 0.035 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 . . .

Grade 45 [310] 0.25 1.35 0.035 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 . . .

Grade 50 [345] 0.25 1.35 0.035 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 . . .

Grade 55 [380] 0.25 1.35 0.035 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.008 0.008 . . .

E

HSLAS:

Grade 45[310] Class 1 0.22 1.35 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min . . .

Grade 45[310] Class 2 0.15 1.35 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min . . .

Grade 50[340] Class 1 0.23 1.35 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min . . .

Grade 50[340] Class 2 0.15 1.35 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min . . .

Grade 55[380] Class 1 0.25 1.35 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min . . .

Grade 55[380] Class 2 0.15 1.35 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min . . .

Grade 60[410] Class 1 0.26 1.50 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min . . .

Grade 60[410] Class 2 0.15 1.50 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min 0.020

Grade 65[450] Class 1 0.26 1.50 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min 0.012

Grade 65[450] Class 2 0.15 1.50 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min 0.020

Grade 70[480] Class 1 0.26 1.65 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min 0.012

Grade 70[480] Class 2 0.15 1.65 0.04 0.04 . . . . . . 0.20 0.20 0.15 0.06 0.01 min 0.005 min 0.020

F,G

HSLAS-F:

Grade 50[340], 60[410], 70[480], 0.15 1.65 0.020 0.025 . . . . . . 0.20 0.20 0.15 0.06 . . . . . . . . .

and 80[550]

A

Where an ellipsis (.) appears in the table, there is no requirement but the analysis shall be reported.

B

The sum of copper, nickel, chromium, and molybdenum shall not exceed 0.50 % on heat analysis. When one or more of these elements are specified by the purchaser,

the sum does not apply, in which case, only the individual limits on the remaining unspecified elements shall apply.

C

When copper is specified, the copper limit is a minimum requirement. When copper steel is not specified, the copper limit is a maximum requirement.

D

For SS steels, the sum of chromium and molybdenum shall not exceed 0.16 % on heat analysis. When one or more of these elements are specified by the purchaser

the sum does not apply, in which case, the individual limit on the remaining unspecified element shall apply.

E

For HSLAS steels, columbium and vanadium may be added singly or in combination.

F

These steels shall also contain one or more of the following elements: vanadium, titanium, and columbium. Other alloying elements may be present, but are not

required.

G

These steels may be treated for inclusion control.

A

TABLE 3 Typical Ranges of Mechanical Properties

8.2.2.4 Tension test specimens shall be taken from the full

B

(Nonmandatory)

thickness of the sheet as-rolled.

For Hot Rolled Steel Sheet and Strip Designations CS and DS

8.2.2.5 Tension test specimens shall be taken from a loca-

Elongation in 2 in. [50

C

Designation Yield Strength tion approximately halfway between the center of sheet and the

C

mm]%

edge of the material as-rolled.

ksi MPa

CS Types A, B, and C 30 to 50 [205 to 340] $ 25

8.2.2.6 Tension test specimens shall be taken with the

DS Types A and B 30 to 45 [205 to 310] $ 28

lengthwise axis of the test specimen parallel to the rolling

A

The yield strength tends to increase and the elongation tends to decrease as

direction (longitudinal test)

the sheet thickness decreases. These properties represent those typical of

8.2.2.7 Test Method—Yield strength shall be determined by

material in the thickness range of 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.